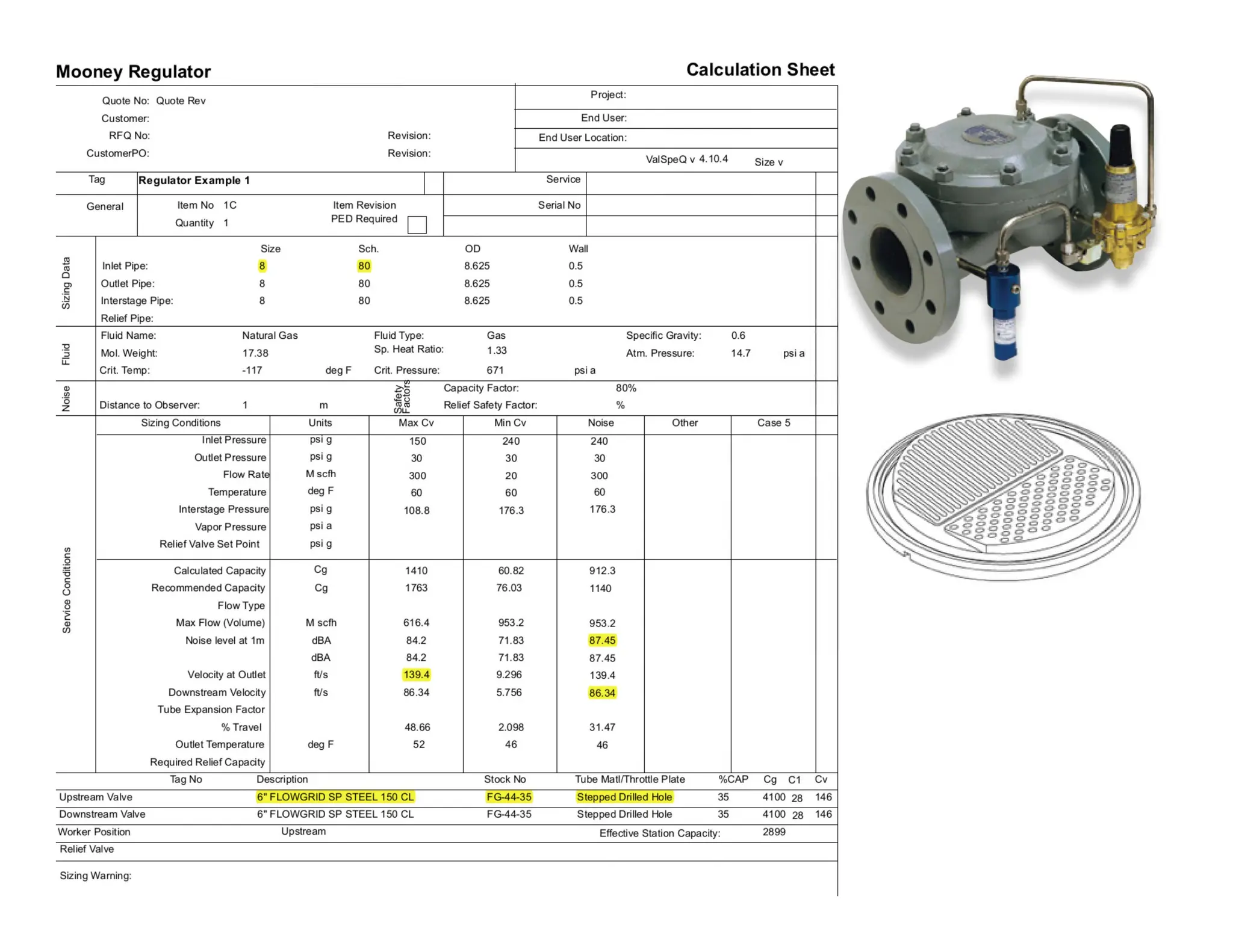

This document provides information on sizing regulators and control valves for gas flow applications. It discusses selecting the proper type of regulator based on factors like response time, pressure differential, and noise level. Charts are included showing typical regulator orifice sizes. Tips are provided on sizing considerations like capacity, noise reduction, differential pressure limits, and addressing issues like freezing due to Joule-Thompson cooling. Examples are given for regulator and control valve sizing calculations based on maximum and minimum flow rate, pressure, and temperature conditions. Options for adding filters, driers, and heaters to address issues like liquid dropout and cooling are also reviewed.