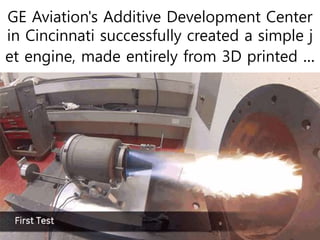

3D printing technology is advancing rapidly in several areas.

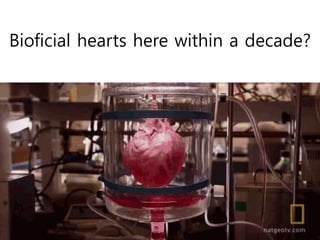

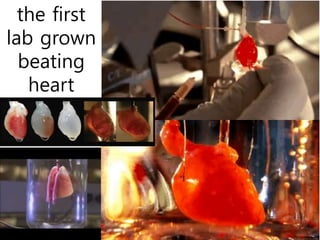

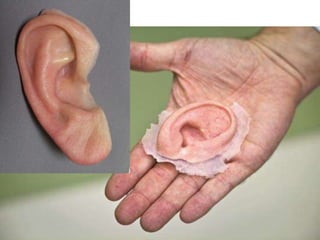

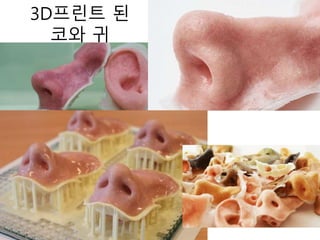

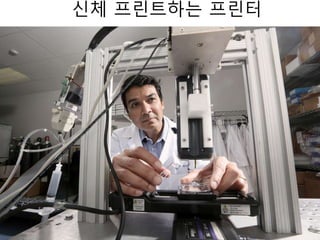

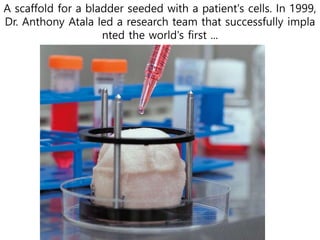

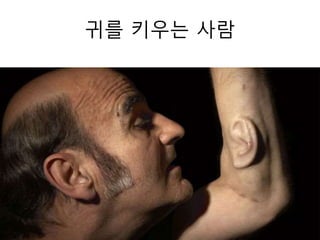

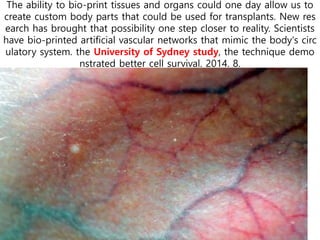

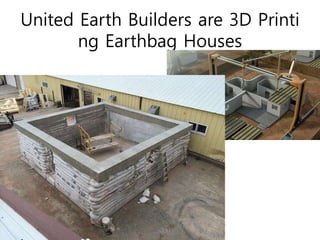

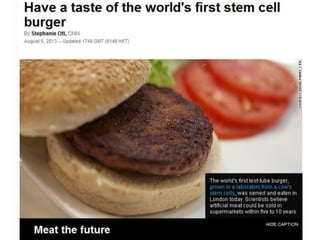

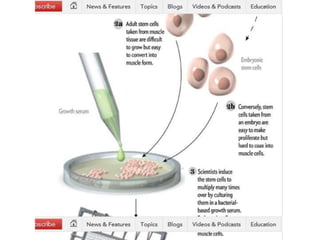

- 3D printers can now print houses and body parts, with the first 3D printed ear transplant having already occurred. Scientists have also successfully printed a mouse's heart.

