Maximizing the Impact of PEMS in Future Compliance Programs

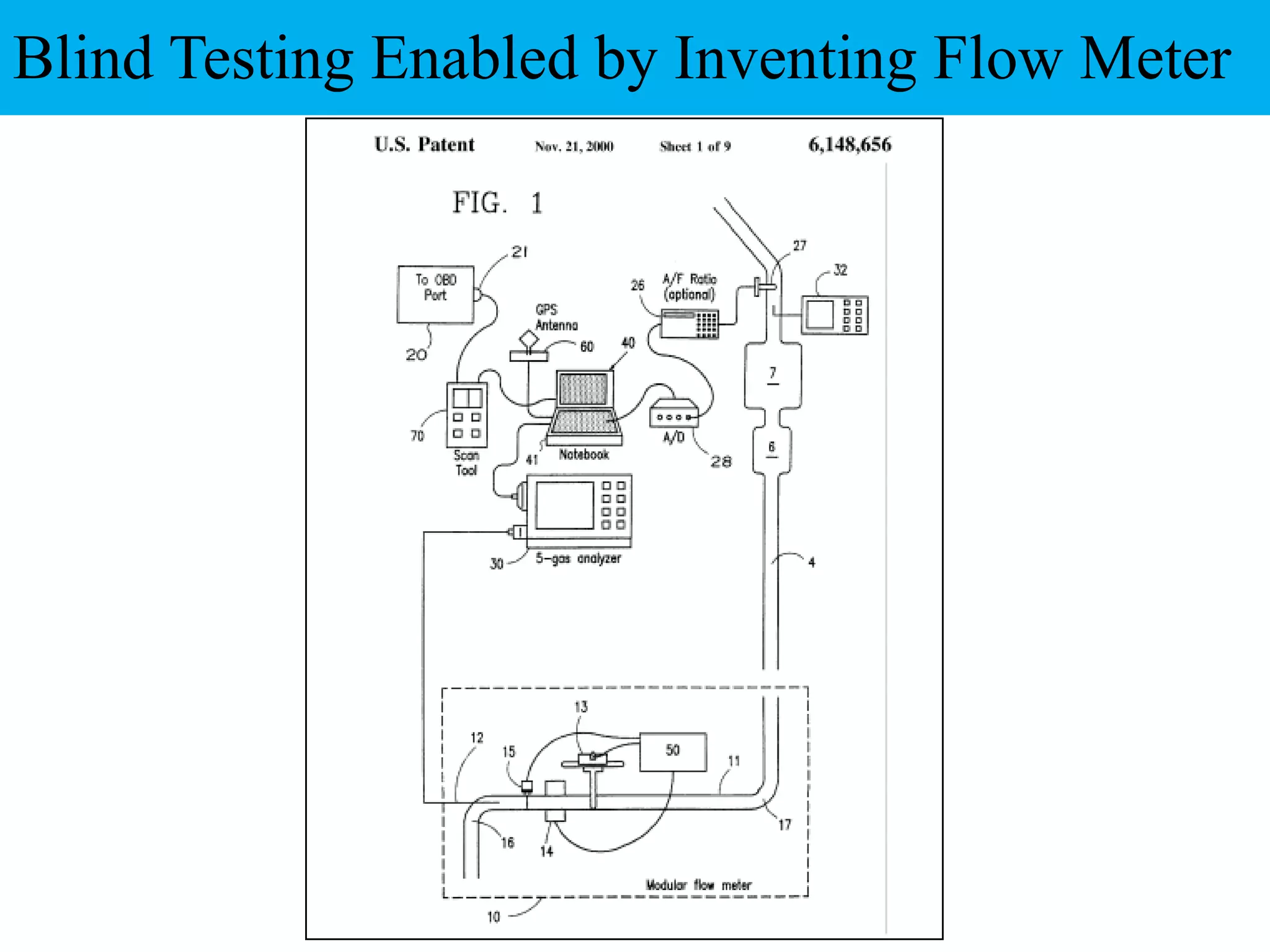

