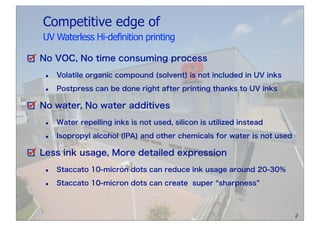

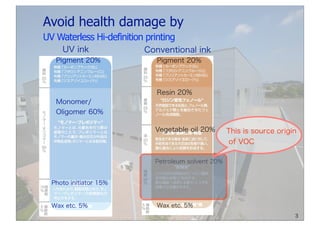

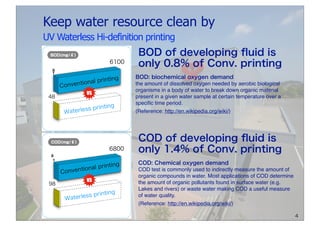

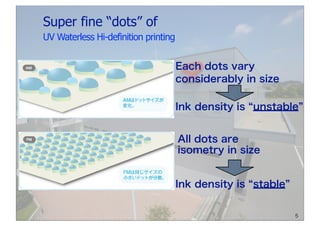

UV waterless hi-definition printing provides several advantages over conventional printing methods in 3 sentences: It uses UV inks that do not contain volatile organic compounds or require water, allowing for faster postpress without chemicals. It can reduce ink usage by 20-30% through 10-micron dots that provide sharper images while avoiding health risks associated with conventional inks. The process also keeps water resources cleaner by producing developing fluid with only 0.8-1.4% of the biochemical and chemical oxygen demand of conventional printing waste.