Mine Site Automation 2011

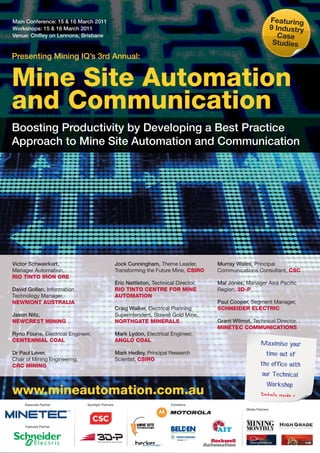

- 1. Main Conference: 15 & 16 March 2011 Featuring Workshops: 15 & 16 March 2011 9 Industry Venue: Chifley on Lennons, Brisbane Case Studies Presenting Mining IQ’s 3rd Annual: Mine Site Automation and Communication Boosting Productivity by Developing a Best Practice Approach to Mine Site Automation and Communication Victor Schweirkart, Jock Cunningham, Theme Leader, Murray Wales, Principal Manager Automation, Transforming the Future Mine, CSIRO Communications Consultant, CSC RIO TINTO IRON ORE Eric Nettleton, Technical Director, Mal Jones, Manager Asia Pacific David Gollan, Information RIO TINTO CENTRE FOR MINE Region, 3D-P Technology Manager, AUTOMATION NEWMONT AUSTRALIA Paul Cooper, Segment Manager, Craig Walker, Electrical Planning SCHNEIDER ELECTRIC Jason Nitz, Superintendent, Stawell Gold Mine, NEWCREST MINING NORTHGATE MINERALS Grant Wilmot, Technical Director, MINETEC COMMUNICATIONS Ryno Fourie, Electrical Engineer, Mark Lydon, Electrical Engineer, CENTENNIAL COAL ANGLO COAL Maximise your Dr Paul Lever, Mark Hedley, Principal Research time out of Chair of Mining Engineering, Scientist, CSIRO CRC MINING the office with our Technical Workshop www.mineautomation.com.au Associate Partner Spotlight Partners Exhibitors TM Media Partners Featured Partner

- 2. Benefits of Attending • Cut costs and save resources by intelligently investing in automation technologies • Hear from industry leaders who have utilised mine automation and communication technologies • Develop a thorough understanding of current industry trends and the latest innovations in mine automation and communications technologies • Scope future industry trends and discover the potential of automation at your mine site Who will you meet at Dear Colleague, Mine Site Automation and 2010 has been an exciting year for the industry, as Australia continues to recover from Communication 2011? the global financial crisis and demand for resources increases. Meeting this increase From Mine Sites in demand will require Australian mine sites to step up and join the next generation of • Technical Directors mining. • Automation Managers • Electrical Engineering Effective automation and communication technologies can hold the key to boosting • Control Systems • Instrumentation productivity and efficiency at Australia’s mine sites, but determining what to invest in • Production can be a struggle. • Process Control Mine Site Automation and Communication 2011 was developed to address all facets From Mining Head Office of mine site automation and communication. • Technical Director • Manager Mine Automation • Electrical Engineering Manager Mine Site Automation and Communication 2011 is your opportunity to • Process Control Manager • Head of Innovation take away key strategies for: From Contractors • Evaluating and overcoming the major risks associated with new technologies • Technical Director • Determining which solution providers to work with in order to maximise ROI • Automation Manager • Electrical Engineering • Communicating the value add of investing in new technologies to senior • Process Control management • Communications Systems • Developing an effective training program for mine staff Who has attended Mining • Up-skilling staff in order to enable them to effectively utilise automation IQ’s Mine Site Automation technologies and Communication events? • Understanding the benefits of investing in these new technologies BHP Billiton • Keeping up to date with the latest offerings for mine site automation and Anglo Coal communication Rio Tinto BMA Coal CRC Mining Mining Automation and Communication 2011 will equip you with the insight to CSIRO successfully implement and operate automation and communication technologies Minara Resources at your mine site. Newcrest Mining Newmont Do not miss your opportunity to take part in this important industry event. Pilbara Iron Company Call Judy Hizon on (02) 9229 1000 to secure your place today or email Xstrata Nickel enquire@iqpc.com.au. Xstrata Zinc Alcoa World Alumina ACARP Kind regards, AECOM Argyle Diamonds Xstrata Copper Centennial Coal Company Goldfields Sanna Trad Iluka Resources Project Director- Mine Site Northgate Minerals Automation and Communication Western Areas NL Mining IQ Atlas Copco Ausenco Kalgoorlie Consolidated Gold Mine Worley Parsons Parsons Brinckerhoff www.mineautomation.com.au Orica Mining Nickel West Mount Keith