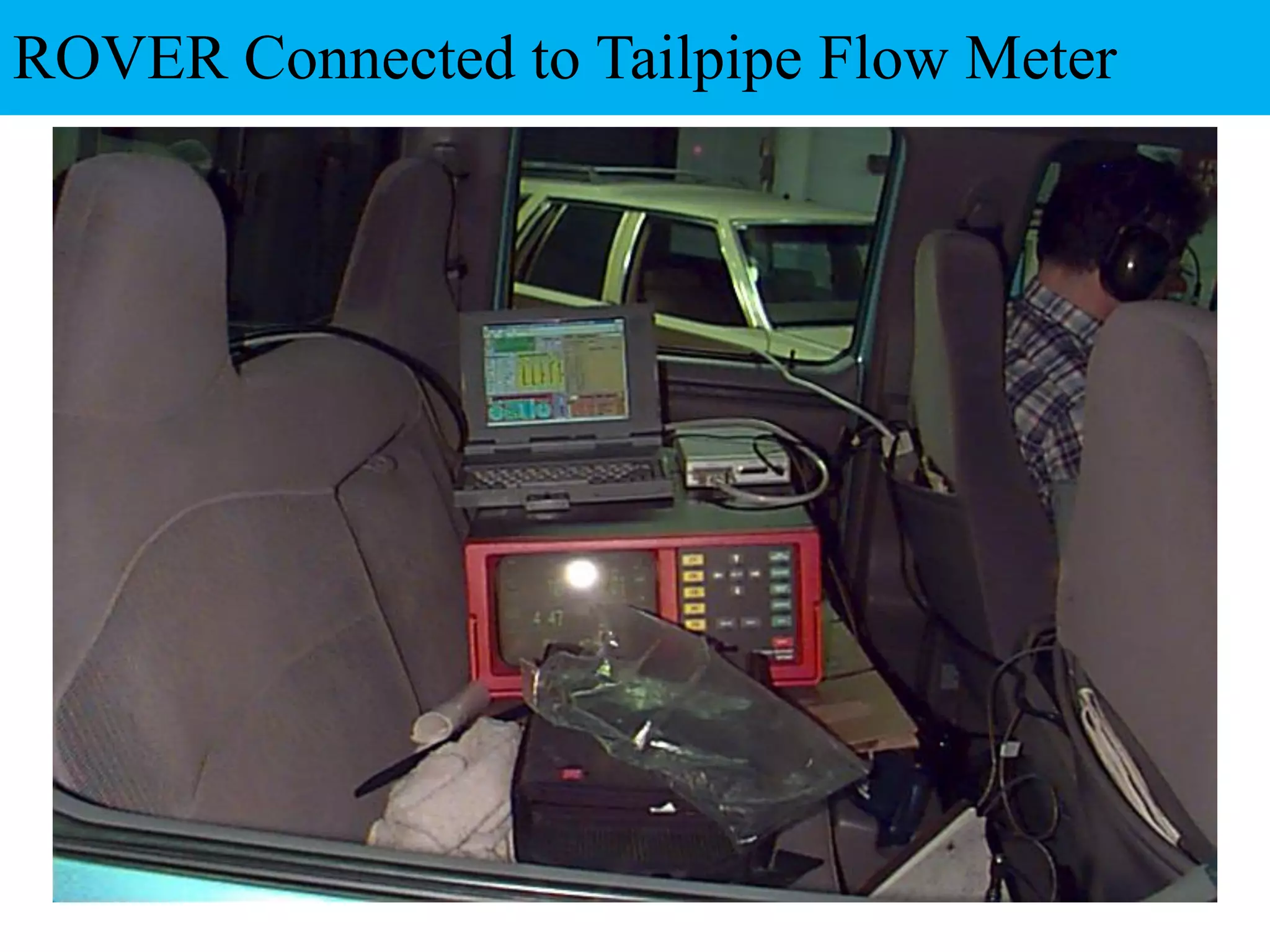

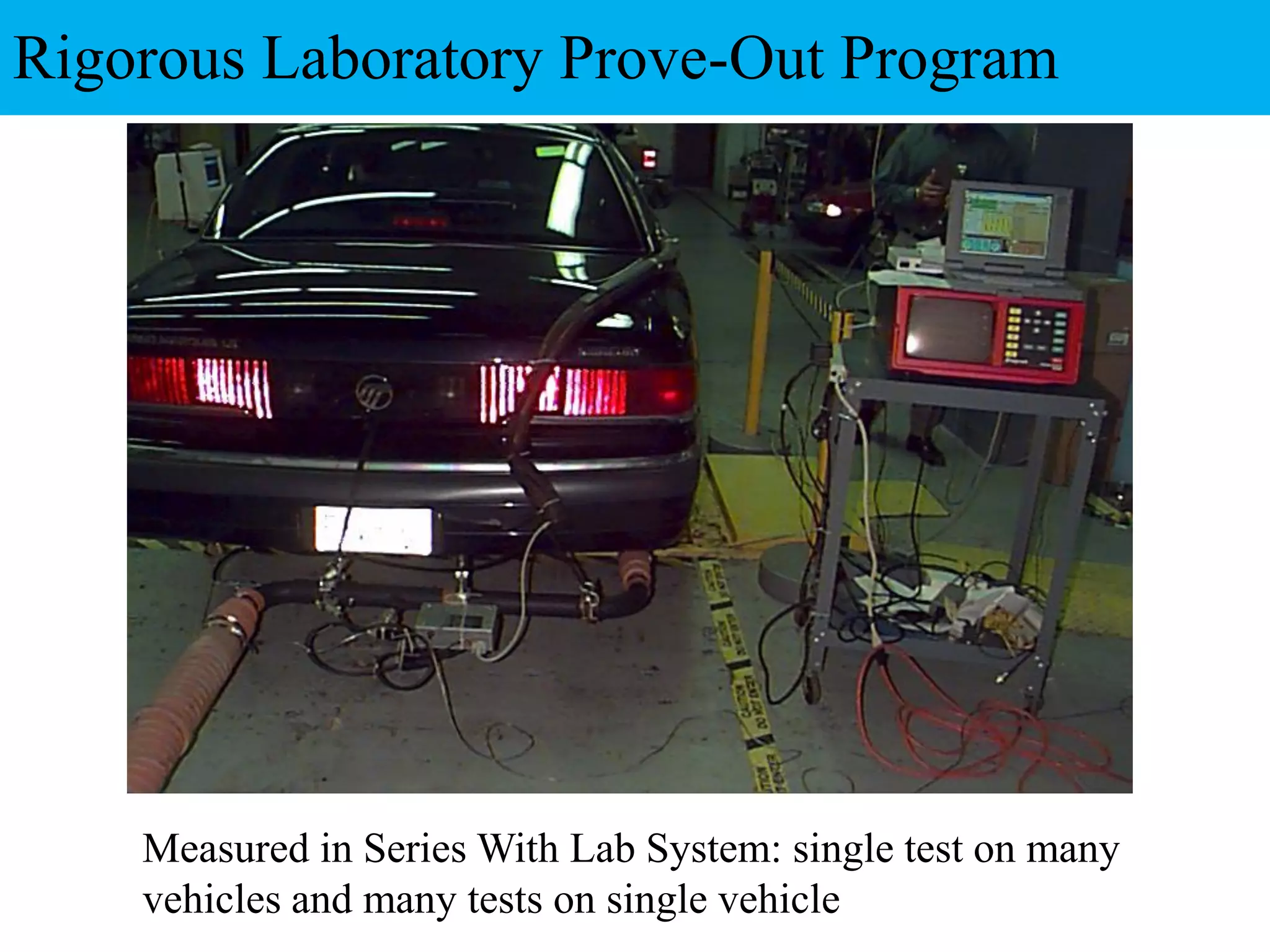

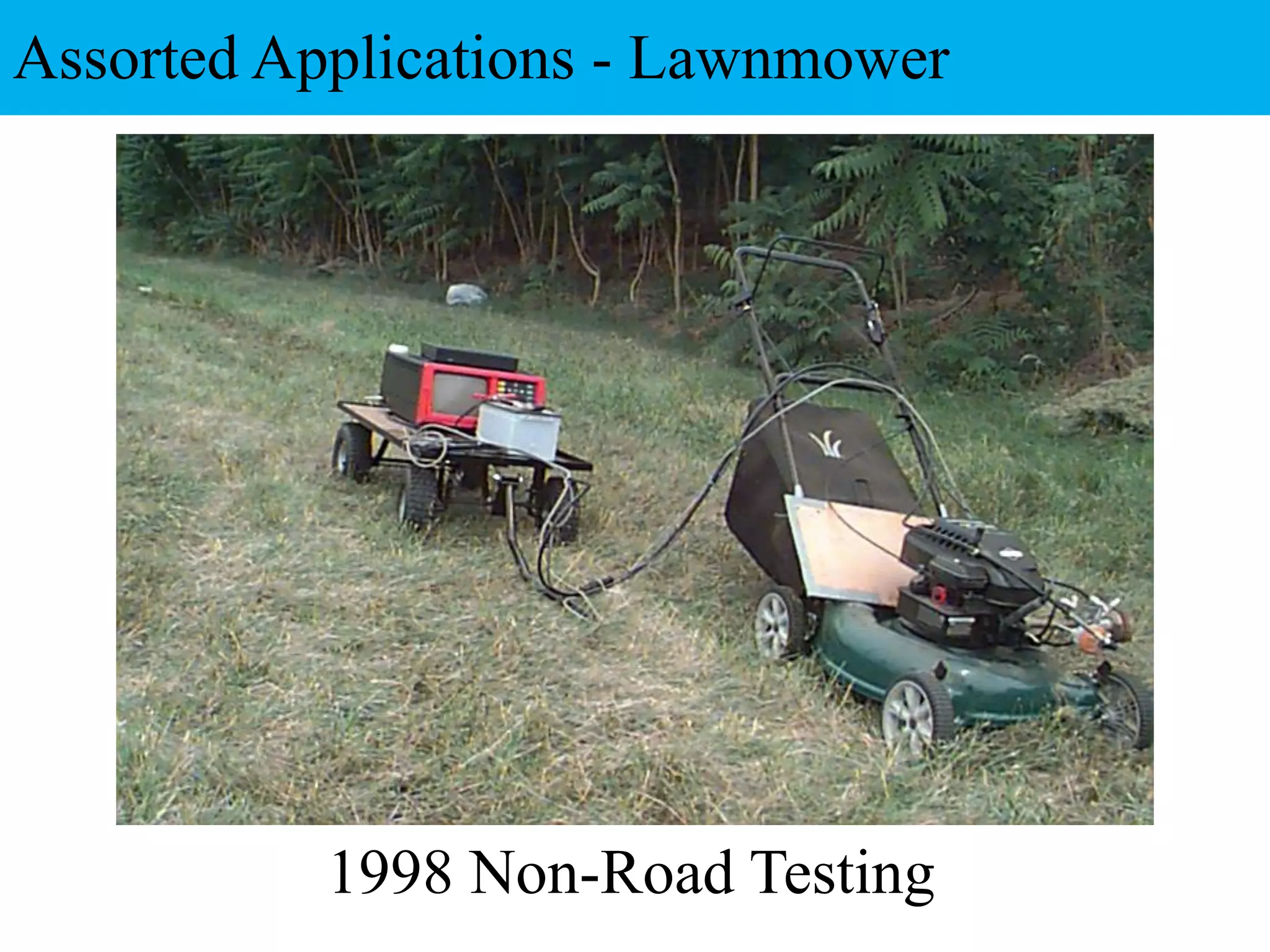

