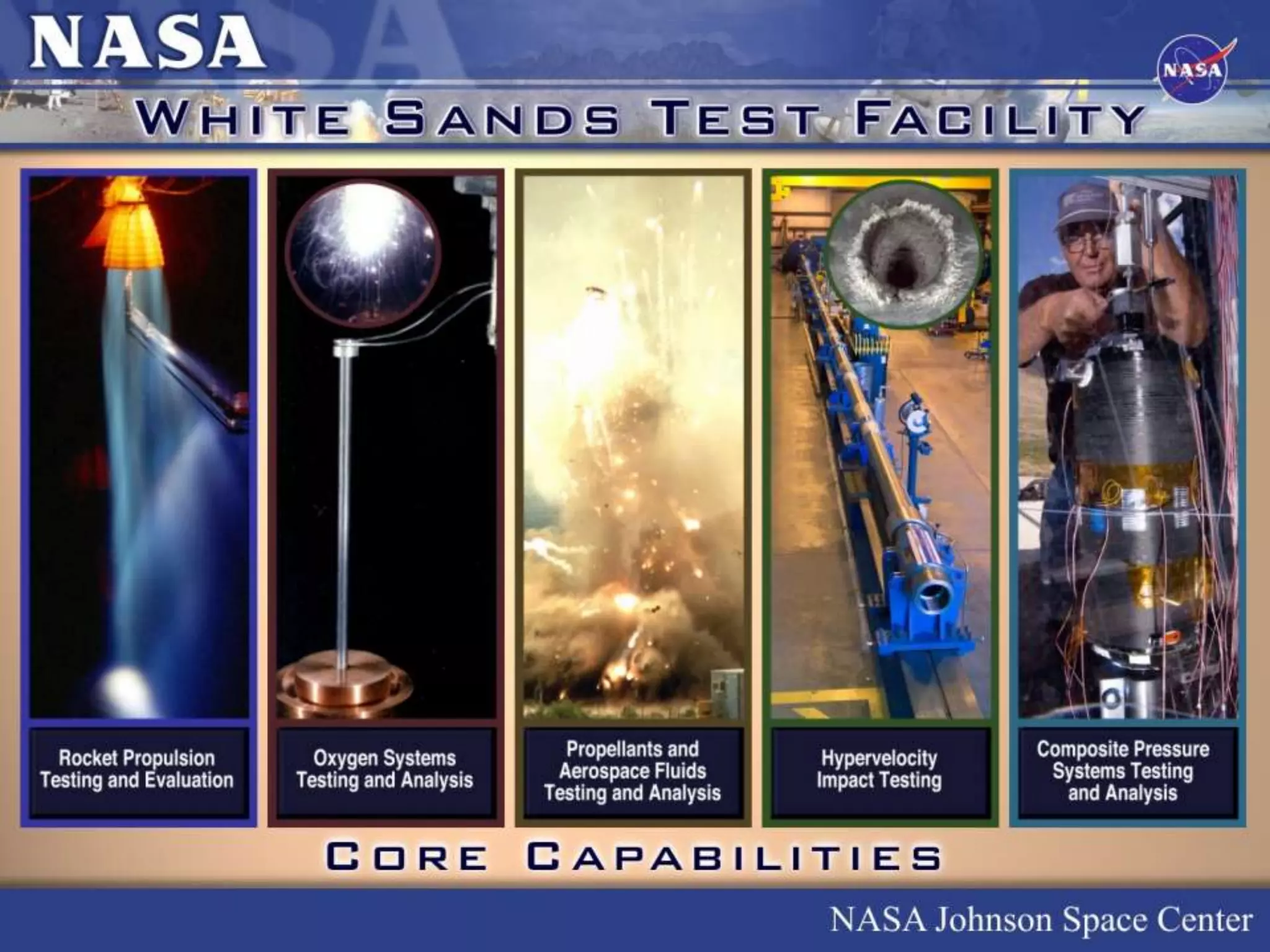

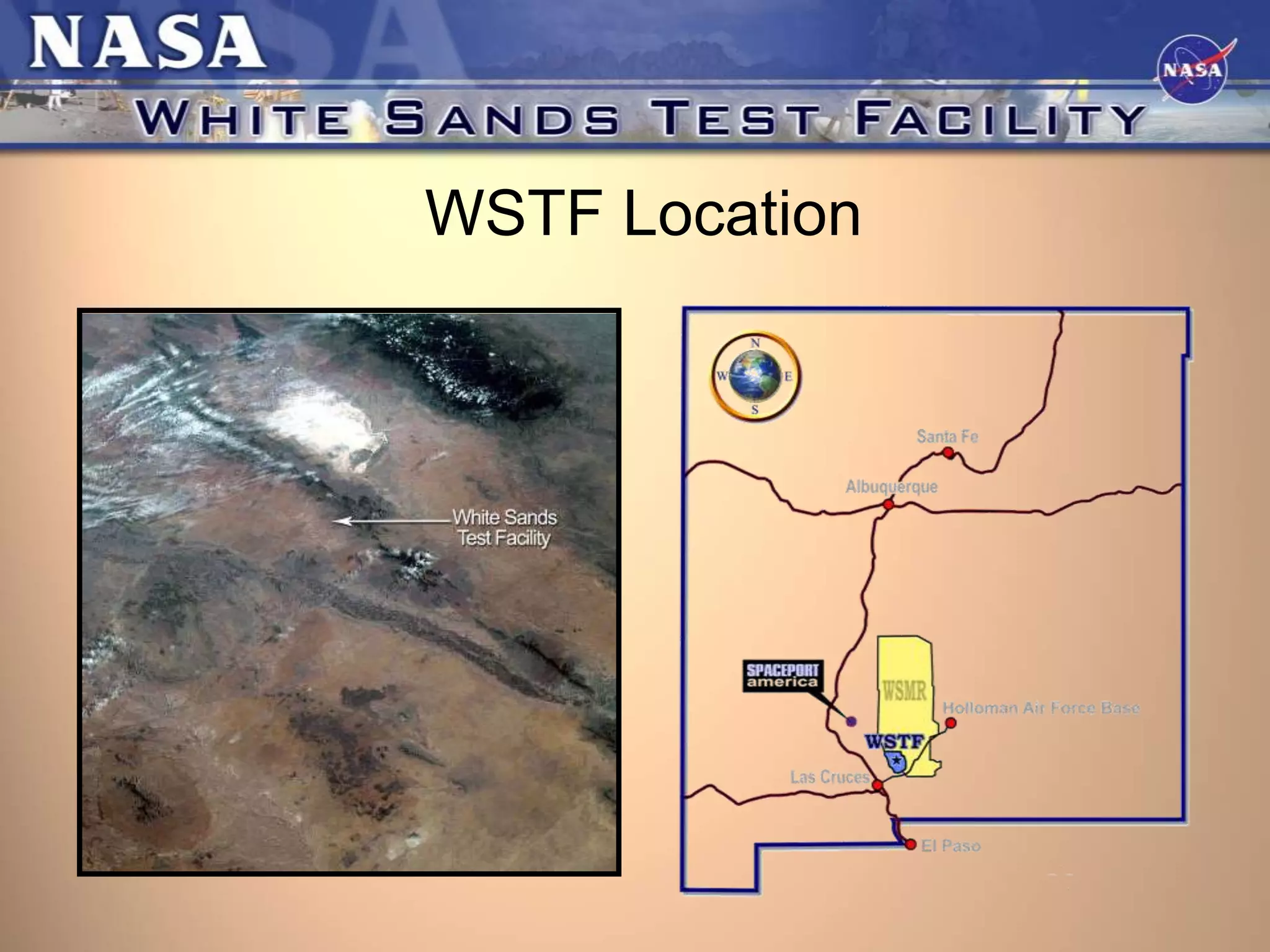

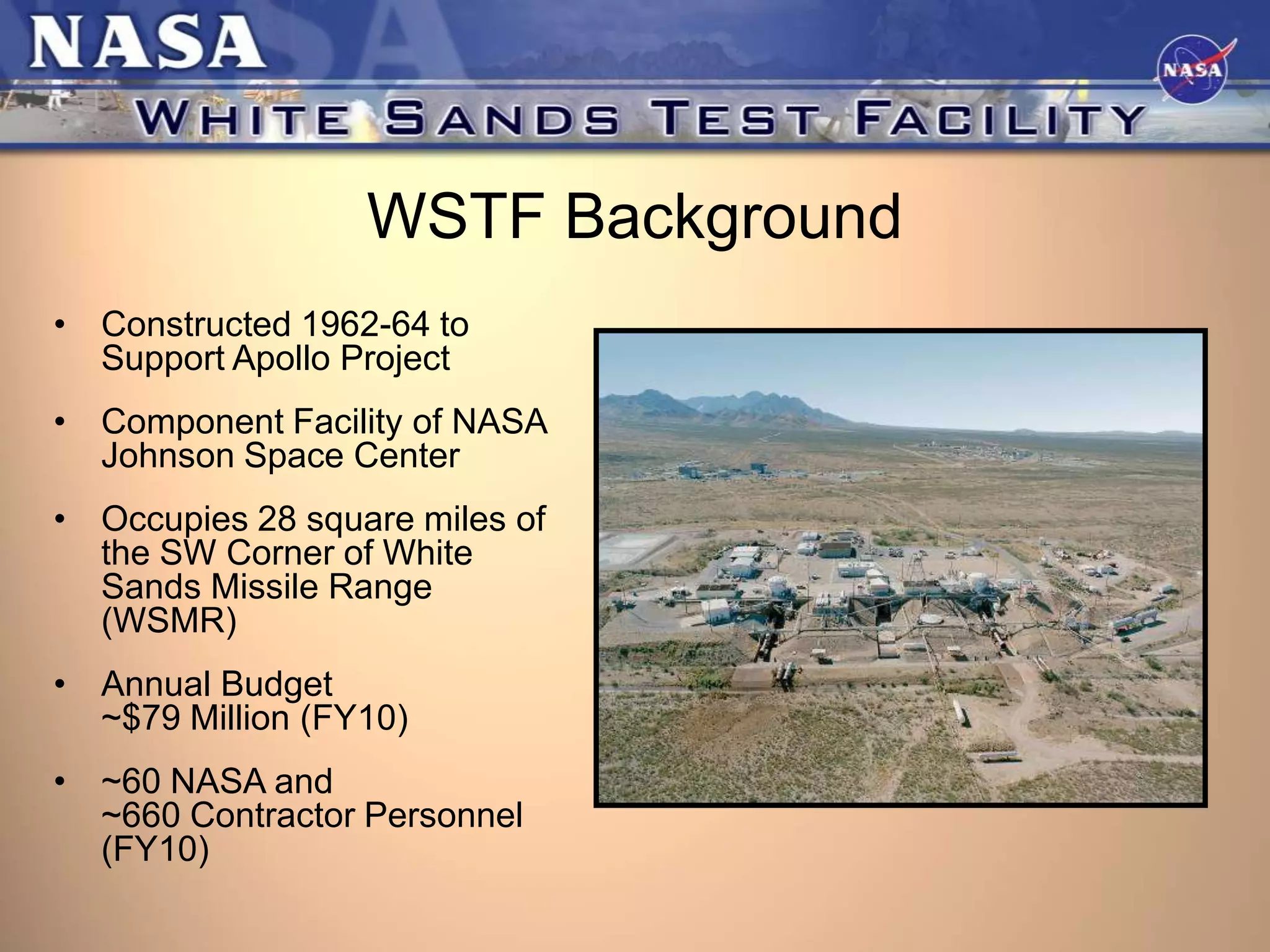

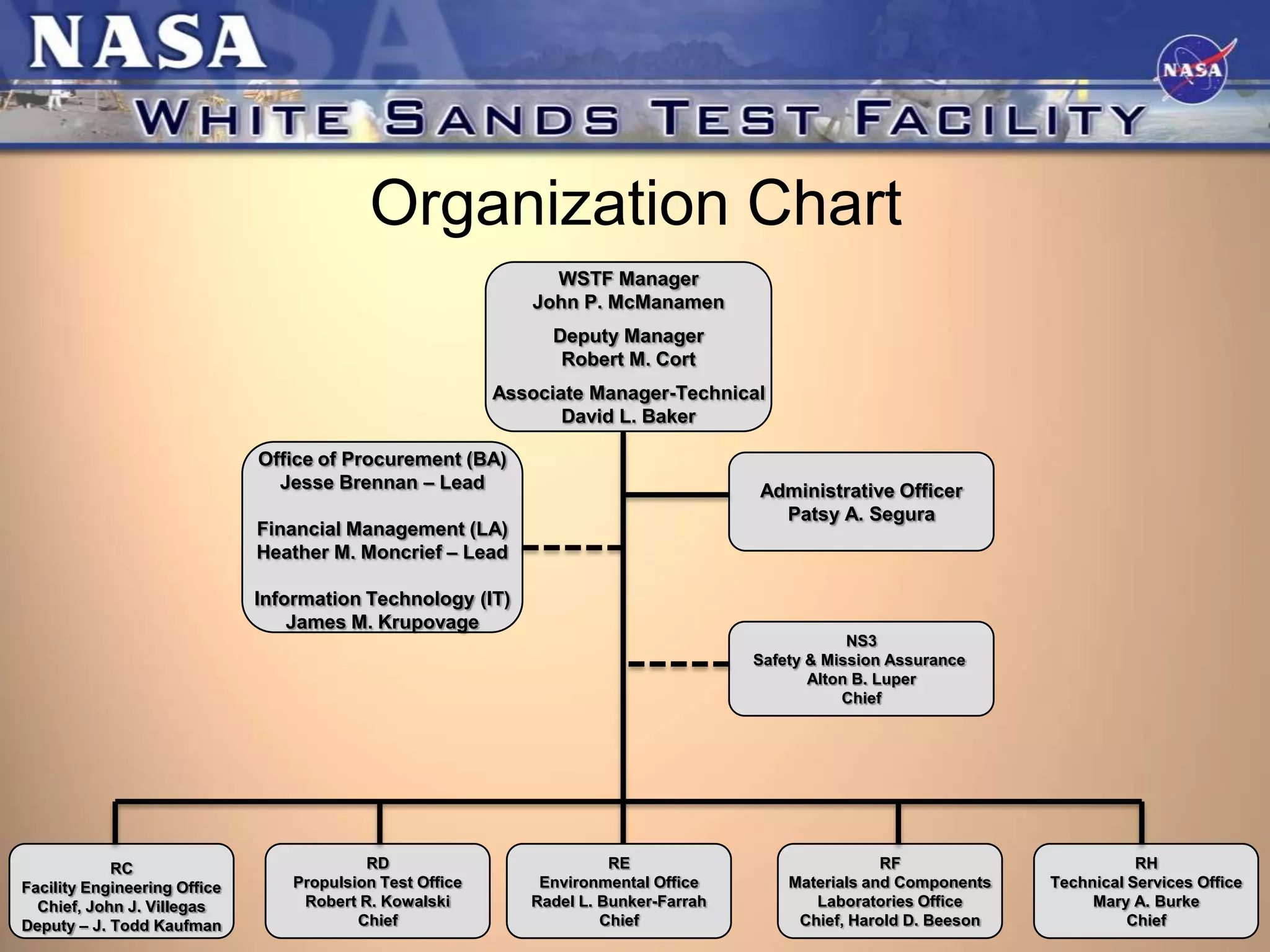

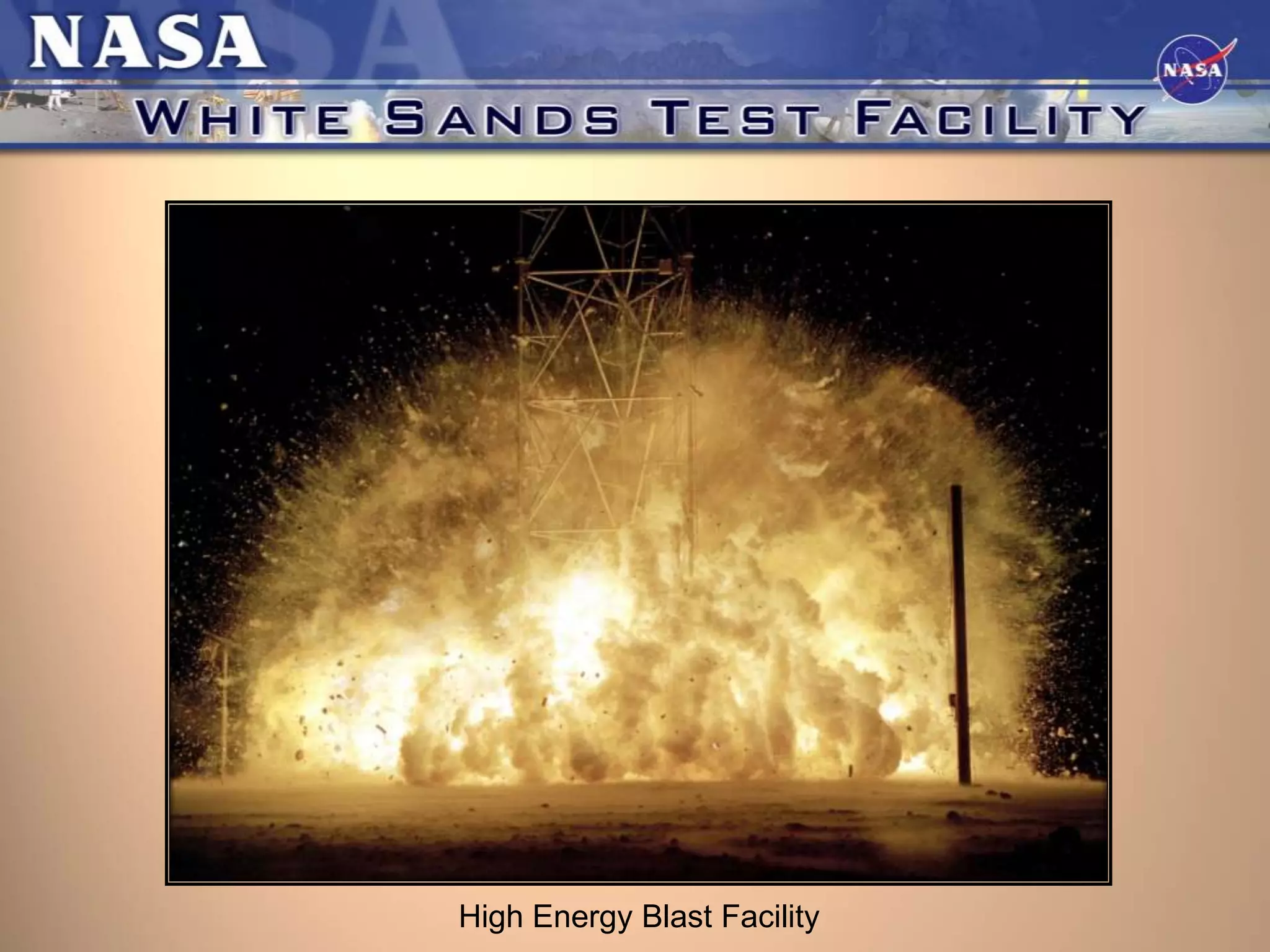

