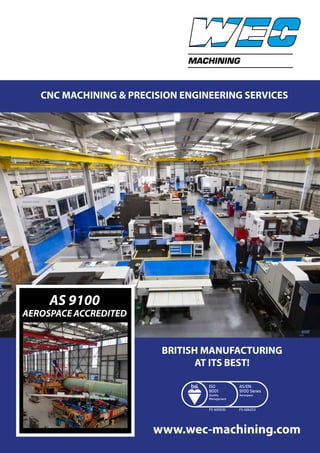

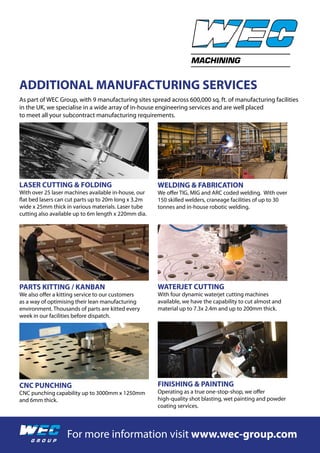

WEC Machining Ltd offers a wide range of subcontract multi-axis CNC machining and precision engineering services from its facility in Blackburn, Lancashire, featuring over 35 CNC machines. The company is accredited to AS 9100 and ISO 9001:2015, serving industries such as aviation, space, and defense with high-quality machined components. In addition to machining, WEC provides various additional services including laser cutting, welding, and fabrication, positioning itself as a comprehensive manufacturing provider.