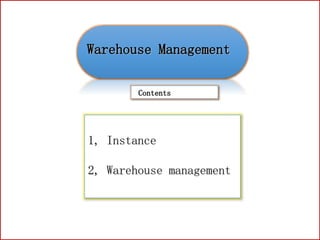

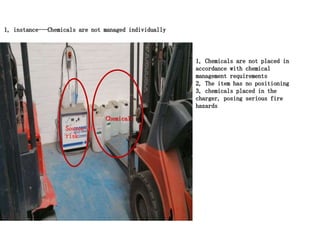

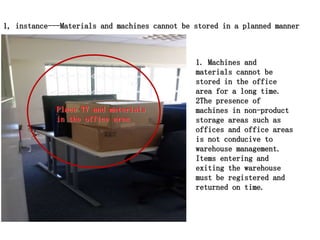

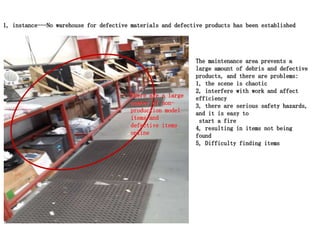

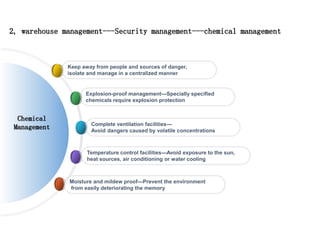

1. The document discusses warehouse management and highlights issues with improper chemical storage posing fire hazards, lack of positioning of items, and materials not being stored according to requirements.

