Hm international mold flow standard

•Download as PPT, PDF•

1 like•465 views

mold design, mold structure, mold analysis

Report

Share

Report

Share

Recommended

Recommended

More Related Content

Similar to Hm international mold flow standard

Similar to Hm international mold flow standard (20)

Moldflow analysis for plastic injection mold parts

Moldflow analysis for plastic injection mold parts

How to calculate gate area require for hpdc die casting part

How to calculate gate area require for hpdc die casting part

Asahitec Solder Paste Stencil- Solder Wave Pallet Design Guidelines

Asahitec Solder Paste Stencil- Solder Wave Pallet Design Guidelines

AJK2011-03023 (Conference Paper DR) Modelling Multiphase Jet Flows for High V...

AJK2011-03023 (Conference Paper DR) Modelling Multiphase Jet Flows for High V...

Recently uploaded

Recently uploaded (20)

Top profile Call Girls In Thrissur [ 7014168258 ] Call Me For Genuine Models ...![Top profile Call Girls In Thrissur [ 7014168258 ] Call Me For Genuine Models ...](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

![Top profile Call Girls In Thrissur [ 7014168258 ] Call Me For Genuine Models ...](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

Top profile Call Girls In Thrissur [ 7014168258 ] Call Me For Genuine Models ...

Top profile Call Girls In Ranchi [ 7014168258 ] Call Me For Genuine Models We...![Top profile Call Girls In Ranchi [ 7014168258 ] Call Me For Genuine Models We...](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

![Top profile Call Girls In Ranchi [ 7014168258 ] Call Me For Genuine Models We...](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

Top profile Call Girls In Ranchi [ 7014168258 ] Call Me For Genuine Models We...

What Does It Mean When Mercedes Says 'ESP Inoperative See Owner's Manual'

What Does It Mean When Mercedes Says 'ESP Inoperative See Owner's Manual'

Is Your Volvo XC90 Displaying Anti-Skid Service Required Alert Here's Why

Is Your Volvo XC90 Displaying Anti-Skid Service Required Alert Here's Why

+97470301568>>buy vape oil,thc oil weed,hash and cannabis oil in qatar doha}}

+97470301568>>buy vape oil,thc oil weed,hash and cannabis oil in qatar doha}}

John Deere Tractors 5415 Diagnostic Repair Service Manual.pdf

John Deere Tractors 5415 Diagnostic Repair Service Manual.pdf

What Does The Engine Malfunction Reduced Power Message Mean For Your BMW X5

What Does The Engine Malfunction Reduced Power Message Mean For Your BMW X5

Top profile Call Girls In Darbhanga [ 7014168258 ] Call Me For Genuine Models...![Top profile Call Girls In Darbhanga [ 7014168258 ] Call Me For Genuine Models...](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

![Top profile Call Girls In Darbhanga [ 7014168258 ] Call Me For Genuine Models...](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

Top profile Call Girls In Darbhanga [ 7014168258 ] Call Me For Genuine Models...

Is Your Mercedes Benz Trunk Refusing To Close Here's What Might Be Wrong

Is Your Mercedes Benz Trunk Refusing To Close Here's What Might Be Wrong

John deere 7200r 7230R 7260R Problems Repair Manual

John deere 7200r 7230R 7260R Problems Repair Manual

Washim Call Girls 📞9332606886 Call Girls in Washim Escorts service book now C...

Washim Call Girls 📞9332606886 Call Girls in Washim Escorts service book now C...

Hm international mold flow standard

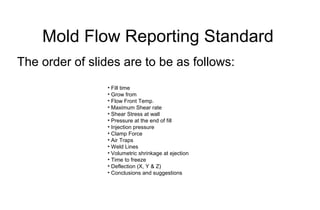

- 1. Mold Flow Reporting Standard The order of slides are to be as follows: • Fill time • Grow from • Flow Front Temp. • Maximum Shear rate • Shear Stress at wall • Pressure at the end of fill • Injection pressure • Clamp Force • Air Traps • Weld Lines • Volumetric shrinkage at ejection • Time to freeze • Deflection (X, Y & Z) • Conclusions and suggestions

- 2. Part picture Actual No. of cavities: IE: 1+1 Number of cavity analysis: IE 1+1 Part Material: IE: PC+10%GF Material used in simulation: IE: PC+10%GF Type of analyses: IE: Cool+Flow+Warp

- 3. Material Data General: Recommended Processing: Rheology: PVT properties: The material datas are from supplier is in moldflow database and shown in the pictures below

- 4. Process Setup Part Details and Tool Description Part 、 Tool 、 Setup Part Name: 2157000801 CAD File / Version/ Date 2157000801/ug/2010.0128 Part Volume 195.265cm^3 Nominal Wall Thickness 0.5-3.0mm Tool Description One mold with one cavity Injection machine Tonnage 300T Material PC+10%GF Material Present In Moldflow Database Yes Injection time Automatic Material temp 320[deg.c] Mold temp 100[deg.c] Velocity/Pressure Transfer (% volume) 99% Packing Pressure 80%filling pressure Project Area 296.541cm^2

- 5. Mesh statistics Mesh statistics Mesh for analysis

- 7. Gate Location and size The mold is hot feed system. Detail dimension was based on the drawing.

