Report

Share

Download to read offline

Recommended

Recommended

More Related Content

What's hot

What's hot (20)

Turbine selection through Fuzzy Logic presentation

Turbine selection through Fuzzy Logic presentation

IRJET- Experiment Study on Rotational Behaviour of a Savonous Wind Turbin...

IRJET- Experiment Study on Rotational Behaviour of a Savonous Wind Turbin...

Theoretical and Design Analysis of SAVONIUS TURBINE

Theoretical and Design Analysis of SAVONIUS TURBINE

Similar to vertical axis turbine test results

When discussing energy savings and variable frequency drives (VFD) the attention often focuses on a centrifugal fan or pump application. However, you should not overlook other applications which also have large potential energy savings and energy recovery. Applications involving regeneration, power factor correction, common bus applications or a combination of the three can also quickly achieve a signi cant reduction in energy use.Variable Frequency Drives and Energy Savings: It‘s More Than Just Fan and Pum...

Variable Frequency Drives and Energy Savings: It‘s More Than Just Fan and Pum...Instrument Specialties, Inc.

Similar to vertical axis turbine test results (20)

Enhancing Power Coefficient of a Wind turbine Using Diffuser Augmentation in ...

Enhancing Power Coefficient of a Wind turbine Using Diffuser Augmentation in ...

IRJET- Manufacturing System of Hybrid Vertical Axis Wind Turbine

IRJET- Manufacturing System of Hybrid Vertical Axis Wind Turbine

IRJET- Automated Machine Design through Software Controller Support

IRJET- Automated Machine Design through Software Controller Support

IRJET- Flywheel Power Generation and Multiplication

IRJET- Flywheel Power Generation and Multiplication

IRJET- Theoretical & Computational Design of Wind Turbine with Wind Lens

IRJET- Theoretical & Computational Design of Wind Turbine with Wind Lens

Active and Reactive Power Control of a Doubly Fed Induction Generator

Active and Reactive Power Control of a Doubly Fed Induction Generator

Variable Frequency Drives and Energy Savings: It‘s More Than Just Fan and Pum...

Variable Frequency Drives and Energy Savings: It‘s More Than Just Fan and Pum...

Modeling and simulation of dfig to grid connected wind power generation using...

Modeling and simulation of dfig to grid connected wind power generation using...

Using position control to improve the efficiency of wind turbine

Using position control to improve the efficiency of wind turbine

Experimental investigation on effect of head and bucket splitter angle on the...

Experimental investigation on effect of head and bucket splitter angle on the...

IRJET- Cost Effective Improvement in the Design of E- Mobility

IRJET- Cost Effective Improvement in the Design of E- Mobility

vertical axis turbine test results

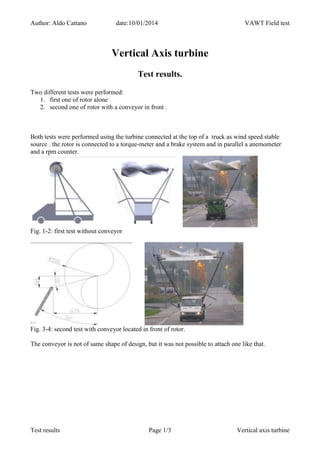

- 1. Author: Aldo Cattano date:10/01/2014 VAWT Field test Test results Page 1/3 Vertical axis turbine Vertical Axis turbine Test results. Two different tests were performed: 1. first one of rotor alone 2. second one of rotor with a conveyor in front . Both tests were performed using the turbine connected at the top of a truck as wind speed stable source . the rotor is connected to a torque-meter and a brake system and in parallel a anemometer and a rpm counter. Fig. 1-2: first test without conveyor Fig. 3-4: second test with conveyor located in front of rotor. The conveyor is not of same shape of design, but it was not possible to attach one like that.

- 2. Author: Aldo Cattano date:10/01/2014 VAWT Field test Test results Page 2/3 Vertical axis turbine Find below the diagram of power in the 2 tests: 50 150 250 350 450 550 650 750 850 950 1050 1150 1250 1350 5 6 7 8 9 10 11 12 13 14 15 16 17 18 wind speed m/s p o w e r W Fig. 5: power production versus wind speed. The increase in power is of 50% over 13 m/s and 30% below. With these results we can find the power production with real conveyor system that is 3 times larger . Considering the actual shape the rotor had a too low torque , so it would be necessary to increase the diameter from 1 mt till 1,5 mt and length can go from 5 mt till 7 mt. In this situation the power production will increase till our goal.

- 3. Author: Aldo Cattano date:10/01/2014 VAWT Field test Test results Page 3/3 Vertical axis turbine To measure the power increase we take in consideration the 10 m/s wind speed power. Actual measured power with out conveyor: 275 watt Actual measured power with conveyor: 375 Watt Correct increase due to difference between drag coefficient ( 1.4-0.4 ) x 1.4=1.4 Theoretical power with designed conveyor: 375 x 2= 750 Watt In this case the wind will blow 1.4 times faster and rpm will also be same increase. Theoretical power with designed conveyor and increased lenght: 750 x 1.4( 7/5)= 1050 Watt The increase is proportional to the length increase Theoretical with designed conveyor and increased lenght: and increased diameter : 1050 x 2.25 ((1.5/1)2 )= 2360 Watt The increase is quadratic with the area increase. The power coefficient measured at 10 m/s is 0.125 and the practical achievable is 0, 25, so we can Reach the target with conveyor and dimension increase.