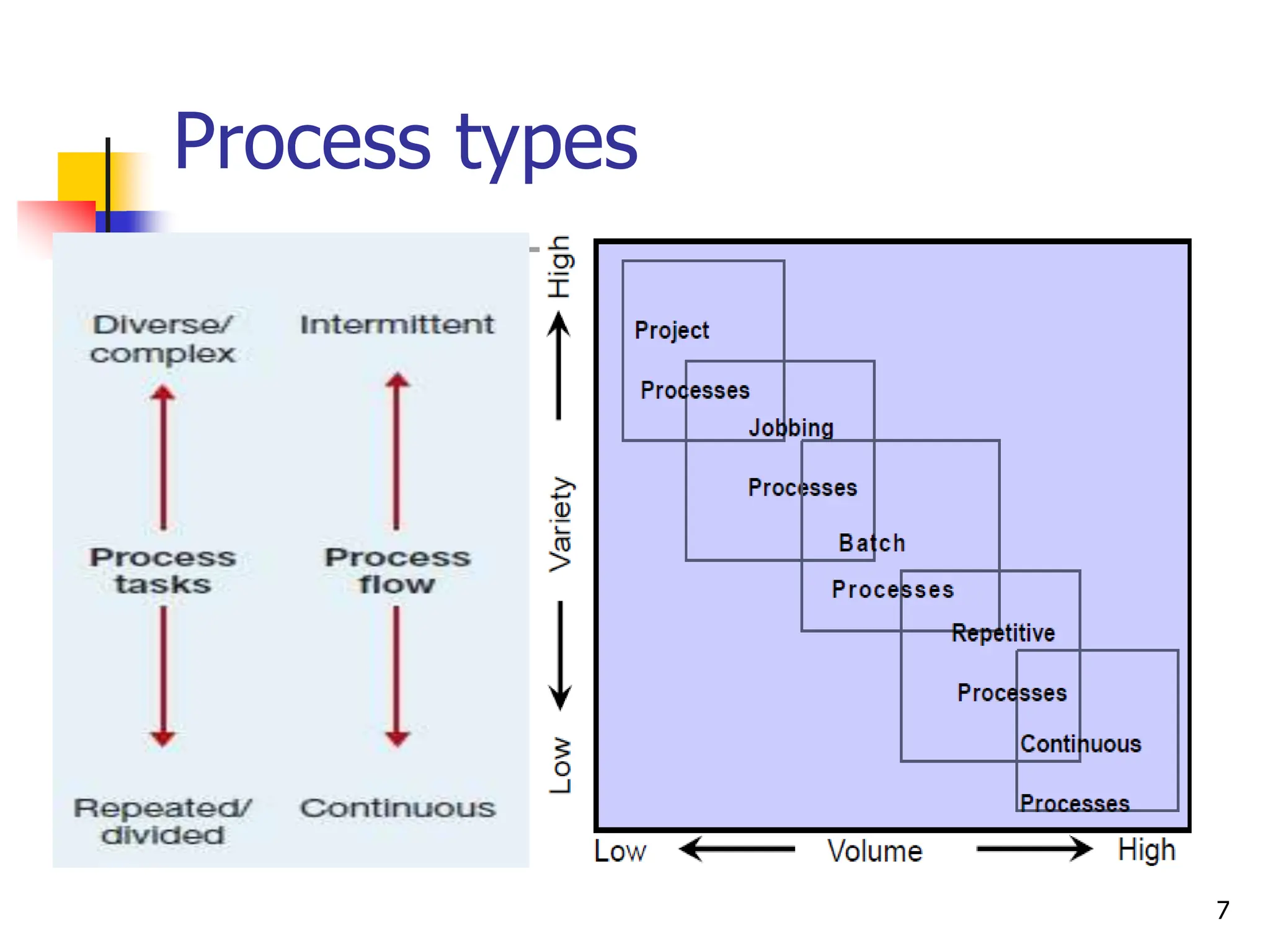

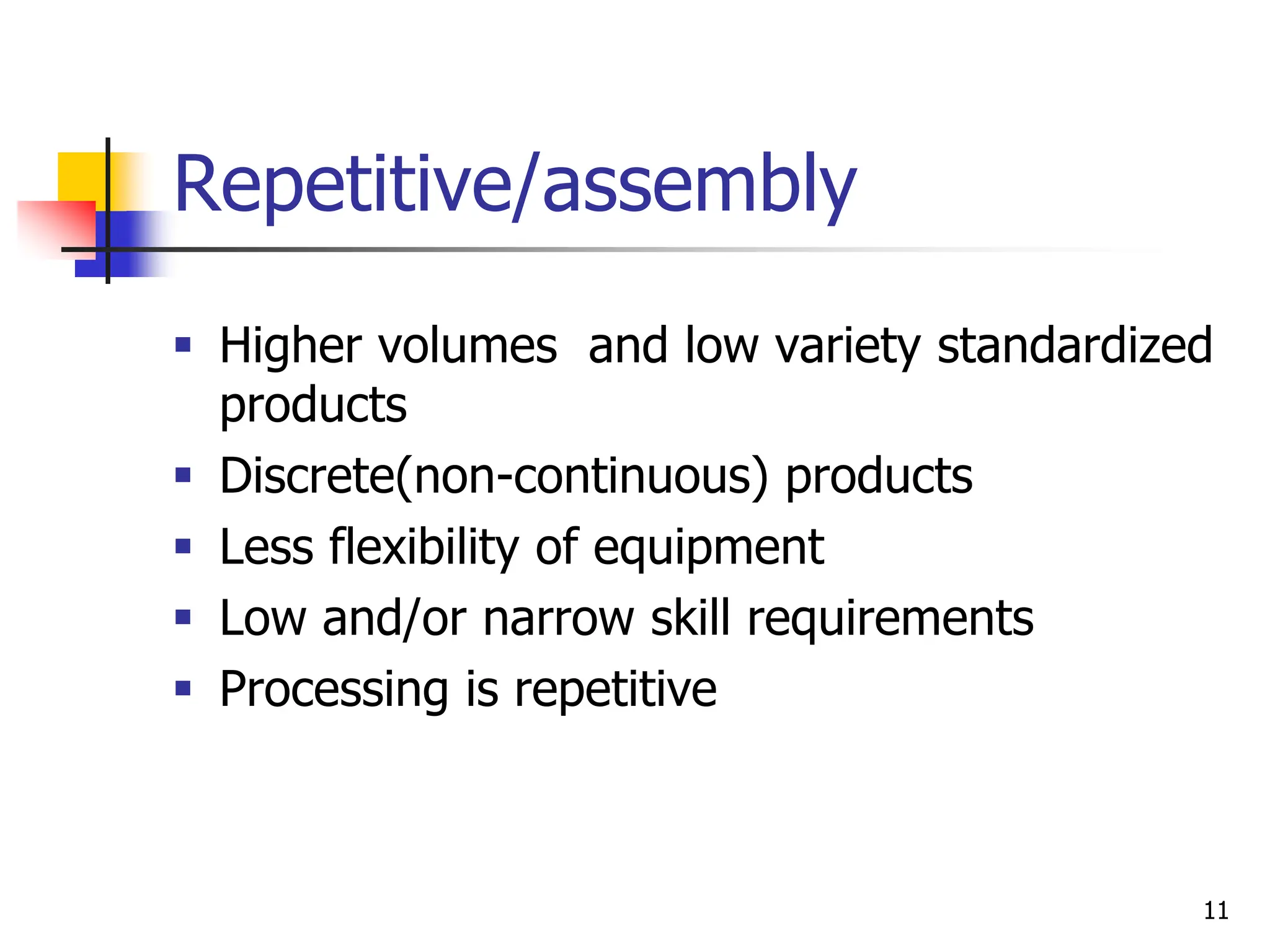

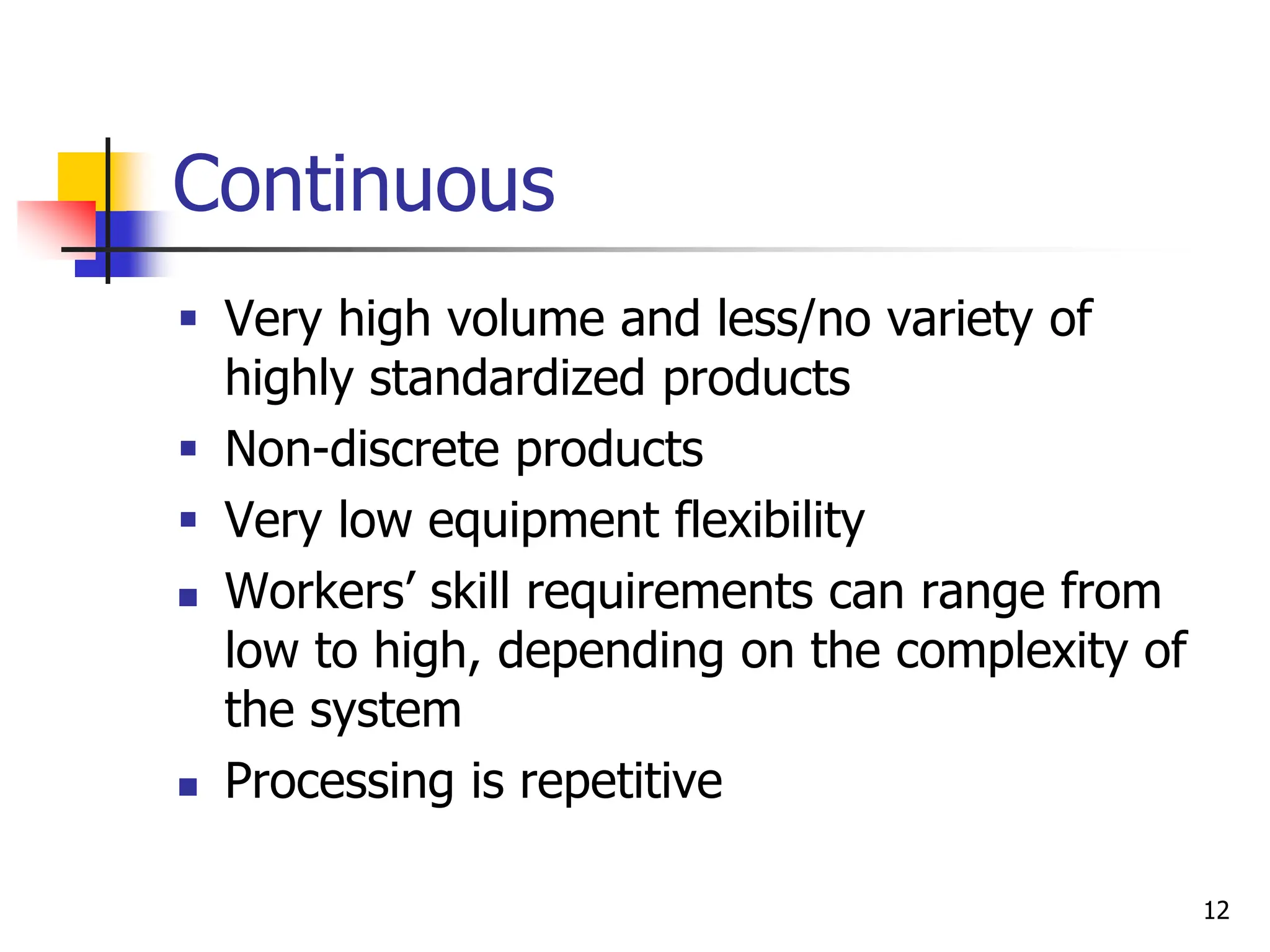

