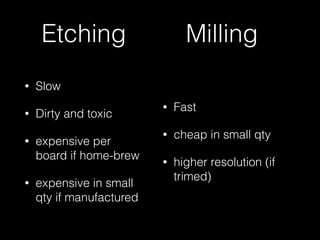

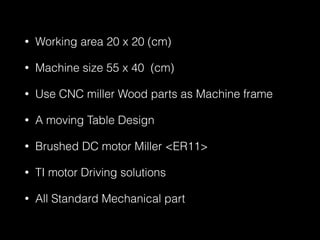

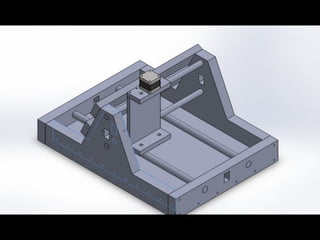

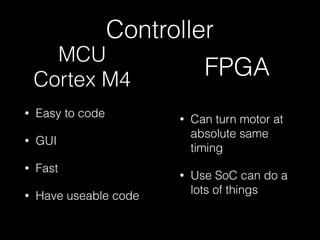

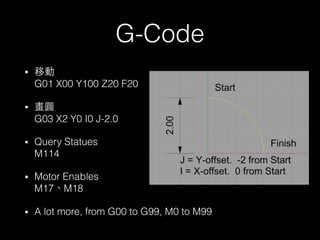

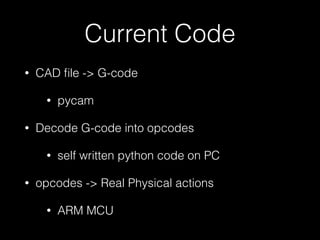

This document proposes a PCB milling machine project. It will use a CNC milling machine frame made of wood with a moving table design. A brushed DC motor and TI motor driver will be used to mill PCB boards from FR-4 sheets. An ARM MCU running FreeRTOS will control the machine by decoding G-code instructions from design files into motor movements. The goals are to enable quick and cheap production of small PCB batches for maker projects. Challenges include implementing more G-code instructions and dealing with floating point numbers on the ARM core.