- 3. Agenda DAY 1 Tuesday 15 March 2011 8:30 Coffee and Registration Implementing Technology to Develop an Efficient 9:00 Opening Remarks from Forum Chair Communication Process for Your Mine Site 1:40 Case Study: Transitioning to a Paperless Communication Determining the Best Technologies to Suit the Needs of System your Mine Site and Maximise ROI • Developing the best communication system for your mine site • Implementing new communication technologies 9:10 Case Study: From Implementation to Operation – Automating • Benefits of a paperless communication system Mine Operations • Exploring best practice for automated mining • Getting staff and management buy-in and selling the benefits of the system • The benefits of the implementation of automated mining Ryno Fourie, Electrical Engineer, • Accurately forecasting the costs of investing in new technology CENTENNIAL COAL • Understanding and overcoming the challenges associated with implementing automation at your mine site 2:20 Case Study: Deploying a Wireless Communication System at your Mine Site 9:50 Minetec – A Different Approach! • Deploying proper and reliable communication systems to • An overview of communication network challenges in the Mining decrease machine breakdown Industry • Facilitating instant messaging from underground to surface • OTN features & benefits within the Mining Sector for normal mining operations as well as necessary rescue • Voice communications over wireless networks and an operations in case of emergency introduction to digital radio solutions. • Reaching all areas of your mine site where wired communication • Demonstration of Minetec’s ELF, MineMesh, Tracking & Tagging is not possible and Traffic Management technologies • Outlining wireless communication systems for transmission of Grant Wilmot, Technical Director, data, voice and video MINETEC COMMUNICATIONS David Gollan, Information Technology Manager, 10:30 Morning Tea and Networking Opportunity NEWMONT AUSTRALIA 11:00 Case Study: Implementing Automation and Developing a Best 3:00 Afternoon Tea and Networking Opportunity Practice Approach 3:30 Case Study: Developing a Selection Criterion for Deciding on • Achieving buy-in from staff and senior management Automation and Communication Technologies • Ensuring your monitoring processes are upheld to pre-empt • Determining what you want to gain from investing in automation delays and problems before they become costly technologies • Training staff on the utilisation and maintenance of automated • Establishing which technologies are the best fit for your mining equipment operations • Managing the maintenance of your automated equipment • Examining the main risks associated with investing in new • Working with third party contractors and assigning accountability technologies • Minimising breakages and technology malfunctions on your site Victor Schweirkart, Manager Automation, RIO TINTO IRON ORE 11:40 Case Study: Stawell Gold Mine: Utilising Automated Mine Technologies to Enable Round the Clock Mine Operations 4:10 Closing Remarks from Conference Chair • Determining the best solutions to invest in to maximise ROI 4:20 Close of Conference Day 1 • Mitigating the risks of automated technologies • Achieving senior management buy-in for automation 4:30 Networking Drinks investments • Exploring benefits of a parts management agreement 5:30 Workshop A: Determining the Which Technologies to Invest in • Working with service providers to get the most out of your to Suit the Needs of Your Mine Site and Maximise ROI products Craig Walker, Electrical Planning Superintendent, STAWELL GOLD MINE – NORTHGATE MINERALS 12:20 The Integrated Mining Demand Chain This session explores the benefits in operating your mining business as a demand chain with an integrated solution. Paul Cooper, Segment Manager, SCHNEIDER ELECTRIC 12:40 Lunch and Networking Opportunity Associate Partner Featured Partner TM Minetec has been designing, With mining activity increasing, your business supplying and installing will benefit from an integrated mining solution cutting-edge technical designed to reduce engineering effort, drive communications to the Mining standards compliance and improve productivity. and Oil & Gas Industries for ten years. Existing clients include Rio