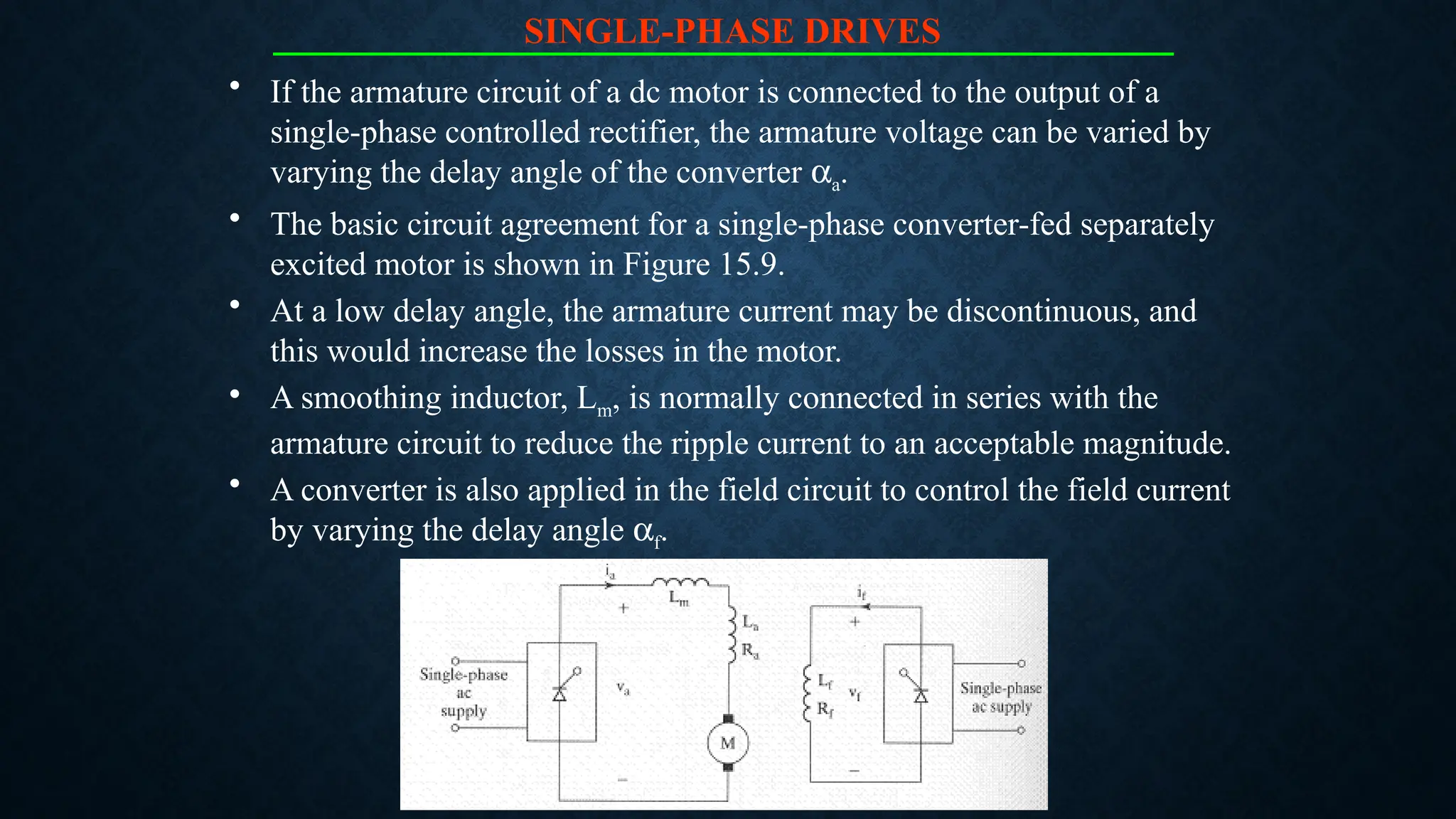

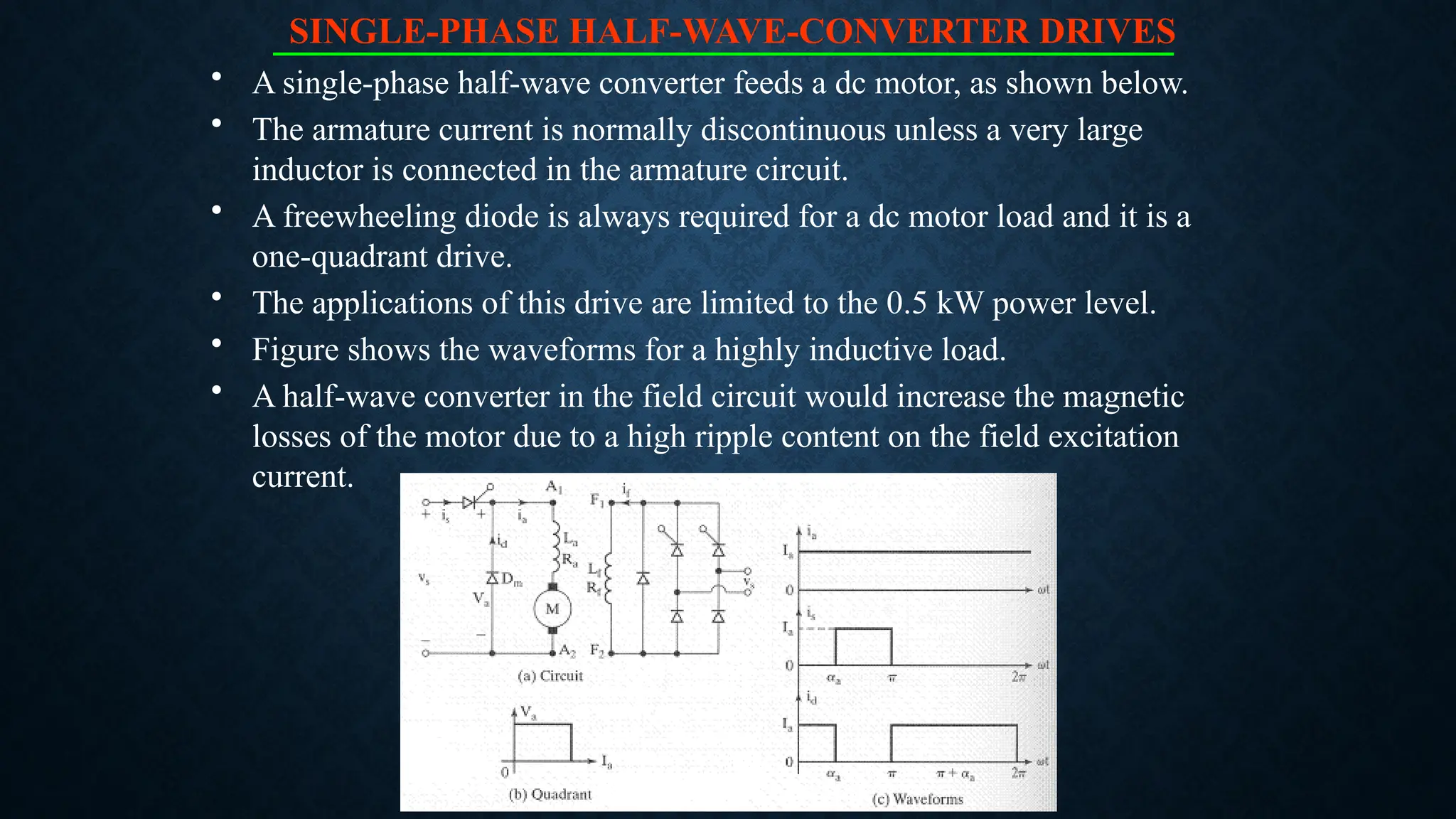

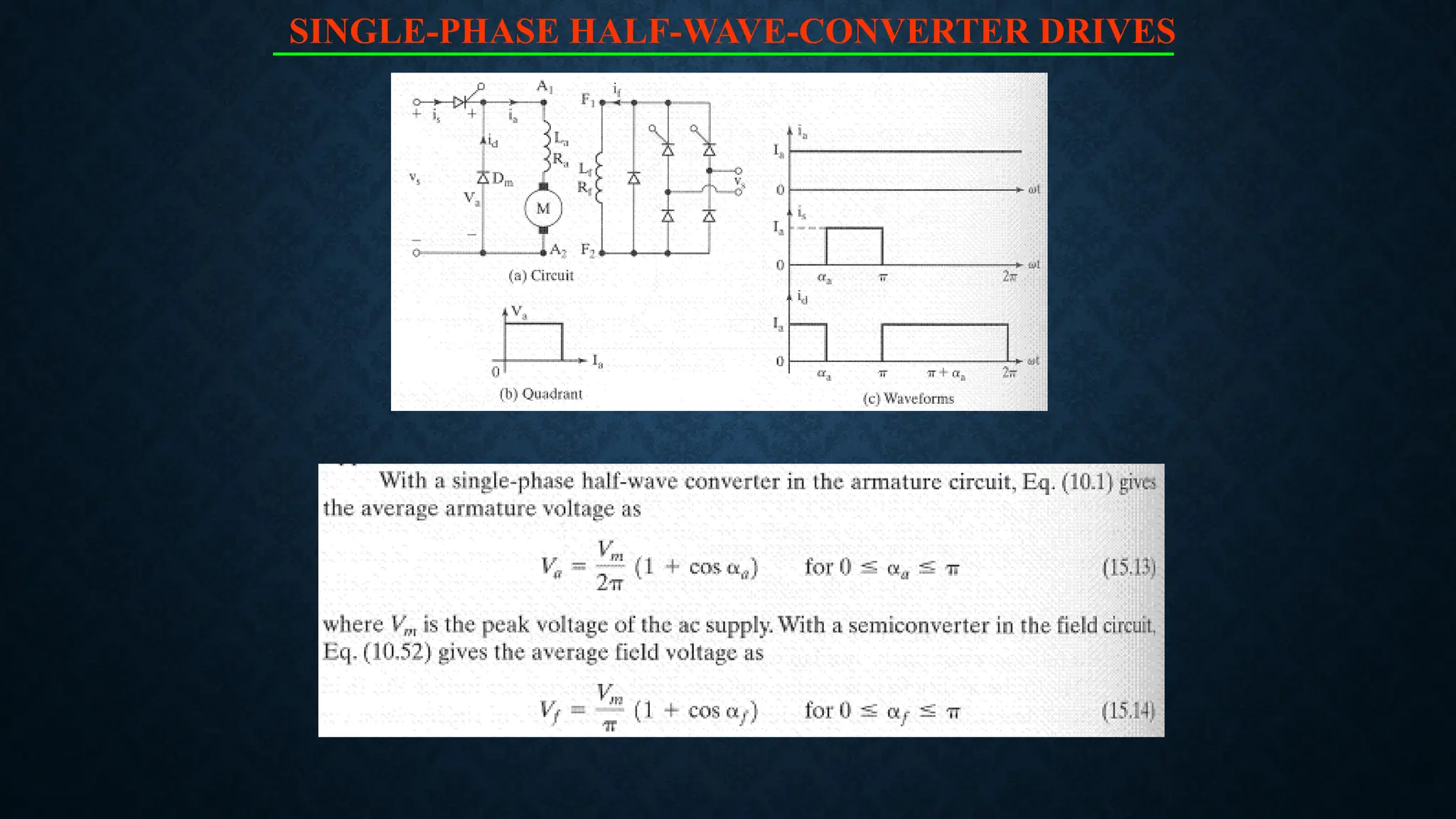

