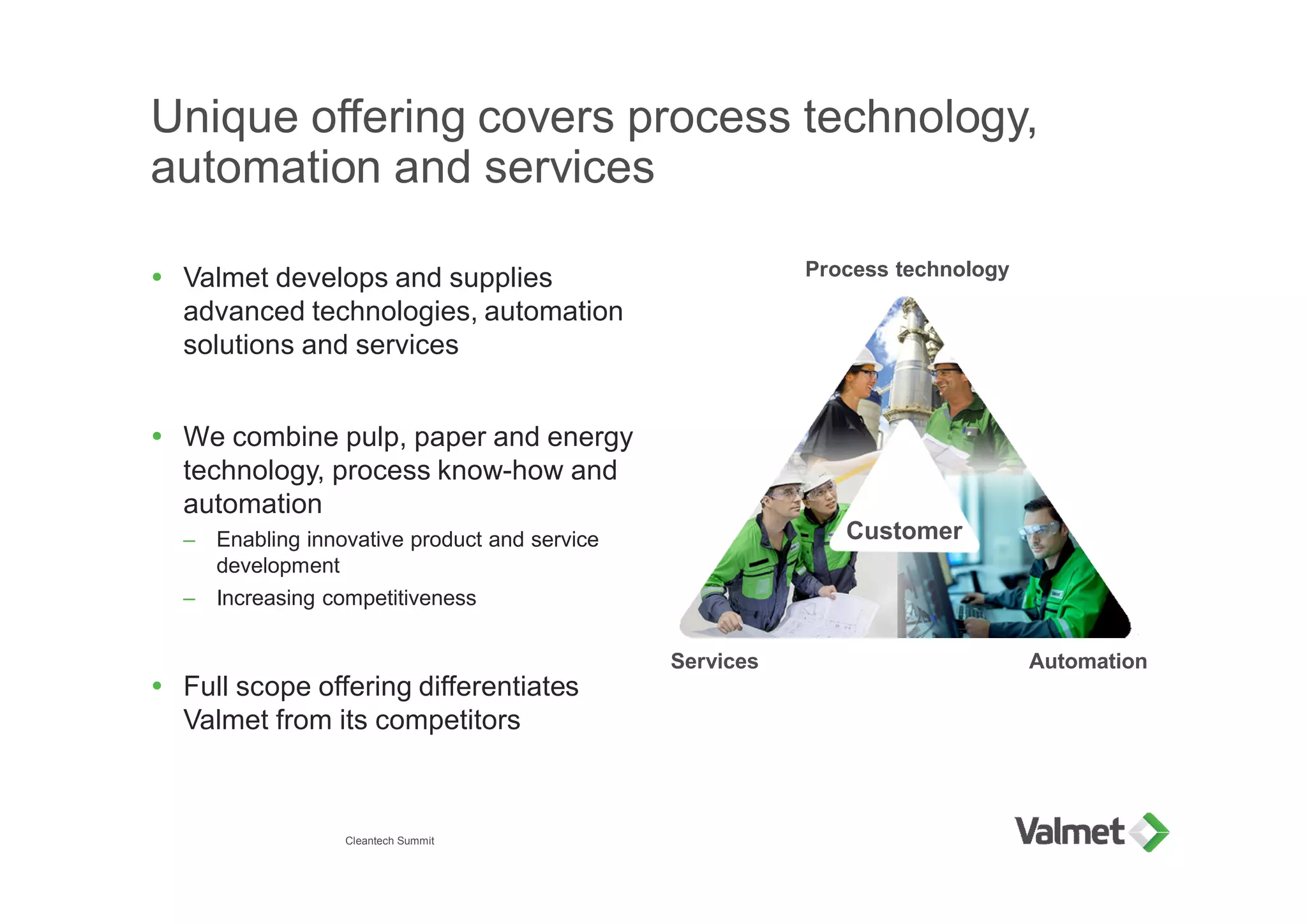

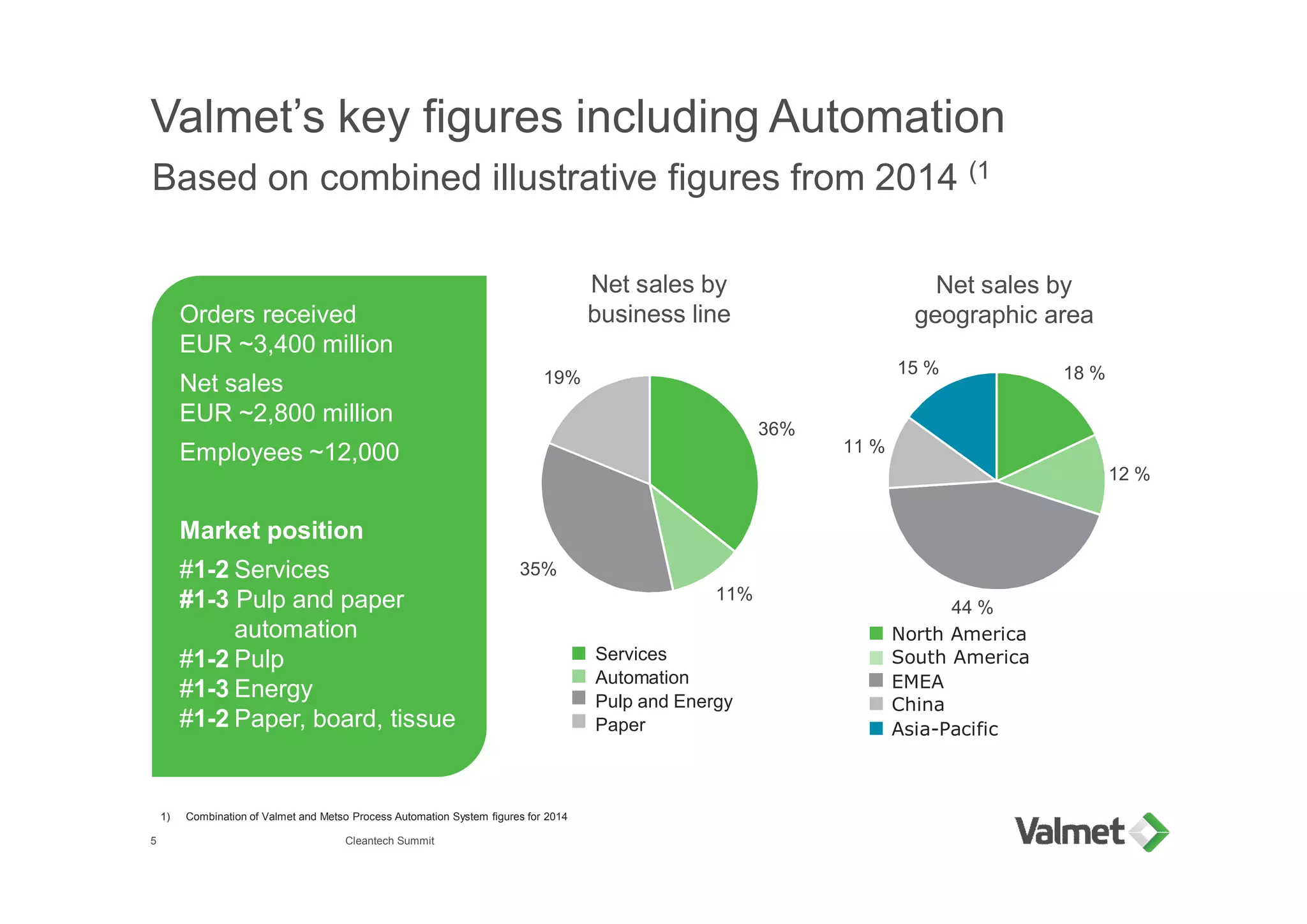

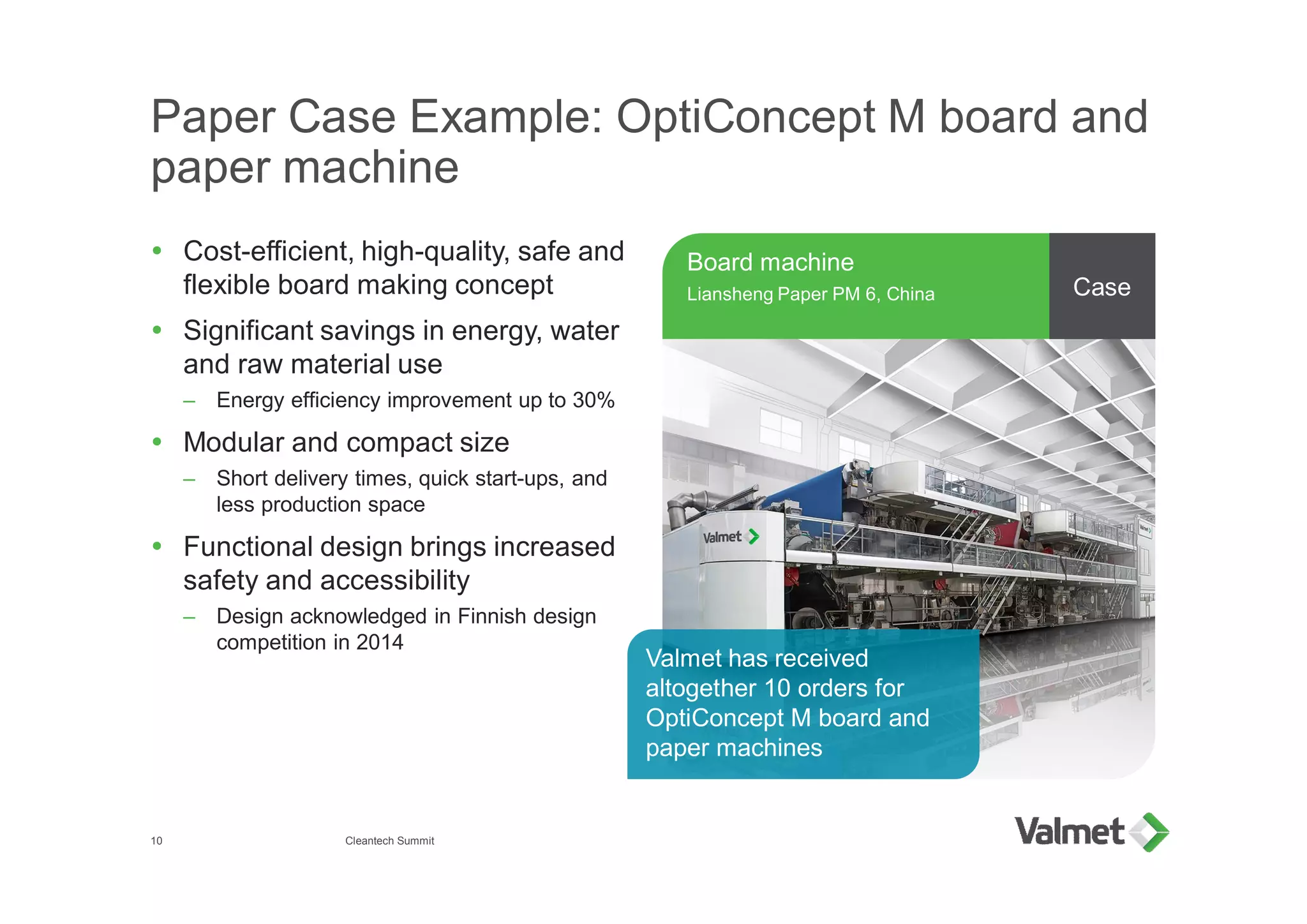