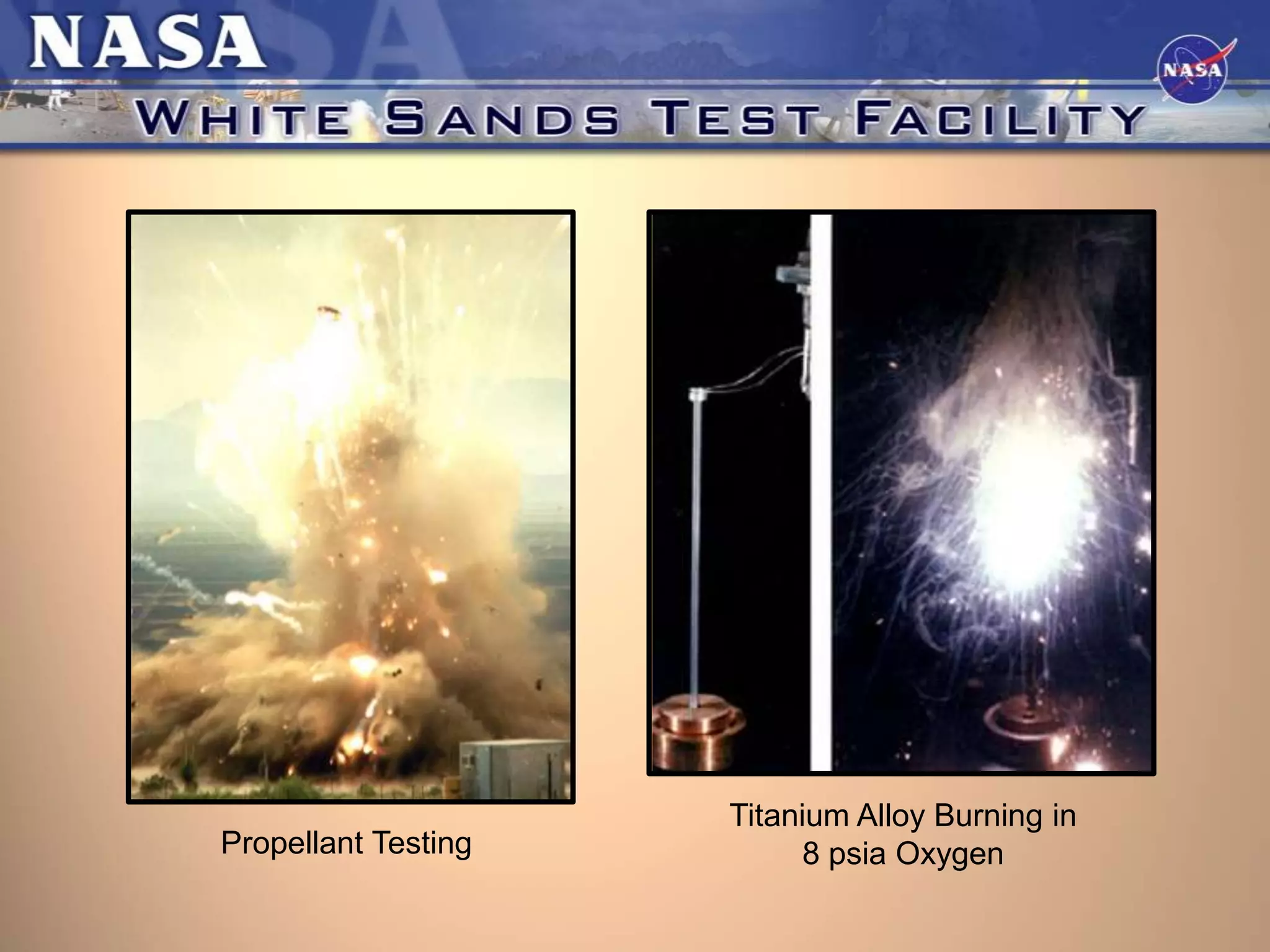

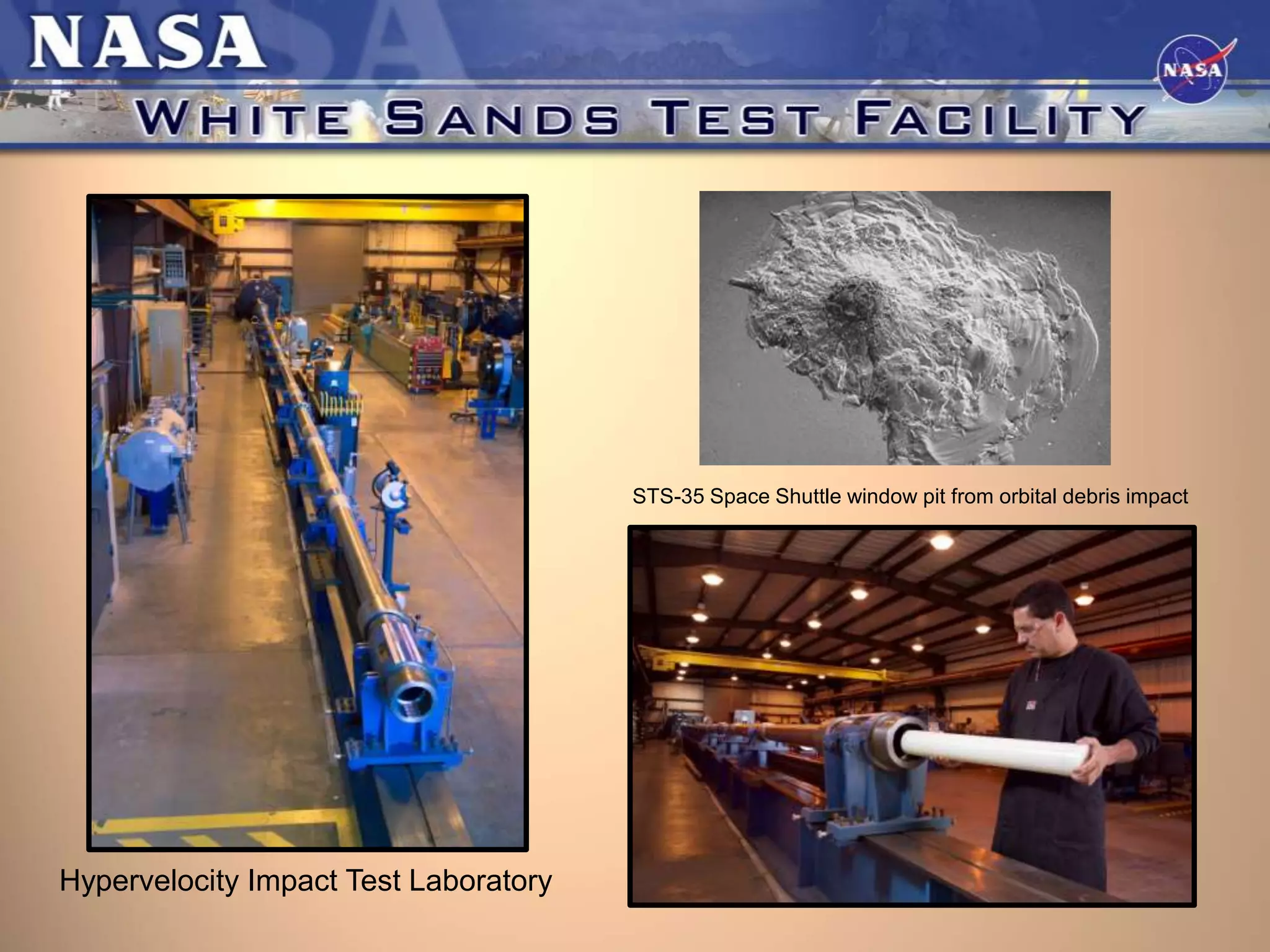

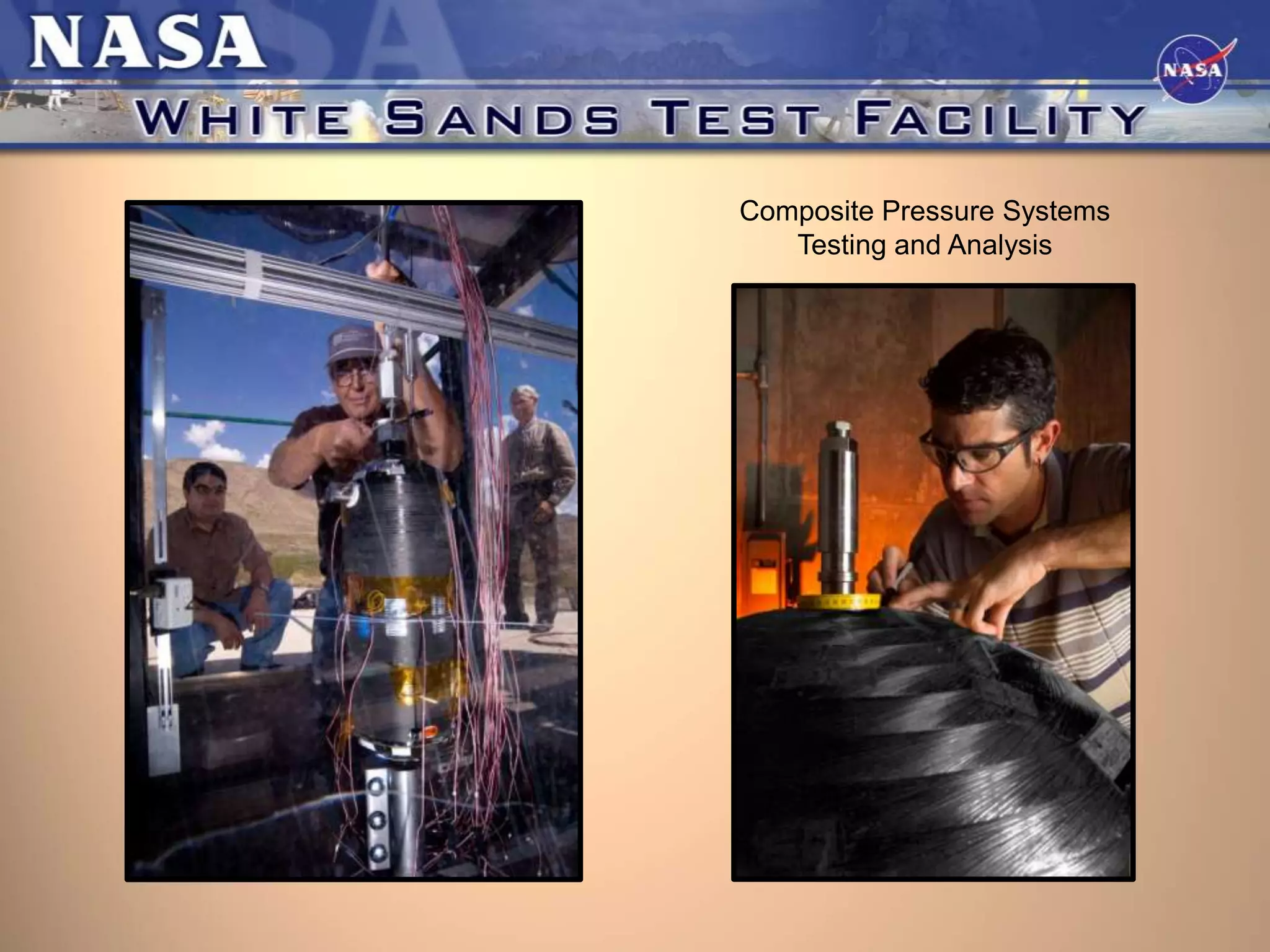

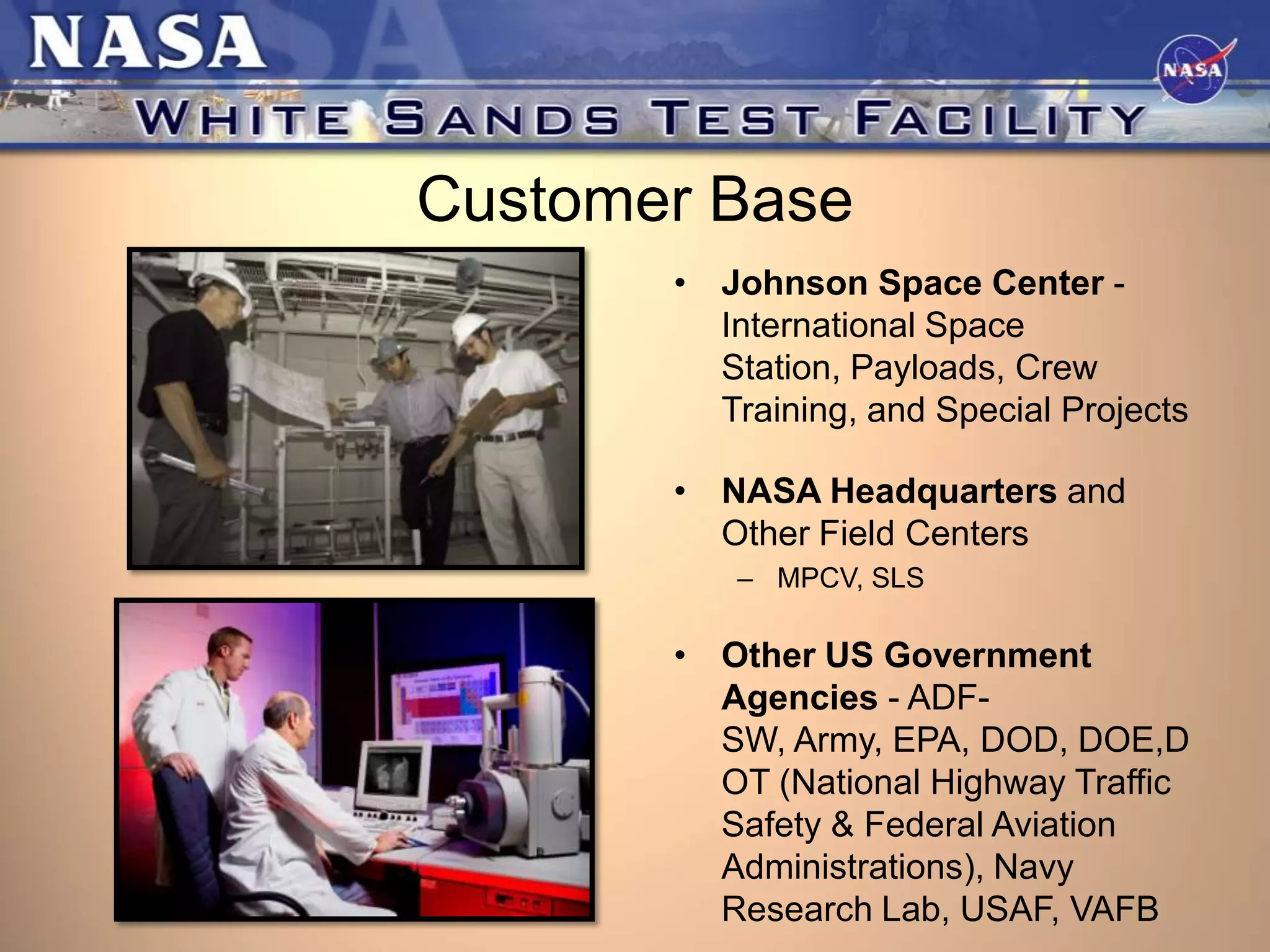

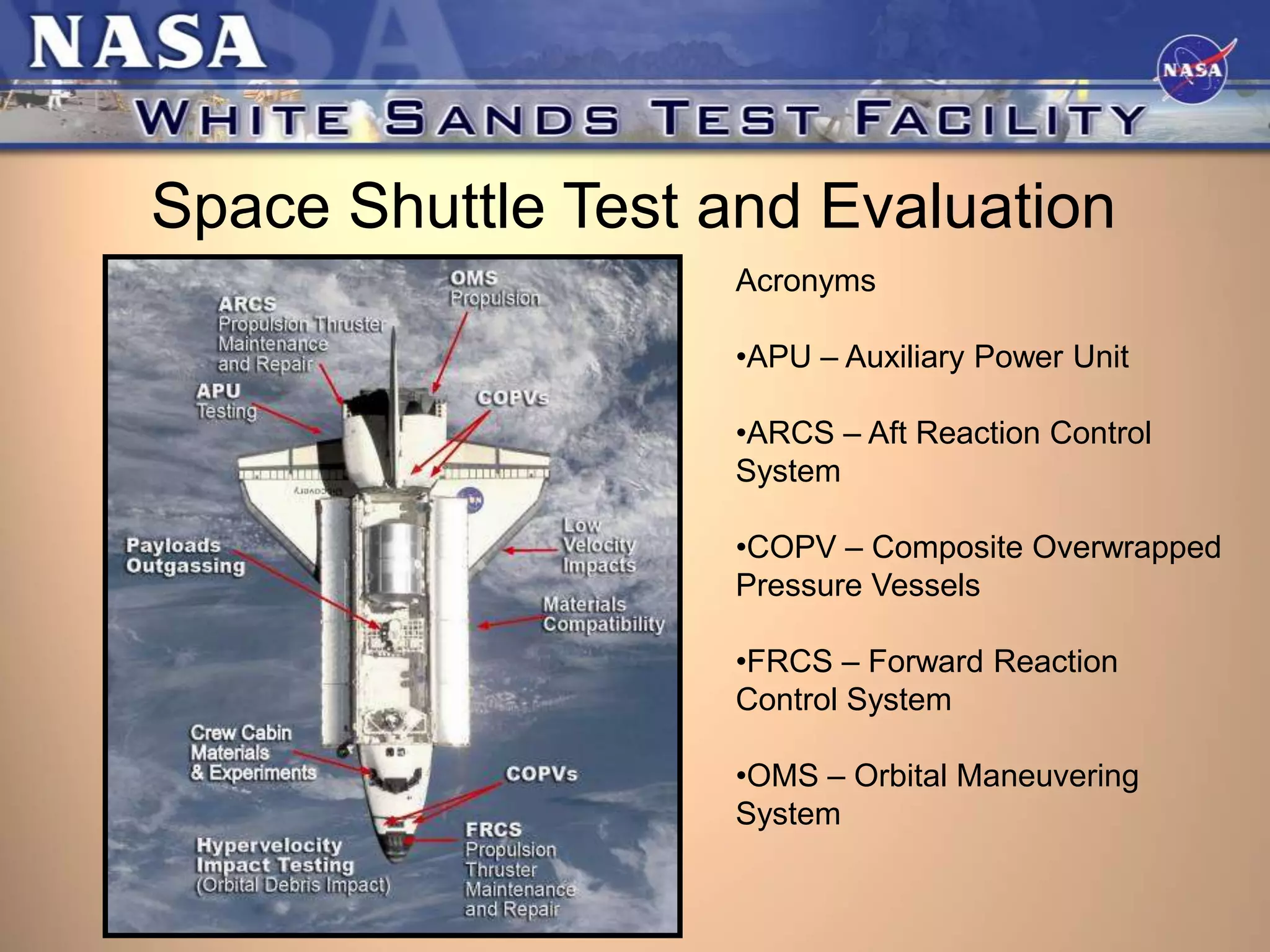

