This document contains diagrams and information about various water flow processes at a facility including:

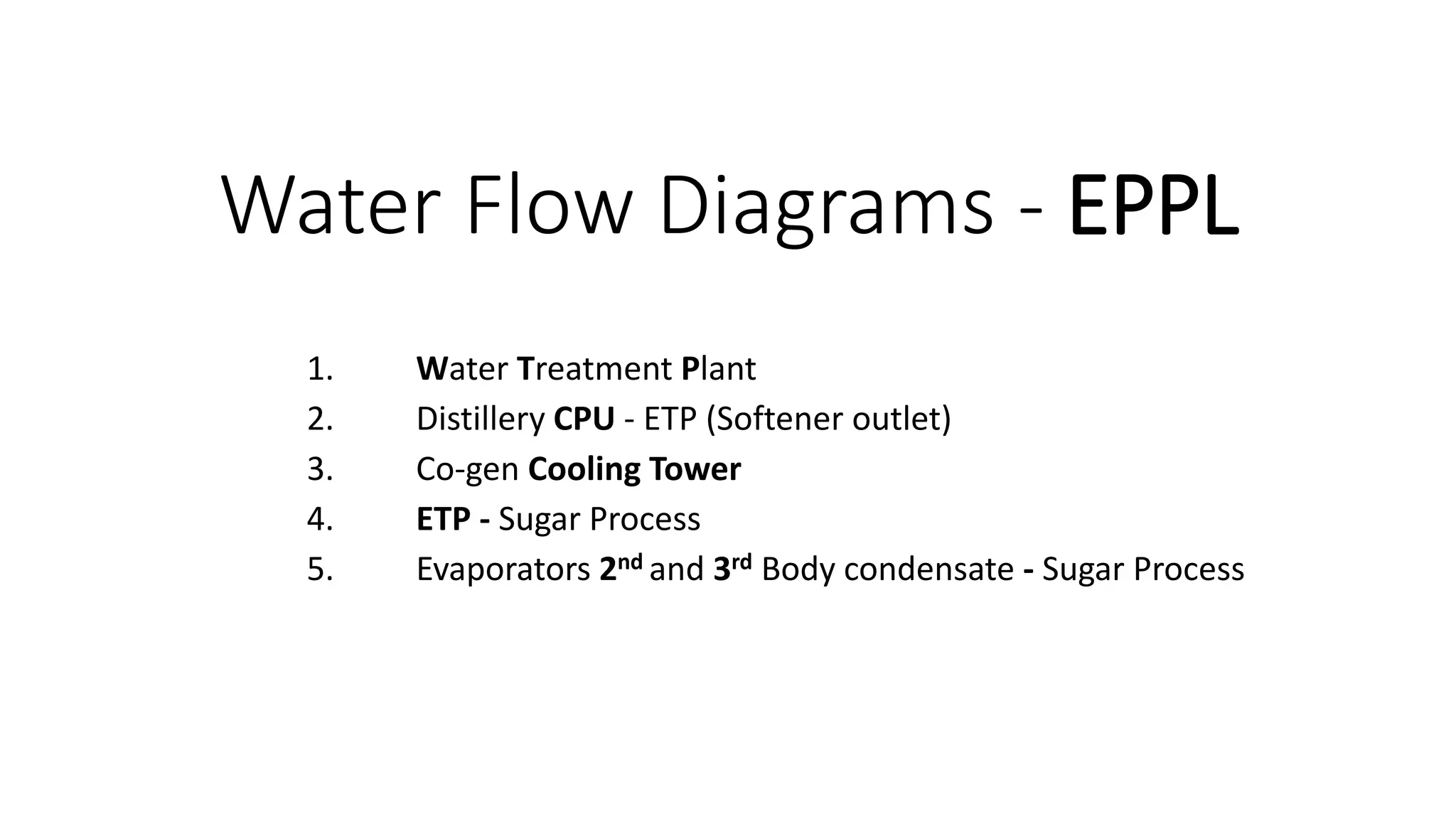

1. The water treatment plant which treats raw river water through various filters and membranes to produce DM water.

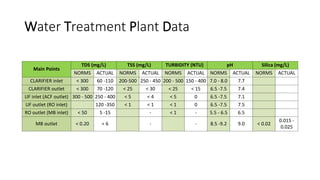

2. The CPU ETP which treats effluent water through neutralization, aeration, and clarification to meet certain outlet parameters.

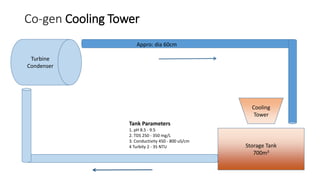

3. The co-gen cooling tower which uses a cooling tower to cool turbine condenser water.

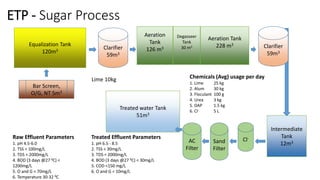

4. The sugar process ETP which treats sugar process effluent through equalization, aeration, clarification and filtration to meet treated effluent standards.

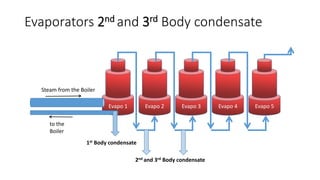

5. The evaporator condensate flow which returns 2nd and 3rd body cond