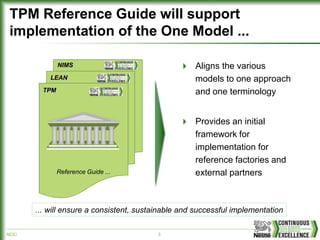

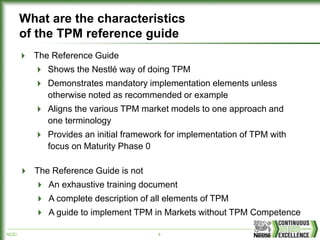

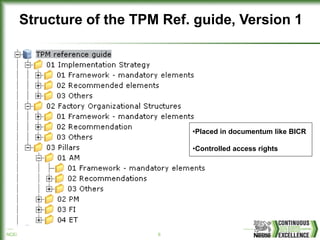

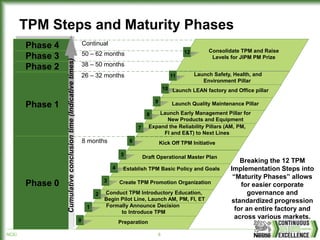

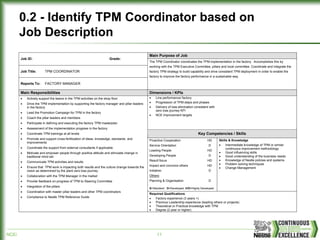

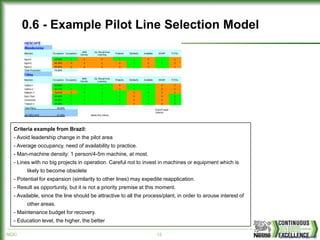

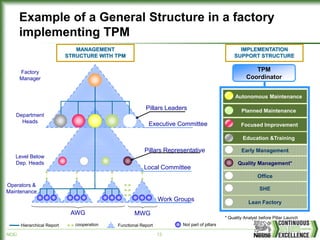

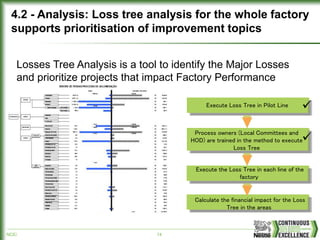

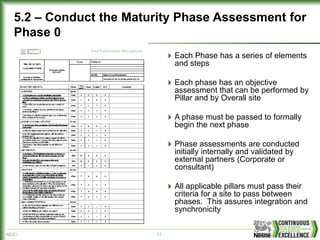

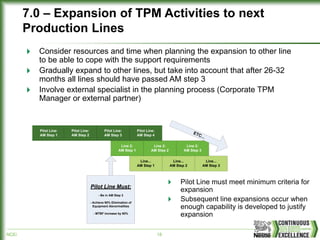

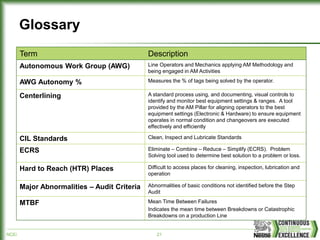

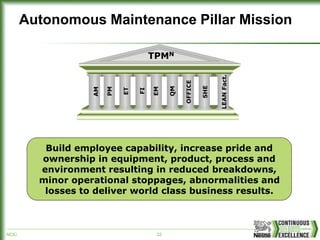

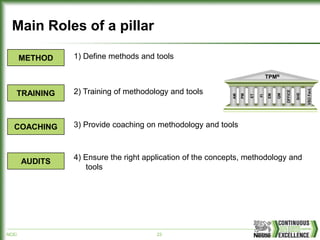

The document discusses Nestlé's TPM reference guide, which provides a framework for factories to implement Total Productive Maintenance (TPM) consistently. It outlines the structure and content of the guide, including implementation strategies, examples of selecting a pilot line, and defining the roles and responsibilities in the TPM organization structure. The guide is designed to align various TPM models under one common approach and terminology. It focuses on the initial implementation phase for reference factories and partners.