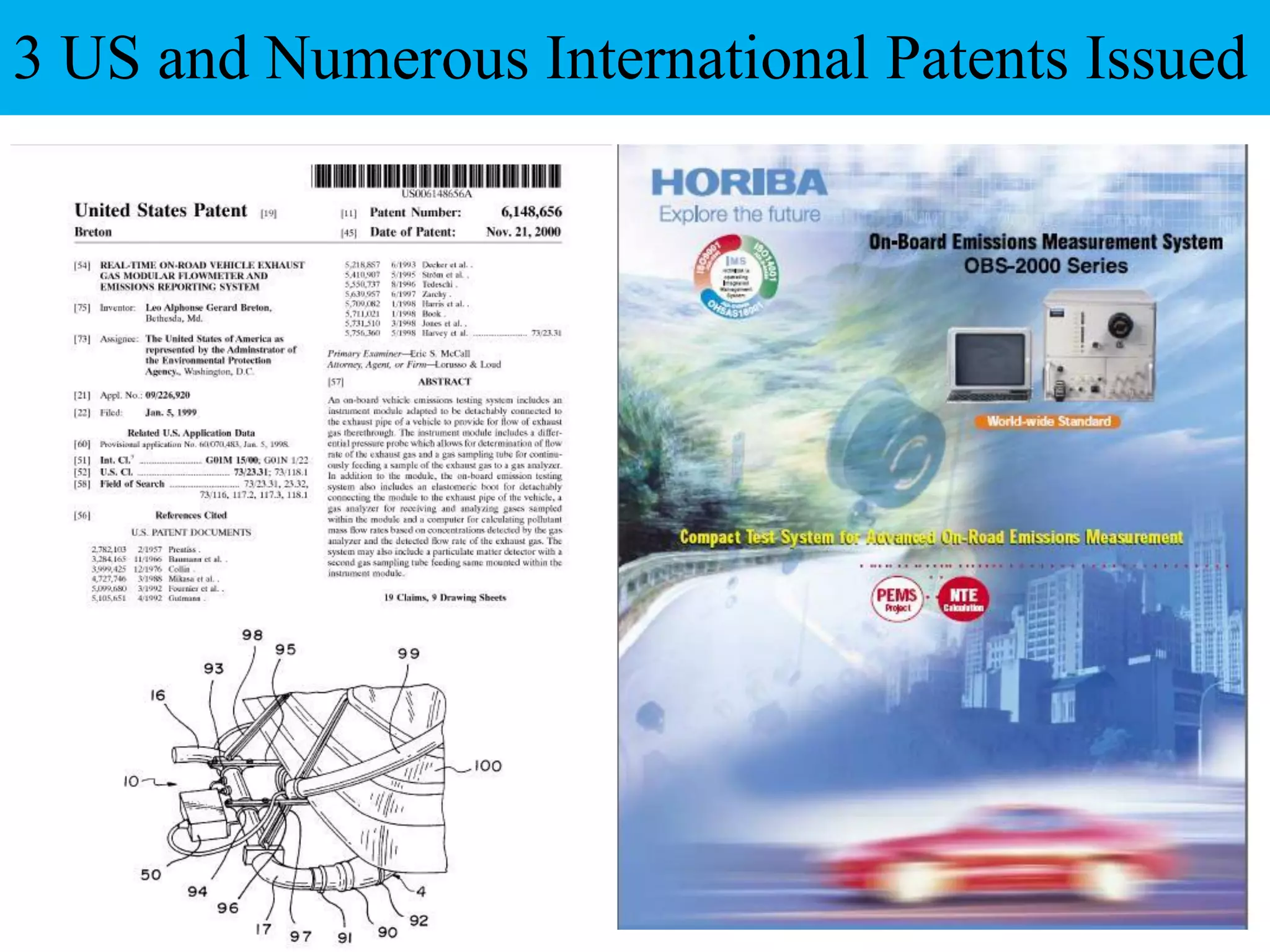

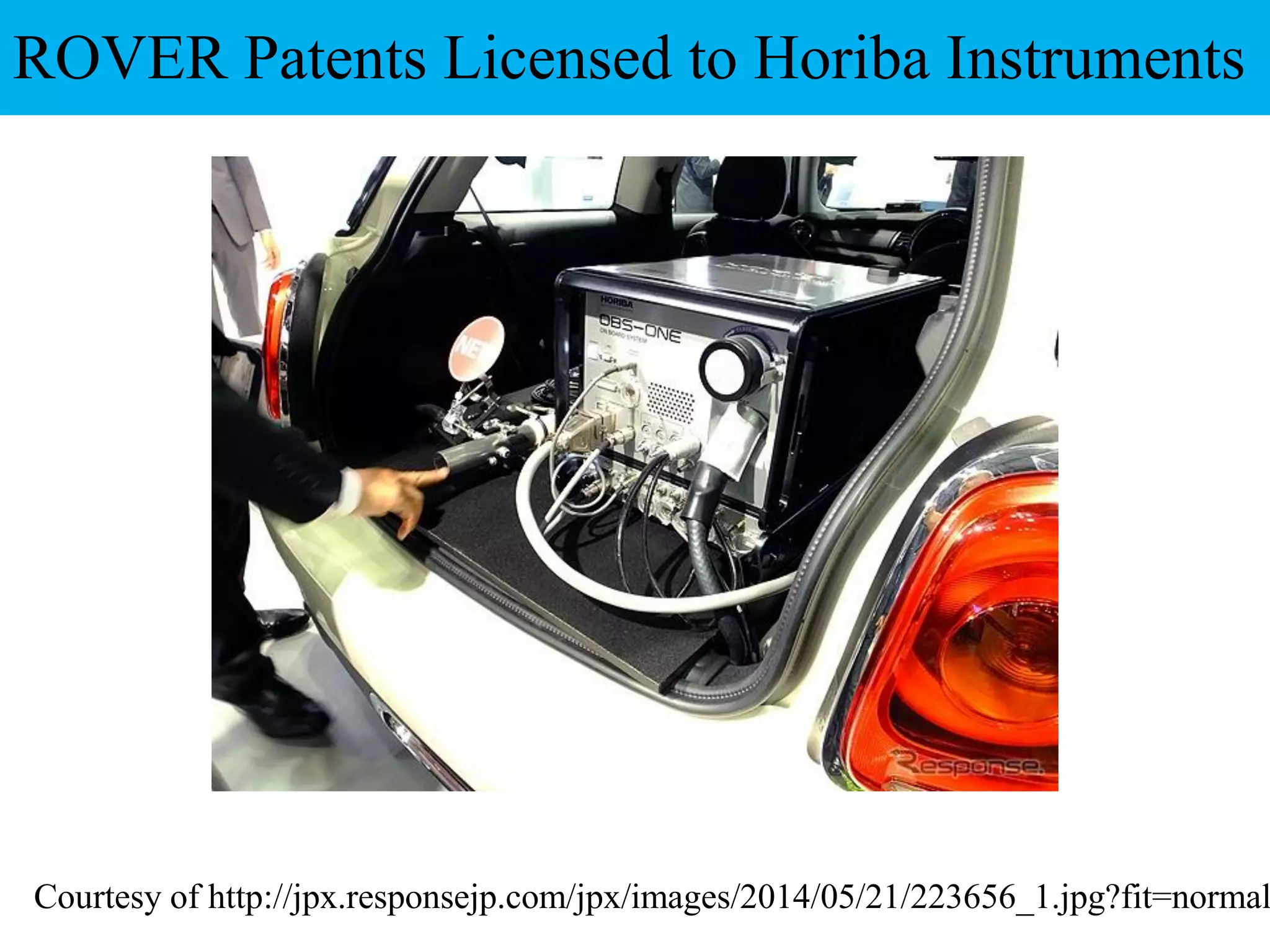

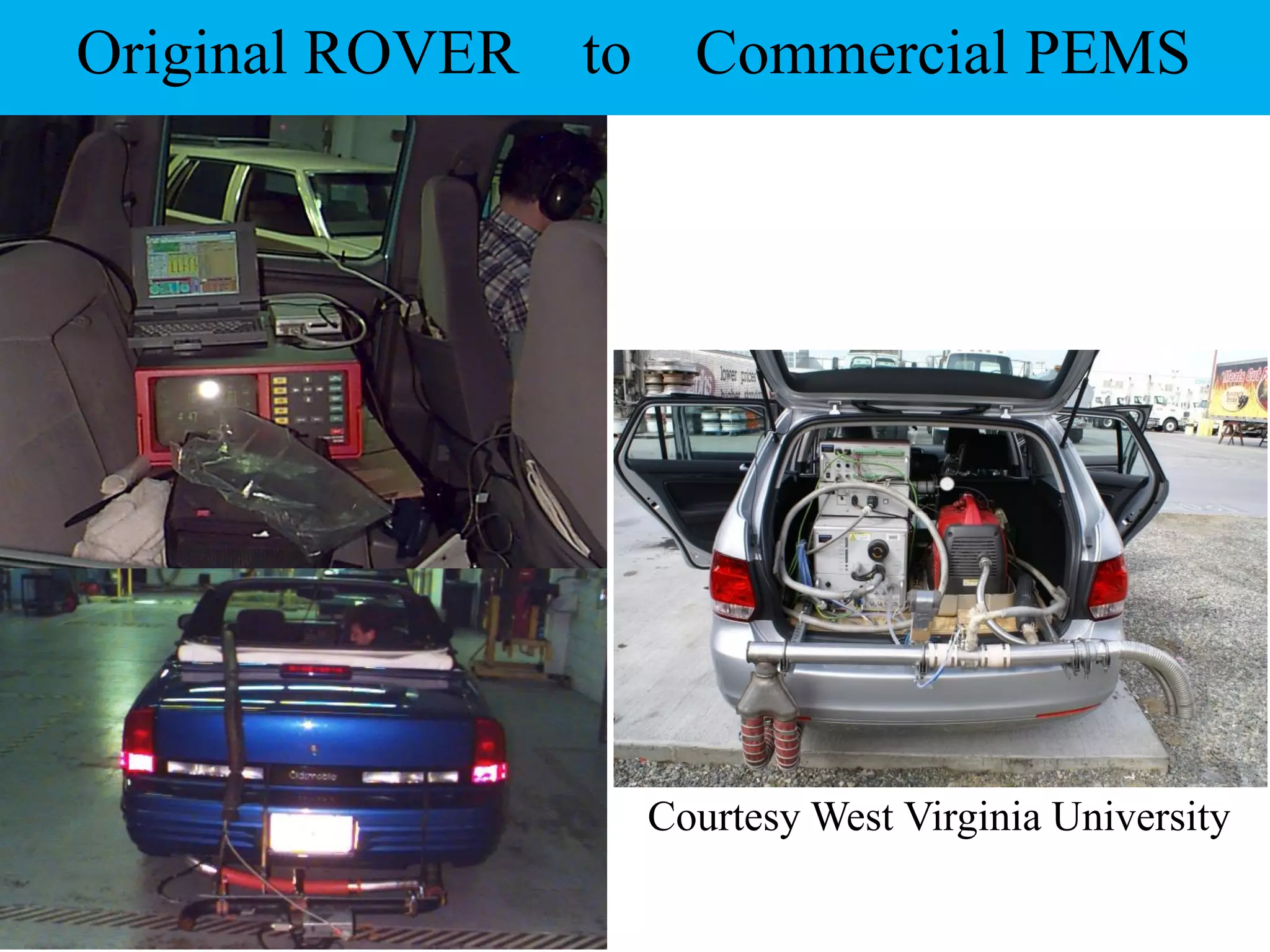