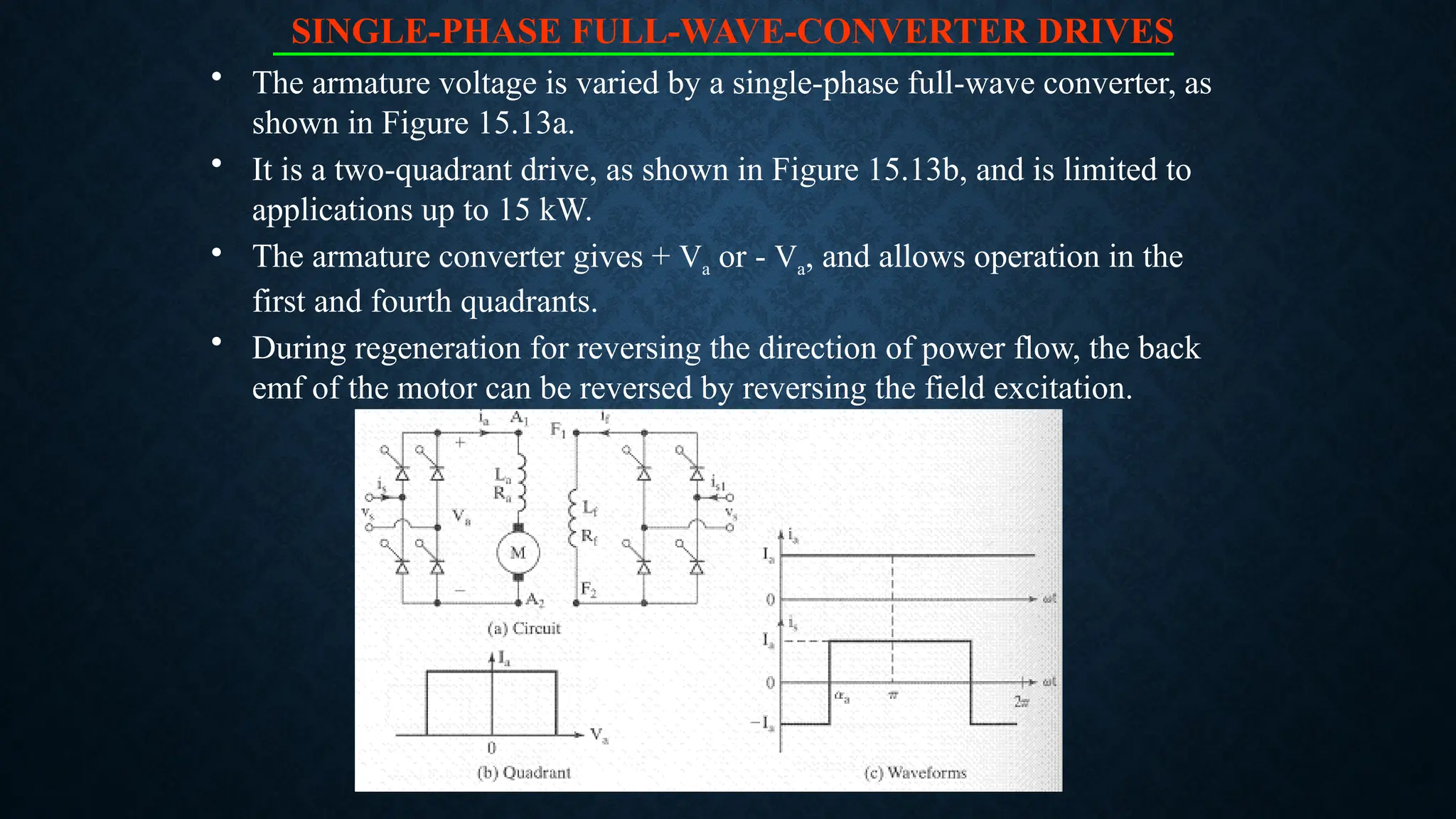

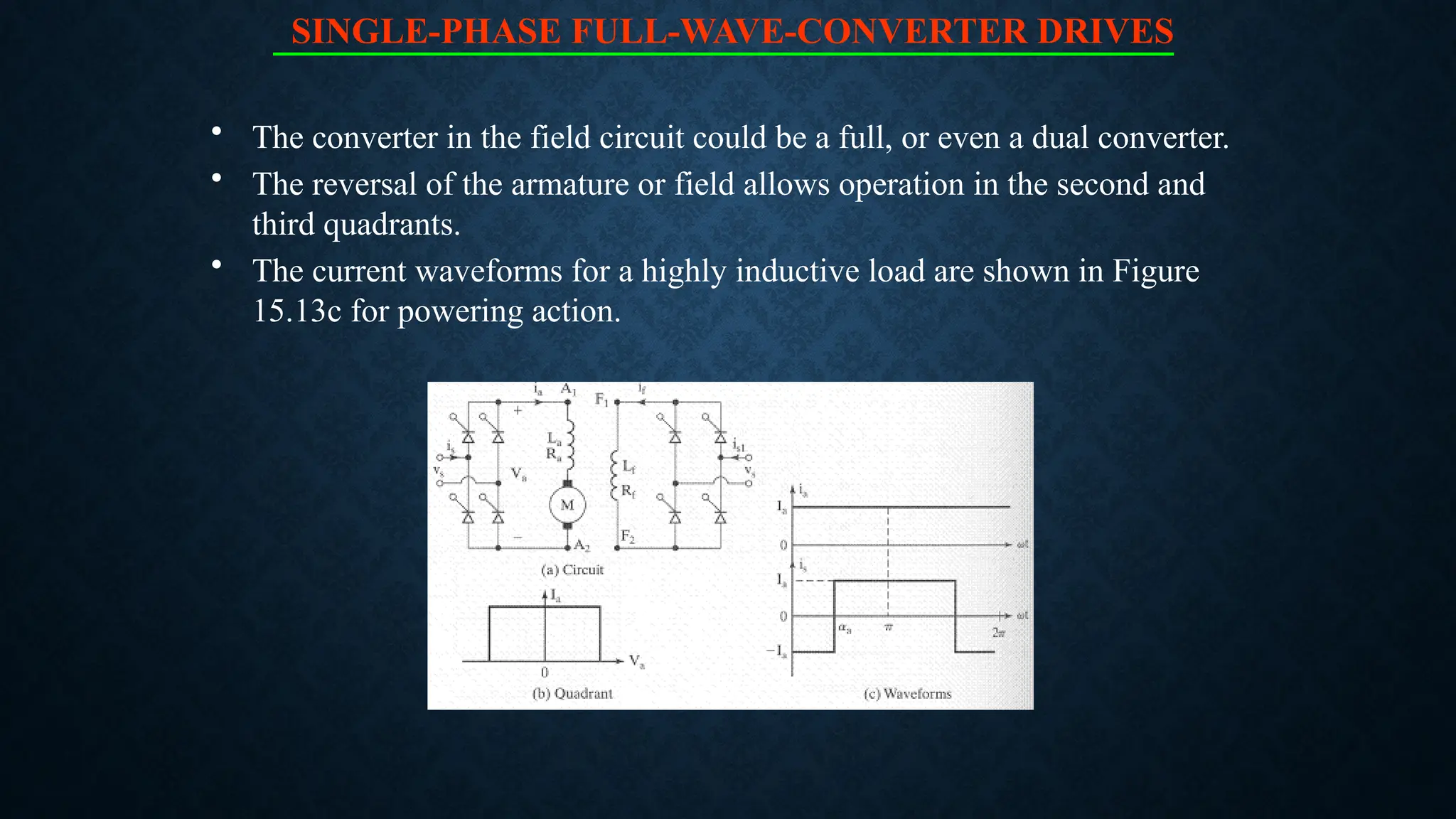

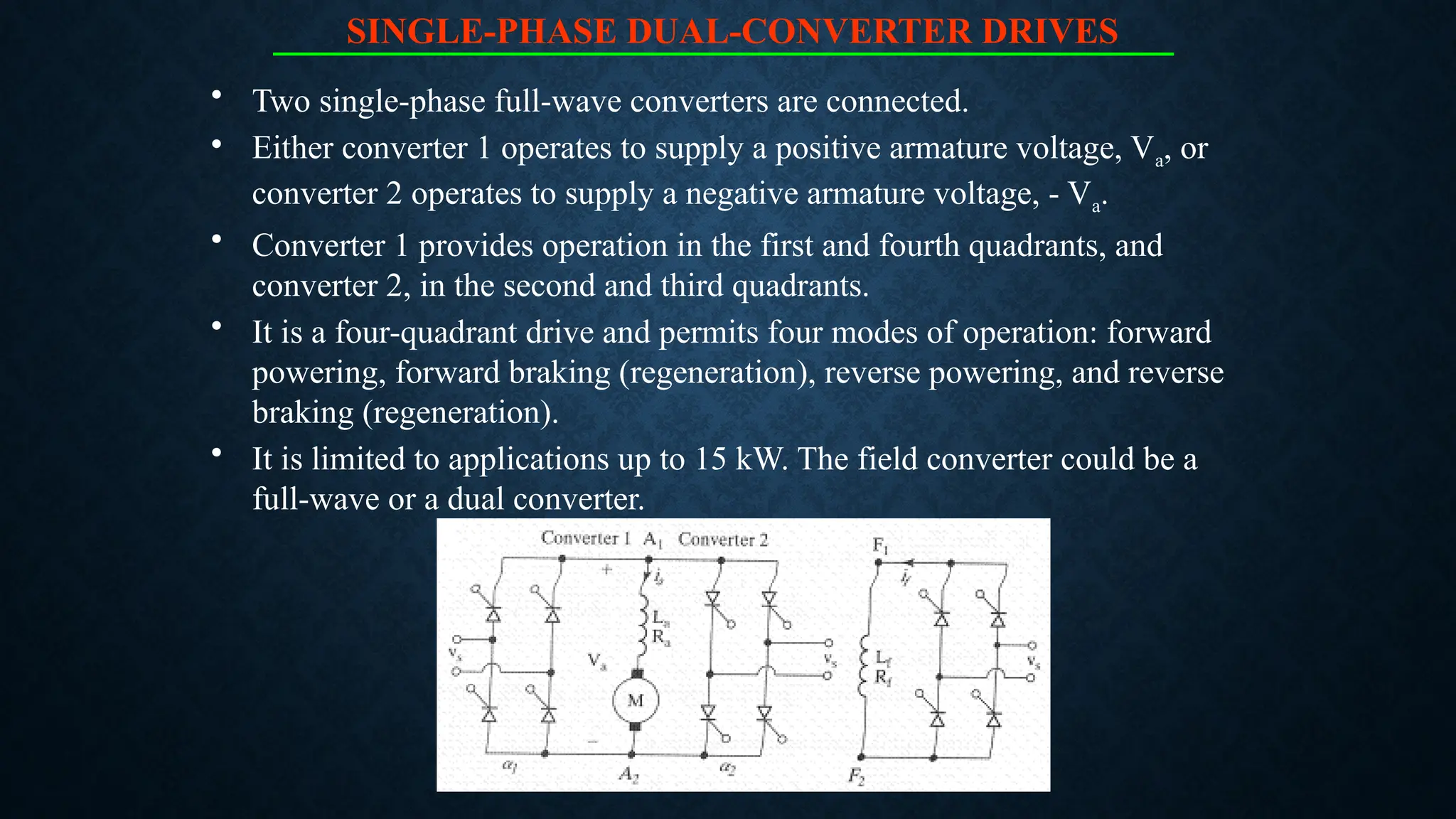

