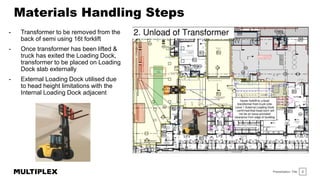

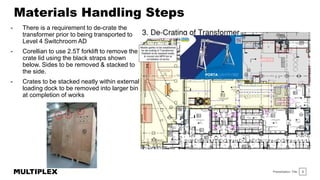

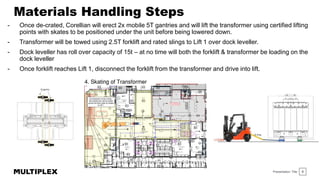

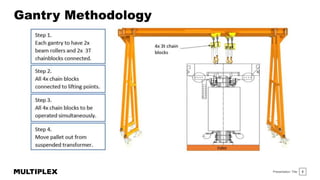

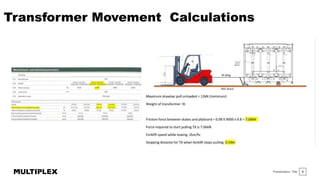

The document outlines the steps for handling and moving a transformer from the loading dock to level 4 of the building. It involves using forklifts and mobile gantries to lift the transformer out of its crate, transport it to an elevator, and maneuver it down corridors to its destination. Safety precautions include establishing exclusion zones, using spotters to monitor equipment stability, prohibiting phone use by operators, and ensuring only qualified staff operate machinery.