Yasin - Resume

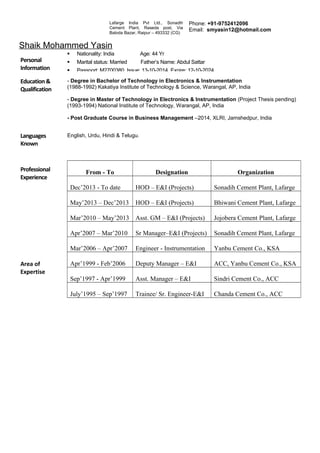

- 1. Lafarge India Pvt Ltd., Sonadih Cement Plant, Raseda post, Via Baloda Bazar, Raipur – 493332 (CG) Phone: +91-9752412096 Email: smyasin12@hotmail.com Shaik Mohammed Yasin Personal Information Nationality: India Age: 44 Yr Marital status: Married Father’s Name: Abdul Sattar Passport: M2700380, Issue: 13-10-2014, Expire: 12-10-2024 Education& Qualification - Degree in Bachelor of Technology in Electronics & Instrumentation (1988-1992) Kakatiya Institute of Technology & Science, Warangal, AP, India - Degree in Master of Technology in Electronics & Instrumentation (Project Thesis pending) (1993-1994) National Institute of Technology, Warangal, AP, India - Post Graduate Course in Business Management –2014, XLRI, Jamshedpur, India Languages Known English, Urdu, Hindi & Telugu. Professional Experience Area of Expertise From - To Designation Organization Dec’2013 - To date HOD – E&I (Projects) Sonadih Cement Plant, Lafarge May’2013 – Dec’2013 HOD – E&I (Projects) Bhiwani Cement Plant, Lafarge Mar’2010 – May’2013 Asst. GM – E&I (Projects) Jojobera Cement Plant, Lafarge Apr’2007 – Mar’2010 Sr Manager–E&I (Projects) Sonadih Cement Plant, Lafarge Mar’2006 – Apr’2007 Engineer - Instrumentation Yanbu Cement Co., KSA Apr’1999 - Feb’2006 Deputy Manager – E&I ACC, Yanbu Cement Co., KSA Sep’1997 - Apr’1999 Asst. Manager – E&I Sindri Cement Co., ACC July’1995 – Sep’1997 Trainee/ Sr. Engineer-E&I Chanda Cement Co., ACC

- 2. Technical Expertise General Management: As head of E&I function and direct reporting to VP-Projects, I have developed a strong experience on project management perspectives viz budget, cost, contract management, planning, erection, commissioning. Initial 11 years cement plant operation & maintenance coupled with latest 8 years in new cement plants project execution has extended self-confidence. Plant Management: Leading team of engineers/supervisors and technicians to achieve challenged targets both in project execution and O&M. My experience is mainly on maintenance of Electrical & Instrumentation system of large integrated state-of-art cement plants, shutdown maintenance, new projects execution that includes contract negotiation, erection, commissioning, performance tests and handover for operation. Areas of Expertise: - Project Management - Maintenance Management Project Management: Ensuring execution of project activities within time & budgetary parameters. Monitoring projects with respect to Cost, Resource Deployment, Time over-runs, Quality Compliance and Manpower planning to ensure timely execution of projects. Responsible for E&I execution of following projects: • Clinker rail wagon loading station and 23 km railway line corridor project – Year 2014 • 1500 TPD PPC blending & packing plant project, Beumer Group, India – Year 2013 • 3500 TPD PSC grinding & packing plant project, supplied by KHD & Loesche, Germany -Year 2011 • 5000 TPD Cement Clinkerization project. Supplied by TCDRI, China – Year 2008 • Kiln upgradation from 7000 to 8500 TPD and 190 TPH new cement mill at Yanbu, KSA. Supplied by KHD, Germany - Year 2005 • 3000 TPD PSC grinding and packing plant. VRM supplied by Kobe Steel, Japan – Year 1998 • 150 TPH clinker pre grinding roller mill at Chanda Cement plant – Year 1996 Maintenance Management: • Identify & implement cost effective maintenance practices. Work upon areas of chronic problems/breakdowns and initiate steps to solve problems through root cause analysis. • Ensured operations to be as per set parameters/ standards and experience of developing procedures for operational excellence. • Intra department liaising and coordination with external agencies. • Look for modifications in direction of achieving increased productivity and quality operations. • Planning and scheduling maintenance to increase equipment reliability & plant availability. • Increasing mean time between failures & reducing mean time to repair of equipment, thereby increasing productivity. • Efficient problem solving skills in functioning of electrical, automation and process equipment. • ORACLE based plant maintenance, inventory and purchase system. • Implementation of ISO-9001, ISO-14001, company’s safety and health policy. Responsible of E&I annual budget: Good knowledge of Operation and CAPEX budget preparation, feasibility studies and contract preparation and management. Inventory Management: • Inventory and spares management, working on Strategic Planning for a period of one year. • Prepare contingency plans to cater emergencies. • J. D. Edward plant inventory and purchase system HR Experience: • Skilled at inspiring confidence, conducting brain storming sessions, subordinate development, leading by example, self-initiating, goal-oriented and logical in approach. • Assess subordinates & arrange suitable training and skill development programs. Manpower development through drawing career path & succession plan in E&I department.

- 3. Electrical: Erection, Testing & Commissioning of 132/6.6kV, 25MVA Transformers at 132KV Outdoor Switchyard. 145 kV SF6 breakers, CT/PT, isolators and 6.6 kV VCBs Testing & co-ordination of microprocessor based relays (Schneider SEPAM Series & ABB) HT & LT Motor, HT & LT PCC, MCC, Soft starters and APFC. ESP, compressor and stand alone panels Instrumentation: Networking on MB, MB+, TCP/IP, Profibus and Modbus communication. Schneider, ABB and Elsag Bailey DCS system ABB, Siemens and Honeywell PLC systems Schenck and Pfister weighing systems ABB ACS 800, ACS 1000, Rockwell, Siemens LV and MV Variable Speed Drives. Field Instrumentation viz smart process transmitters, vibration, dust monitoring, kiln shell scanners and stand alone PLC panels. Safety instrumentation of transport equipment. Pfaff auto sampling, XRF analysers, Minimax & Total Walther Fire Alarm and extinguishing systems, CCTV and communication systems of cement plant. Hydraulics and Pneumatics: Knowledge of hydraulic drives, valves, regulators, manifolds, actuators & final control elements. Knowledge of pneumatic valves, regulators, actuators, I-P converters and final control elements. Training General Training: - Total Productive Maintenance Course - Internal Quality Audit Training Technical Training: - Schneider Automation Training, Beijing, China - ABB DCS – Industrial IT 800 XA, Yanbu, Saudi Arabia - Honeywell PLC System, Pune, India - Siemens UPS System, Kolkata, India S M YASIN