- 9. Simulation results list • Fill time • Grow from • Flow Front Temp. • Maximum Shear rate • Shear Stress at wall • Pressure at the end of fill • Injection pressure • Clamp Force • Air Traps • Weld Lines • Volumetric shrinkage at ejection • Time to freeze • Deflection • Conclusions and suggestions

- 10. Result : Fill Pattern • This result shows how the melt flows through the cavity. Click the plot, you will see the animated flow.Click the plot, you will see the animated flow. Fill time is about 0.9904sec.

- 11. Fill time/Short Shot Series The following plots are a series of short shots. Each plot represents a specific time at which the cavity is filled. These plots illustrate the flow front progression and pressure . distribution at that specified time. 80% filled 95% filled 100% filled 30% filled 50% filled 75% filled

- 12. Fill time/Contour The area with dense lines in the above picture represents the area with lower flow velocity; and the area with sparse lines represents the area with higher flow velocity.

- 13. Grow from This result uses numbers to identify which gate the polymer was injected into, showing us what areas of the part were filled from what gate.

- 14. Temp. at flow front Above figure showed the temperature at the part. As you see above figure, the temperature value normally uniformed all over the part.

- 15. Maximum Shear rate The picture shows the distribution of the shear rate at wall when fulfilled. The maximum value in the gate area is 95621 1/s when fulfilled. The maximum shear rate is 40000 1/s which recommended in the material database of moldflow.

- 16. Shear Stress at wall The picture shows the distribution of the shear stress at wall when fulfilled. The maximum value is 4.03MPa when fulfilled.

- 17. Pressure at the end of fill Above figure shows the pressure distribution through the flow path inside the mold, at the end of the filling phase.

- 18. Injection pressure Packing profile plot The maximum value is 100.6MPa, at 0.974s. Injection pressure specified at Packing is 80.52MPa

- 19. Clamp force Max. clamp force during filling is 117.53Tons; Max. clamp during packing is 225.2Tons. The maximum clamp force is 225.2Tons.

- 20. Weld lines locations Above figure shows the location of weld-line on the part. To move or moderate these weld-lines, we have to optimize the processing condition. Increase the melt temperature, injection speed, or injection pressure or packing pressure can improve the quality of weld lines.

- 21. Air trapped area • This result shows areas of the cavity that may require additional venting– it should be viewed in combination with the filling pattern result. Air traps locations are shown by small pink balls. Most of them can be vented easily. But note venting in region where flow fronts meet.

- 22. Volumetric shrinkage at ejection The maximum shrinkage at ejection is 5.739%.The minimum shrinkage at ejection is 0.4268%.

- 23. Time to freeze, part The result shows the amount of time taken for all of the elements in the part to freeze to ejection temperature.

- 24. Deflection (x10) The maximum deflection value is about 0.371mm. The transparent shape is the original. The scaled factor is 10.

- 25. X -deflection (x10) Above figure shows the X-deflection distribution. The transparent shape is the original. The scaled factor is 10. The area where red arrow indicates on the side of part moved inward about 0.2352~0.2403mm.

- 26. Y -deflection (x10) Above figure shows the Y-deflection distribution. The transparent shape is the original. The scaled factor is 10. The area where red arrow indicates on the side of part moved inward about 0.3012~ 0.3192mm.

- 27. Z -deflection (x30) The area where red arrow indicates on the side of part moved upward about 0.0906mm. The side area where black arrow indicates moved downward about 0.0857mm. Above figure shows the Z-deflection distribution. The transparent shape is the original. The scaled factor is 30.

- 28. Conclusions &Suggestions From the above analysis: Fill time is about 0.9904sec. The deflection in Z axis direction is about 0.17mm and it is mainly caused by product structure and the shrinkage. The bulk stress exceed the allowable value (0.5MPa) in most area, and need to adjust injection velocity in molding. The volumetric shrinkage of the product is non-uniform. Shrinkage is large in the thick region. Volumetric shrinkage can be controlled by the use of packing profiles. Increase the melt temperature, injection speed, or injection pressure or packing pressure can improve the quality of weld lines. Fill time Weld line Flow Front temperature Injection pressure Volumetric shrinkage Deflection:Z Component 0.9904sec Note venting 313.1~324.5deg.C 100.6MPa 0.4268 ~ 5.739% -0.0857~+0.0906mm