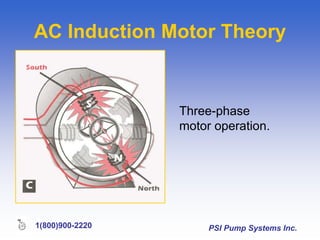

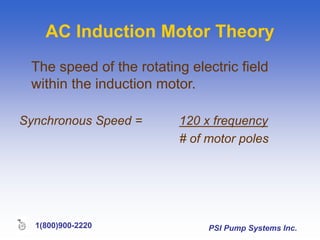

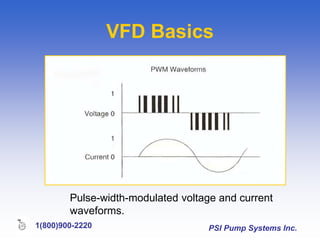

PSI Pump Systems Inc. presents information on variable frequency drives (VFDs). VFDs can provide energy savings, better process control, and safe speed adjustment of machines. They work by converting incoming AC power to DC, and then using an inverter to convert the DC back to variable frequency AC to control motor speed. VFDs allow electric motors to meet application needs for torque and speed control.