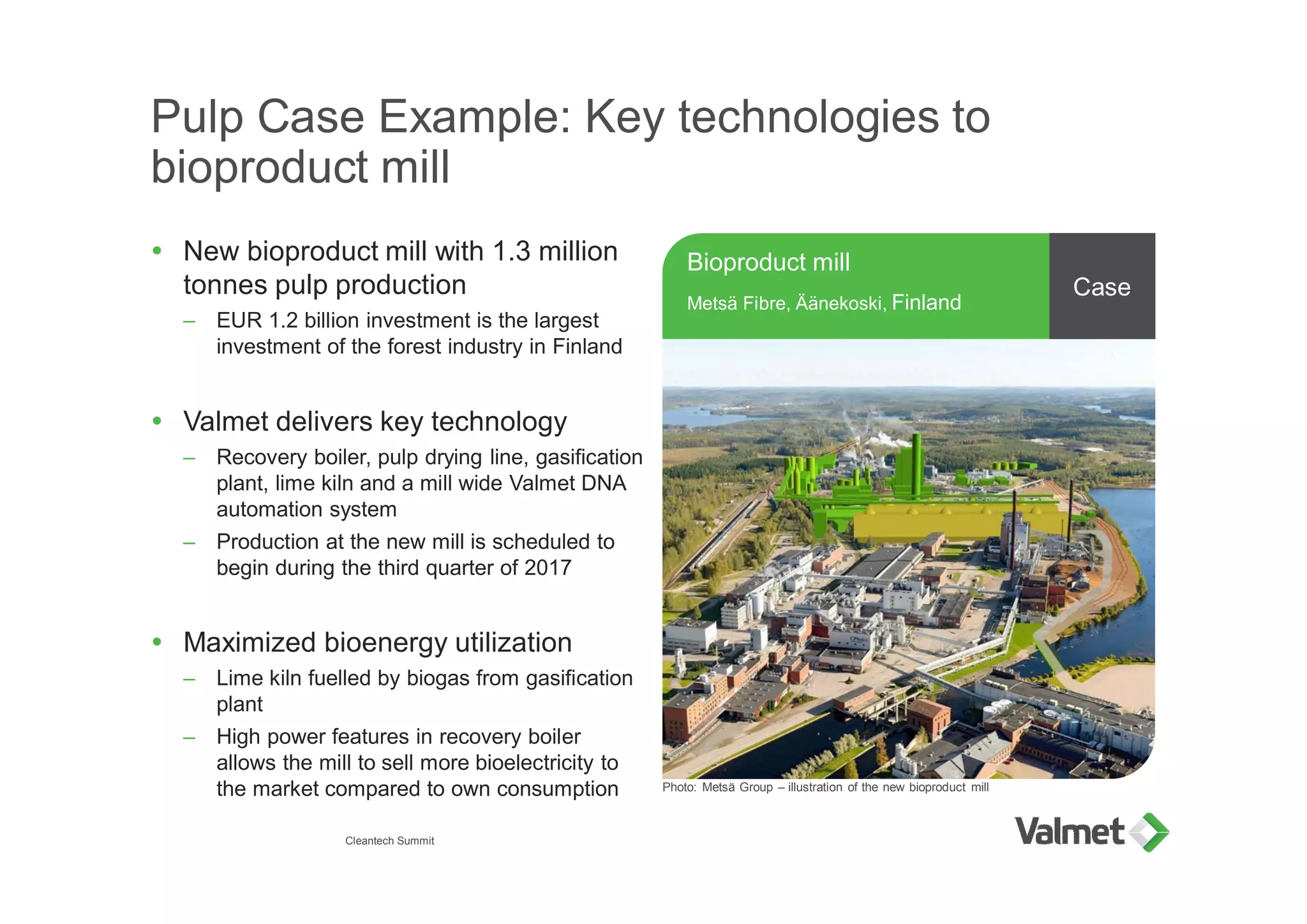

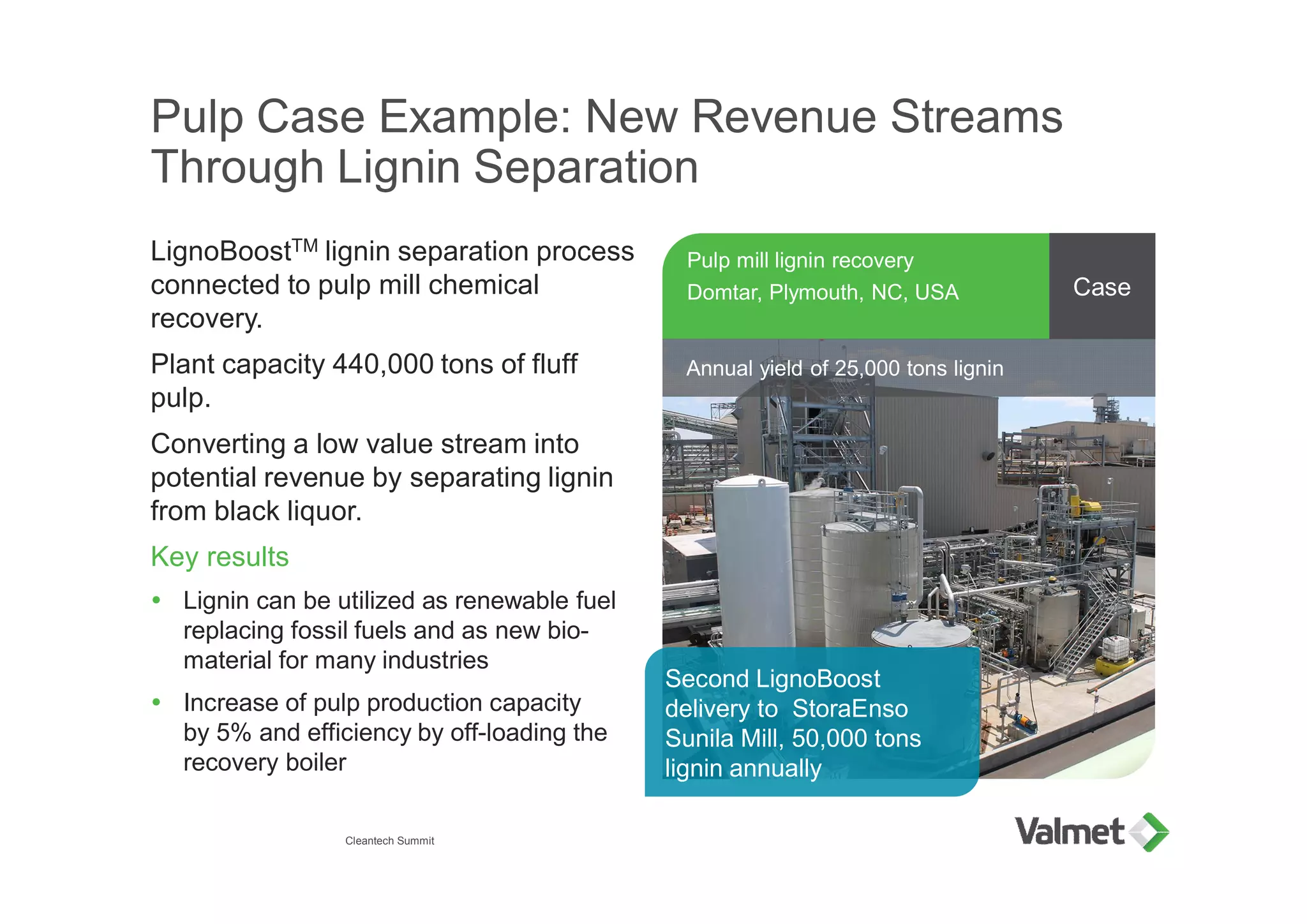

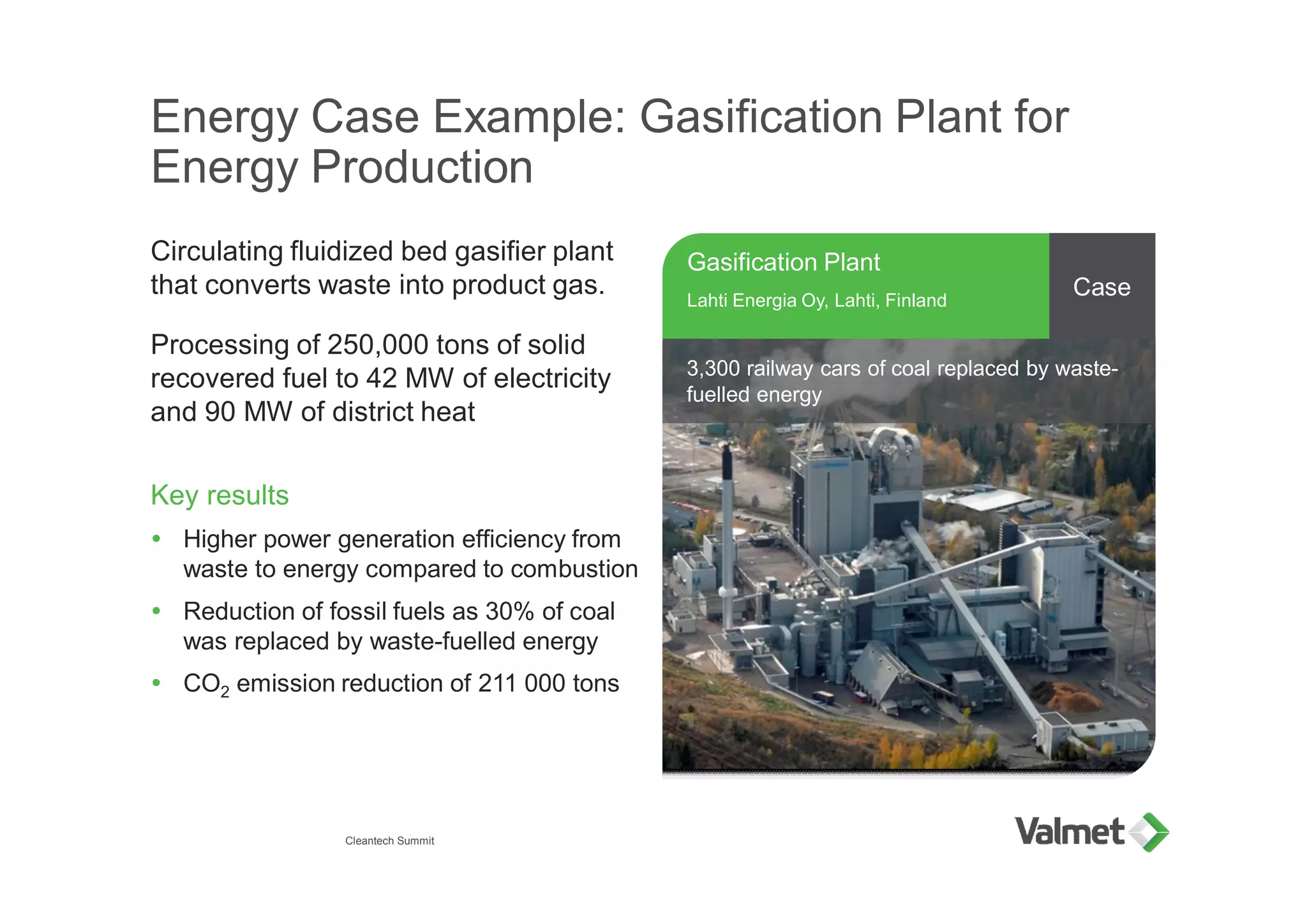