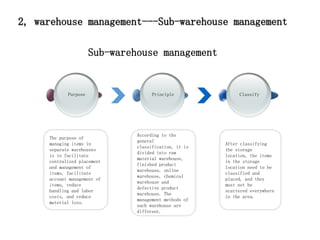

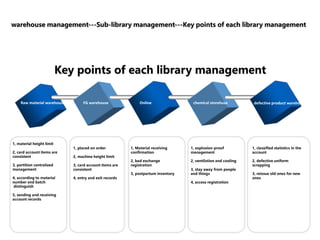

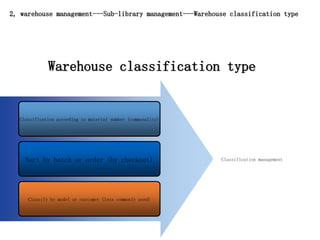

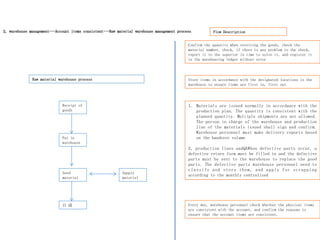

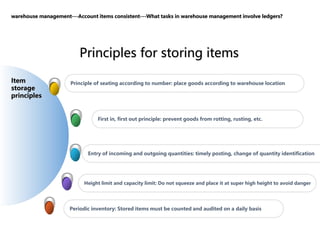

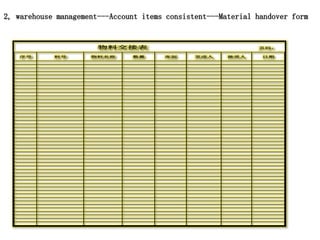

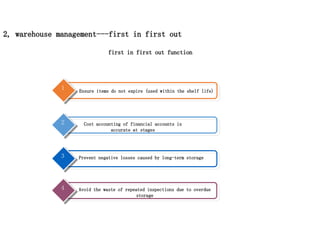

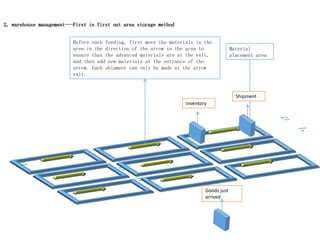

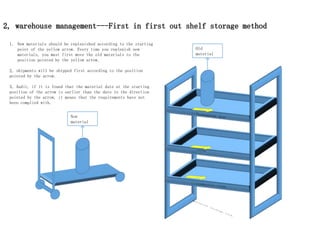

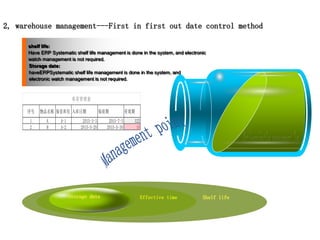

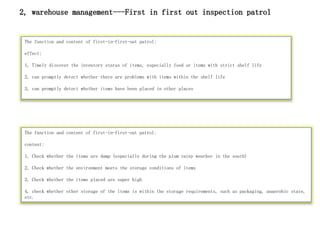

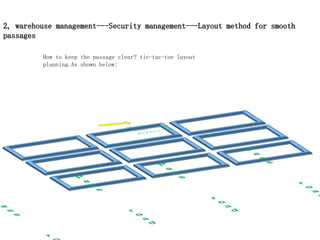

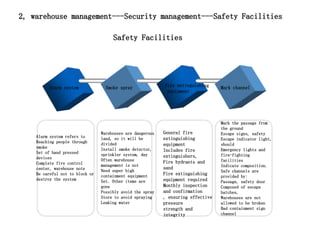

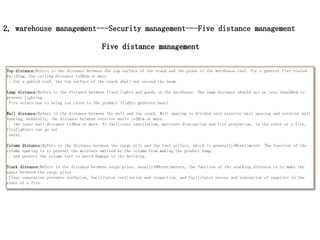

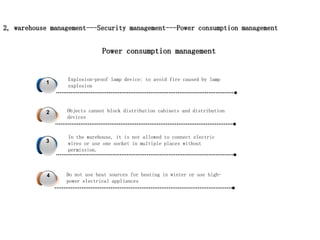

2. It emphasizes the importance of sub-warehouse management according to material type, first-in first-out management, consistent inventory accounting, and security management.