Tinto, BHP Schneider Electric achieves this with an intelligent Billiton, FMG, Theise and Newcrest in Australia, Barrick Gold and Lycopodium management system called EcoStruxure which ties in Tanzania and Grande Cache Coal Canada. Deliverables include Wi-Fi and Wi- together Schneider Electric’s key domains of expertise to make energy, operations Max solutions, Tracking, Tagging, Proximity Awareness and Messaging systems, and engineering productive, safe, reliable and efficient. In this intensive business Digital Radio, Ethernet over Leaky Feeder, Fibre Optic & Microwave solutions as Schneider Electric’s experts in systems architecture design, automation process well as Mining Camp Facilities all backed by on-site maintenance. control and energy efficiency are able to deliver on your engineering, production www.minetec.com.au and maintenance needs. www.schneider-electric.com/mining BOOK NOW! T +61 2 9229 1000 F +61 2 9223 2622 E registration@iqpc.com.au W www.mineautomation.com.au

- 4. Agenda DAY 2 Wednesday 16 March 2011 8:30 Coffee and Registration 1:20 Benefits of Investing in Automated Mining Technologies • Understanding the capabilities and limitations of automated 9:00 Opening Remarks from Forum Chair mine site technology 9:10 Exploring the Current Environment Surrounding Mine • Exploring the benefits of automated mining Automation and Scoping Future Trends • Operational improvement through automation • Mine site automation today and what has changed in the last • Monitoring the overall impact of introducing automated five years technologies at your mine site • How does Australia compare to the rest of the world in relation Dr Paul Lever, Chair of Mining Engineering, CRC MINING to implementing automation? • The future of mine site automation in Australia and internationally 2:00 Case Study: Demonstrating the Value of Investment in New Technologies Eric Nettleton, Technical Director, • Understanding and communicating the full benefits of investing RIO TINTO CENTRE FOR MINE AUTOMATION in new technology 9:50 Case Study: Latest Innovations in Mine Site Automation • Exploring how automation can benefit mine safety Technologies for Mine Sites • Benefits of 24 hour production and operations • Exploring the latest technologies and keeping up to date with industry innovation 2:40 Afternoon Tea and Networking Opportunity • Introducing new automation technologies into your mine site 3:10 Utilising Automation to Overcome the Major Challenges in the operations Mining Industry • Maximising ROI when investing in technology • The latest developments in mining automation and what they can do for your operations 10:30 Morning Tea and Networking Opportunity • The safety benefits of utilising automation 11:00 Case Study: Determining Which Solution Providers to Work • How automated mining technologies are being used to boost with in Order to Maximise ROI productivity • When looking outside your organisation for help, which vendors • Getting round the clock service from your automation should you consider? technologies • Determining the scope of the vendor market and what they can Jock Cunningham, Theme Leader, Transforming the Future Mine, do for you CSIRO • Understanding the problems that you may have as a potential customer in selecting a vendor to work with 3:50 Future Technologies for Mine Site Wireless Communication • What processes can you use to narrow down your options? and Tracking • Exploring emerging technologies for wireless communications Mark Lydon, Electrical Engineer, ANGLO COAL • Challenges and emerging solutions for accurate tracking on 11:40 Intelligence at the End Point-Management and Control of mine sites Applications and Wireless Networks at the Machine. The • Future opportunities for mines presented by emerging Missing Piece of the Puzzle technologies • Is it “plug and play” or “plug and pray” - The curse of the Mark Hedley, Principal Research Scientist, CSIRO technology buzz word and how corporate standards have removed the words “built for purpose” from “production critical” 4:30 Closing remarks from Forum Chair • Understanding the pieces of the puzzle - An architectural view 4:40 Close of Conference Day 2 of the building blocks required to create a robust and reliable wireless communications network to support automation 5:00 Workshop B: Engaging Senior Management with applications Automation and