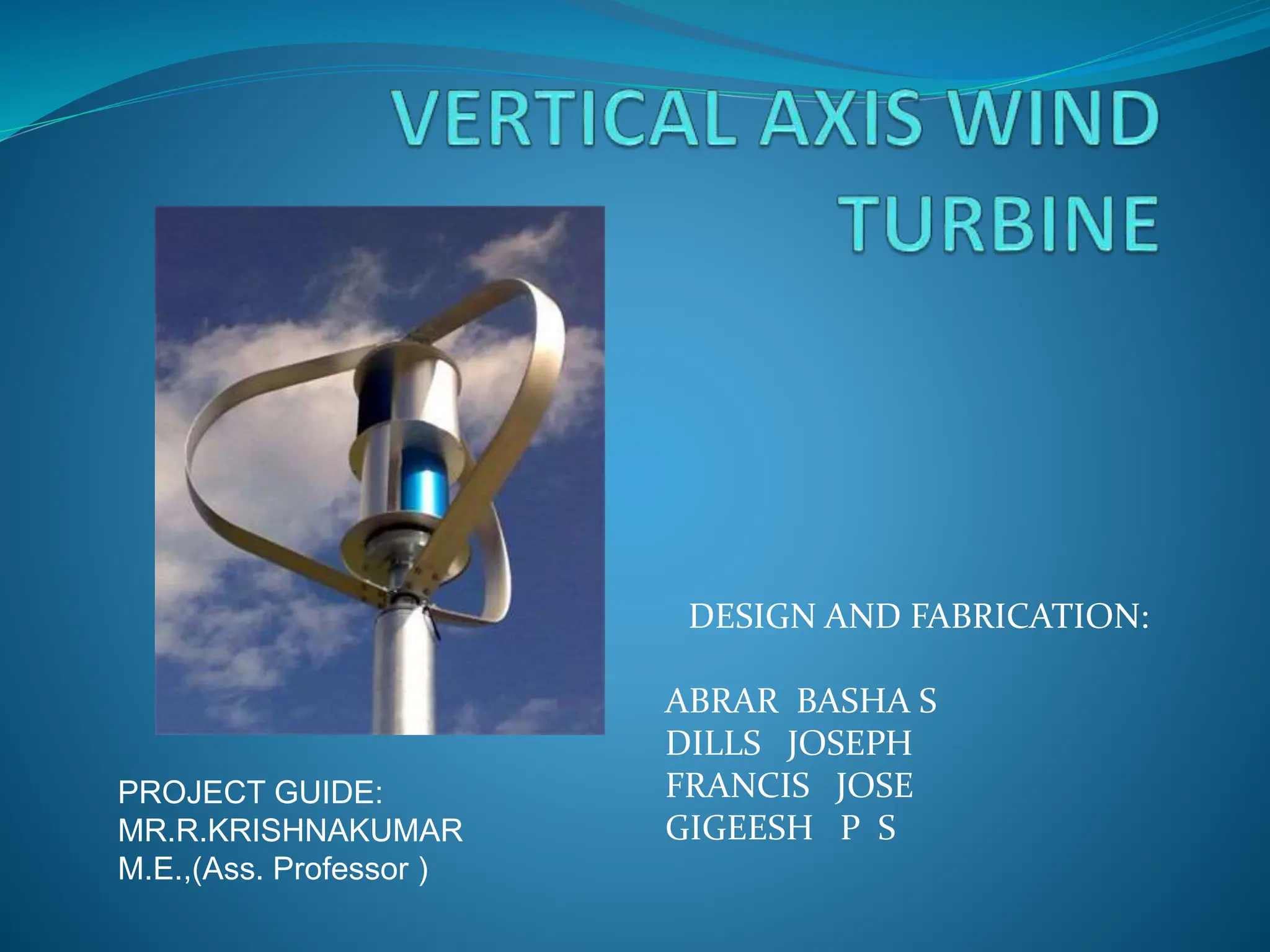

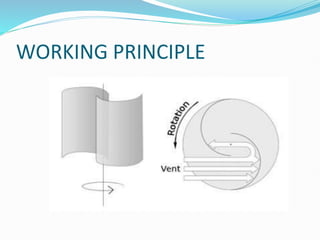

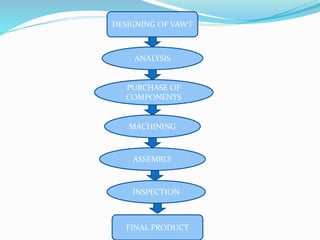

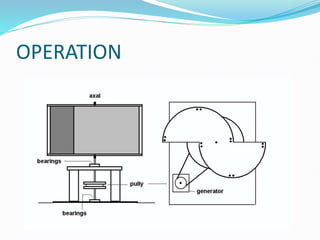

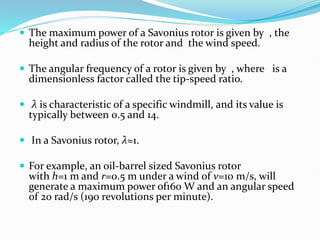

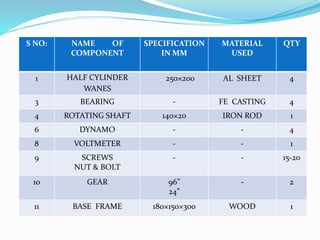

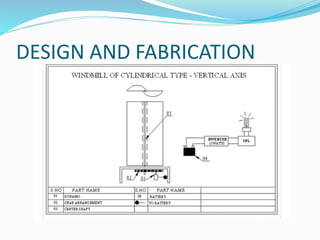

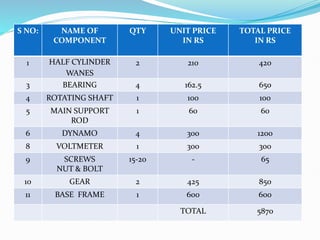

This document describes the design and fabrication of a Savonius windmill. It discusses the objectives of generating electric power through wind energy conversion. It outlines the working principle, methodology, operation, power generation capabilities, materials used, design, budget, applications, advantages, future applications and conclusions of the project. The summaries provide an overview of the key topics and purpose covered in the document.