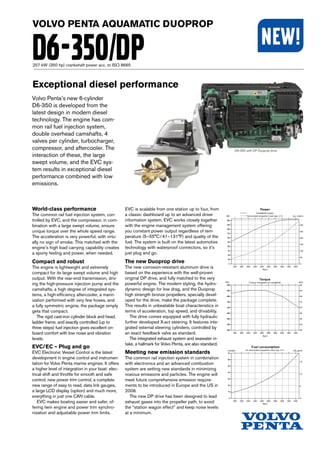

The Volvo Penta D6-350 is a modern diesel engine featuring a common rail fuel injection system, double overhead camshafts, and turbocharging, providing exceptional performance and low emissions. Its DP Duoprop drive enhances acceleration and drivability while minimizing noise and ensuring efficient operations. This engine is designed to meet future emission standards and offers advanced features like electronic vessel control for improved boating safety and ease.