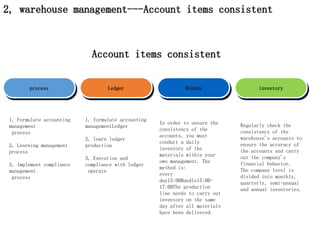

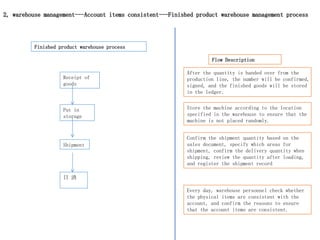

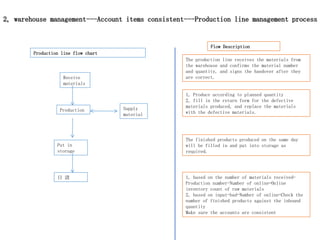

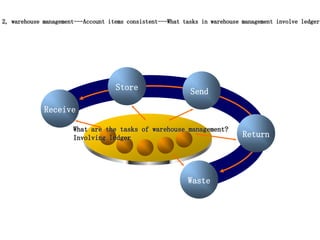

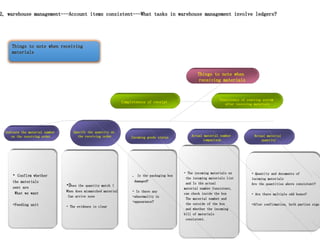

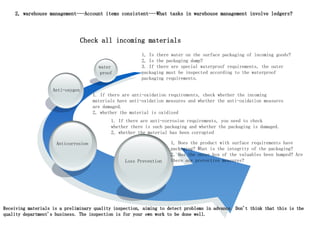

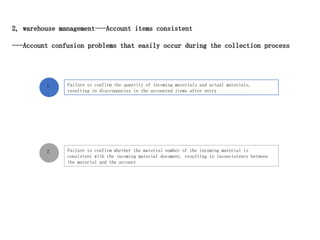

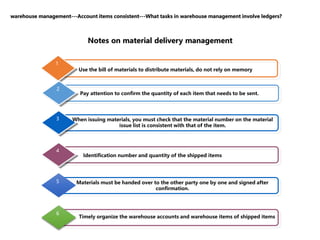

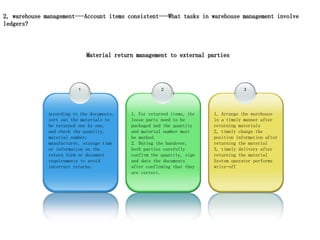

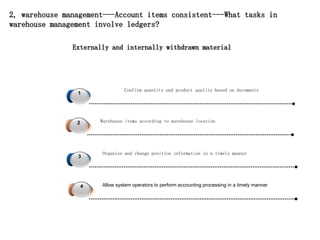

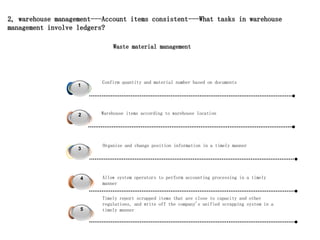

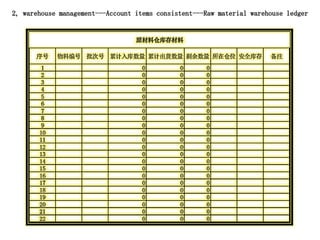

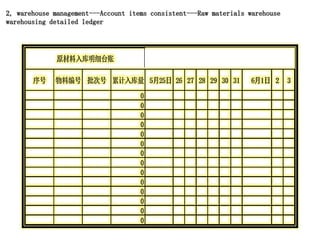

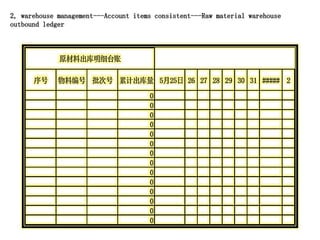

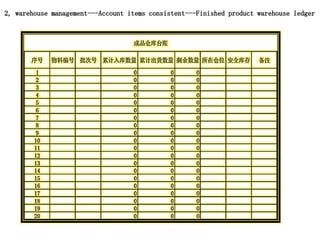

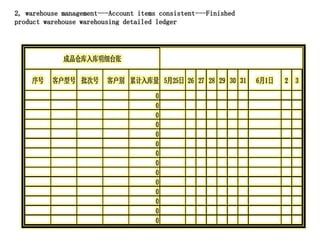

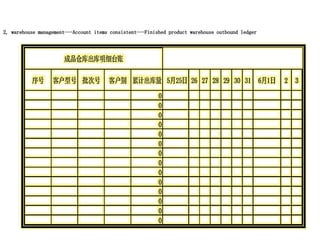

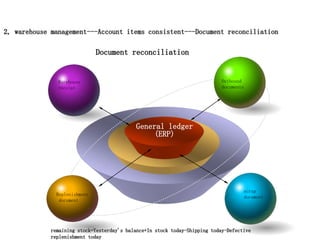

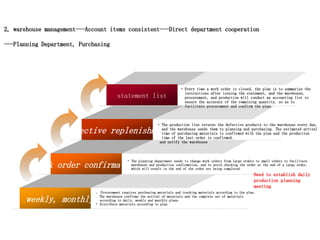

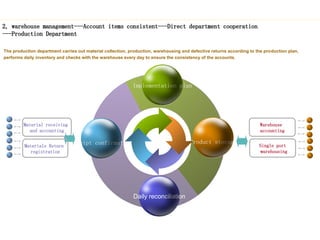

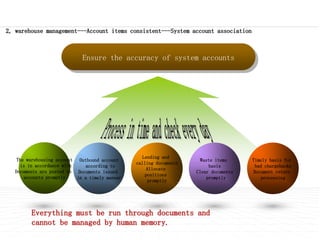

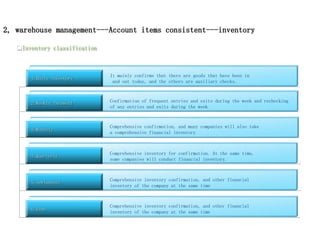

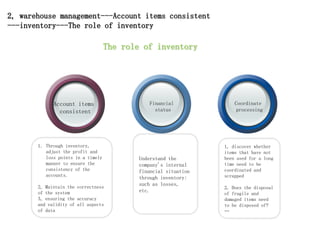

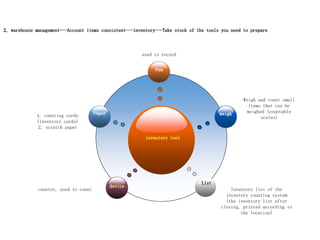

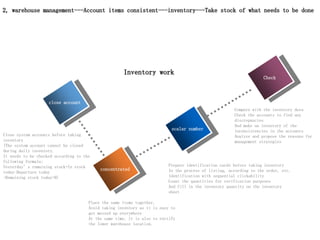

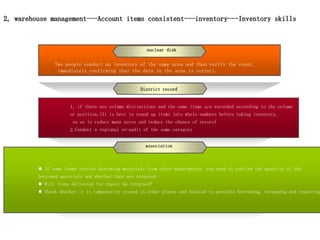

3. Ensuring consistency between inventory accounts and actual stored items is one of the key principles discussed, including maintaining accurate ledgers for receipts, shipments, and daily inventory checks.