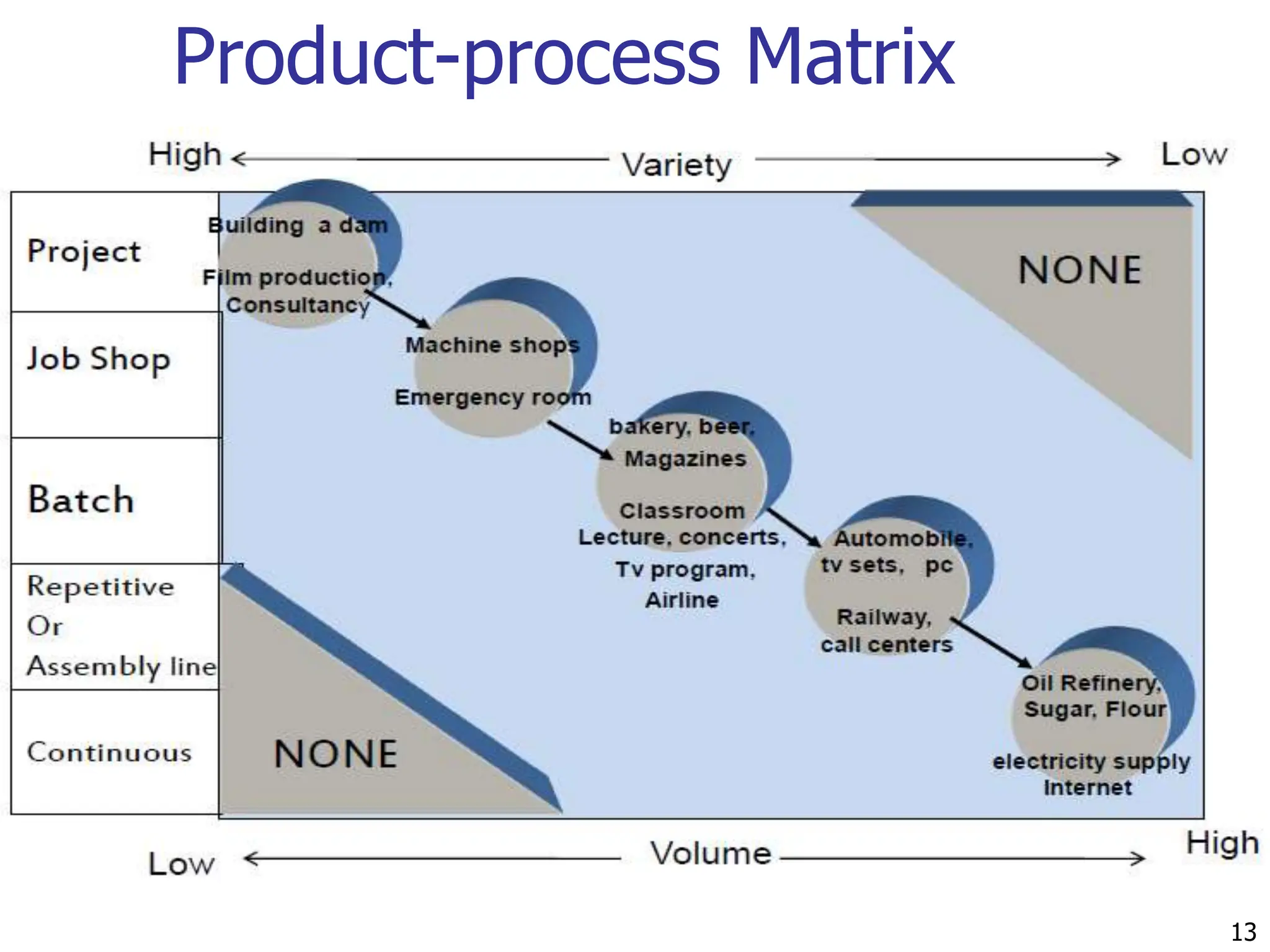

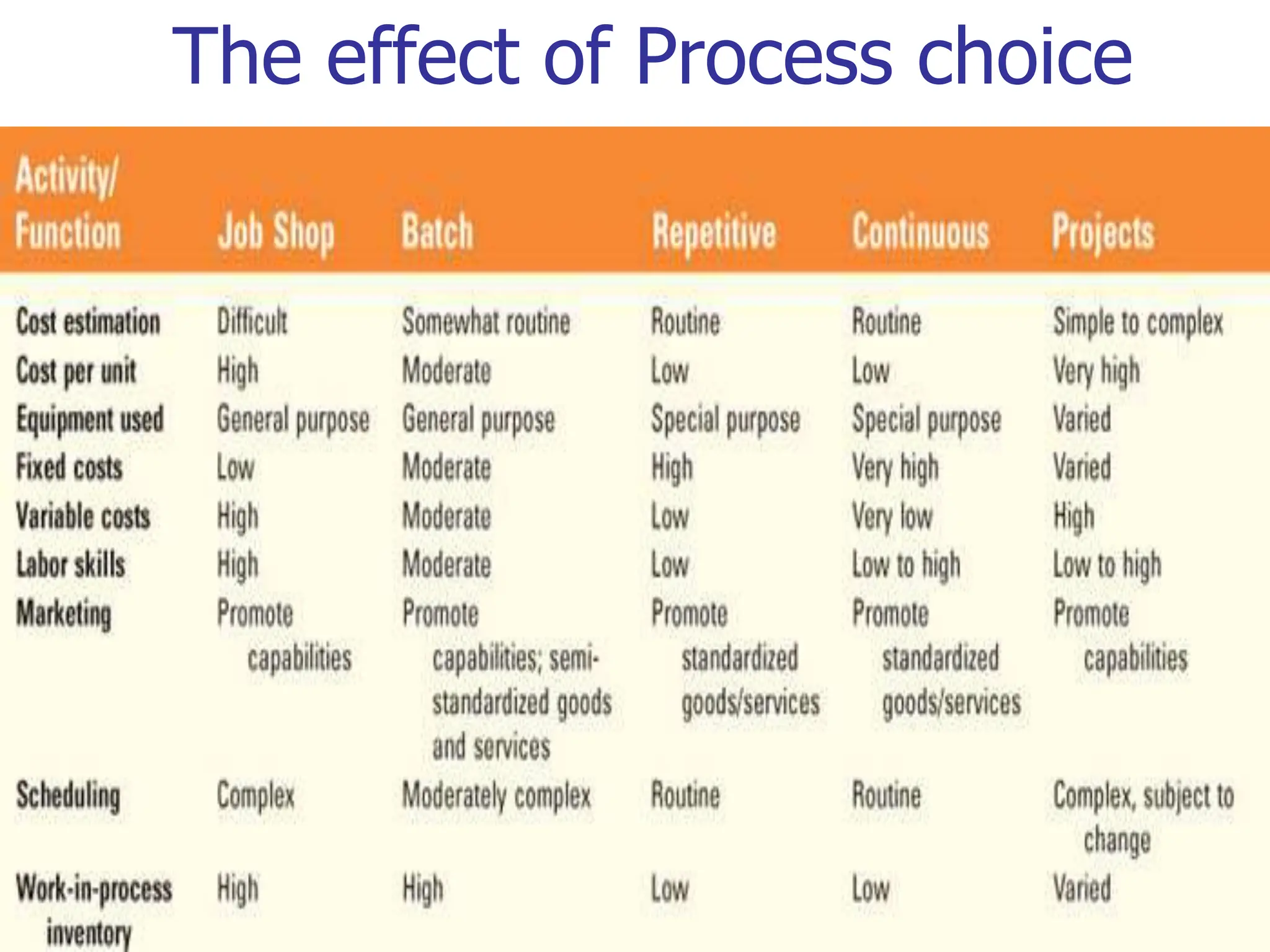

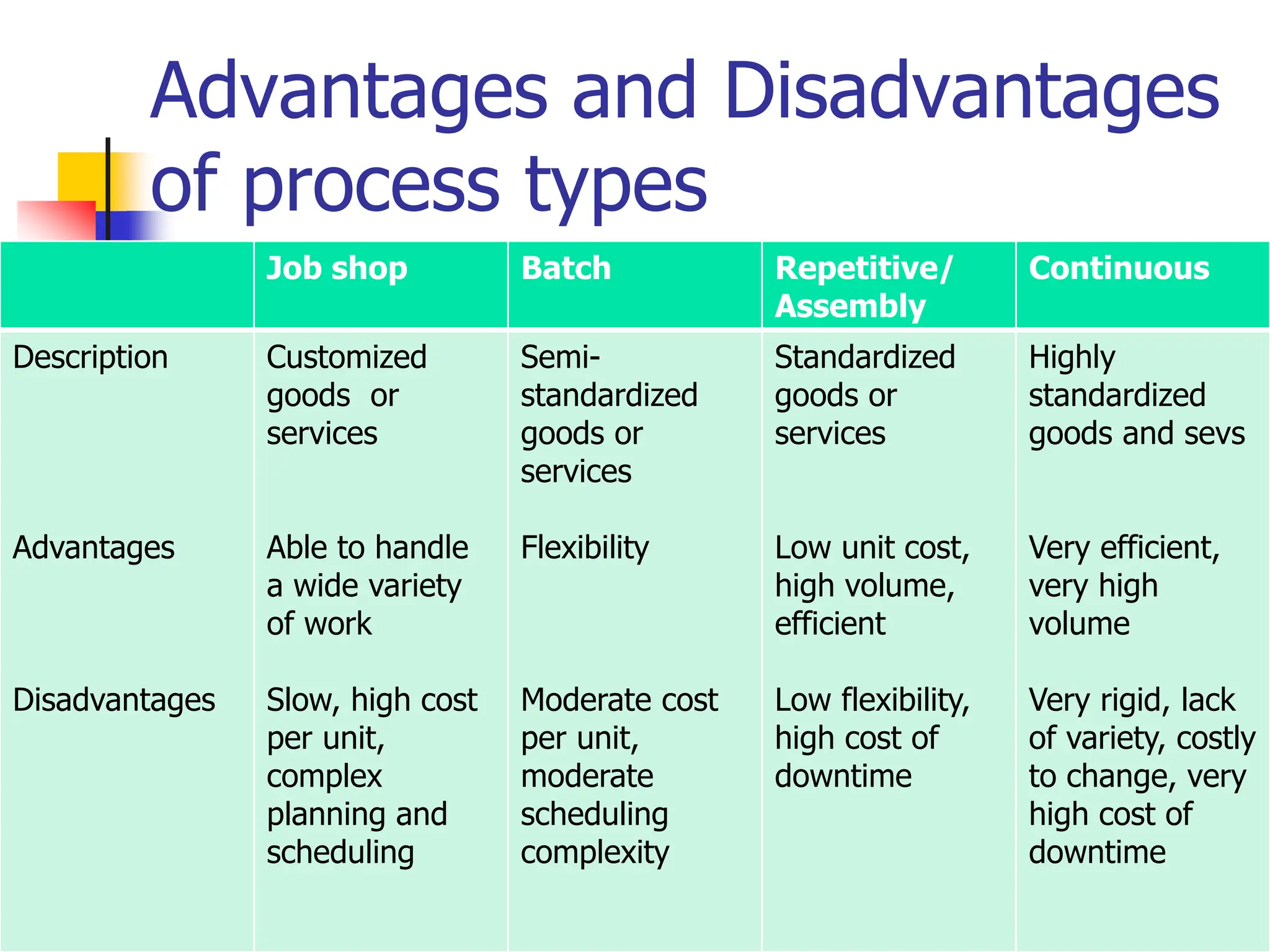

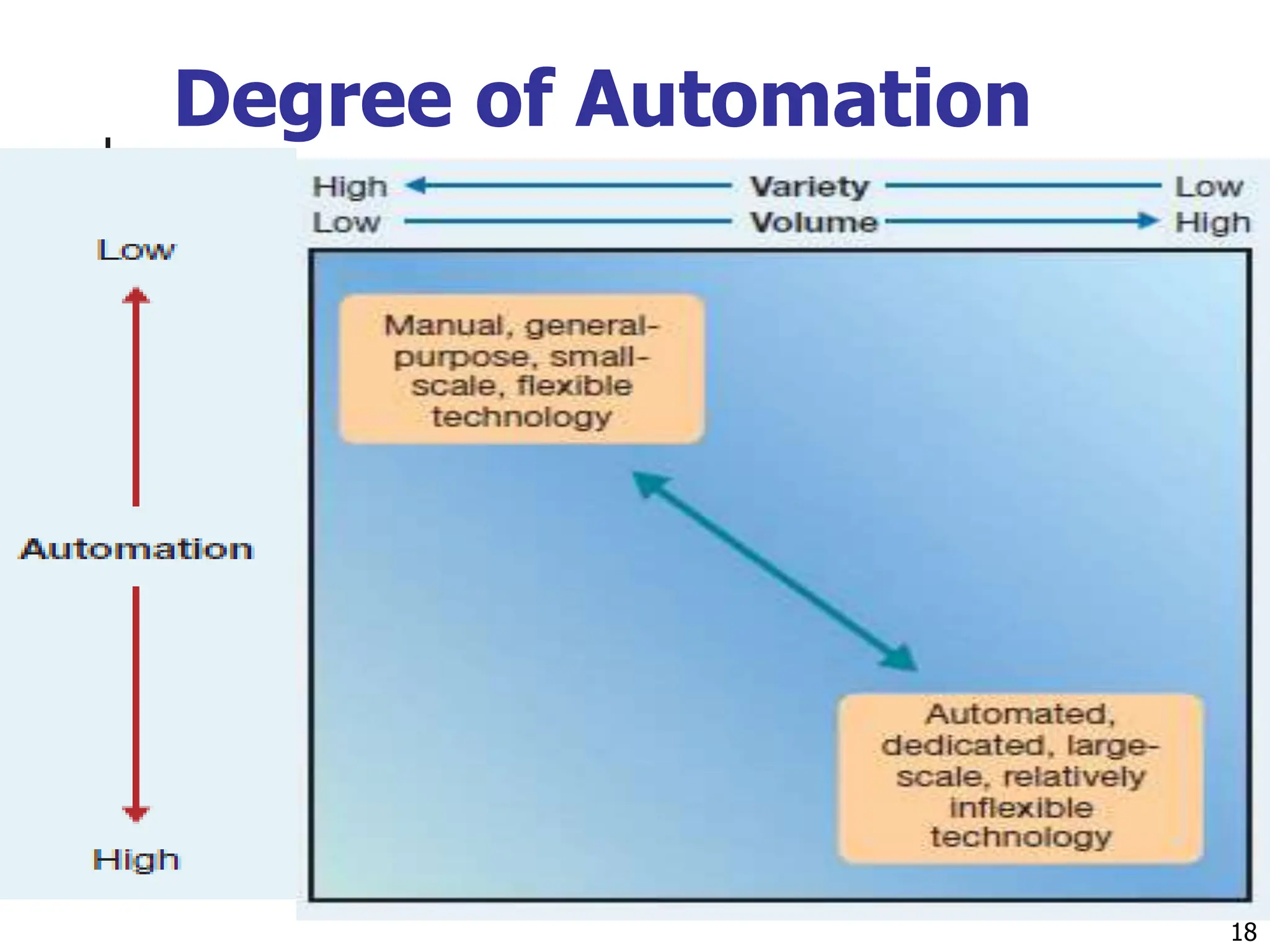