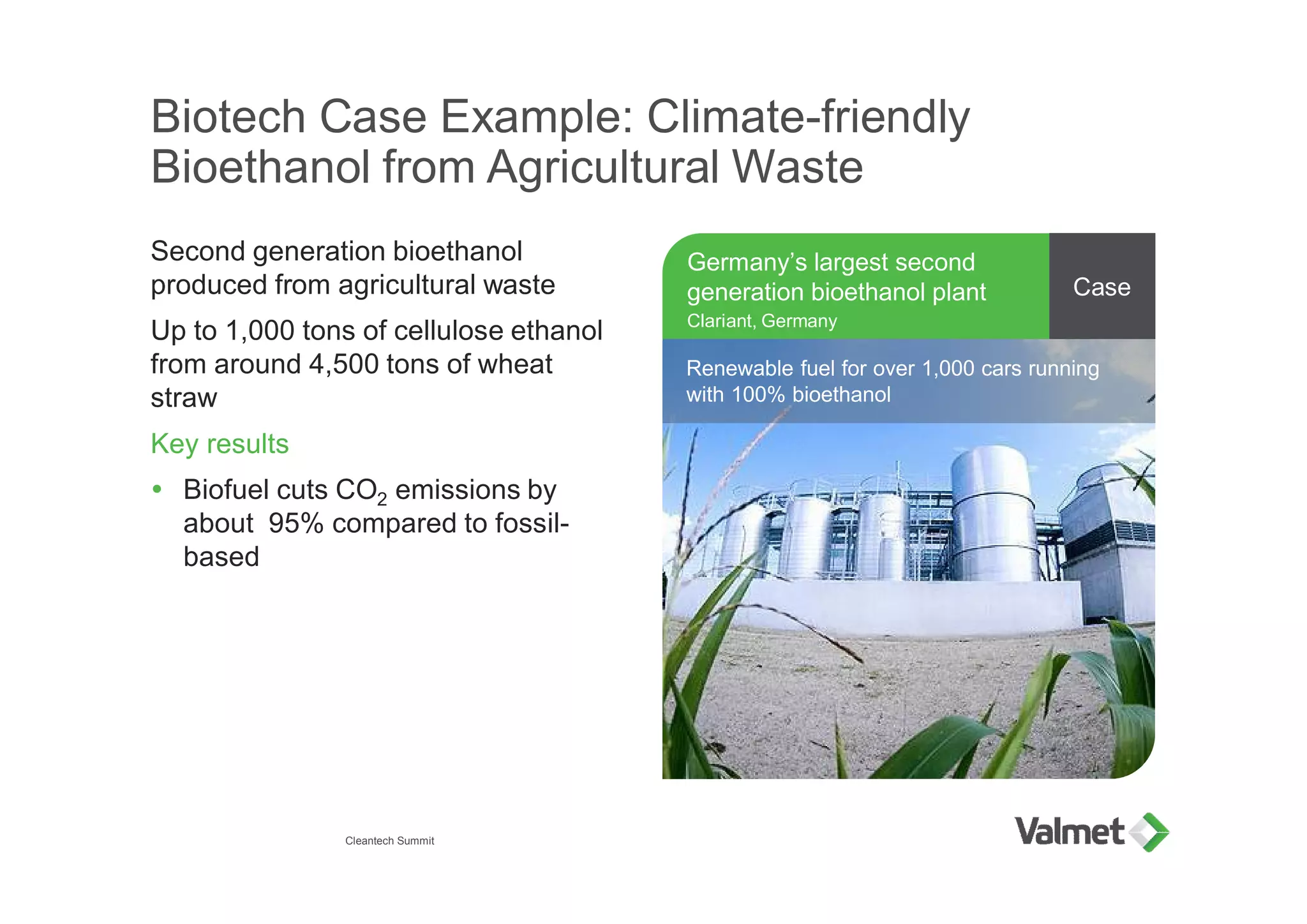

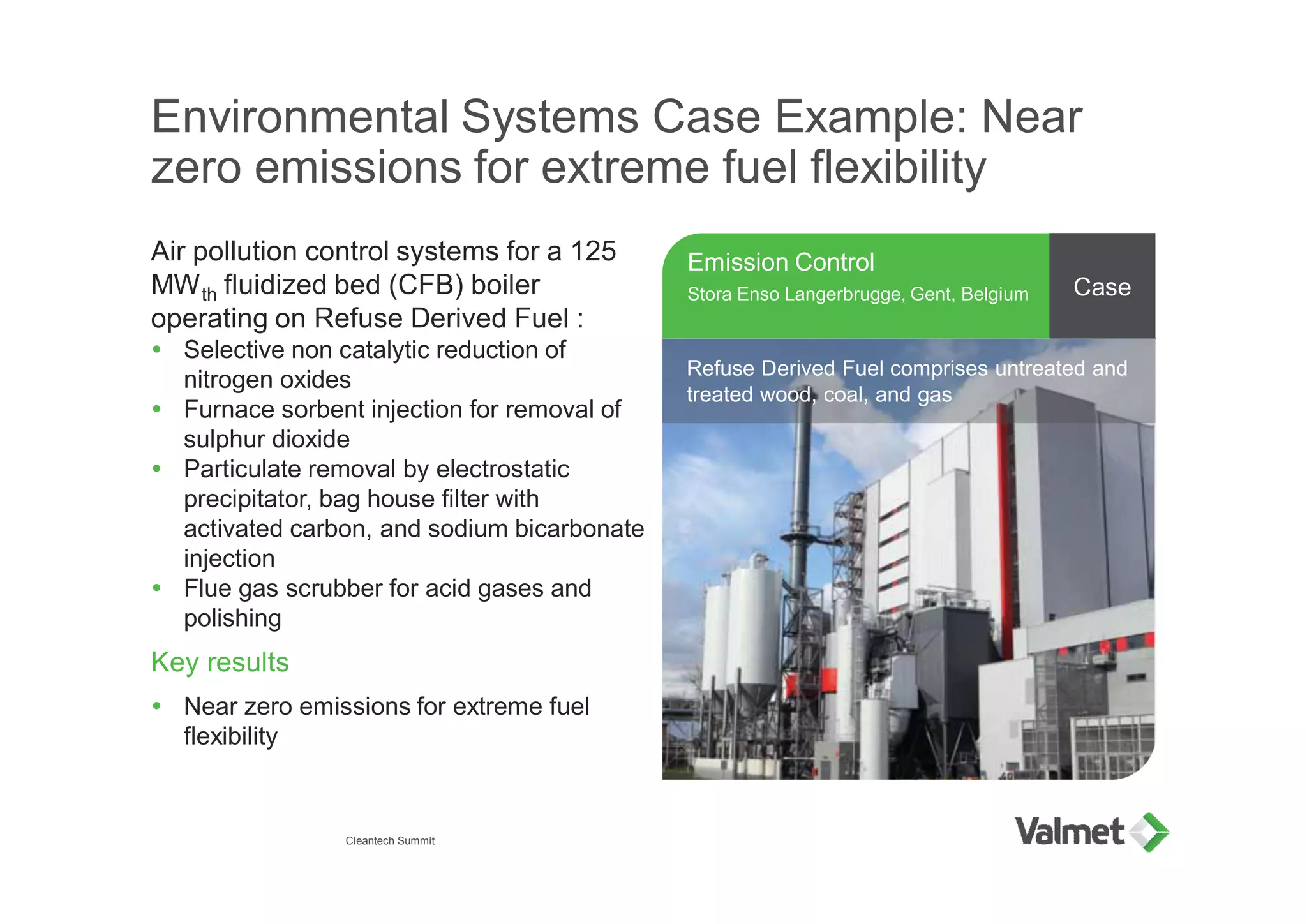

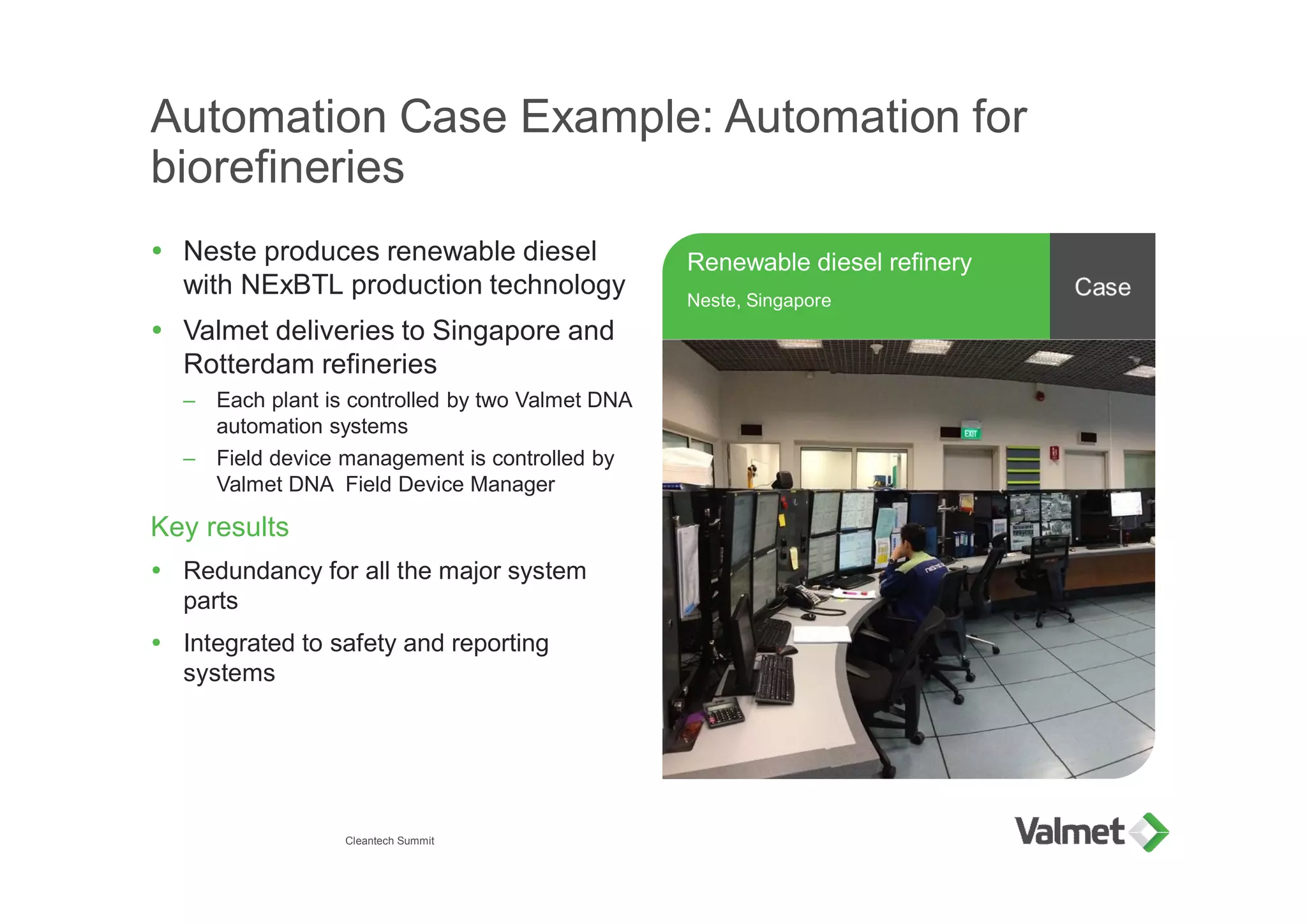