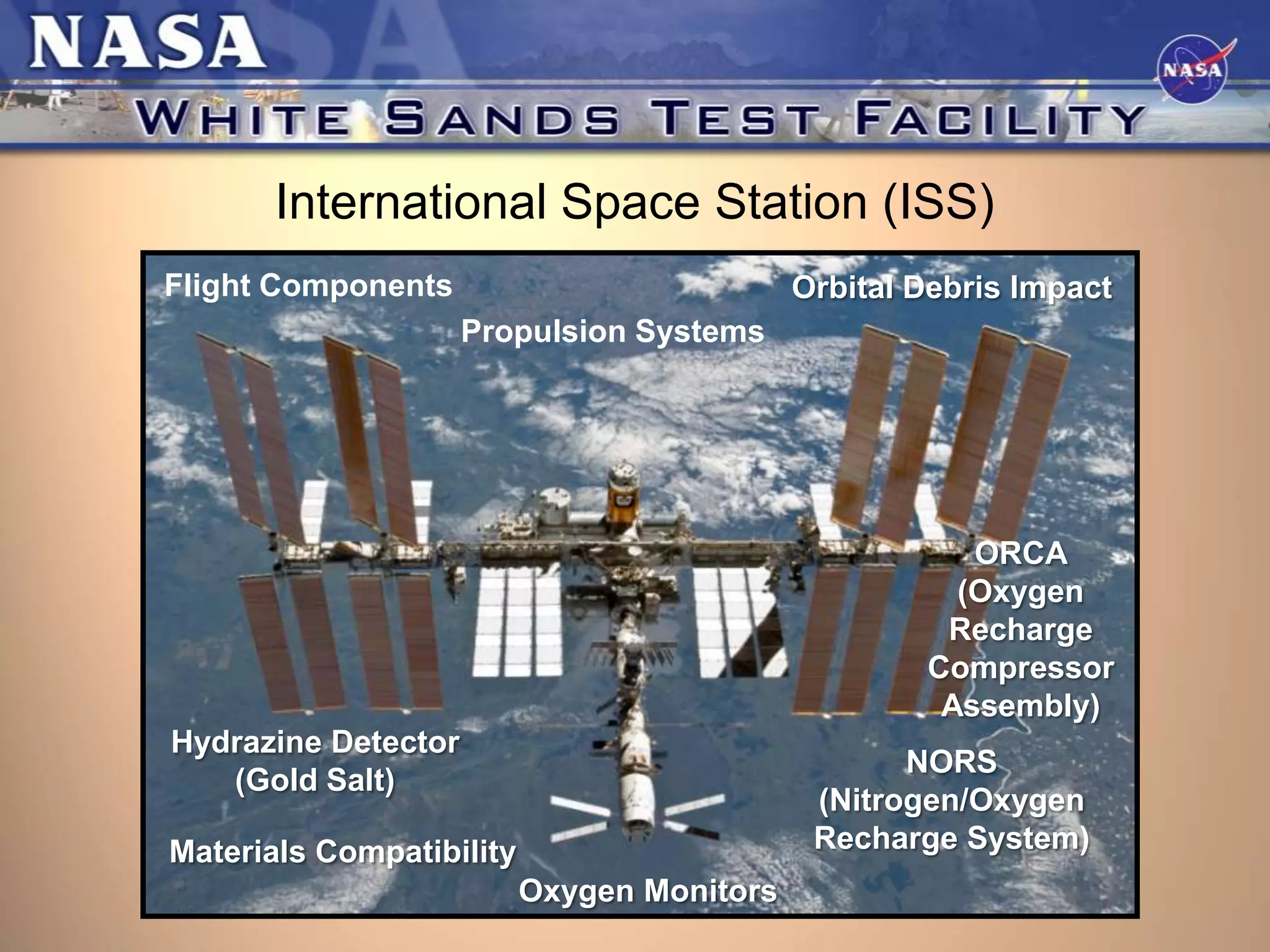

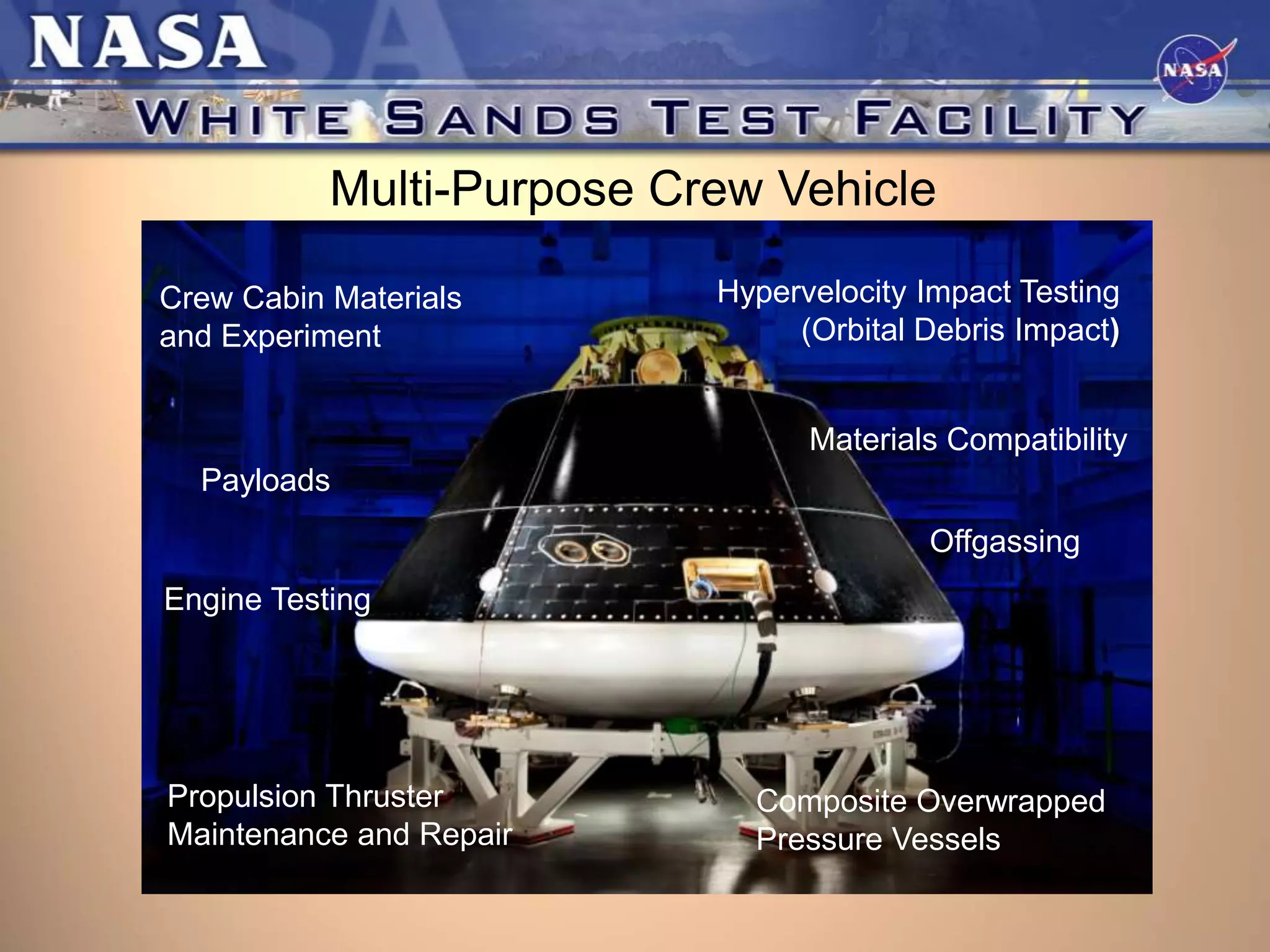

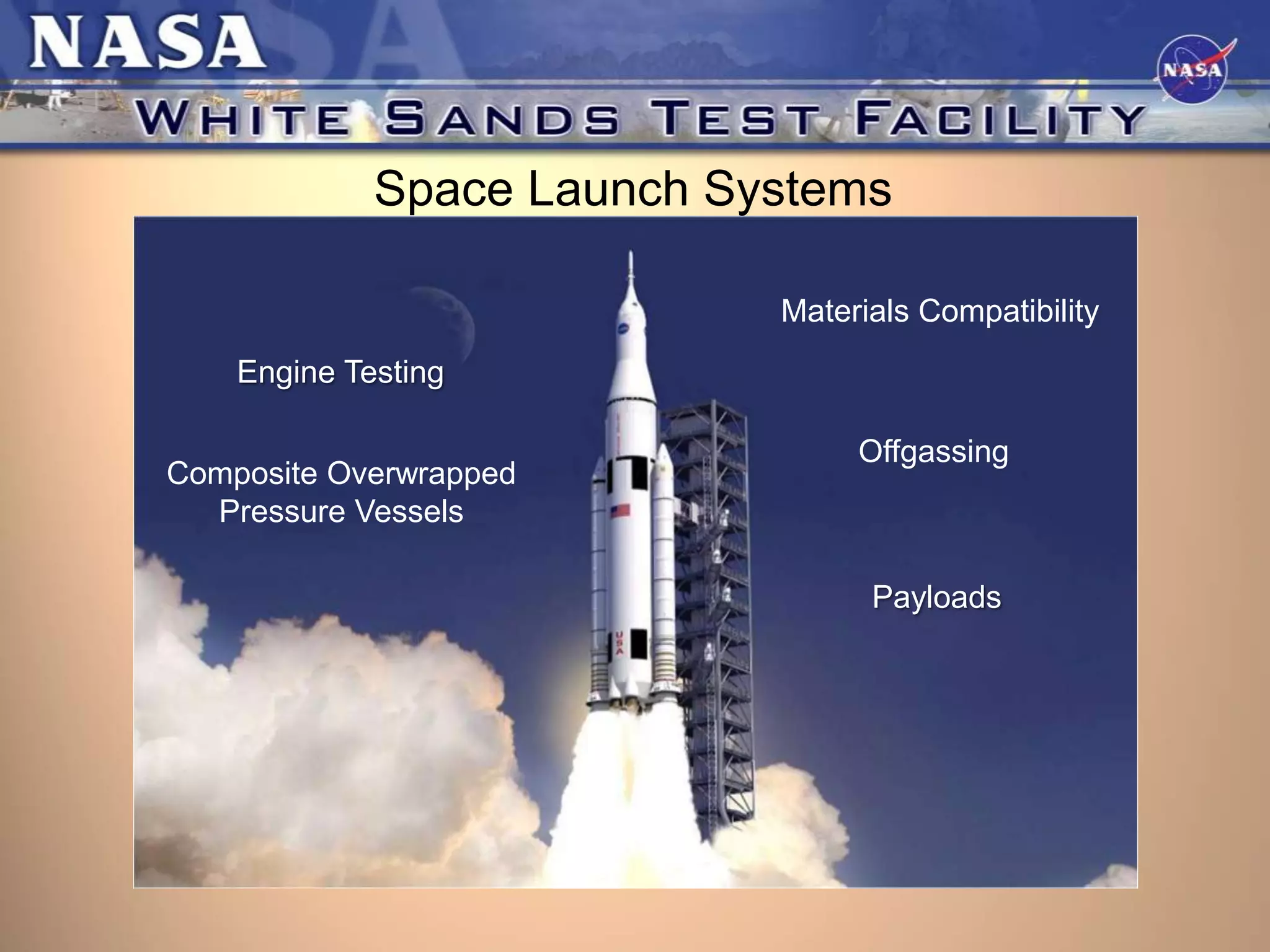

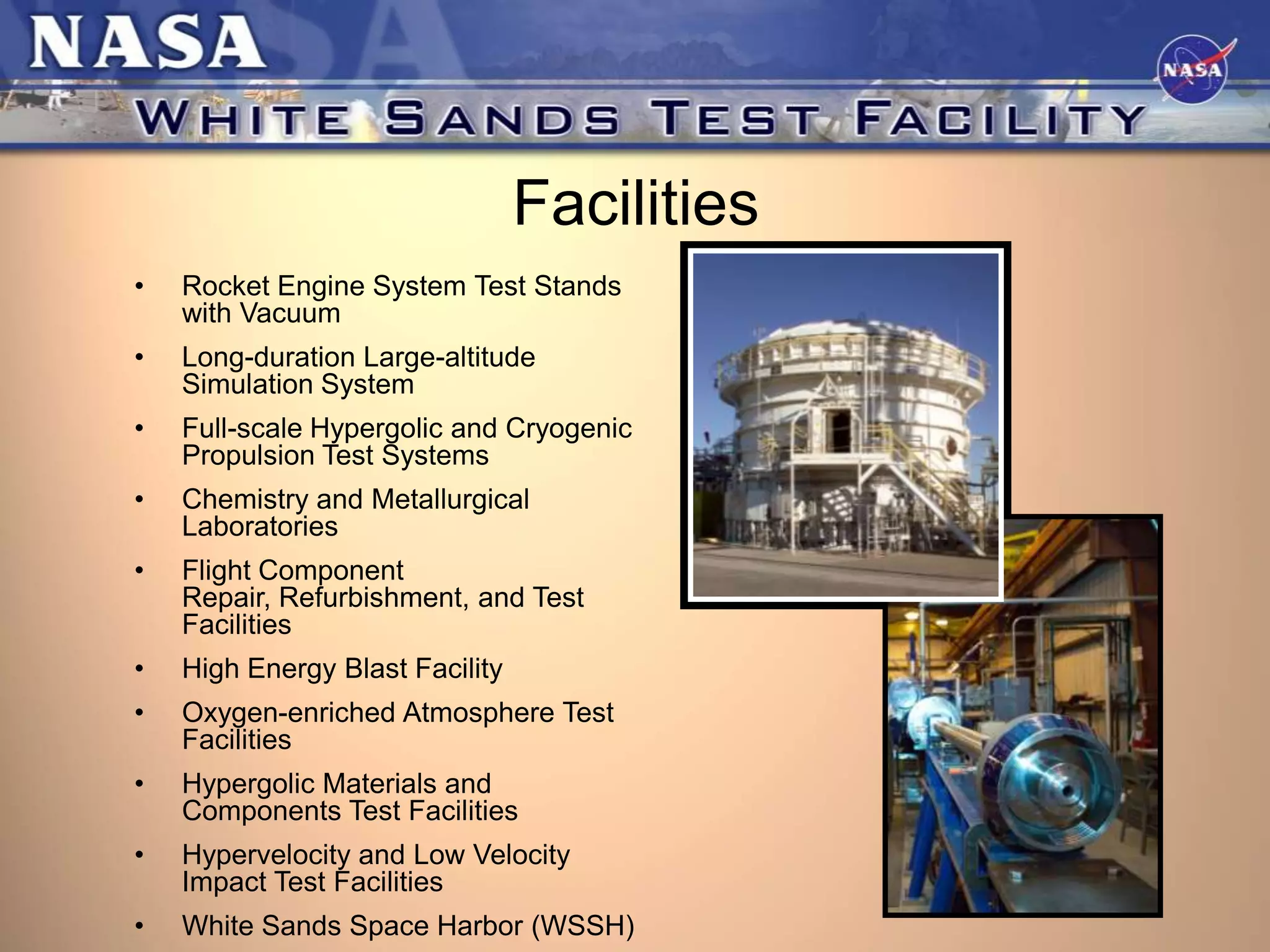

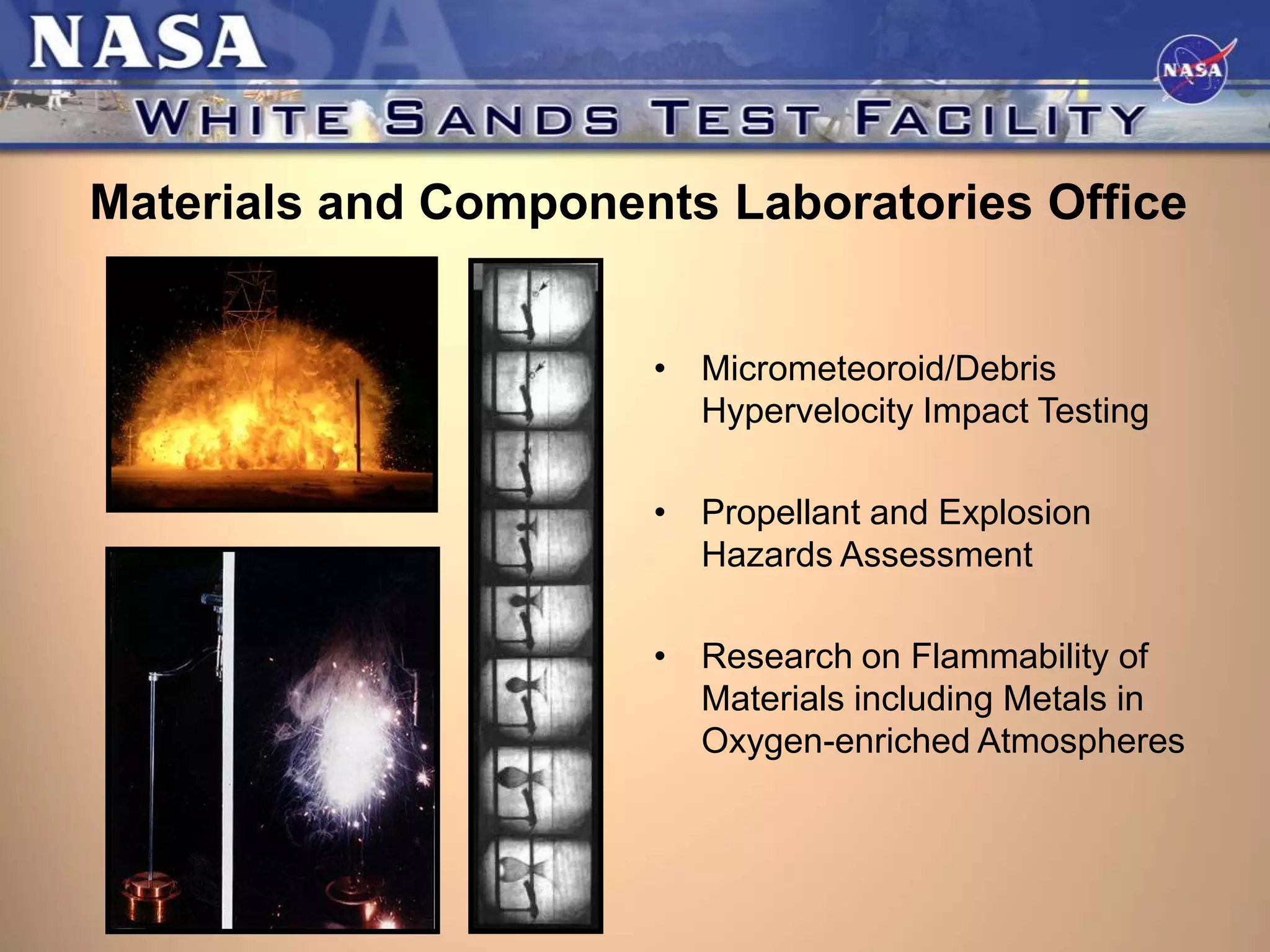