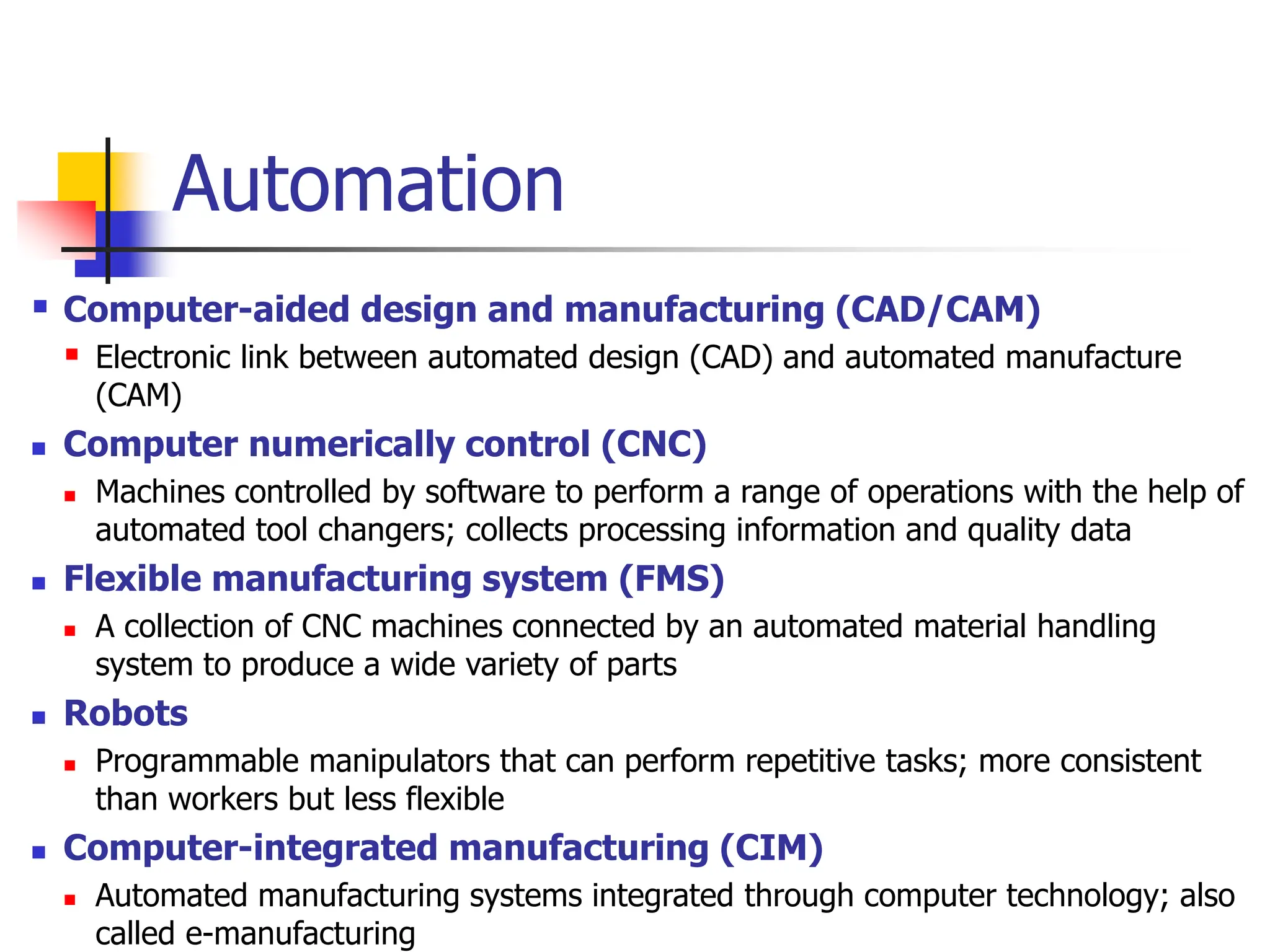

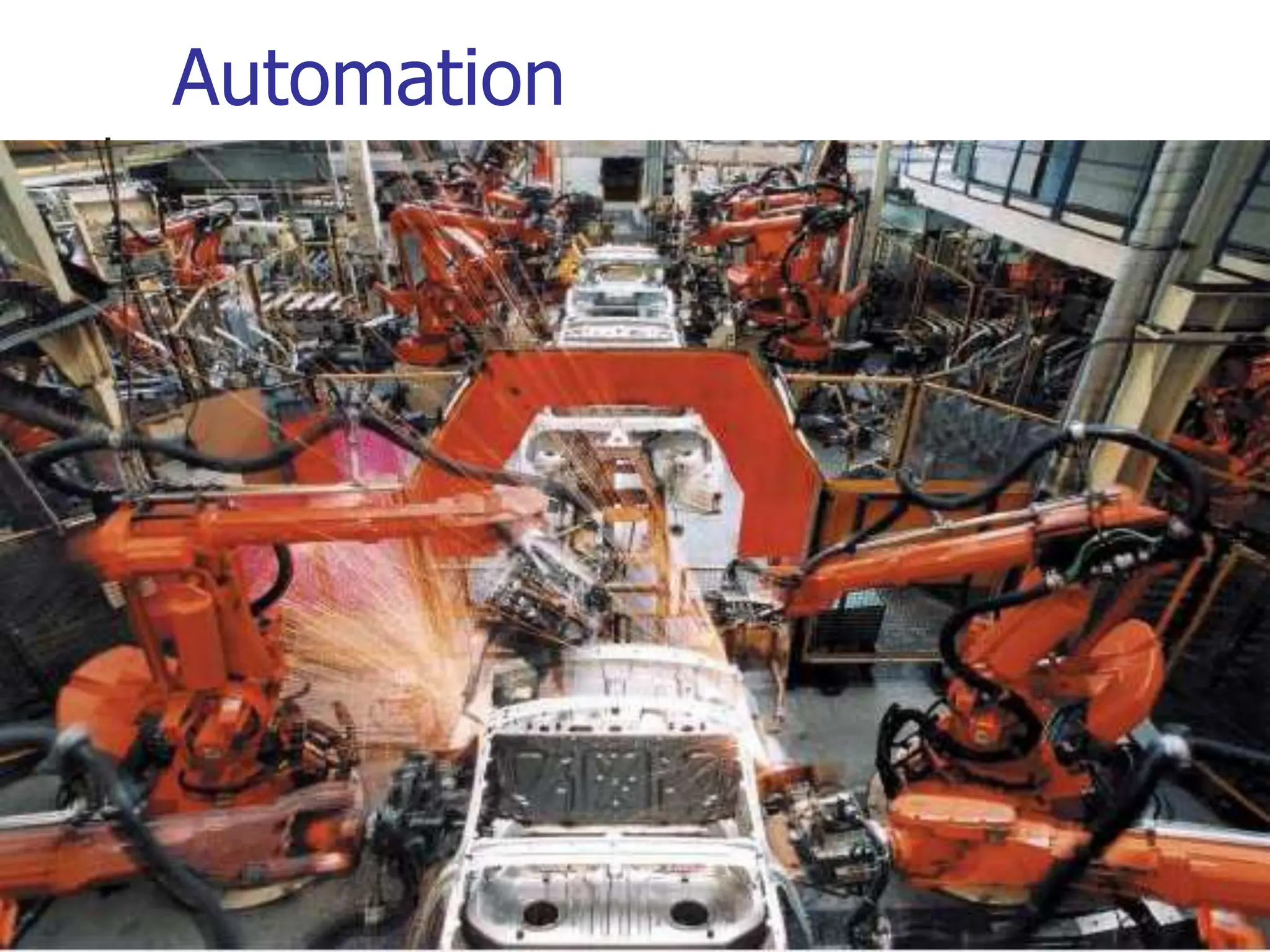

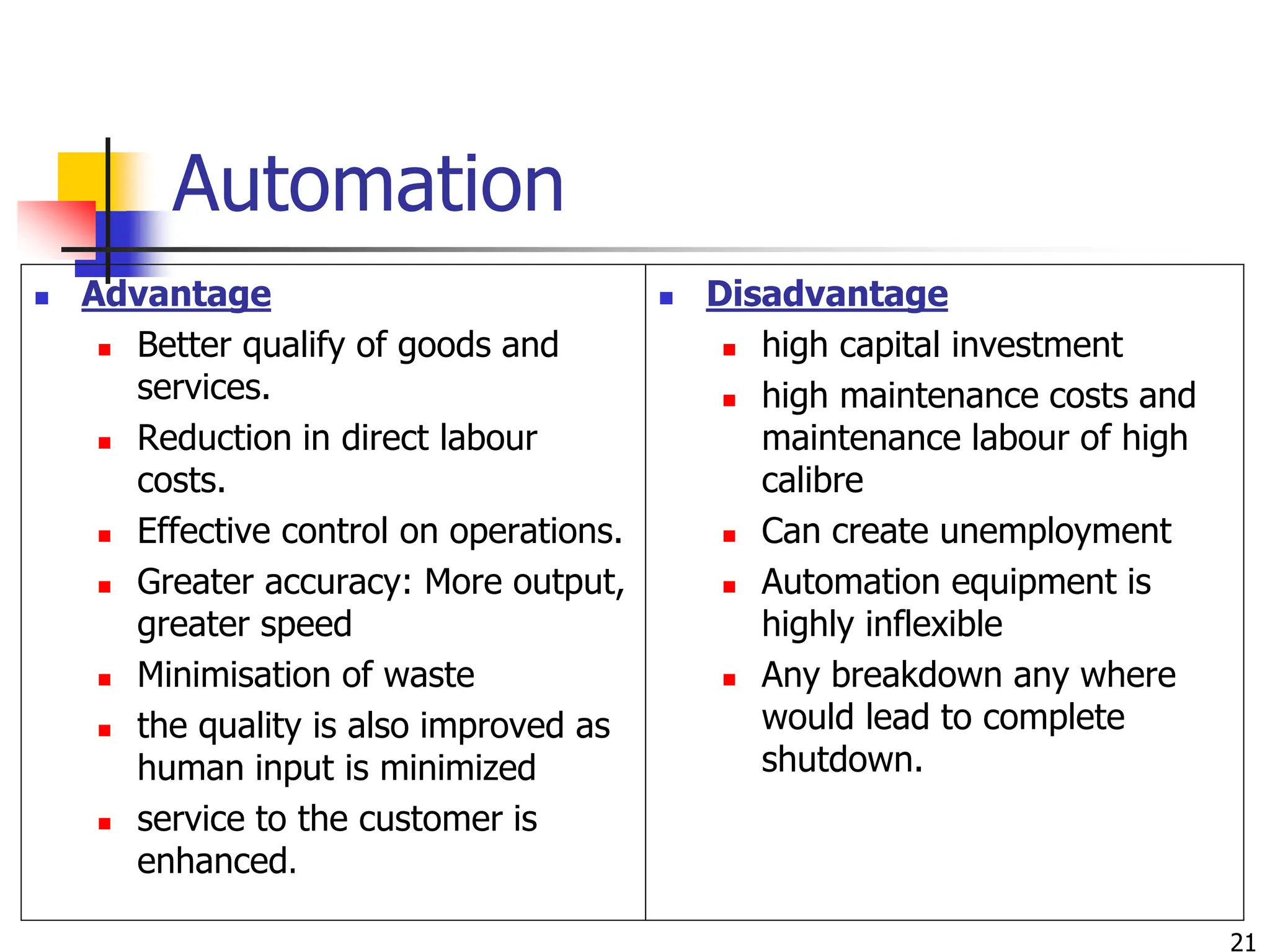