Demonstrating the Value Add of Investing • Application and network management - What it means, where in New Technology and how to use it for mining applications • Future proofing your technology investments - Scalability and upgradeability. The importance of managing change and cost of change • The sales guy said this can do whatever I want, now wheres the on button! - The challenges that technology brings to mining and the dependency on technical expertise to run and support it. Mal Jones, Manager Asia Pacific Region, 3D-P 12:00 Learn from CSC’s and Our Customers’ Experiences • Why wireless mesh is critical in open pit mining • Why all wireless technologies are not the same Download Centre • The benefits of a fully managed service • The benefits of central management and a remote diagnostic Keep abreast of all the latest industry tool set developments in the lead up to the conference. • Getting it right - why the site survey and installation techniques are critical to a successful and robust wireless deployment Join our speakers online for: • What applications are being deployed right now and what’s • interviews around the corner • Requirements to move from FMS and access to real time field • podcasts data, to autonomous automation and the ROC • white papers Murray Wales - Principal Communications Consultant, CSC and much more... 12:20 Lunch and Networking Opportunity www.mineautomation.com.au BOOK NOW! T +61 2 9229 1000 F +61 2 9223 2622 E registration@iqpc.com.au W www.mineautomation.com.au

- 5. Workshops Tuesday 15 & Wednesday 16 March 2011 Tuesday 15 March 2011 (Includes light dinner) What you will learn 5:30 What to look for when investing in new technologies Workshop A Introducing Automation • Is mine site automation right for your mine site? • Why invest in automated mine site technologies? at Your Mine Site • Matching technologies to the needs of your mine site Use this extended workshop session to really analyse the actual 6:30 Evening Break attractiveness of automation for your specific mine site. Determining 7:00 Implementing Automation which technologies are the right fit for your mine site can be a • Achieving staff and senior management buy in challenging process and the implications of getting it wrong are costly. • Developing a training program and recruiting the right staff to This highly interactive workshop will ensure that you can gain benefit support automation and communication technologies from hearing multiple perspectives from your peers and discuss and • Utilising automation to its full potential debate new skills and strategies with your colleagues in this focused • Managing the maintenance of automated equipment environment. 8:30 End of Workshop A Facilitated by: Dr Paul Lever, Chair of Mining Engineering, CRC MINING Wednesday 16 March 2011 (Includes light dinner) What you will learn 5:00 Understanding and communicating the full benefits of investing Workshop B Engaging Senior Management with in new technology • Exploring how automation can benefit mine safety Automation and Demonstrating • Benefits of 24 hour production and operations the Value Add of Investing in New • Examining industry best practice 6:00 Evening Break Technologies 6:30 Convincing Senior Management the Value of Investing in New Technologies Implementing change management will always be a challenge; however • Developing a business case for investing in automation and convincing senior management is the first and most crucial step to communication technologies implement new technologies. This interactive 3 hour workshop will give you the opportunity to discuss strategies with your colleagues in a • Assessing the risk vs potential return of investing automation focused environment. technologies • Communicating the benefit of investing in these technologies • Getting to yes 8:00 End of Workshop B Spotlight Partners Motorola’s portfolio of products and solutions provides your Automation IT is an AS/NZS mining operation with real-time wireless data, video, and ISO9001:2008 3rd party certified A global leader in providing technology- voice communications to enhance HSE compliance and company who provides professional enabled business solutions and services productivity. Our purpose is to help our customers operate control systems engineering services CSC is a $16.7 billion global IT services efficiently, effectively, and