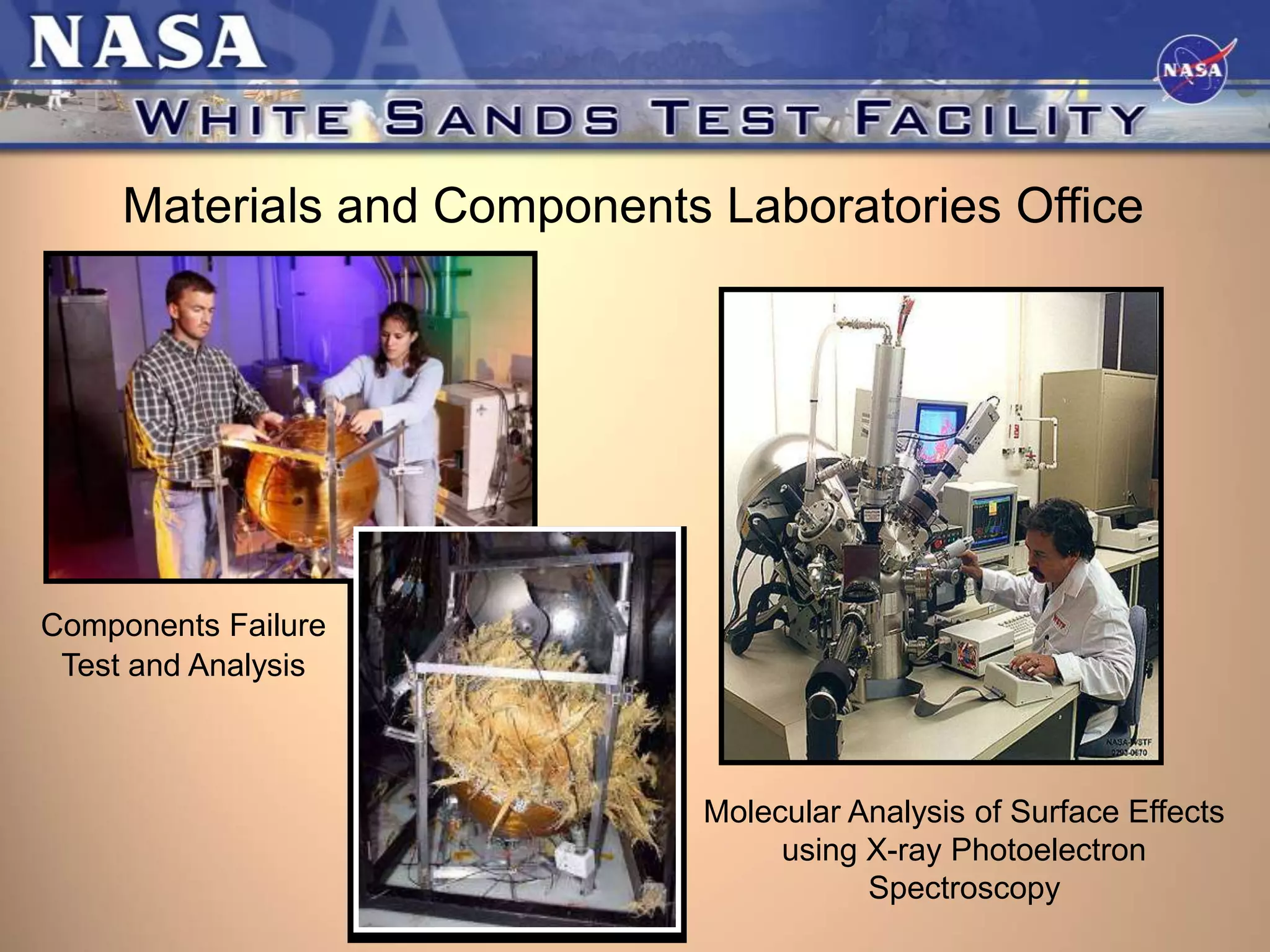

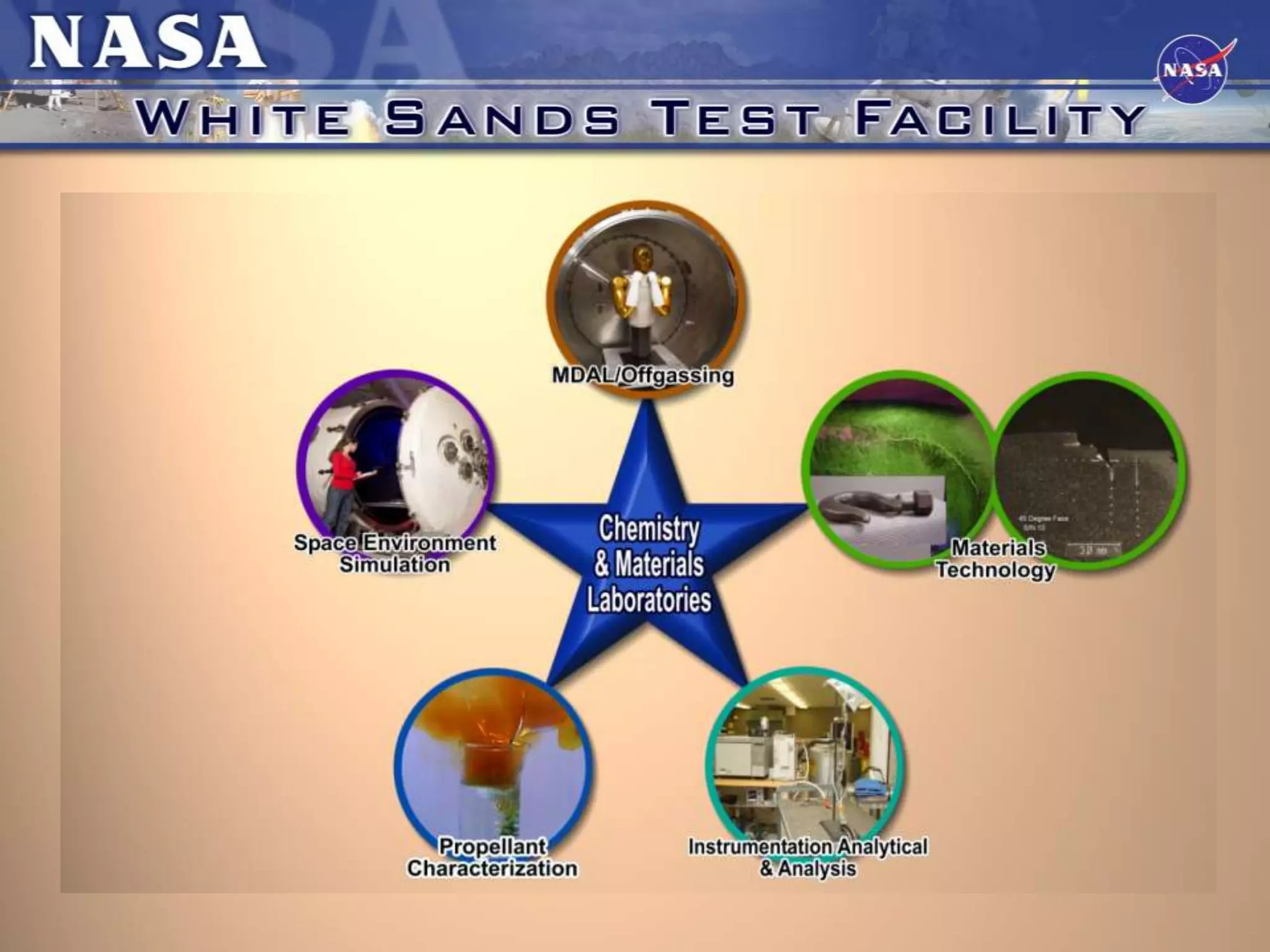

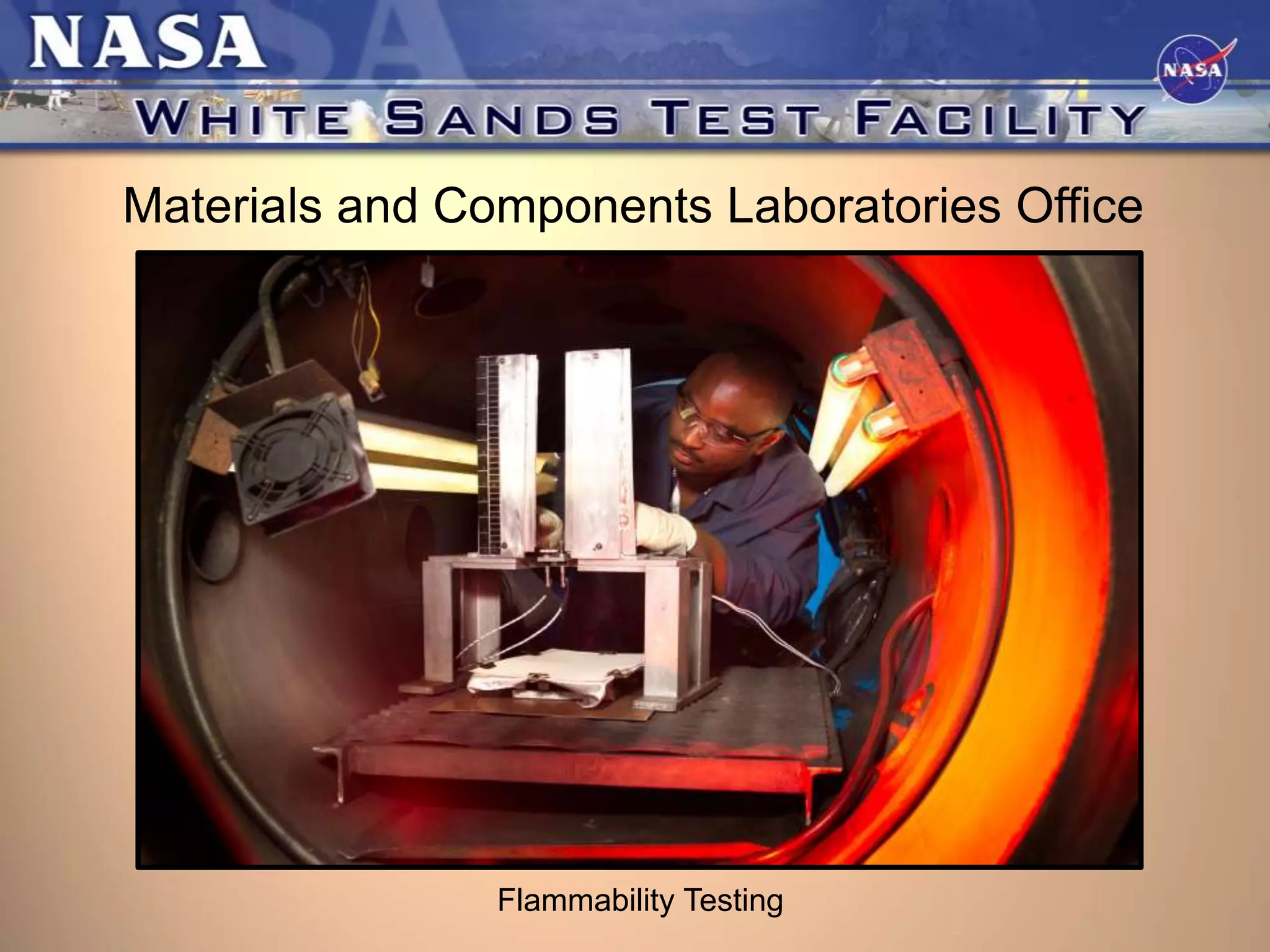

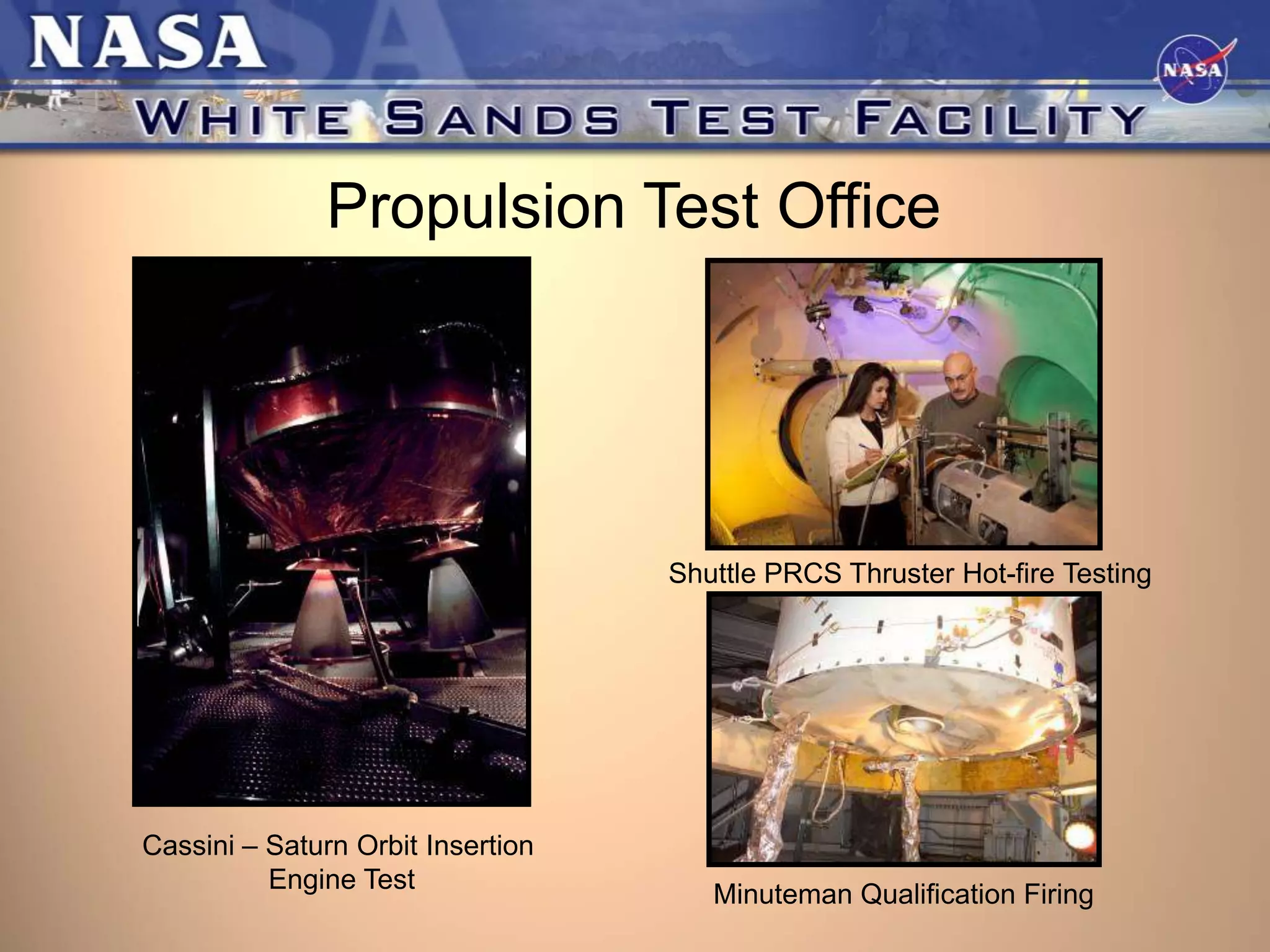

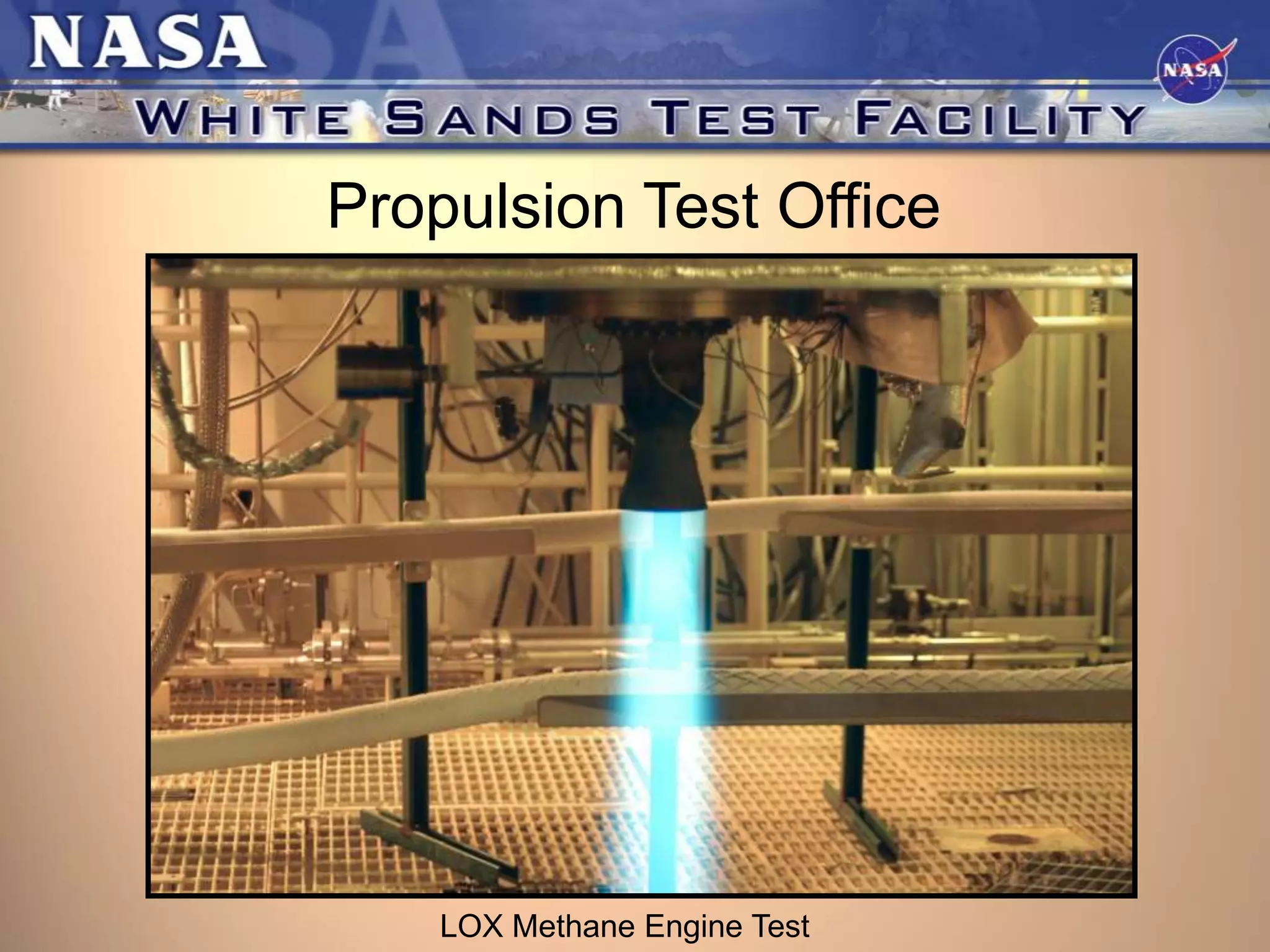