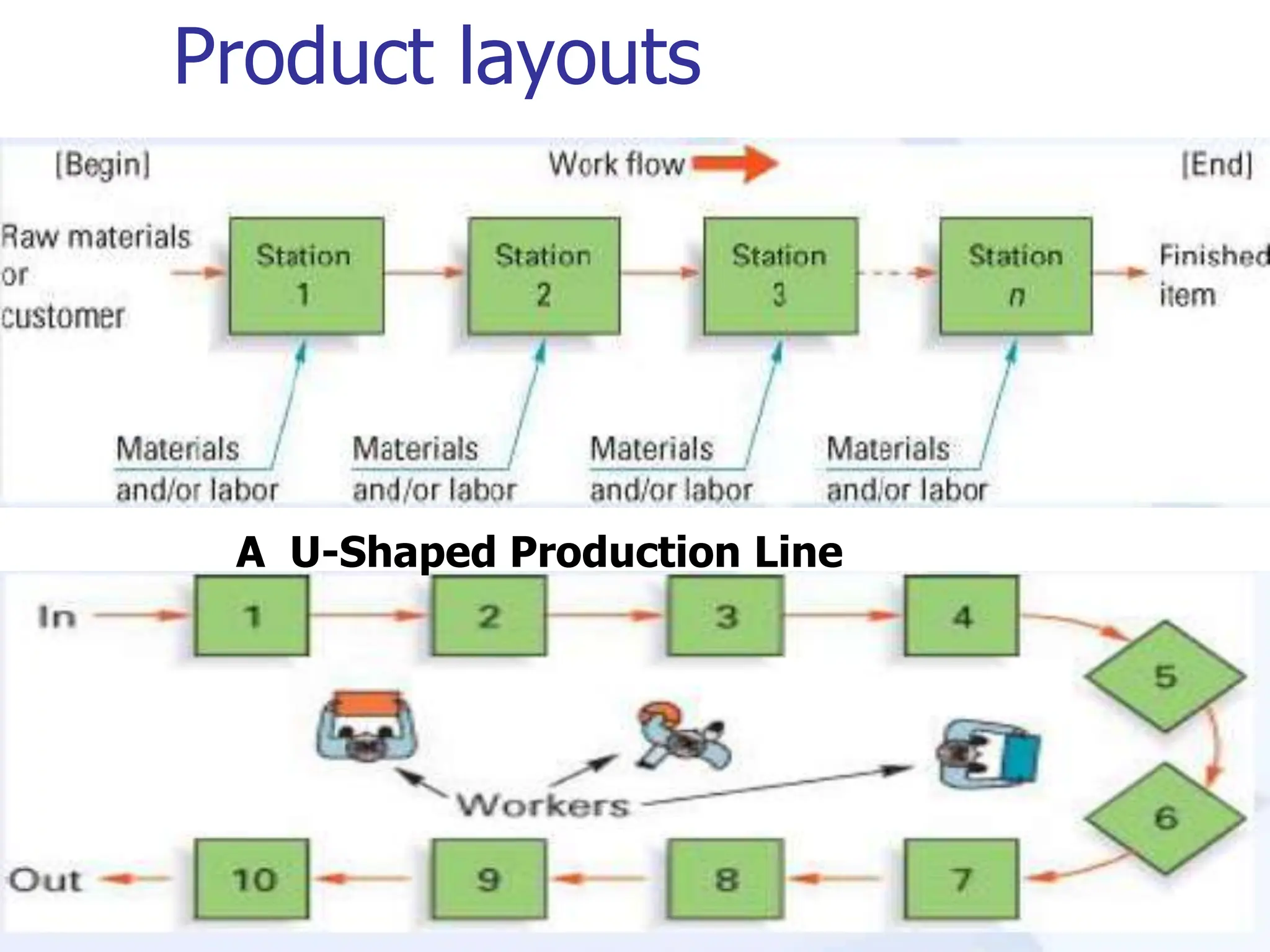

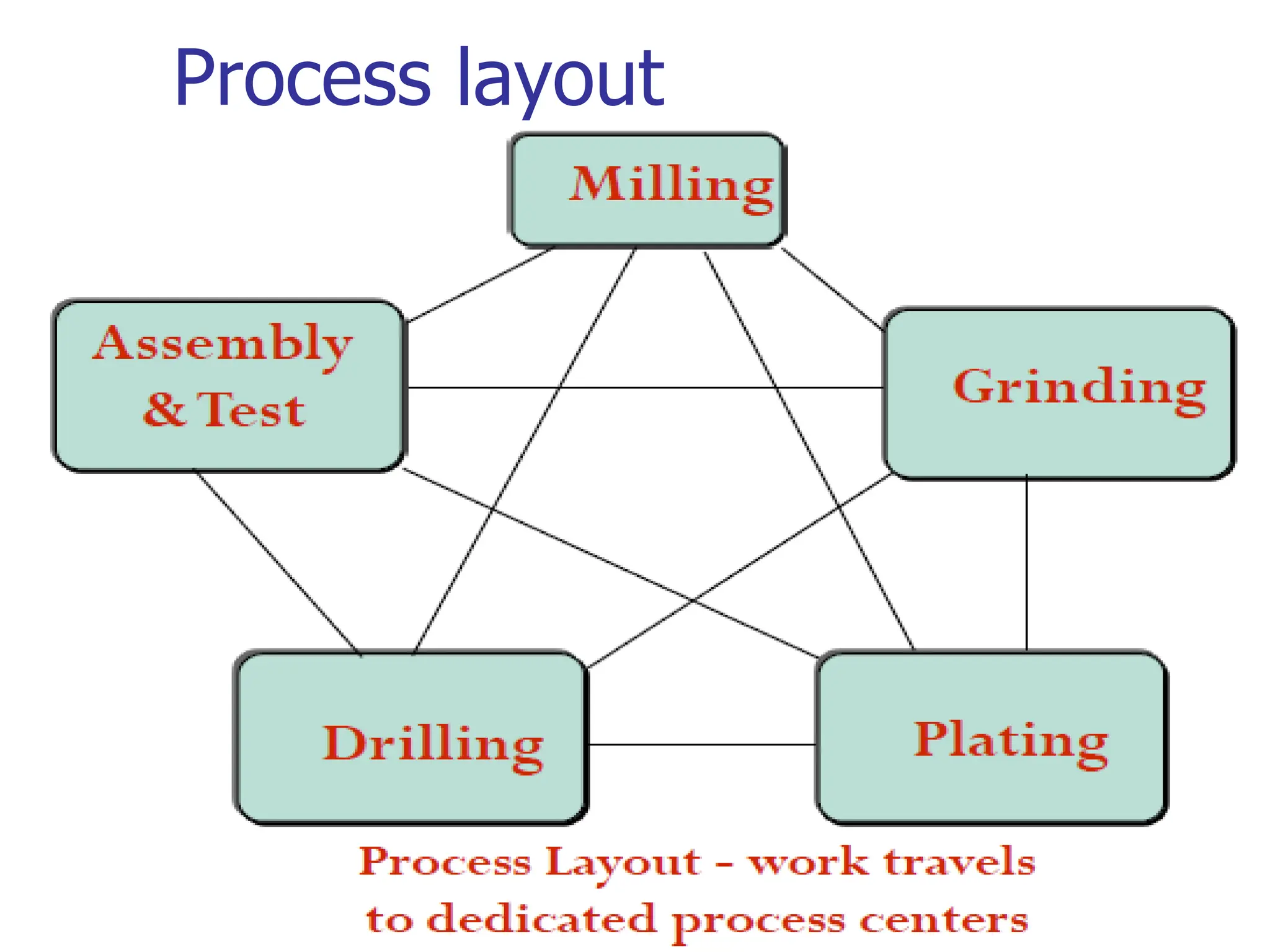

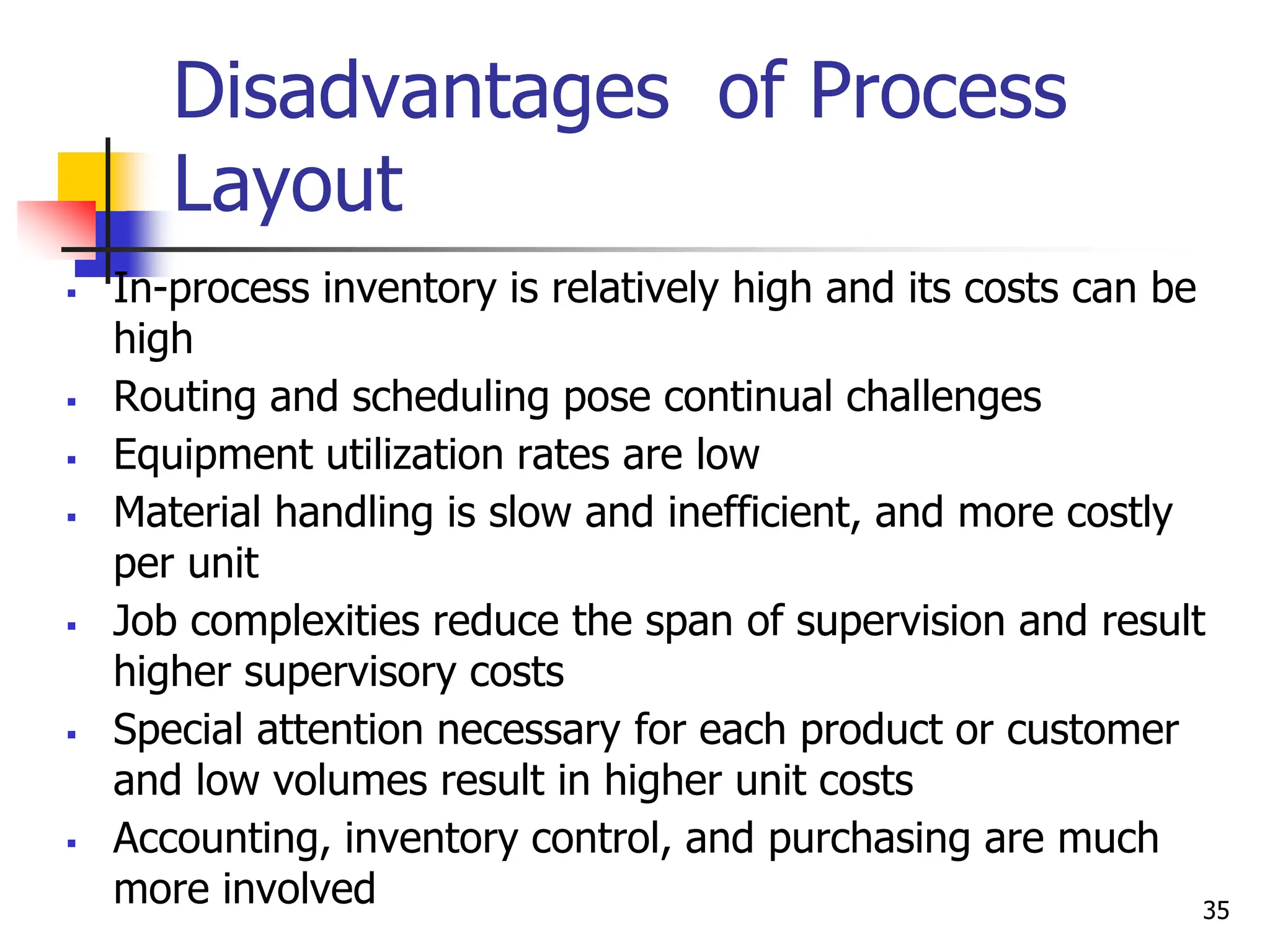

