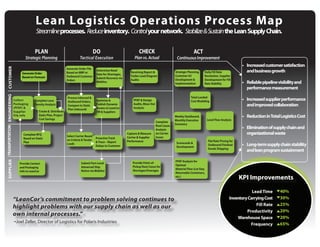

Lean logistics operations process map

- 1. Lean Logistics Operations Process Map Streamline processes. Reduce inventory. Control your network. Stabilize & Sustain the Lean Supply Chain. PLAN DO CHECK ACT Strategic Planning Tactical Execution Plan vs. Actual Continuous Improvement • Increased customer satisfaction CUSTOMER Generate Order File Generate Order Based on MRP or Determine Need Receiving Report & Strategic Planning, Daily Fill Rate and business growth Date for Shortages, Based on Forecast Outbound Customer Trailer Load Diagram Customer A3 Resolution, Supplier Submit Recovery via Orders Audits Development & Development for Fill Weblinx Implementation Rate Stability • Reliable pipeline visibility and performance measurement SUPPLIER TRANSPORTATION ENGINEERING Process Inbound & Total Landed Collect Complete Lane Outbound Orders, Optimize & PFEP & Design Cost Modeling • Increased supplier performance Packaging Density Analysis Compare to Static Publish Dynamic Audits, Blow-Out and improved collaboration (PFEP) & Plan (Inbound) Routes to LeanCor Analysis Supplier Create & Distribute TM & Suppliers File Info Static Plan, Project Weekly Dashboard, • Reduction in Total Logistics Cost Cost Savings Monthly Executive Level Flow Analysis Complete Summary Root Cause Analysis • Elimination of supply chain and Complete RFQ Capture & Measure on Carrier organizational waste Select Carrier Based Carrier & Supplier Issues Based on Static Proactive Track on Criteria & Tender Performance Flat Rate Pricing for Plan & Trace – Report Scorecards & Loads Delays to Customer Development Outbound Finished • Long-term supply chain stability Goods Shipping and lean program sustainment Provide Point-of- PFEP Analysis for Provide Contact Submit Part-Level Pickup Root Cause for Optimal and Packaging Advanced Ship Shortages/Overages Material Flow (Lot Size, Info to LeanCor Notice via Weblinx Returnable Containers, etc.) KPI Improvements Lead Time 40% “LeanCor’s commitment to problem solving continues to Inventory Carrying Cost 30% Fill Rate 25% highlight problems with our supply chain as well as our Productivity 20% own internal processes.” Warehouse Space 20% -Joel Zeller, Director of Logistics for Polaris Industries Frequency 65%