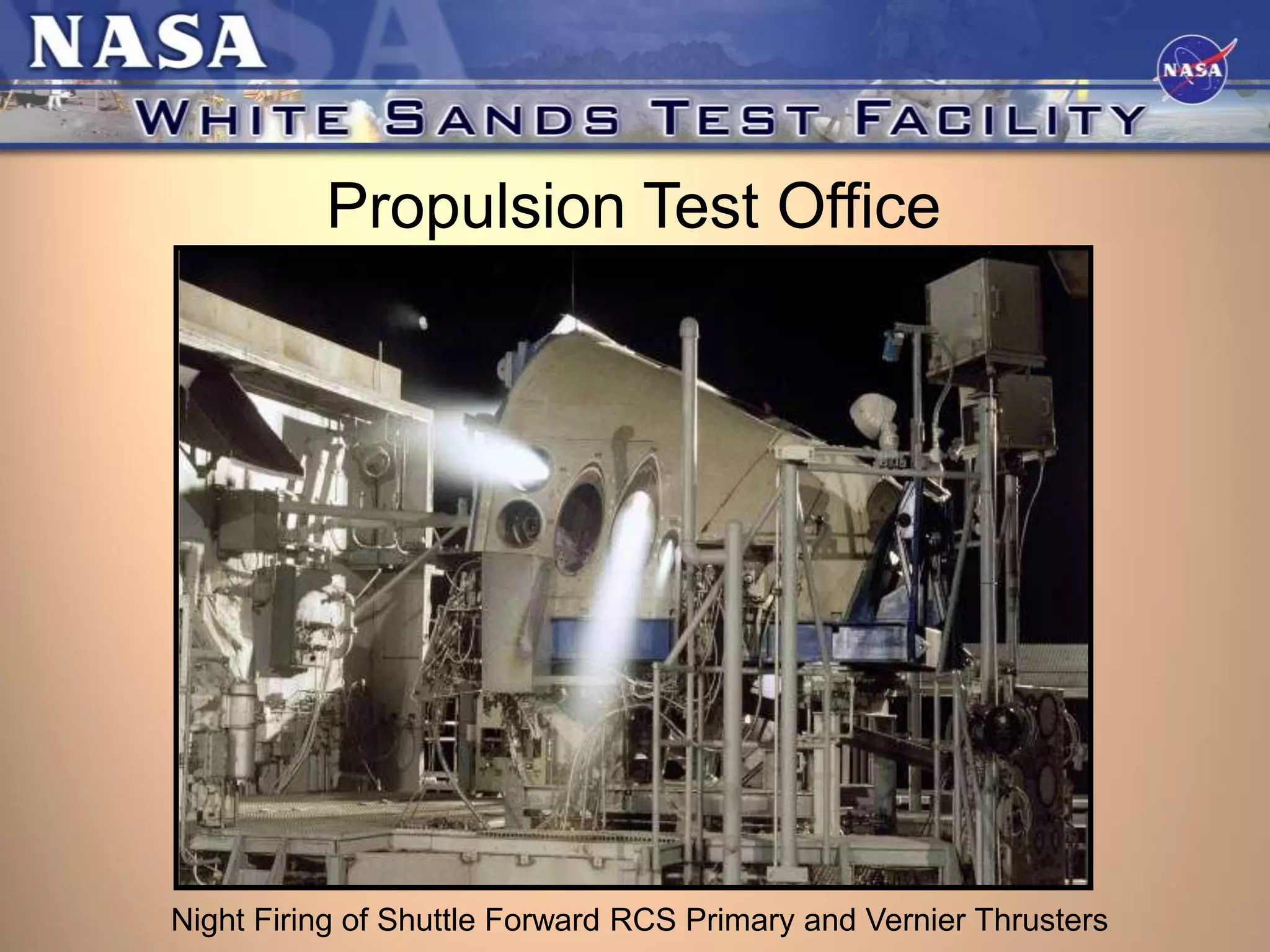

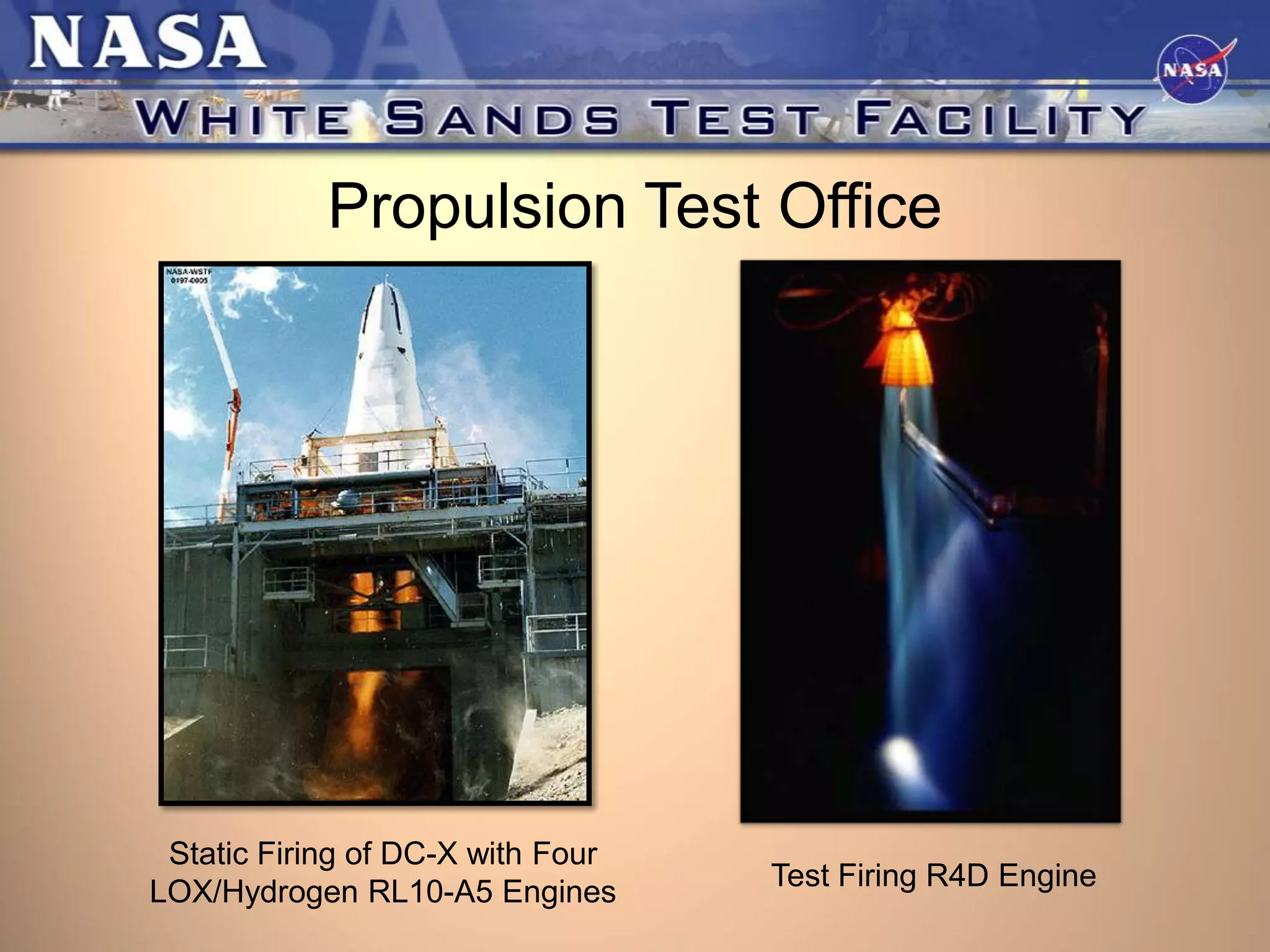

The White Sands Test Facility (WSTF) located in New Mexico provides testing and evaluation services for NASA, other government agencies, and commercial customers. In Fiscal Year 2011, WSTF had an annual budget of $79 million and employed around 60 NASA personnel and 660 contractor personnel. WSTF utilizes its facilities, expertise, and remote location to test spacecraft materials, components, propulsion systems, and more to enable the safe exploration and use of space. Testing activities included rocket engine testing, hypervelocity impact testing, composite pressure vessels, and more in support of programs such as the Space Shuttle, International Space Station, Orion, and Space Launch System. WSTF also engaged in educational outreach programs in