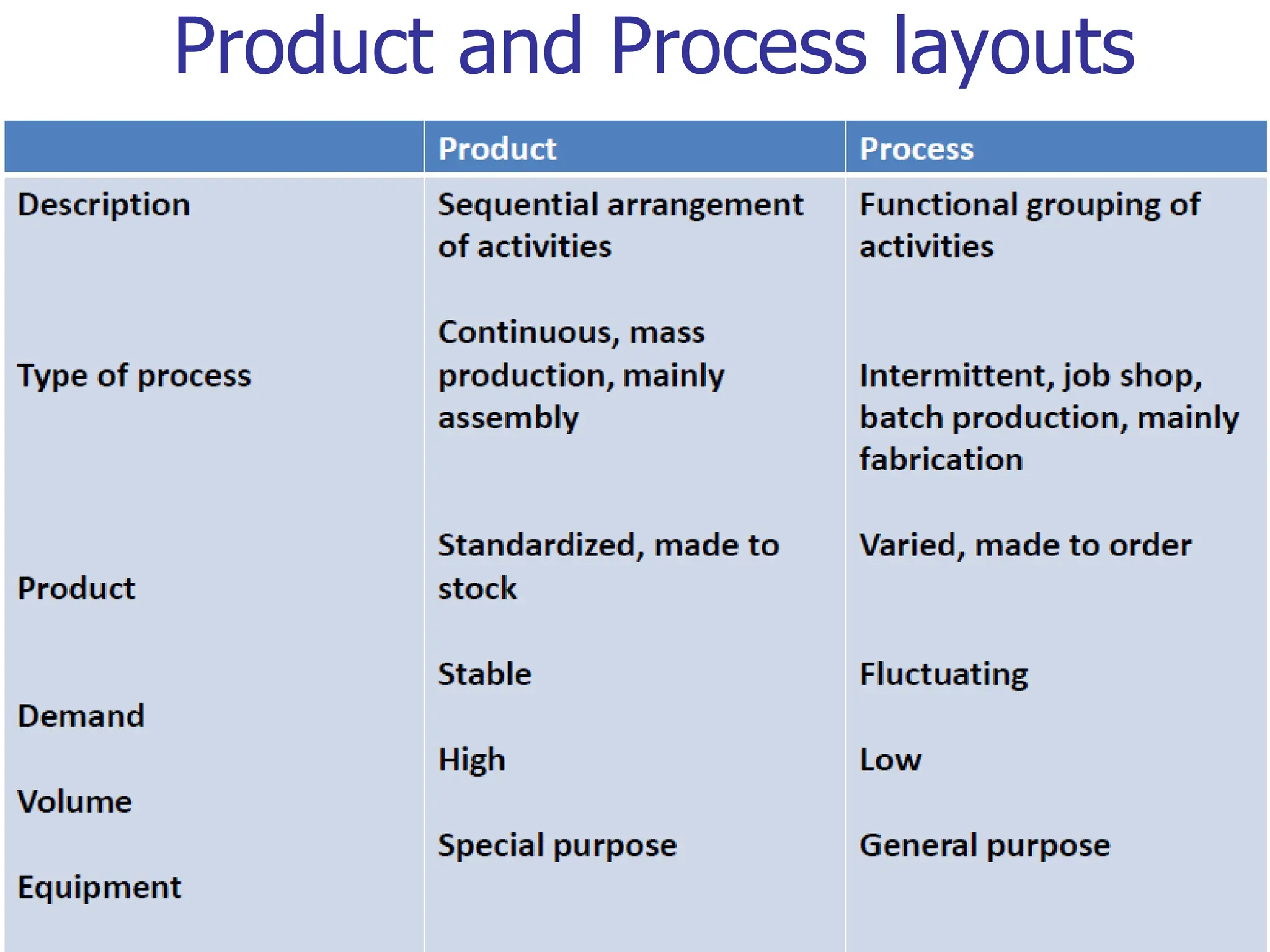

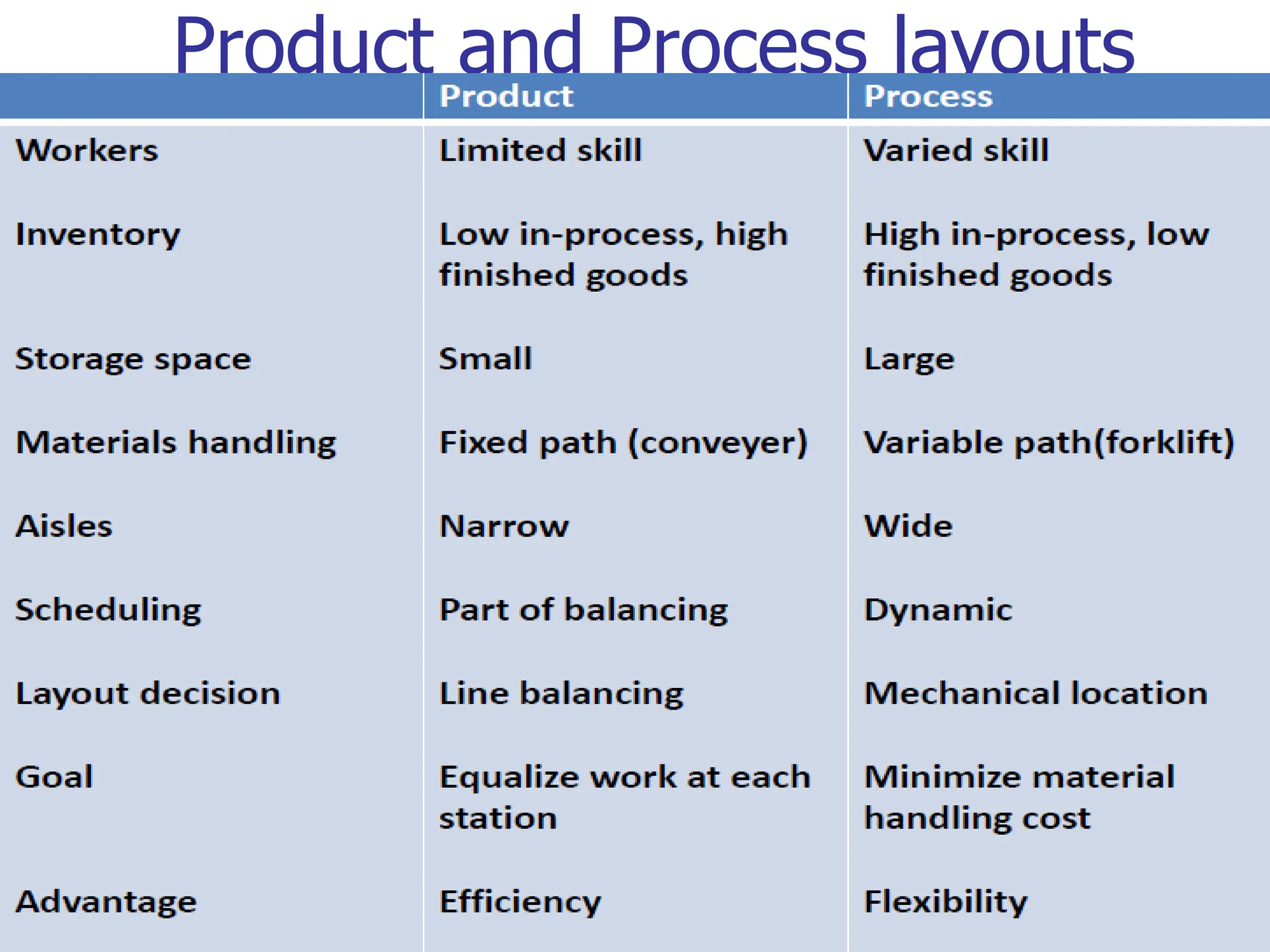

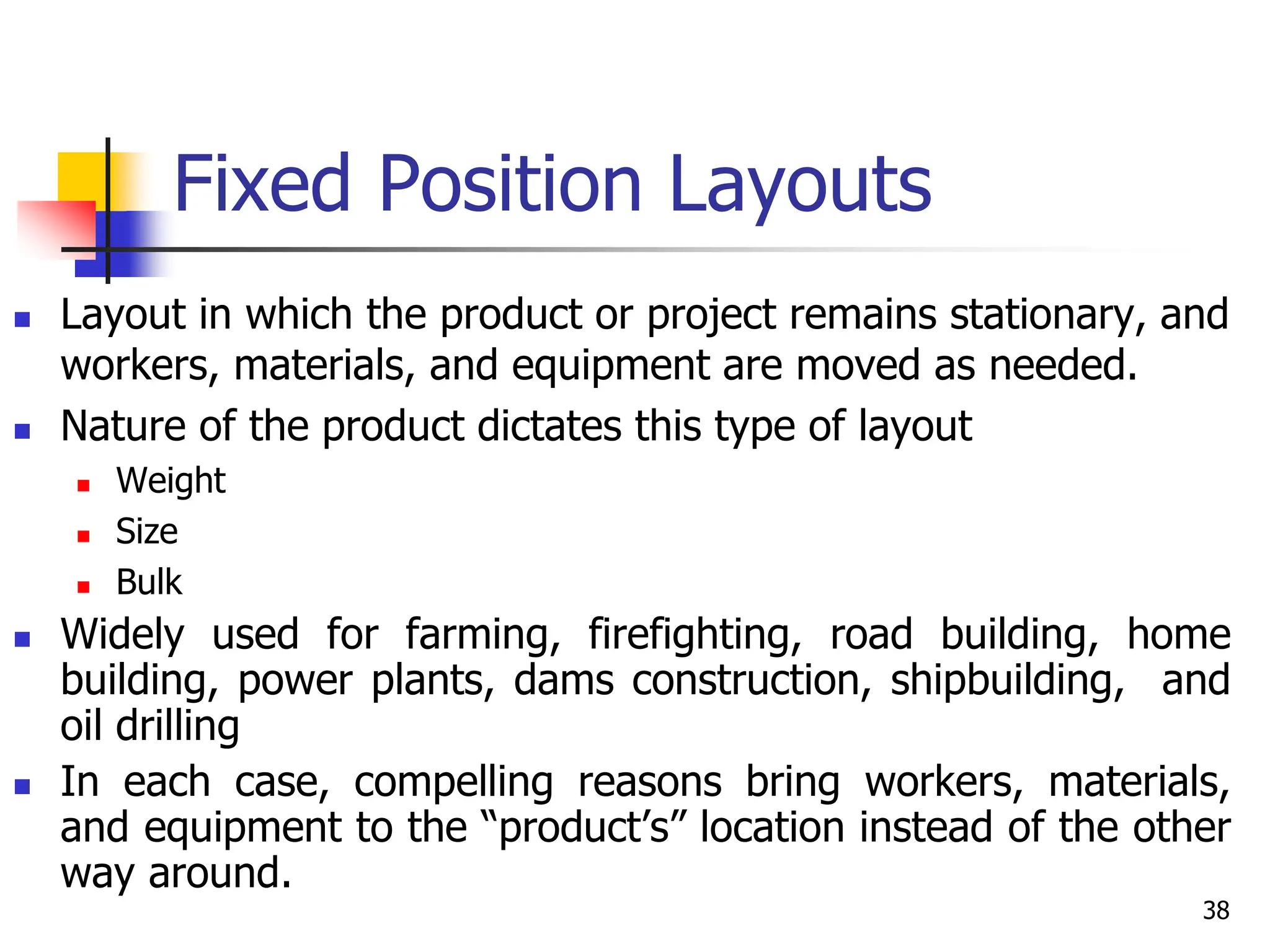

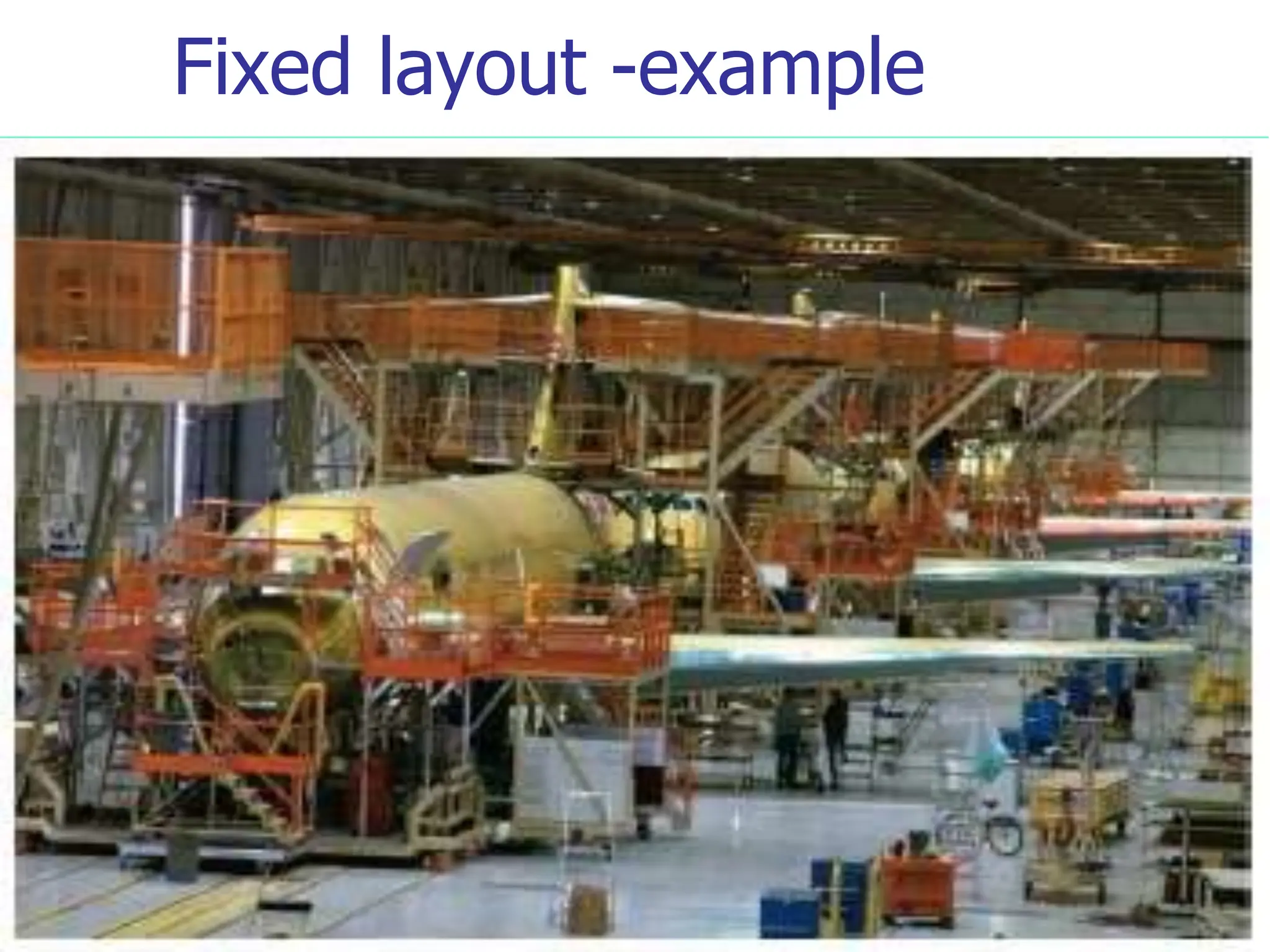

