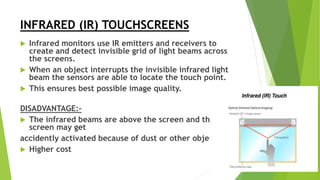

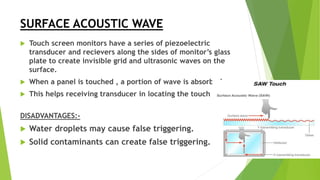

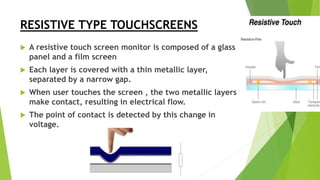

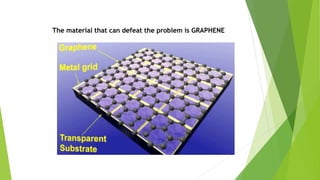

This document discusses different types of touchscreen technologies and recent advancements. It describes four main types: resistive, capacitive, infrared, and surface acoustic wave. Capacitive touchscreens using indium tin oxide electrodes are now most common due to low cost and good image quality, but ITO is becoming expensive and brittle. Graphene has potential to replace ITO as it is more flexible and durable, but mass production of graphene for touchscreens remains challenging due to the difficulties of growing defect-free graphene sheets and transferring them to device substrates.