The document provides information about WEG contactors and starters. It includes:

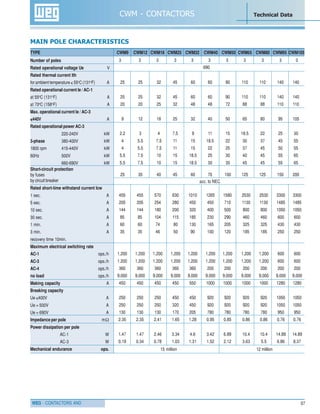

- An overview of the CWM line of contactors for controlling 3-phase motors up to 75HP at 460V, available in 11 sizes from 5-75HP.

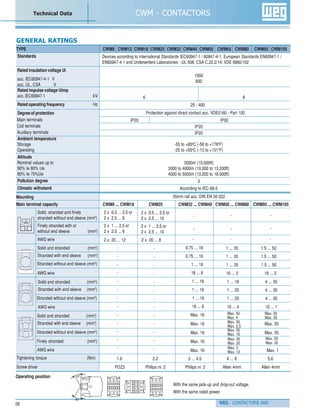

- Tables listing technical specifications for each CWM contactor size, including rated current, horsepower ratings, auxiliary contact configurations, and coil voltage options.

- Descriptions and part numbers for common accessories like auxiliary contact blocks, overload relays, and spare parts.

![WEG - CONTACTORS AND 19

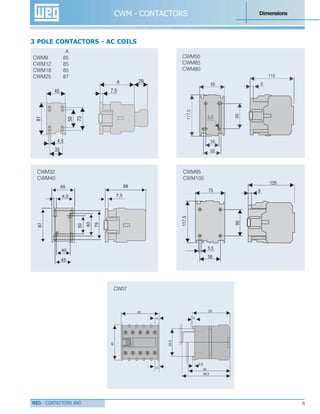

ENCLOSED FULL VOLTAGE STARTERS Product Selection

START/STOP pushbuttons KSSPB A

START/STOP pushbuttons + KSSPB +

HAND-OFF-AUTO switch KHOAS

No Pilot Device - E

ULMax Enclosure Catalog

Amps Size Number(1)

460V

115V 230V 200V 230V 460V 575V

10 1/2 1-1/2 3 3 5 7-1/2 M-04 ESW9xx-

13.8 3/4 2 3 3 7-1/2 10 M-04 ESW12xx-

17.5 1 3 5 5 10 15 M-04 ESW18xx-

22 1-1/2 3 5 7-1/2 15 15 M-04 ESW25xx-

32 2 5 10 10 20 25 M-04 ESW32xx-

34 3 5 10 10 25 25 M-06 ESW40xx-

48 3 7-1/2 15 15 30 40 M-06 ESW50xx-

62 5 10 20 20 40 50 M-06 ESW65xx-

68 5 15 20 25 50 60 M-06 ESW80xx-

E

Table 1 - Enclosed Full Voltage Non-Reversing Non-Combination Starters

Coil voltages - 60Hz

Vac 5th

position

120 A

240 B

480 C

Suffix Overload Suffix Overload

range [A] range [A]

R11 0.28-0.4 R22 10-15

R12 0.43-0.63 R23 11-17

R13 0.56-0.8 R24 15-23

R14 0.8-1.2 R25 22-32

R15 1.2-1.8 R26 25-40

R16 1.8-2.8 R27 32-50

R17 2.8-4 R28 40-57

R18 4-6.3 R29 50-63

R19 5.6-8 R30 57-70

R20 7-10 R31 63-80

R21 8-12.5

Enclosed

NEMA 1

Non-Reversing

Non-Combination

Starter

Coil Voltage

Code

CWM

ContactorWEG

Pilot Device

Code

Overload

Relay Suffix

KIT

Factory installed Pilot Device

Table 4 - Pilot Device for Non-Reversing Non-Combination Starter

Table 2 - Coil Voltages Table 3 - Bimetallic Overload Relay selection

Other coil voltages/frequencies are available

on request.

Maximum Horsepower - 60Hz

Single-phase Three-phase

CODE

6th

position

S W 25 B A R24-

1 2 43 5 6 7

Note: Bimetallic Overload Relay mounting

R11-R25 mounting on ESW9 - ESW32

R26-R31 mounting on ESW40 - ESW80

Important: In the case that you do not know the

full-load motor-running current of the motor,

we are able to ship your ESW with the most typical

overload relay for the horsepower requested.

(1) To Complete the Starter Selection:

Select the appropriate coil voltage from table 2, and insert the coil code in the 5th position of Catalog Number.

Select the appropriate Pilot Device combination from table 4 and insert the Pilot Device code in the 6th position of Catalog Number

Select the Overload Relay from table 3 and add the suffix as the final three digits of the Catalog Number.

Ex.: A ESW 3-phase 5HP-230V with START/STOP Pushbutton and 240V ac coil voltage is required: ESW18BA-R23

Note: A ESW9-ESW32 are supplied with 1N.O. front mounted auxiliary contact and ESW40-ESW80 are supplied with 2N.O. side mounted auxiliary contact.

C](https://image.slidesharecdn.com/1-422-170825104909/85/WEG-Contactors-Oveload-Relays-21-320.jpg)