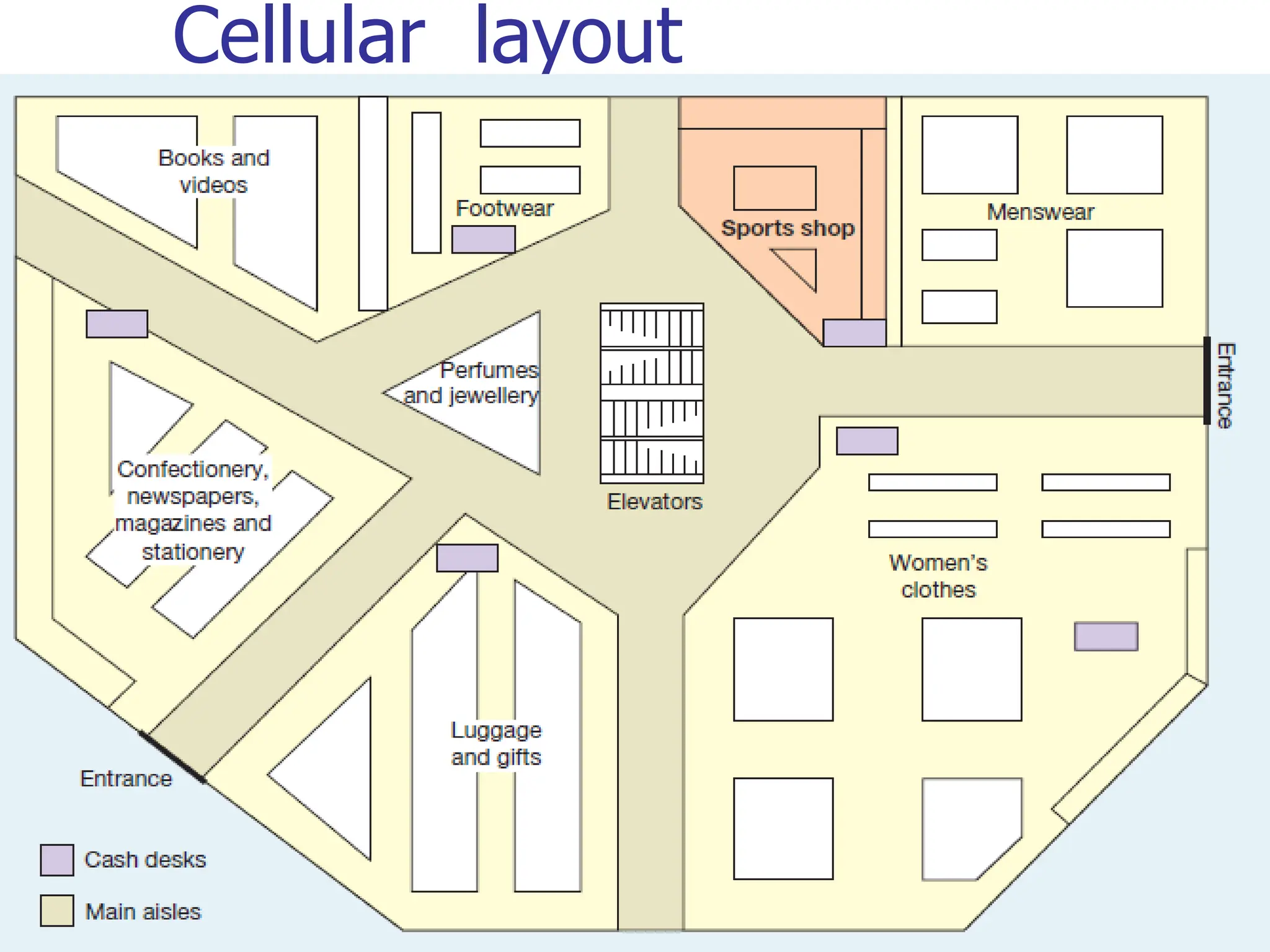

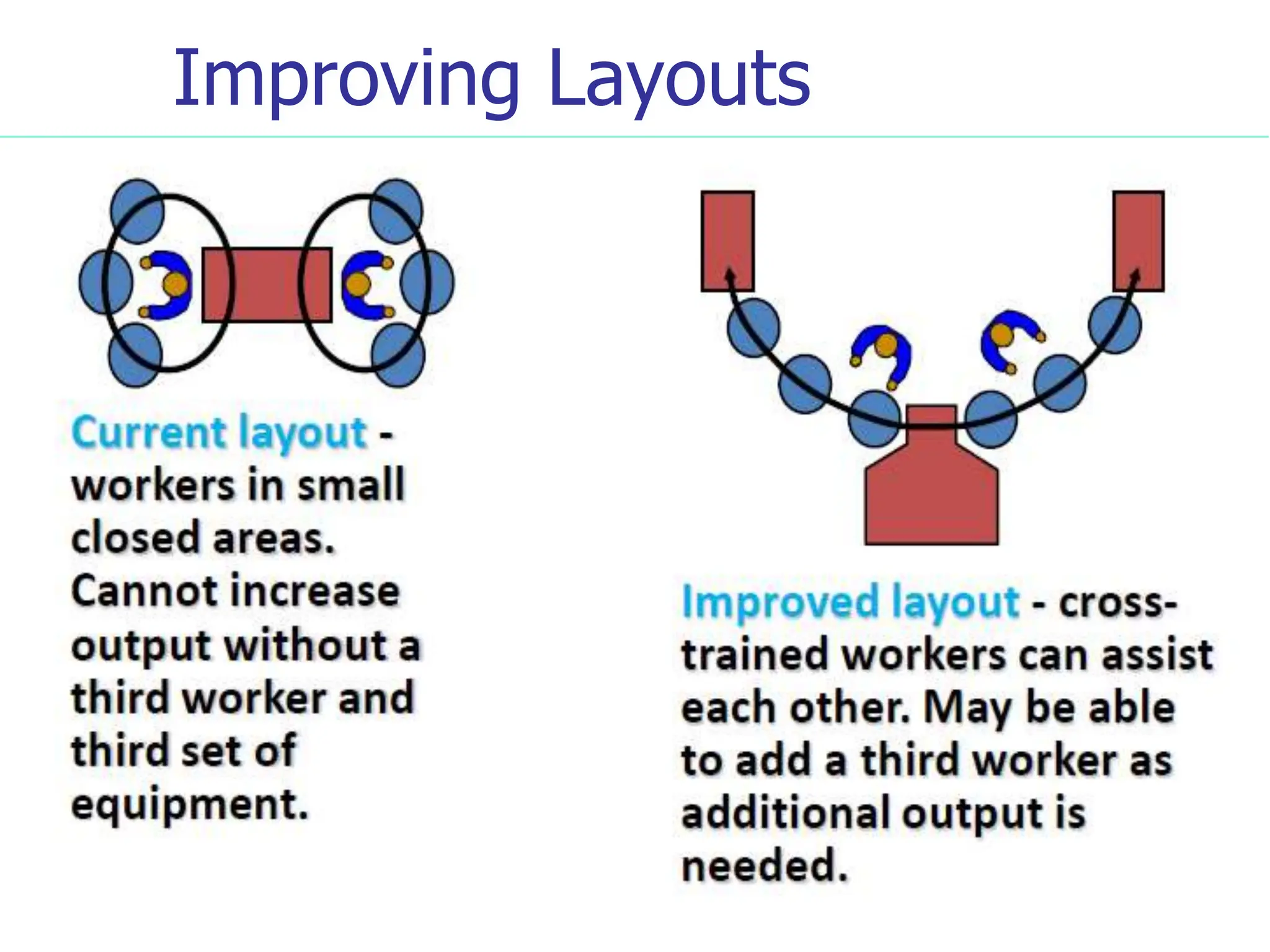

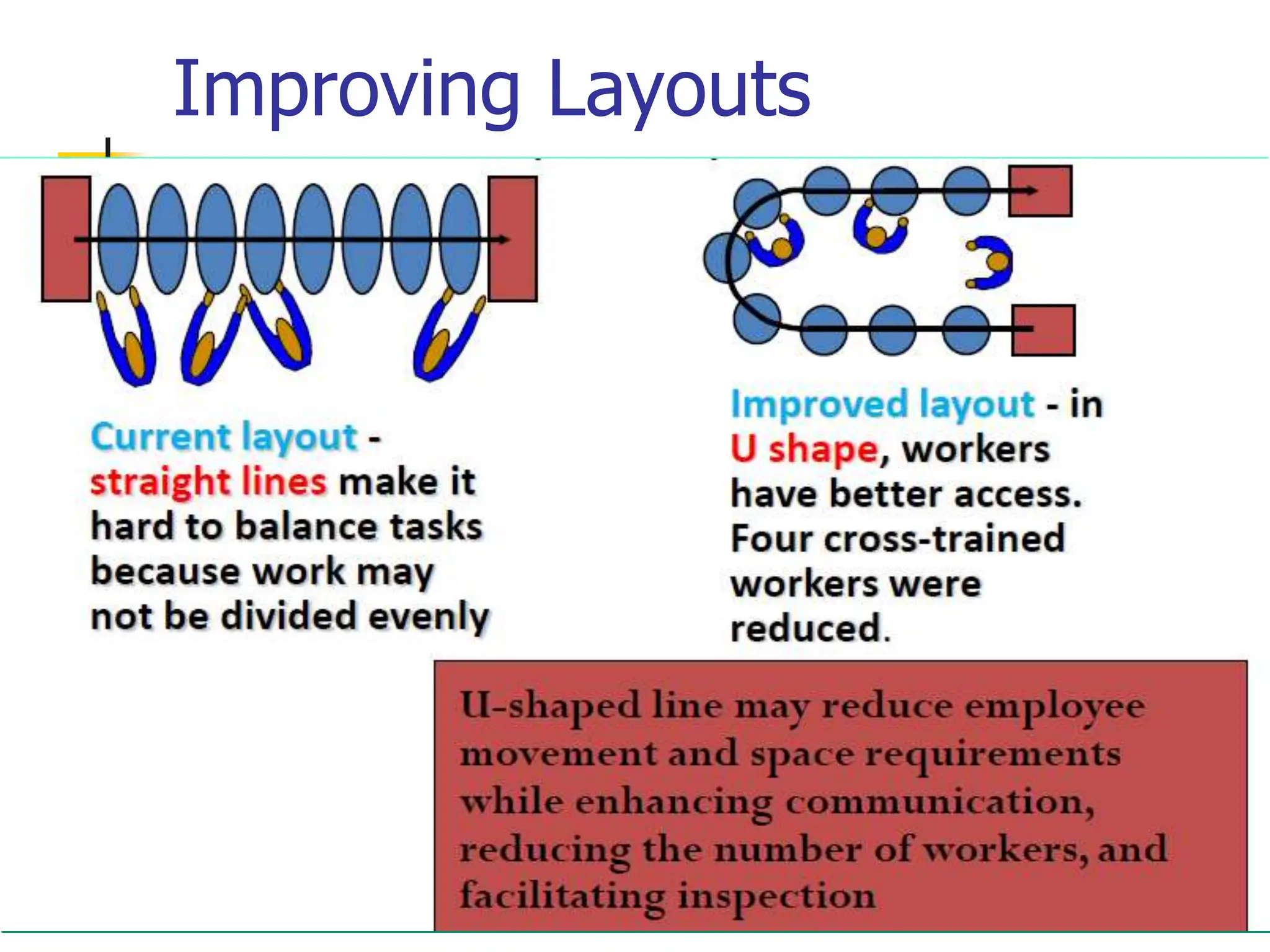

