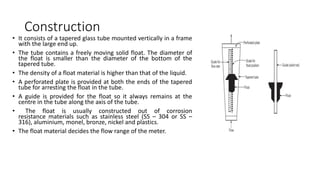

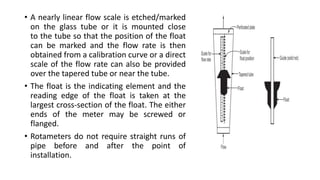

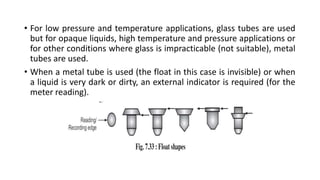

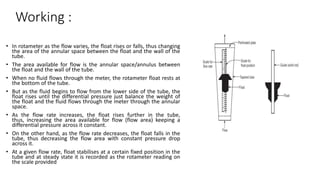

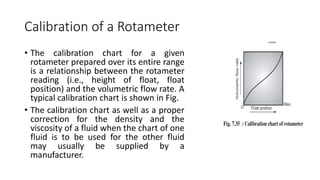

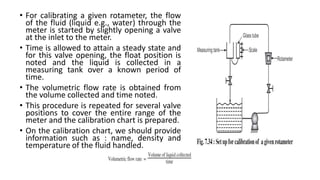

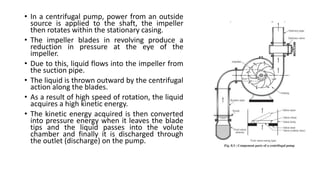

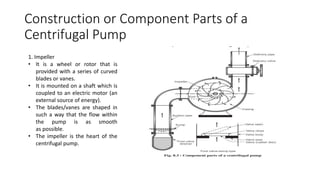

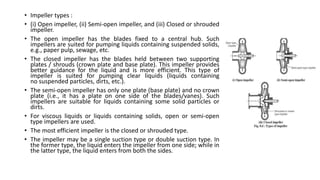

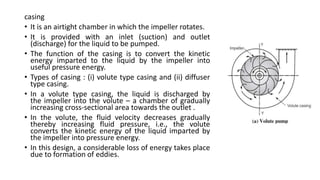

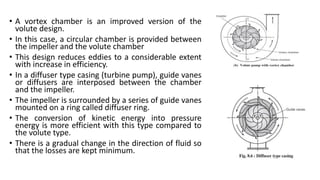

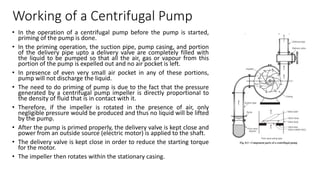

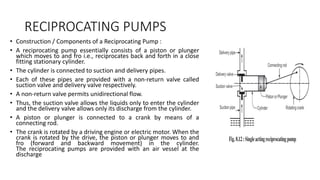

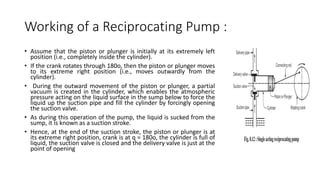

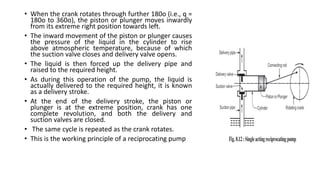

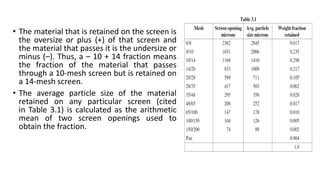

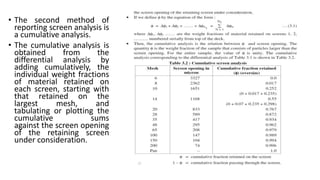

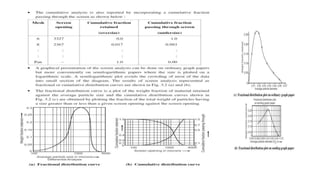

The document discusses rotameters and centrifugal pumps. It provides details on the construction and working principles of rotameters, which measure flow rate by relating the position of a floating indicator to flow. The pressure drop is constant and area of flow varies. Centrifugal pumps are also covered, explaining they work by increasing the kinetic energy and converting it to pressure energy using a rotating impeller in a casing. Key factors for selecting between pump types are flow rate, head, liquid properties and power requirements.