safely in critical environments with using the latest technologies and has experience with all company with 50 years experience and confidence. the major brands of control system hardware and software. over 92,000 employees worldwide, and revenues of $1.3 For more information, please visit www.motorola.com.au. Automation IT has significant experience in industrial control billion and 3,500 employees in Australia. We currently systems for the mining, water & waste water, power and deliver mission-critical services to Natural Resources clients food & beverage industries as well as commercial building MINE SITE TECHNOLOGIES is a global including BHP Billiton, Rio Tinto, Woodside Petroleum, Vale controls such as Network Control Systems (NCS) and Energy leader in mining communications. Our and Newmont Mining. Our expertise spans mine IT planning, Monitoring Systems (EMS). technologies have been installed in over end-to-end plan and execute, logistics, equipment tracking, www.automationit.com 500 underground & surface mines around technical data management, remote communications, and the world and include: information management. Contact Details: CSC Australia Pty • ImPact Digital Communications & RFID Tracking - a digital Becker Mining provides Limited 26 Talavera Rd, Macquarie Park NSW 2113 802.11b/g/n Wi-Fi standards network for underground mines Communications and T:+61 2 9034 3000 F:+61 2 9034 2000 • Wireless Mesh – high bandwidth network for surface mines automation solutions primarily www.csc.com.au • VoIP MinePhone – for two-way voice & texting underground for the underground mining industry. A global company with via the digital network headquarters based in Germany, Becker is renowned for both 3D-P has been a provider • Proximity Detection – underground & surface high quality products and excellent service. The products of mining solutions for over • PED Emergency Warning System Becker will be displaying include communications, wireless 15 years and has current • BlastPED – remote blast initiation networking, tagging, collision avoidance, automation and deployments in the largest mining companies in the world www.minesite.com.au SCADA solutions. Becker has four facilities in Australia that on every continent. Known for their expertise in integration of provide after sale support for their products and solutions. virtually any application and any interface technology, 3D-P www.au.becker-mining.com now pave the way in providing intelligent solutions that enable the reliable and effective integration and management of autonomous applications onto the mobile wireless network. Rockwell Automation Australia Belden Industrial Solutions was formed through the is the subsidiary of Rockwell 3D-P consists of an international team of mining engineers, combnation of three world leading Industrial communication Automation, Inc. – a leading electrical engineers and software engineers and developers businesses. Hirschmann, Lumberg Automation and Belden. global provider of industrial power, automation control and with decades of experience developing advanced customer Hirschmann - the world leader in Industrial Ethernet Switches information solutions that helps miners and manufacturers driven technology solutions for the mining industry. – unmanaged and managed, WiFi, Industrial Firewalls, achieve a competitive advantage in their businesses. The www.3d-p.com Lumberg Automation is a leading supplier of industrial company brings together leading global brands in industrial connectivity products for automation machinery. Belden automation which includes Allen-Bradley® controls and provides a vast range of control and communication cabling Exhibitors and connectivity from, and end-to-end Industrial Fibre and services and Rockwell Software® factory management software. Its broad product mix includes control logic Motorola is known around Copper Networks. Speak to us about your communication systems, sensors, human-machine interfaces, drive the world for innovation requirements. controllers, power devices, and software. in communications and is Email: australia.sales@beldenapac.com www.rockwellautomation.com.au focused on advancing the way the world connects. Motorola’s Call: 1800 500 775 proven portfolio and experience ensures you have a more www.beldensolutions.com reliable, mobile and adaptable mining operation.