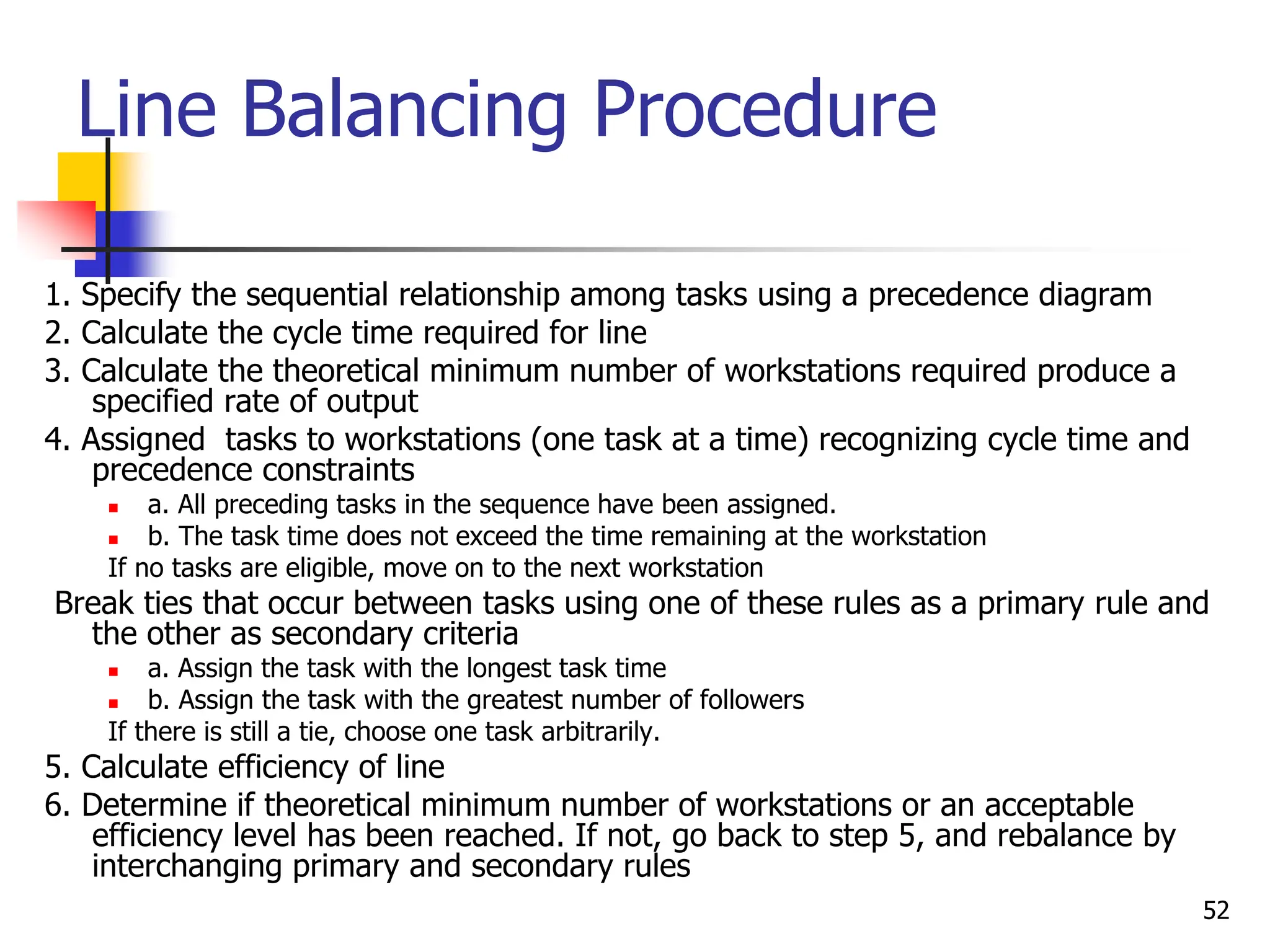

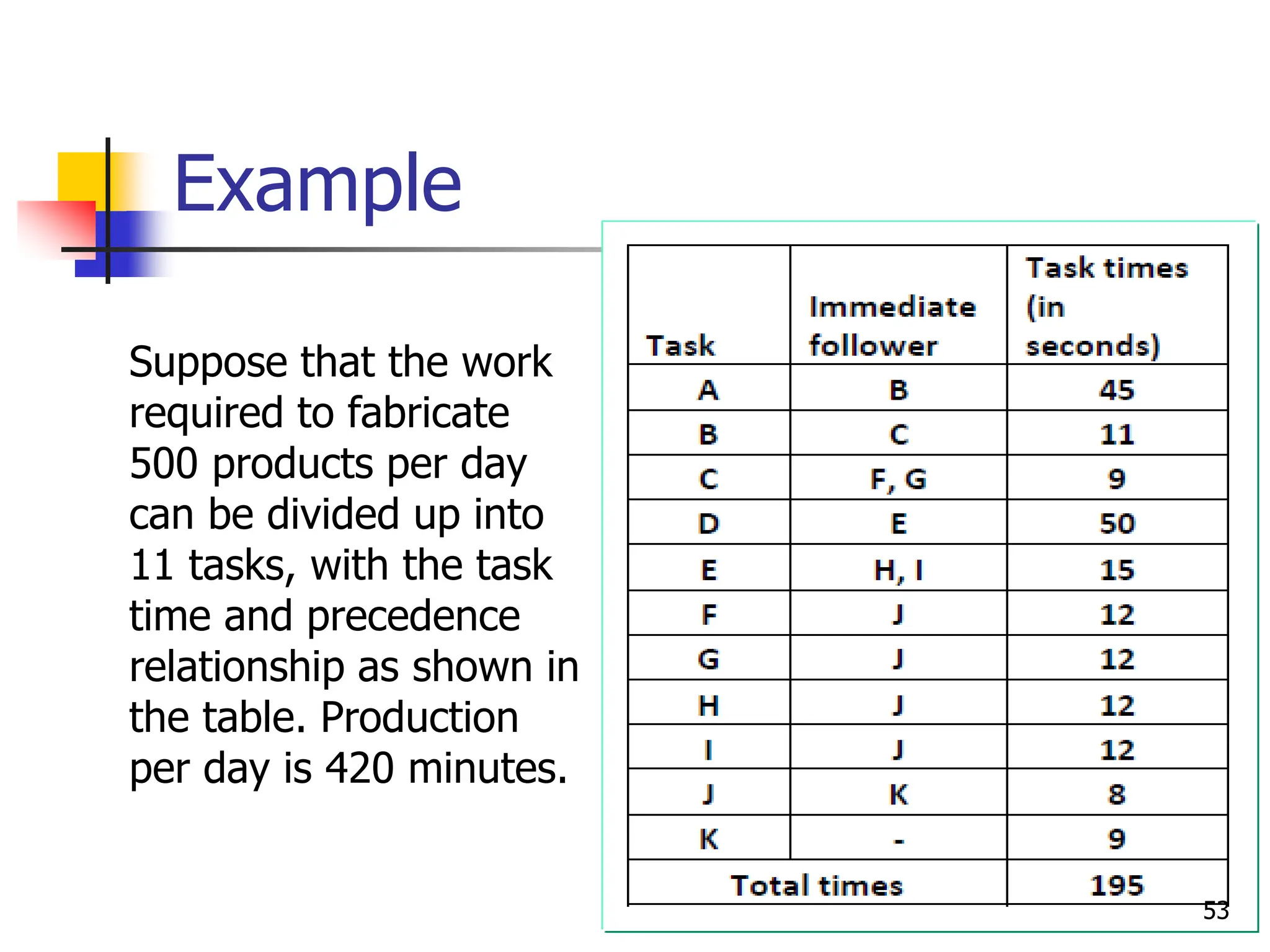

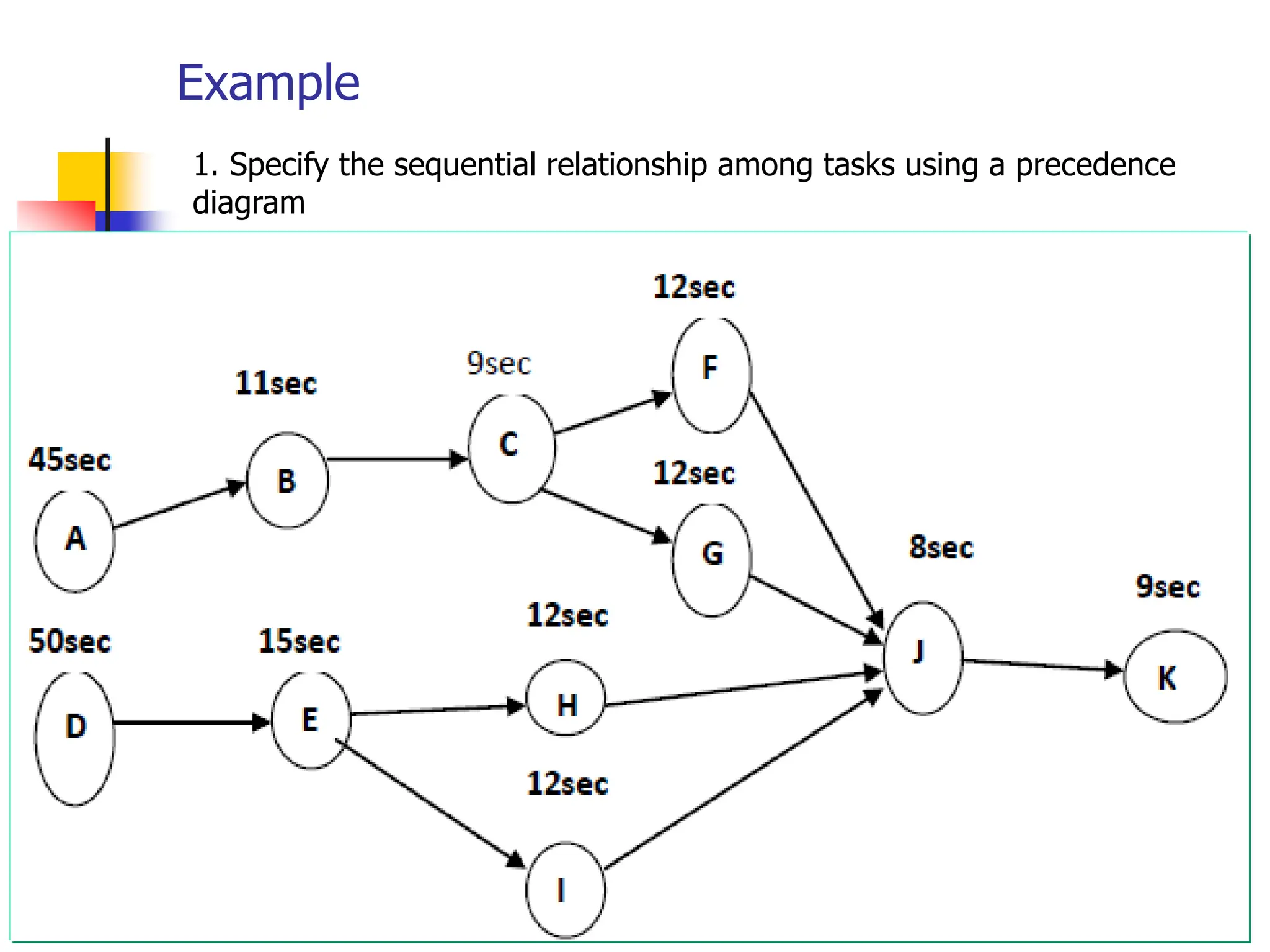

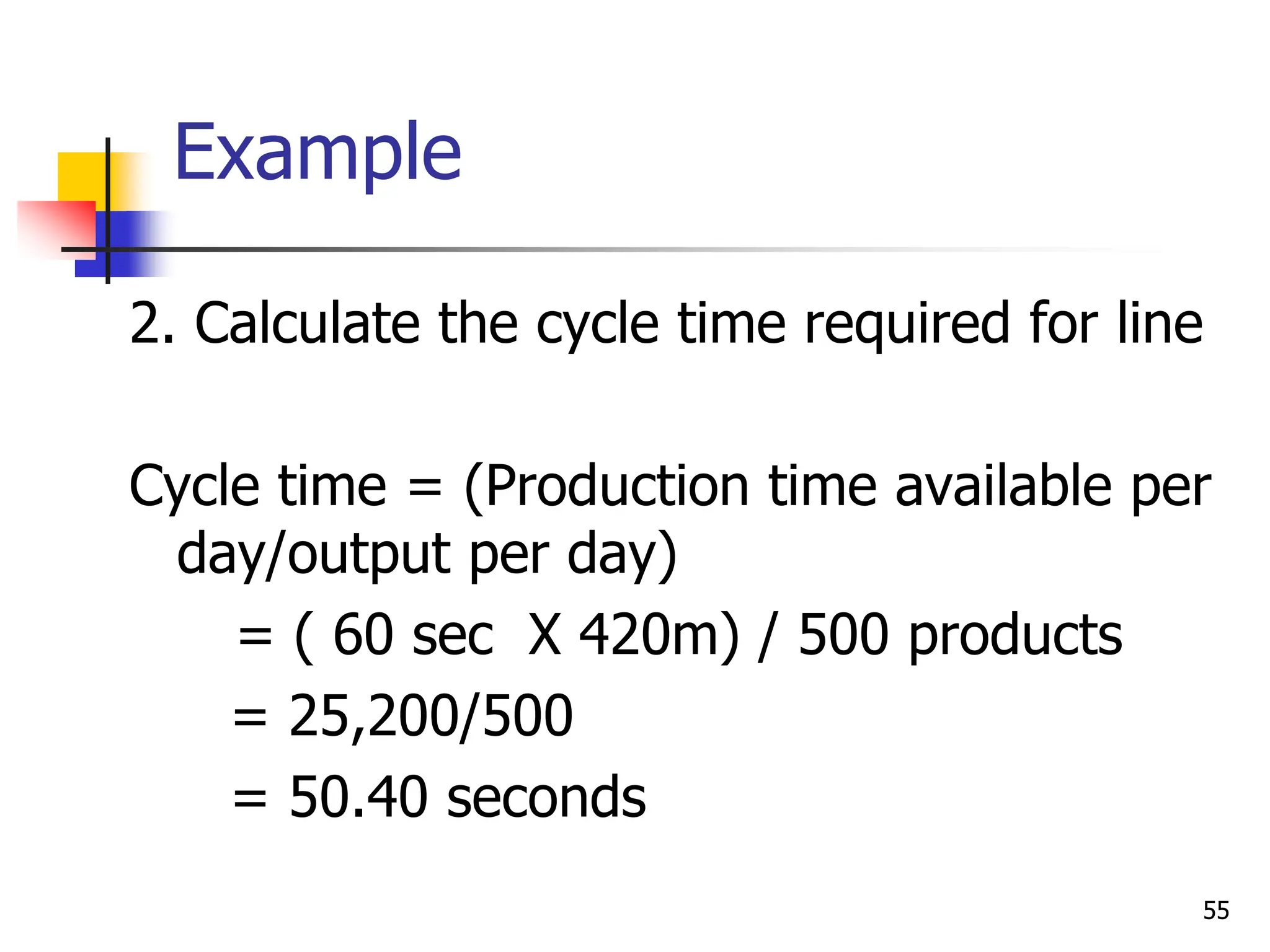