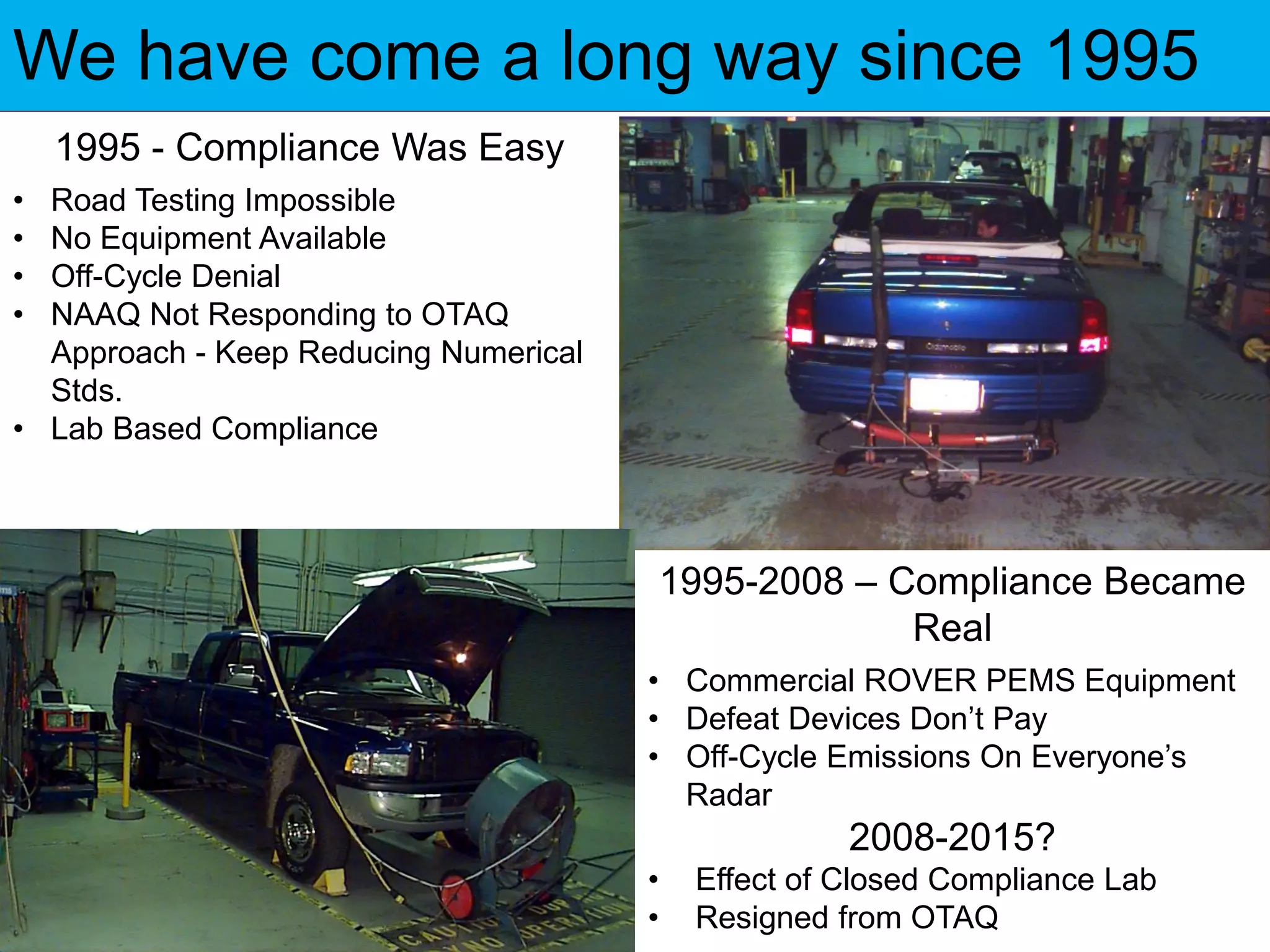

1) Real-world emissions testing is now possible and routinely