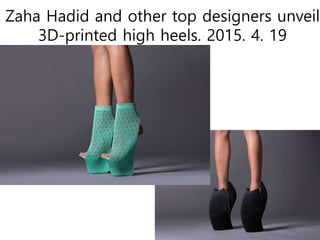

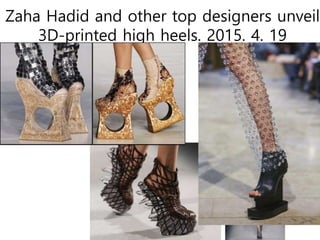

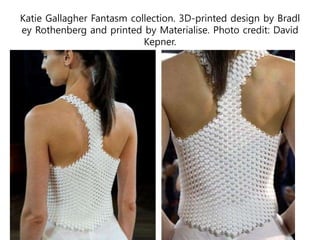

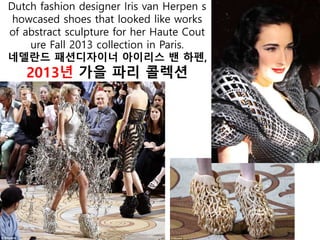

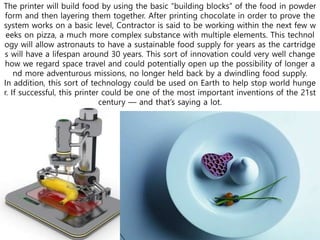

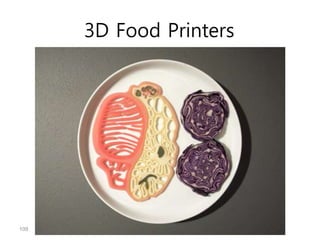

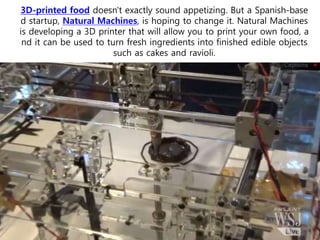

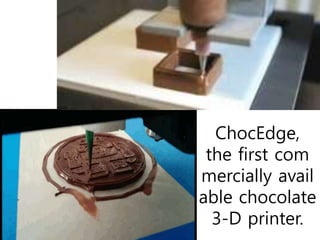

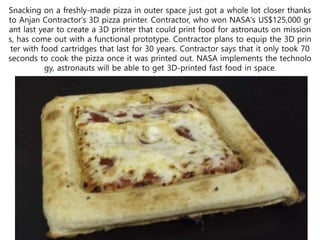

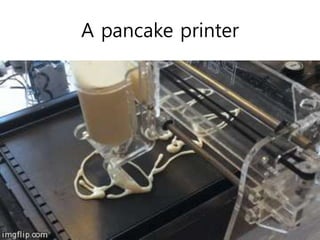

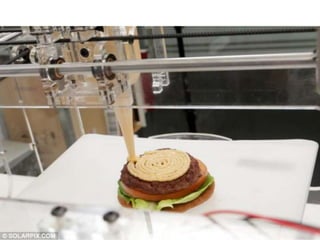

- Food and clothing 3D printers allow for customized, on-demand printing of items tailored to individuals. Designers are utilizing 3D printing for novel shoe and dress designs.

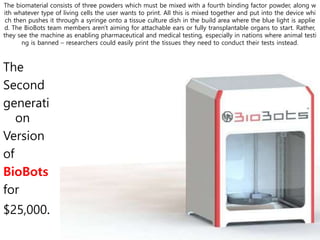

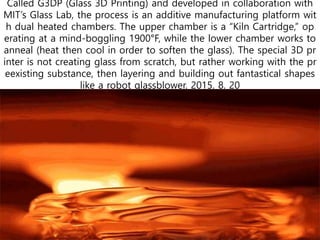

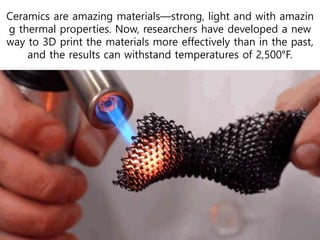

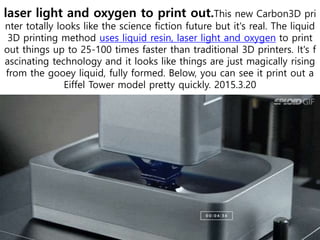

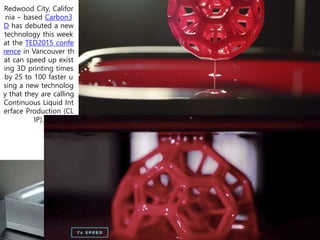

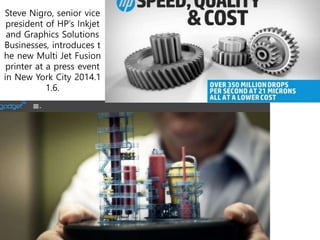

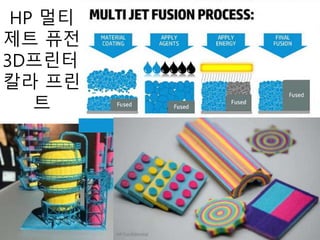

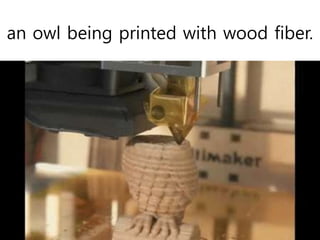

- Advancements in printing materials include glass, ceramics, and living cells. New techniques like Carbon3D's Continuous Liquid Interface Production can print objects over 25 times faster than traditional 3D printing.