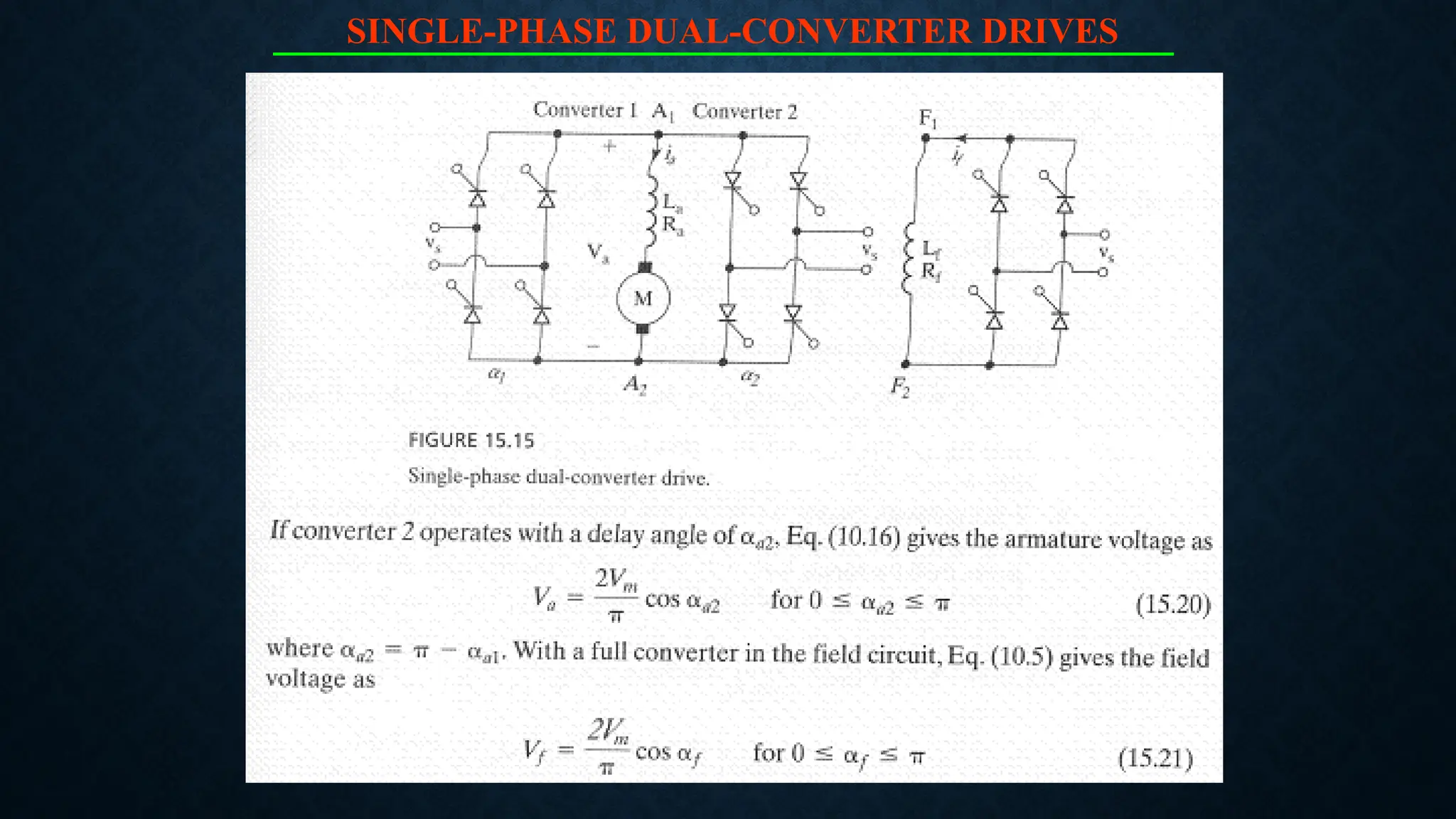

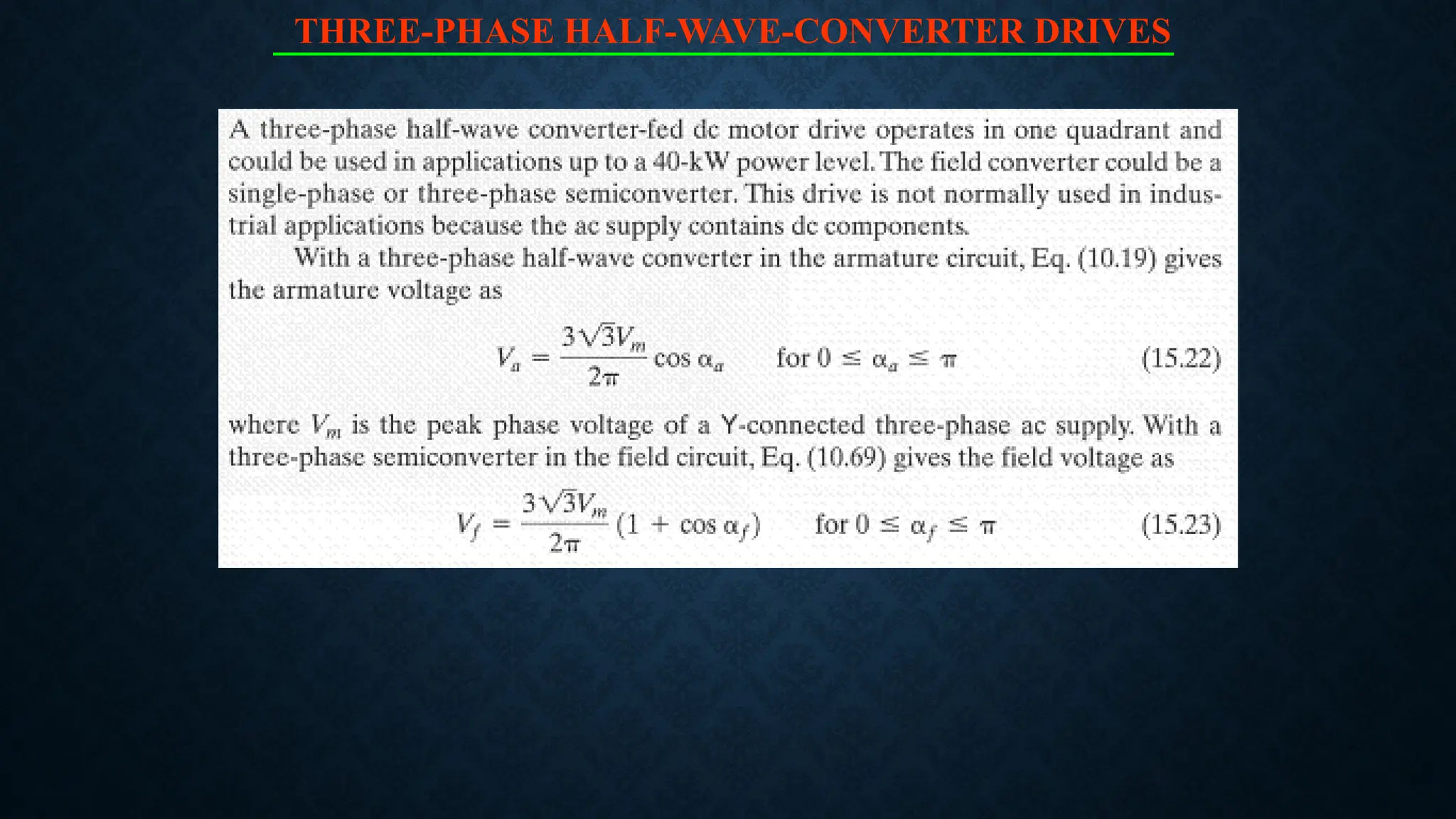

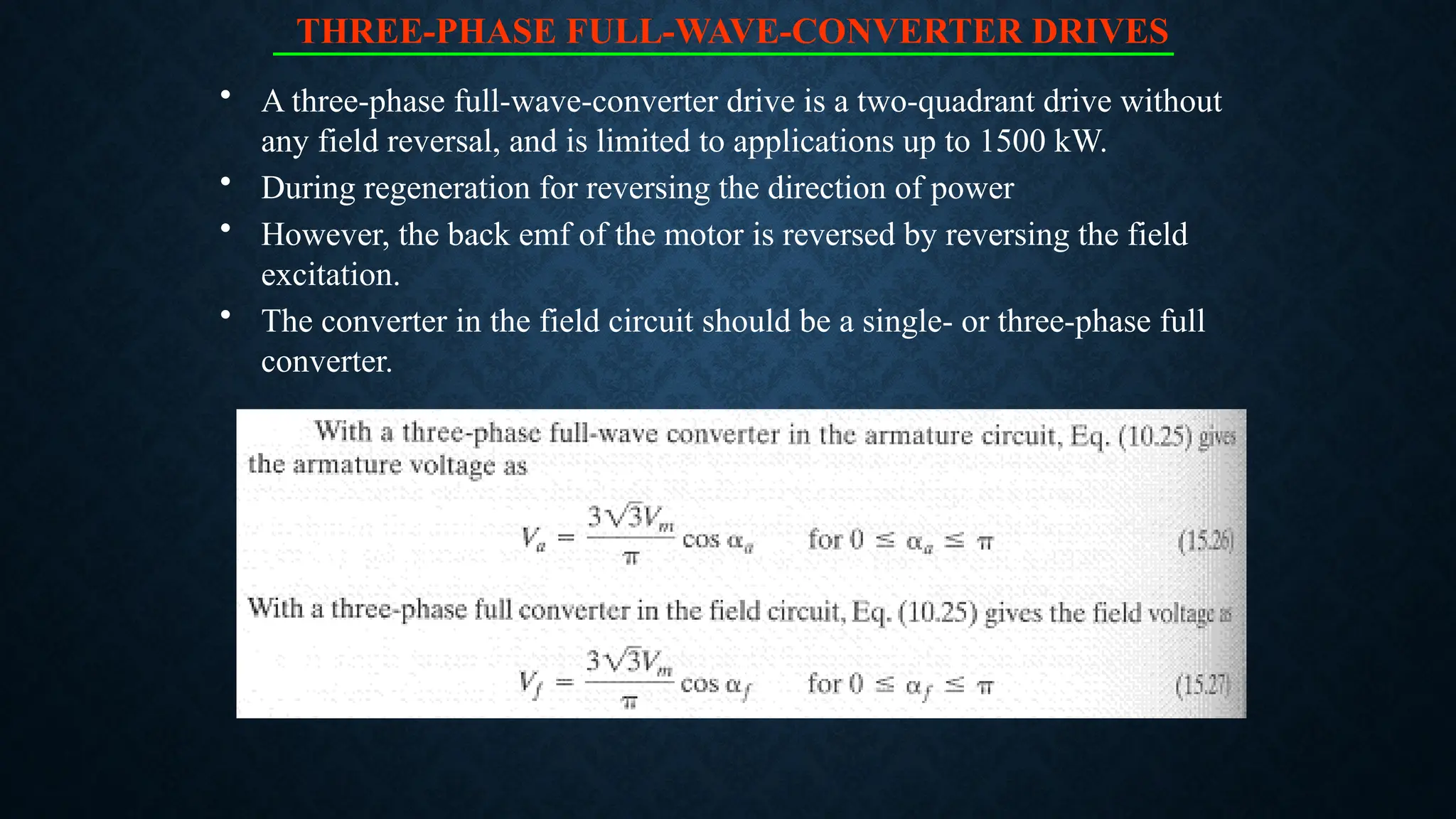

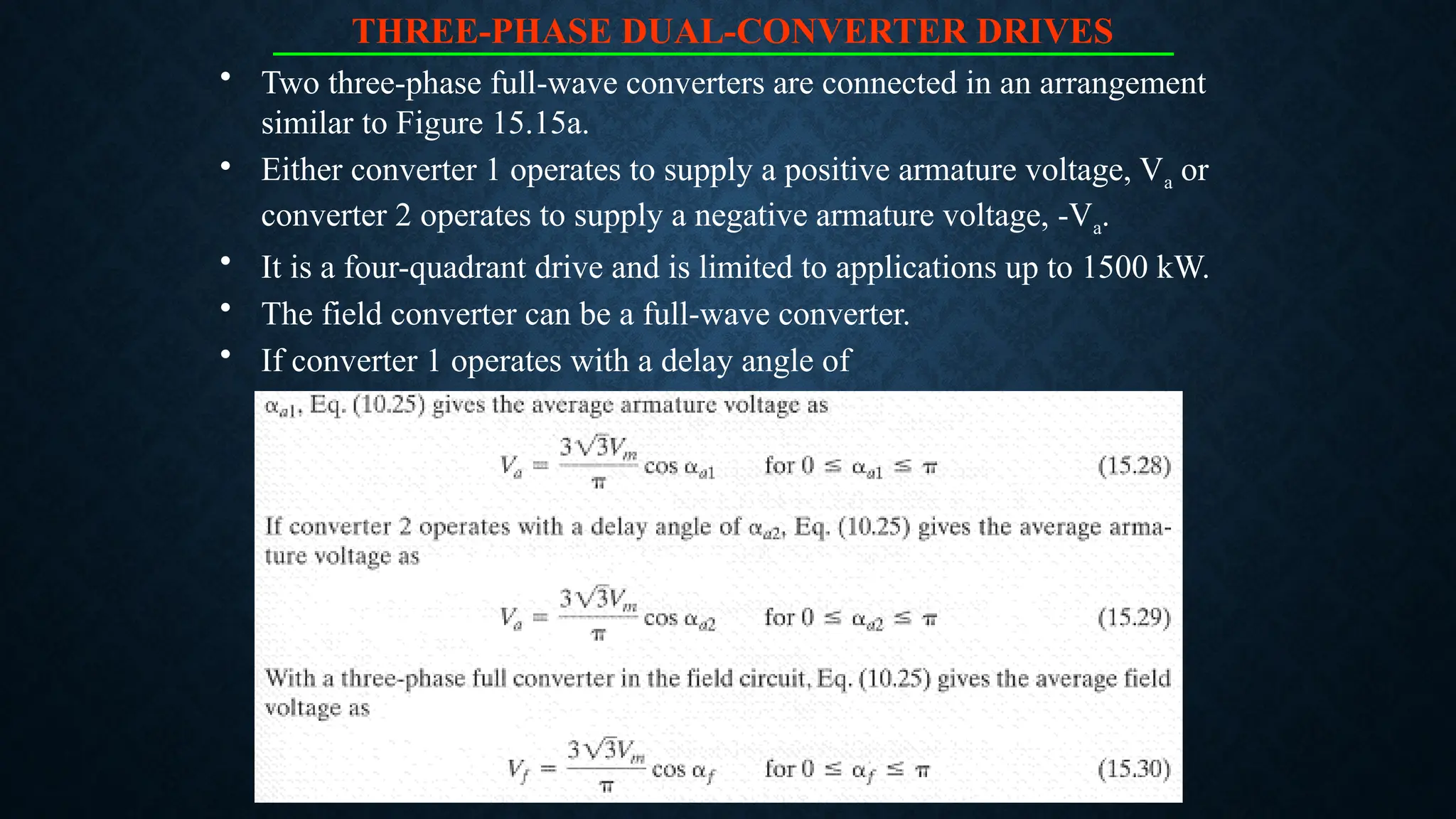