performed due to the development of portable emissions measurement systems (PEMS) like ROVER, which was pioneered in the 1990s.

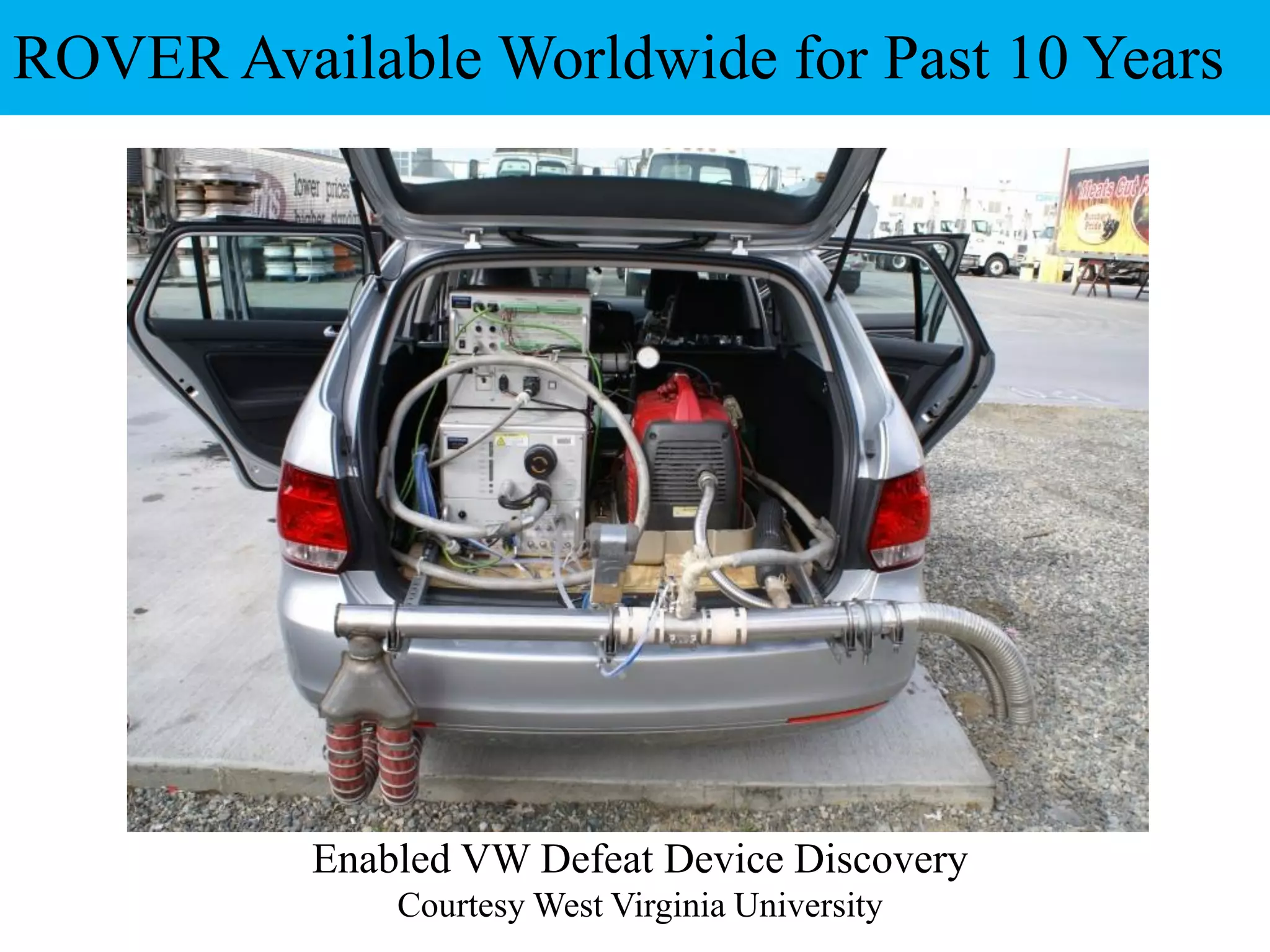

2) ROVER demonstrated that accurate real-world emissions testing was technically feasible, and helped uncover emissions defeat devices, shifting the focus to real-world compliance.