- 6. WHERE Chifley on Lennons, Brisbane Register Early & Save! 66 Queen Street Mall Brisbane QLD 4000 Phone: 07 3222 3222 Fax: 07 3221 9389 To speed registration, please provide the priority code located on the mailing label or in the box below. Web: www.chifleyhotels.com.au ENQNA WHEN? 15 & 16 March 2011 TEAM DISCOUNTS IQPC recognises the value of learning in teams. Take advantage of one of these special rates: Register a team of 3 to the conference at the same time from the same company and receive $500 discount Register a team of 4 to the conference at the same time from the same company and receive a free pass for a 5th delegate Ask about multi-event discounts. Call + 61 2 9229 1000 for more details Please note: Only one discount applies ACCOMMODATION The Lido Group are the official booking agent for the Mine Site Automation and Communication 2011 event. The Lido Group have negotiated event rates at a range of hotels for all attendees of this event. To take advantage of these rates & book direct on the website, please go to www.mineautomation.com.au and click on the Venue & Accommodation page. 13487.003 QUICK and EASY WAYS to REGISTER TELEPHONE +61 2 9229 1000 FAX +61 2 9223 2622 Presenting Mining IQ’s 3rd Annual: EMAIL registration@iqpc.com.au WEBSITE www.mineautomation.com.au Mine Site MAIL IQPC, Level 6, 25 Bligh Street, SYDNEY NSW 2000 Automation and REGISTER ME for Mine Site Automation and Communication PLUS WORKSHOP/S A B Communication (PHOTOCOPY THIS FORM FOR ADDITIONAL DELEGATES) DELEGATE 1 [TITLE] [SURNAME] Boosting Productivity by Developing [FIRST NAME] a Best Practice Approach to Mine Site DELEGATE 2 [TITLE] Automation and Communication [SURNAME] [FIRST NAME] www.mineautomation.com.au POSITION EMAIL SAVE ORGANISATION $400 EARLY BIRD PACKAGES *Register & STANDARD PRICE VENDOR PRICE pay before 17/12/2010 ADDRESS Conference Only $2,899 + GST = $3,188.90 $3,299 + GST = $3,628.90 $3,999 + GST = $4,398.90 POSTCODE Conference + 1 Workshop $3,798 + GST = $4,177.80 $4,198 + GST =$4,617.80 $4,898 + GST = $5,387.80 TELEPHONE ( ) FAX ( ) Conference + 2 Workshops $4,597 + GST = $5,056.70 $4,997 + GST = $5,496.70 $5,697 + GST = $6,266.70 APPROVING MANAGER [TITLE] [SURNAME] * Payment must be received by IQPC prior to 5pm AEST on the cut-off date. # 2 WAYS TO SAVE! Registrations received without payment or a Government PO will incur a processing fee of $99 + GST = $108.90 [FIRST NAME] per registration. Book early for HUGE Please send me set(s) of AUDIO COMPACT DISCS and PRESENTATIONS CD at $878.90 EARLY BIRD savings. ($799 plus GST) or $603.90 ($549 plus GST) Presentations CD only Book as a TEAM, POSITION Please keep me informed via email about this and other related events save & benefit as a team. NOTE: PAYMENT IS DUE WITHIN 7 DAYS FROM REGISTRATION TO SECURE YOUR PLACE. Registrations received without payment EMAIL or a Government PO will incur a processing fee of $99+GST = $108.90 per registration. Payment prior to the conference is mandatory for attendance. Payment includes lunches, refreshments, a copy of conference presentations via FTP website or workbook and all meeting materials. If payment has not been received two weeks before the conference, a credit card hold will be taken and processed. CHEQUE ENCLOSED FOR $ (Please make cheques payable to: IQPC) This card will be refunded once alternate payment has been received. PRIVACY - YOUR CHOICE PLEASE CHARGE American Express Visa MasterCard Diners Club Any information provided by you in registering for this conference is being collected by IQPC and will be held in the strictest confidence. It will be added to our database and will be used primarily to provide you with further information about IQPC events and services. By supplying your CREDIT CARD NUMBER email address and mobile telephone number you are agreeing to IQPC contacting you by these means to provide you further information about IQPC products and services. From time to time IQPC may share information from our database with other professional organisations (including our event sponsors) to promote similar products and services. Please tick the box below if you do NOT want us to pass on your details. To amend your current details, advise of duplicates or to opt out of further mailings, please contact our Database Integrity Maintenance Department, Level 6, 25 Bligh Street, SYDNEY NSW 2000. Alternatively, email database@iqpc.com.au, call 02 9229 1028 or fax 02 9223 2622. AMEX 4 DIGIT CODE EXPIRY DATE I do not wish to have my details made available to other organisations IQPC CANCELLATION AND POSTPONEMENT POLICY: FOR DETAILS OF IQPC’S NAME OF CARD HOLDER [PLEASE PRINT] CANCELLATION AND POSTPONEMENT POLICY PLEASE VISIT: www.iqpc.com.au © 2010 IQPC ABN 92 071 142 446 All RIGHTS RESERVED. The format, design, content and arrangement of this brochure constitute a copyright of IQPC. Unauthorised reproduction will be actionable by law.