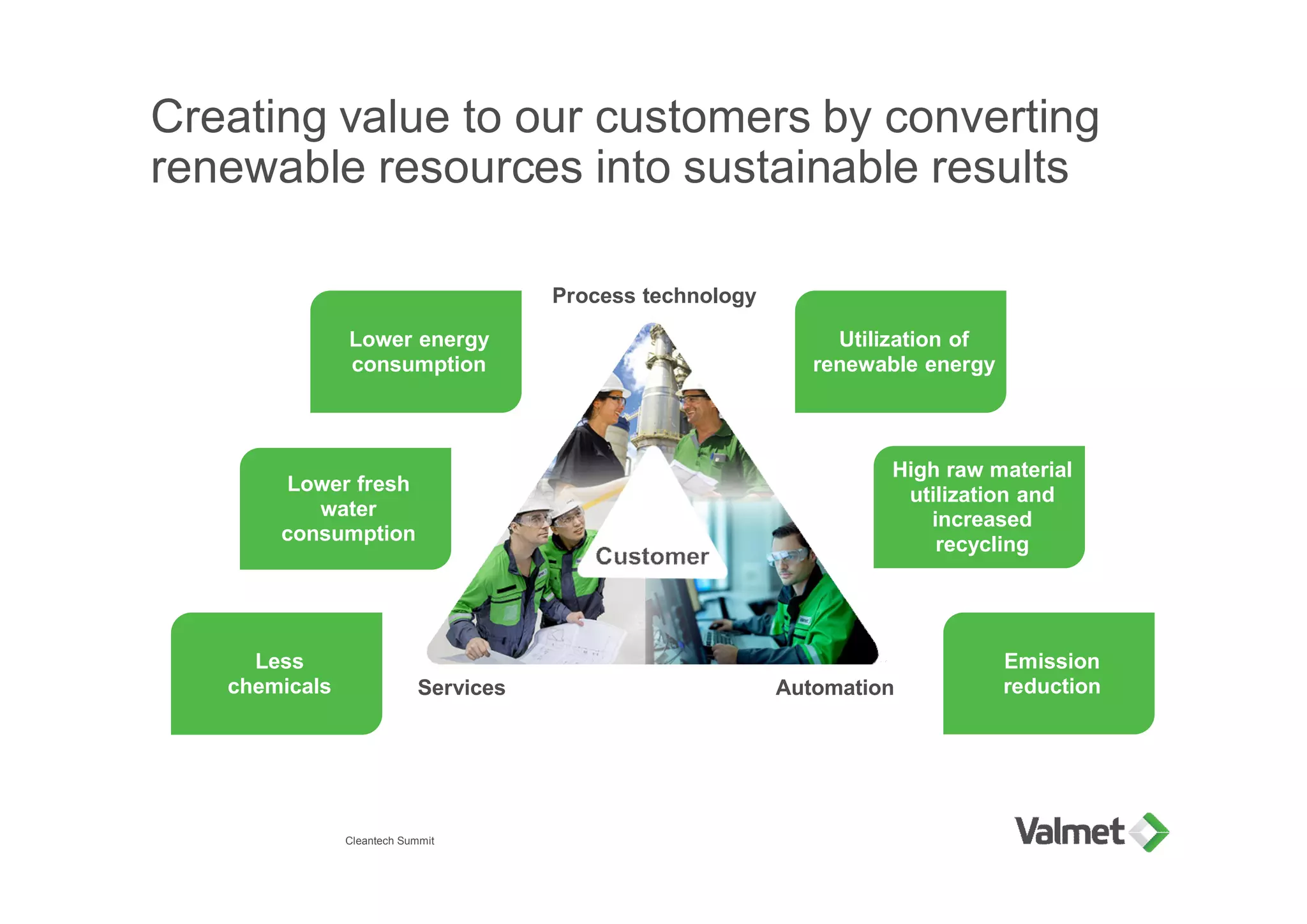

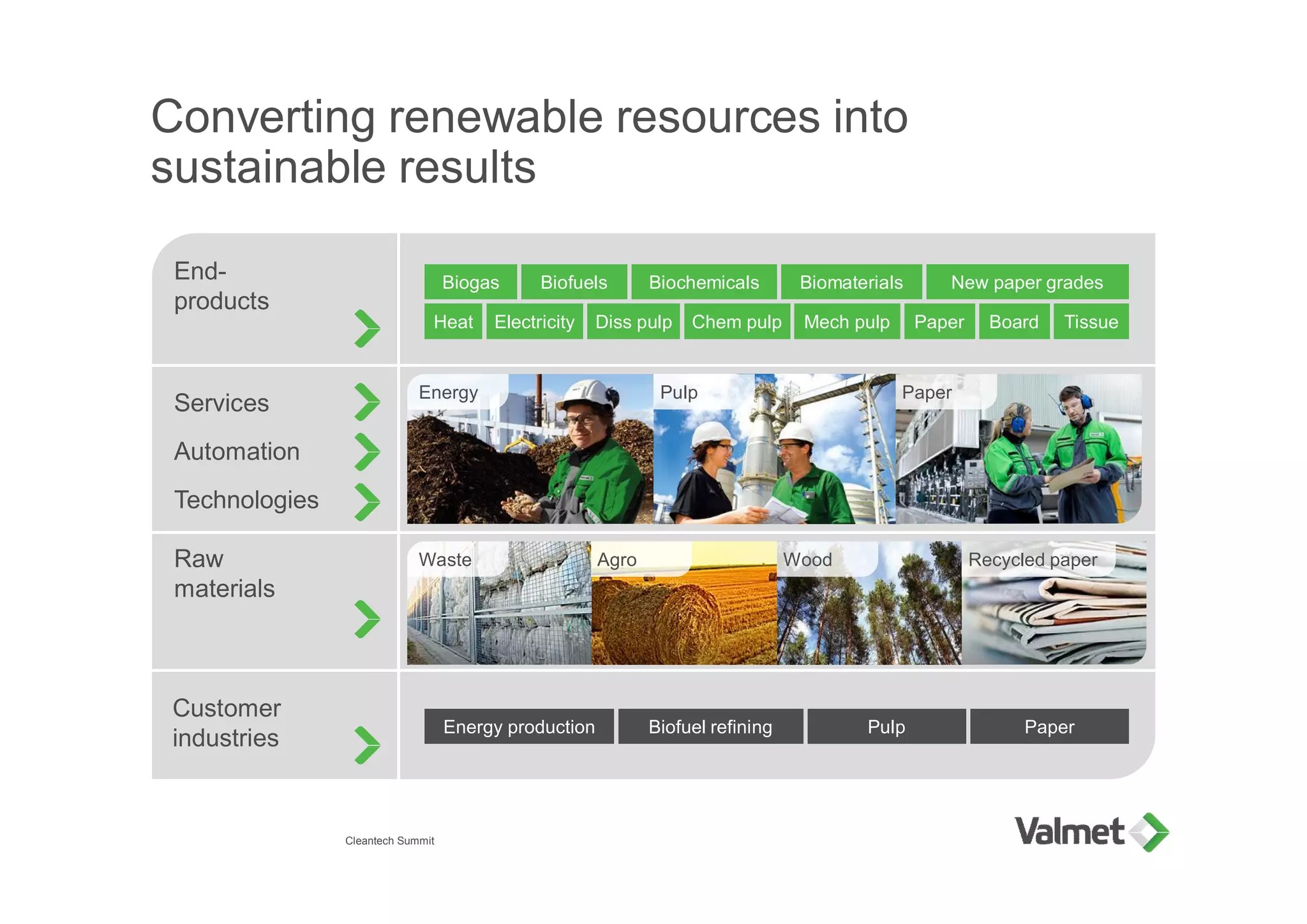

Valmet provides clean technology solutions across pulp, paper, energy and automation. They discussed key trends driving demand for cleantech like population growth, fossil fuel dependence and climate change. Case examples showed how Valmet delivers cost-efficient, high-quality technologies that increase raw material utilization, reduce emissions and fresh water use, and enable new revenue streams from renewable resources like lignin and biofuels. Their integrated solutions and expertise help customers convert renewable resources into sustainable results.