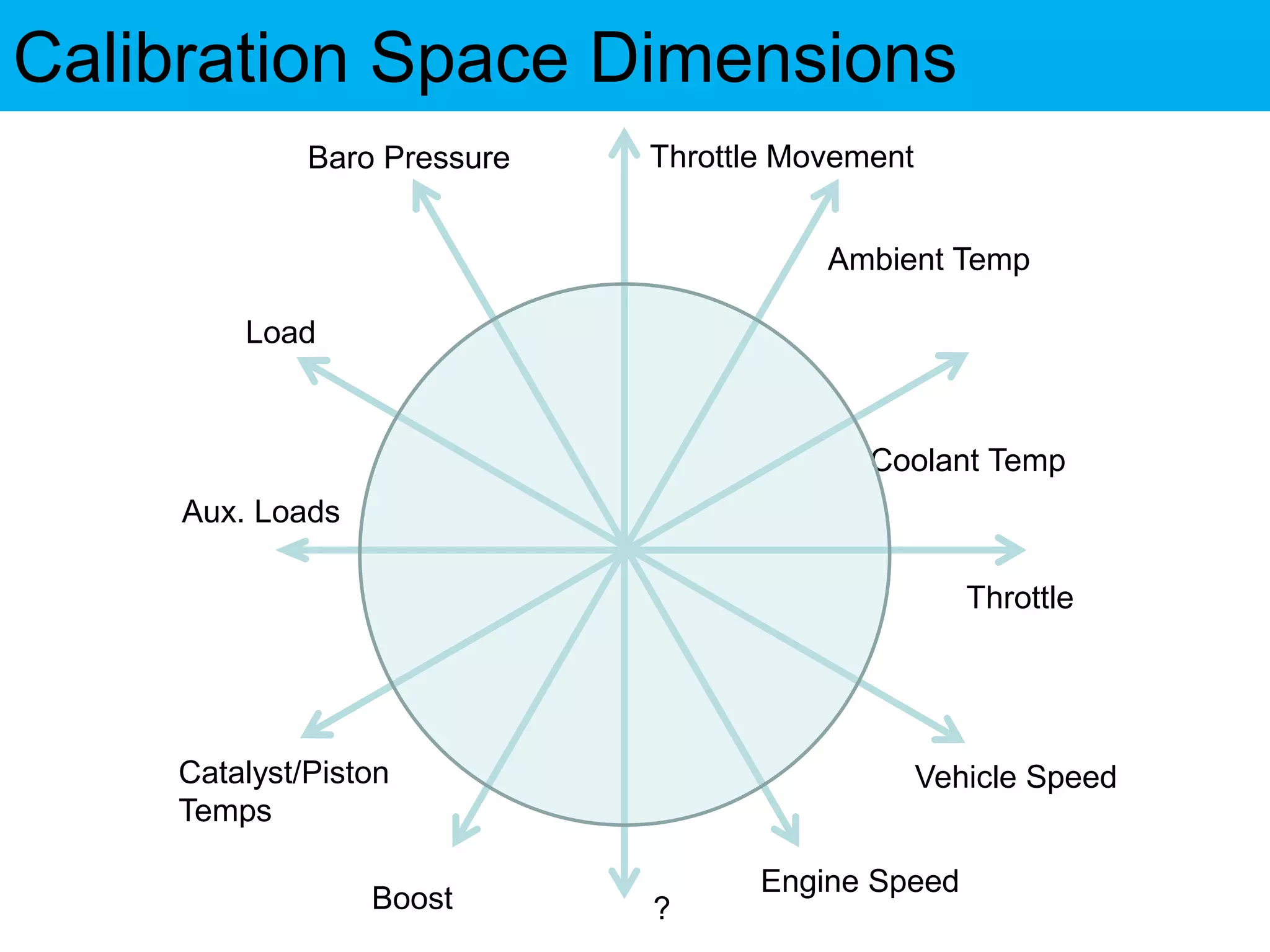

3) To maximize the impact of PEMS, future programs must maintain high equipment quality and accuracy standards to ensure robust and meaningful real-world testing results.