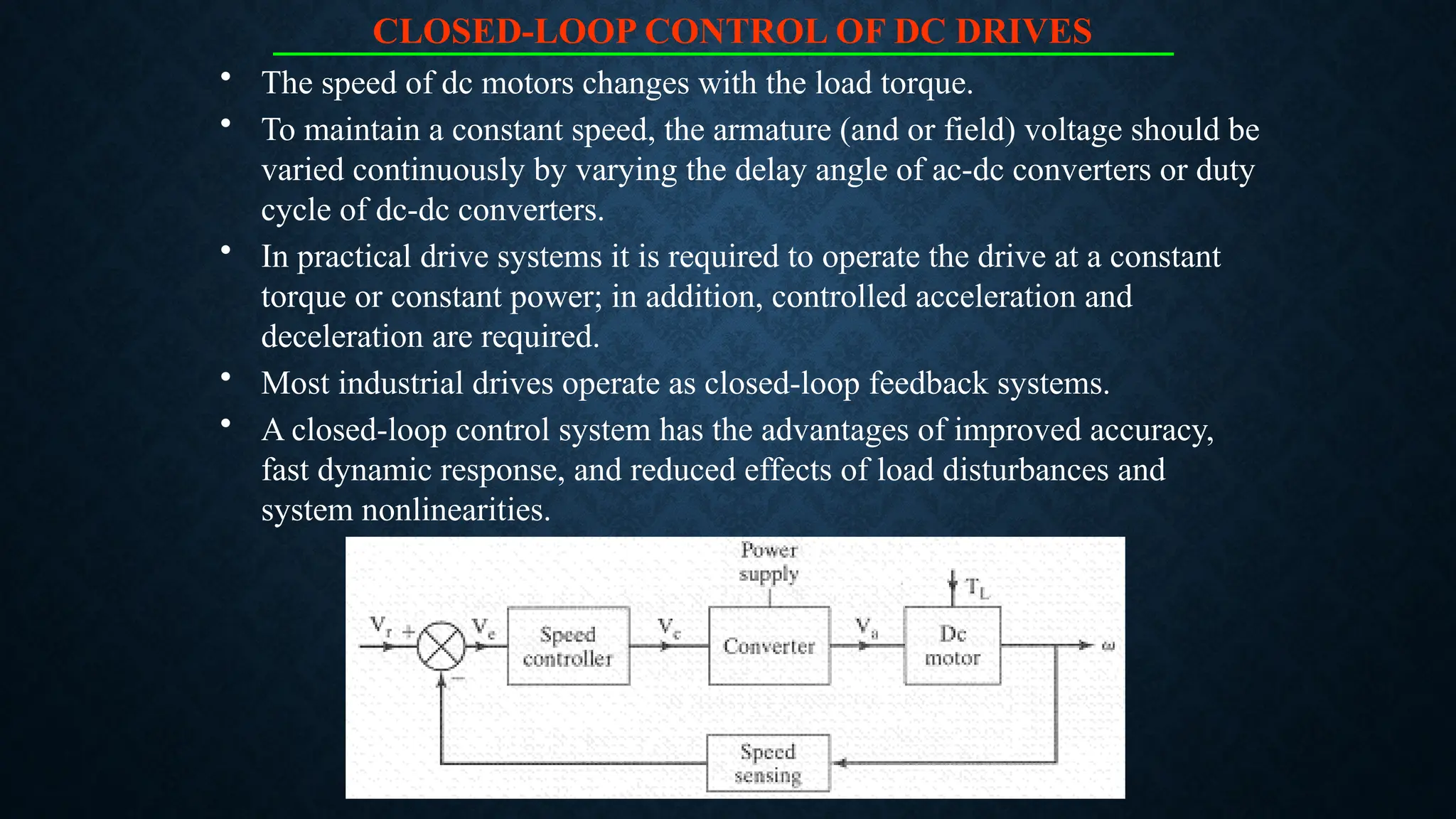

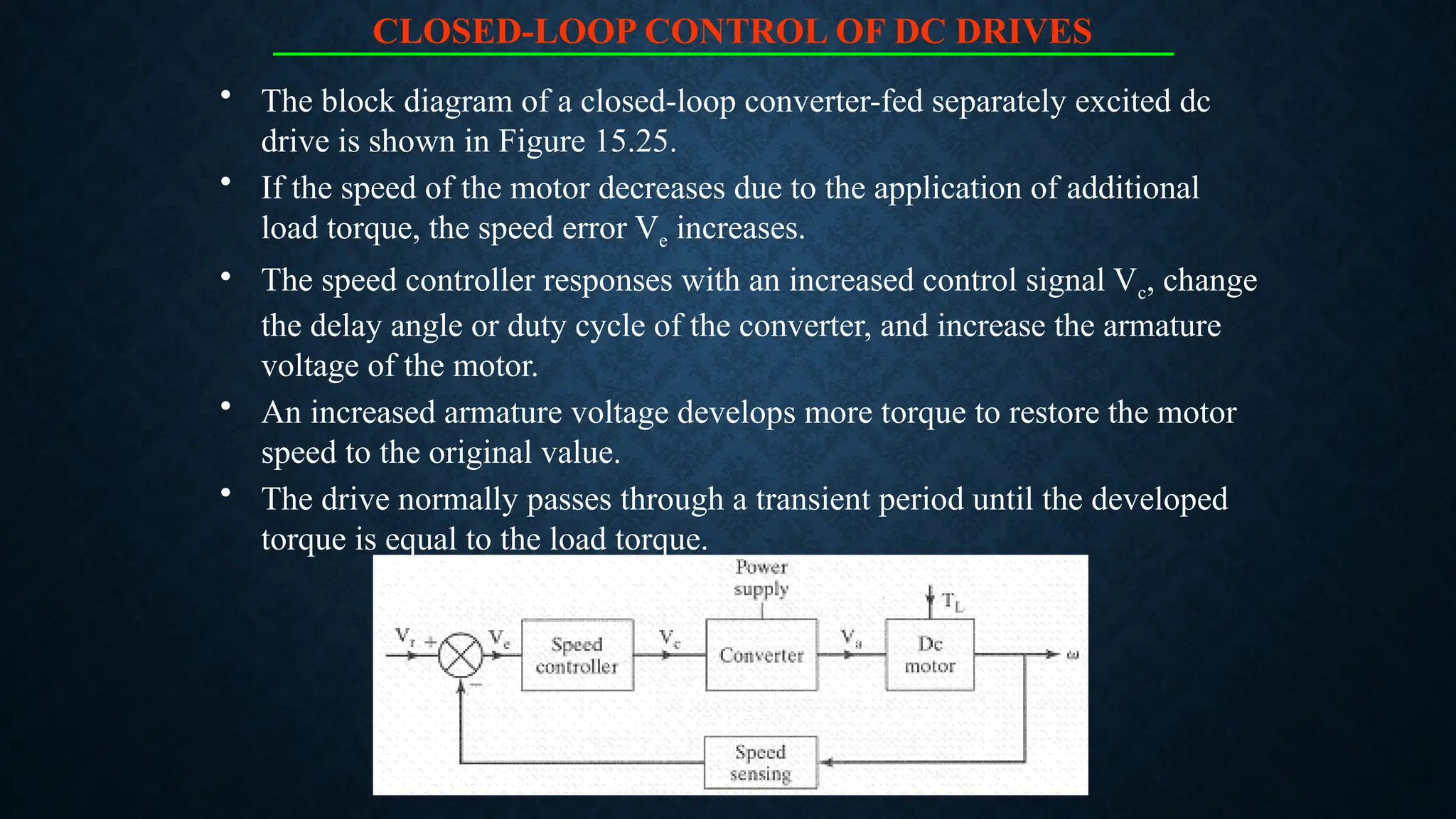

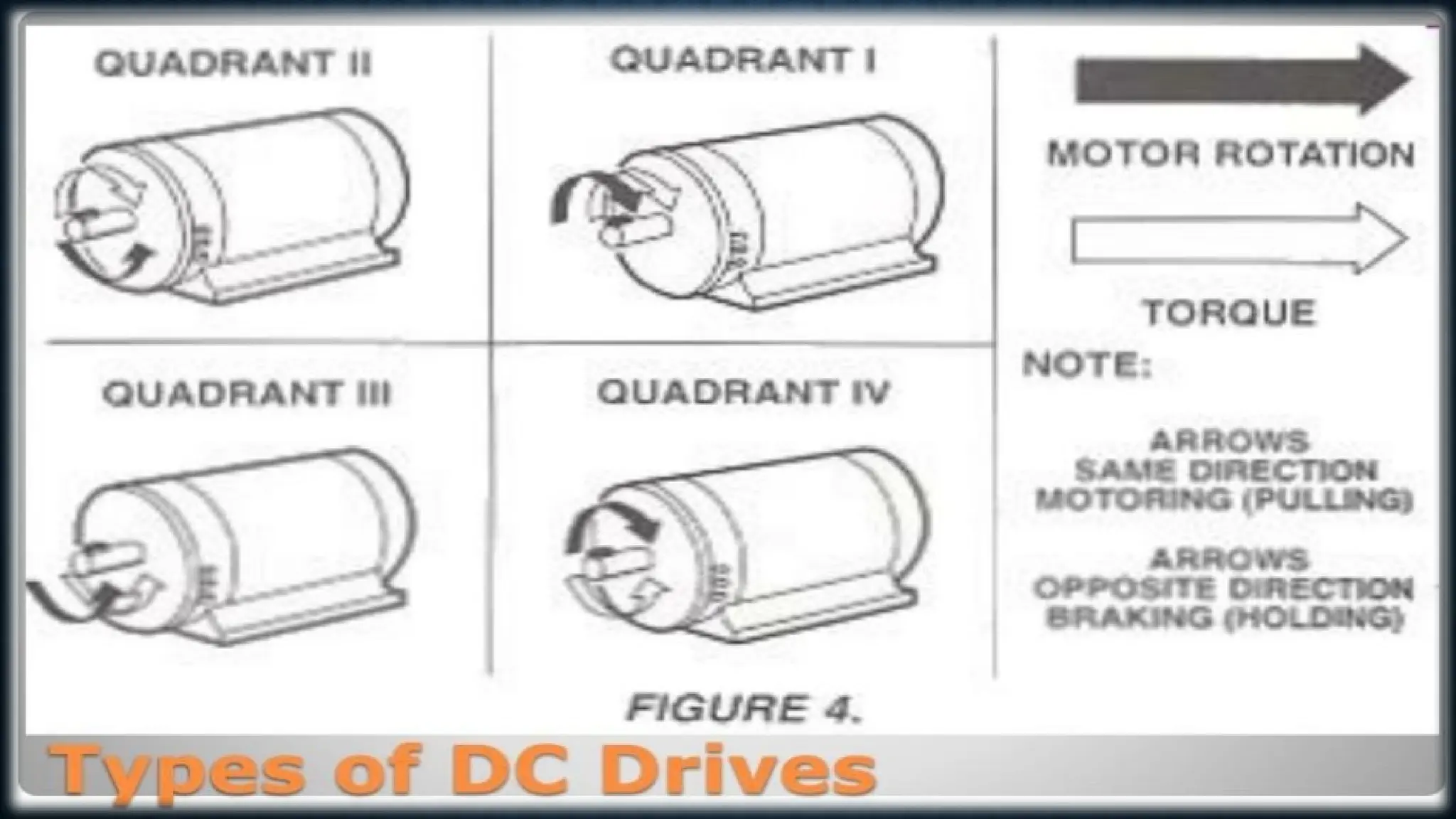

The document discusses DC drives, which control the speed of DC motors, highlighting their importance in industrial applications and detailing their methods of speed control. It explains the types of drives, including single-phase and three-phase drives, as well as the mechanisms like controlled rectifiers and converters that enable variable voltage output. Additionally, the report addresses advancements that are making AC drives more competitive, while acknowledging the continued prevalence of DC drives in various industries.