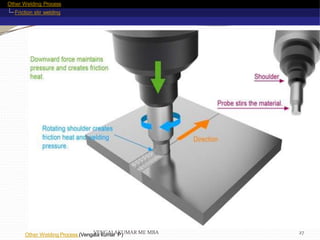

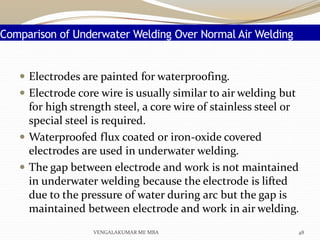

The document discusses various welding processes including thermit welding, electron beam welding, laser beam welding, friction stir welding, and underwater welding. Thermit welding uses an exothermic reaction to generate heat and join metals. Electron beam welding uses a concentrated beam of electrons to melt materials in a vacuum. Laser beam welding focuses intense laser light to join metals. Friction stir welding is a solid-state process that uses a rotating pin to plasticize and join metals without melting. Underwater welding can be done wet using shielded metal arc welding or dry using gas tungsten arc welding inside a pressurized chamber.