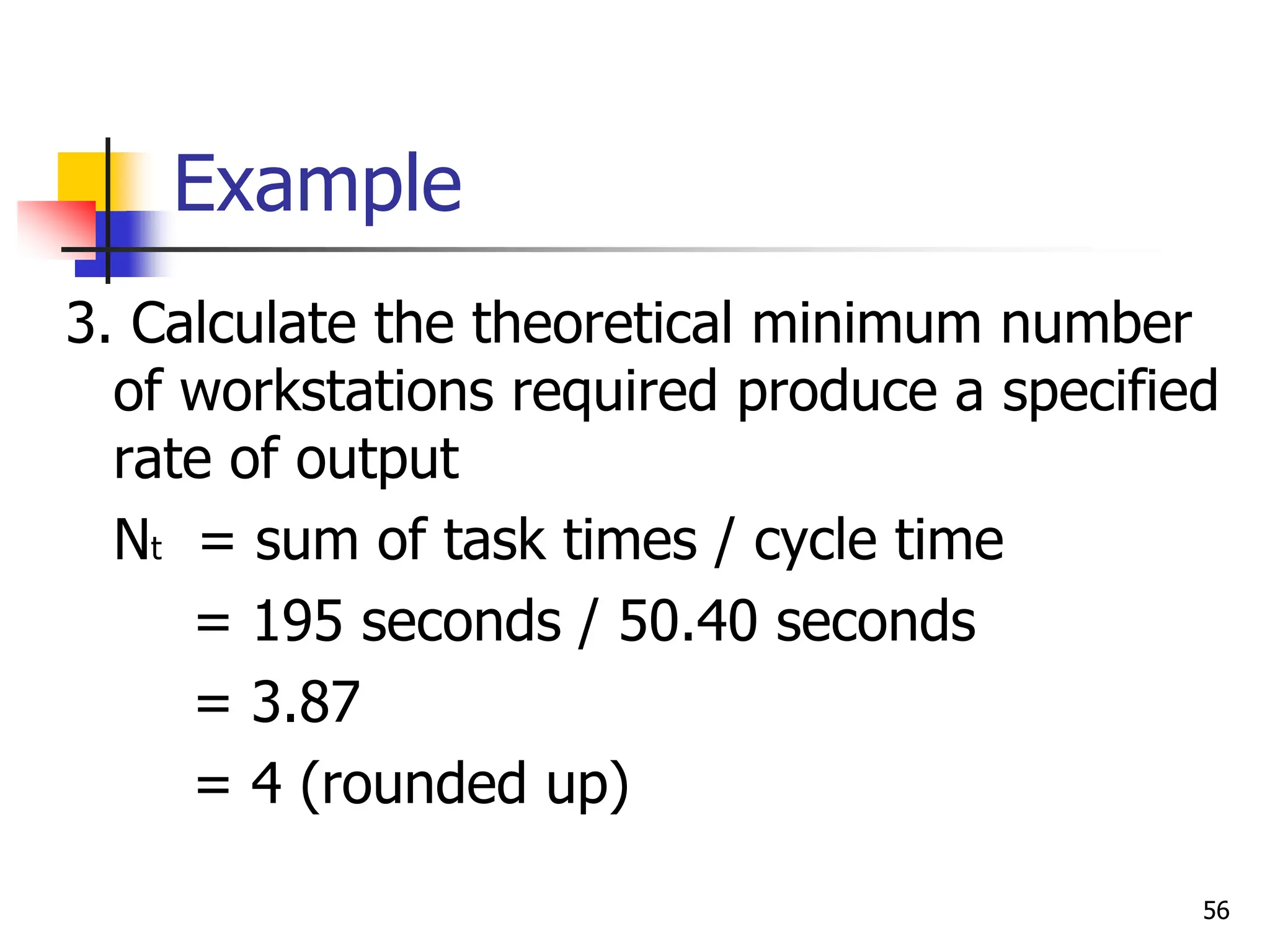

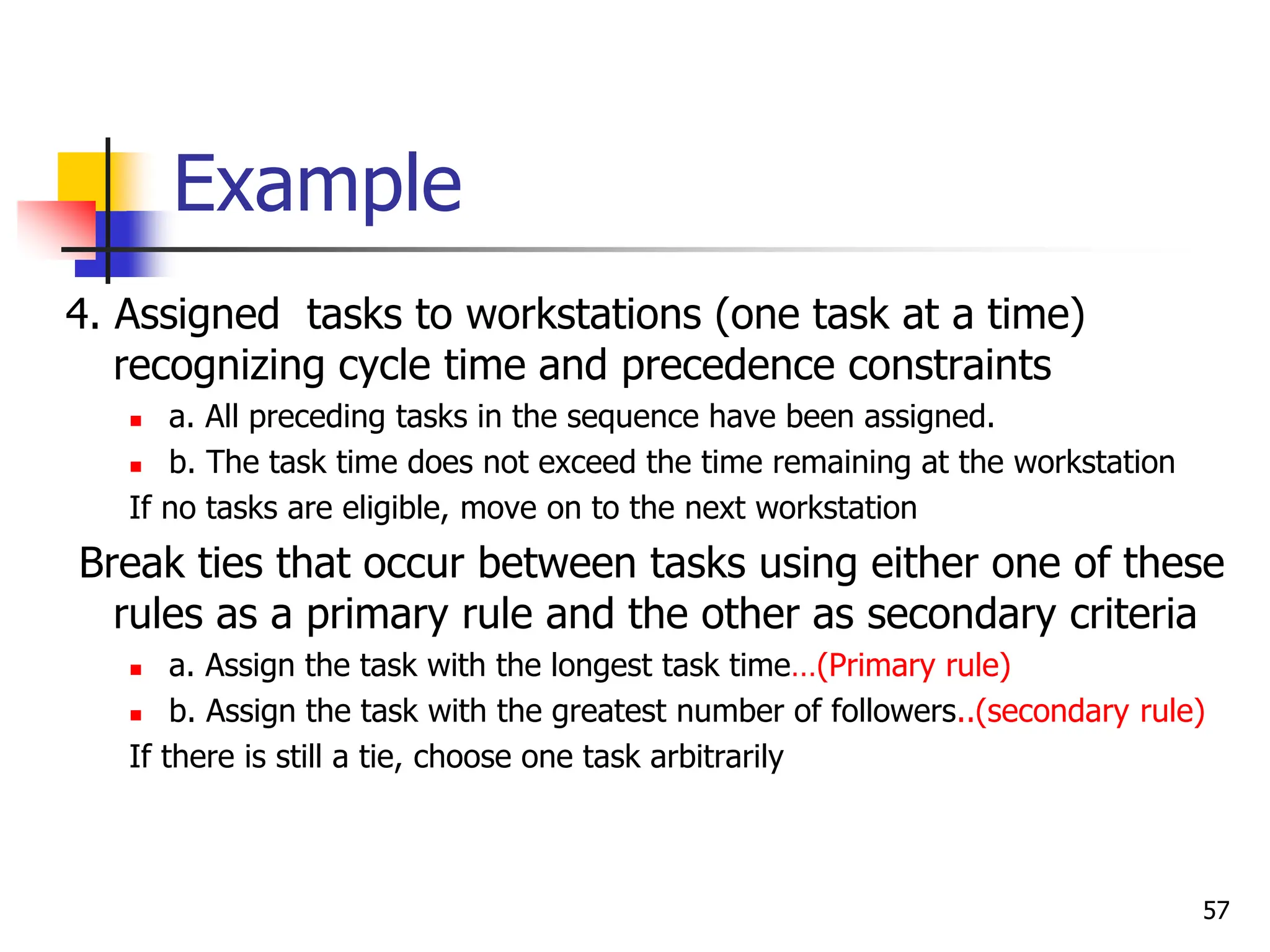

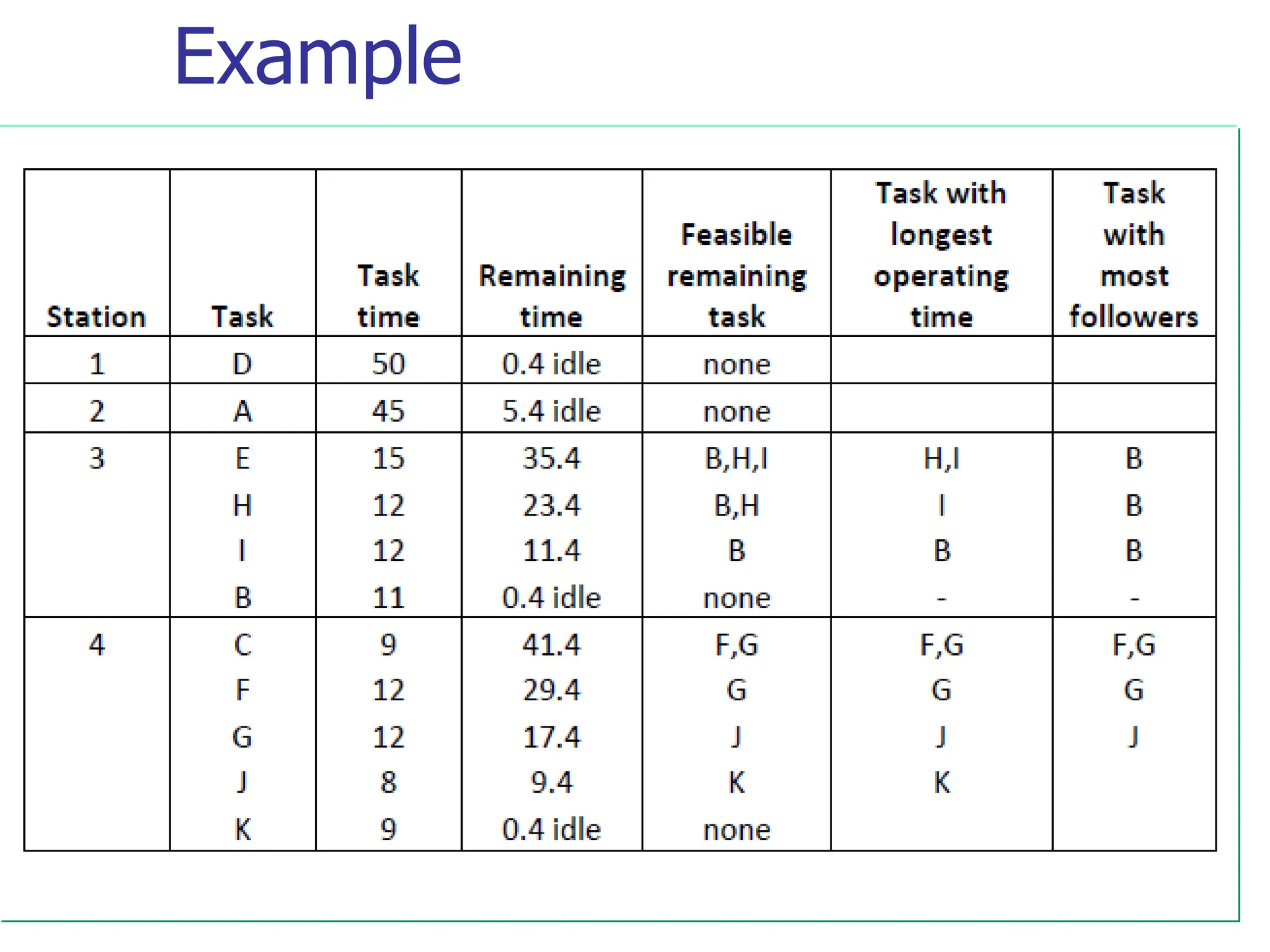

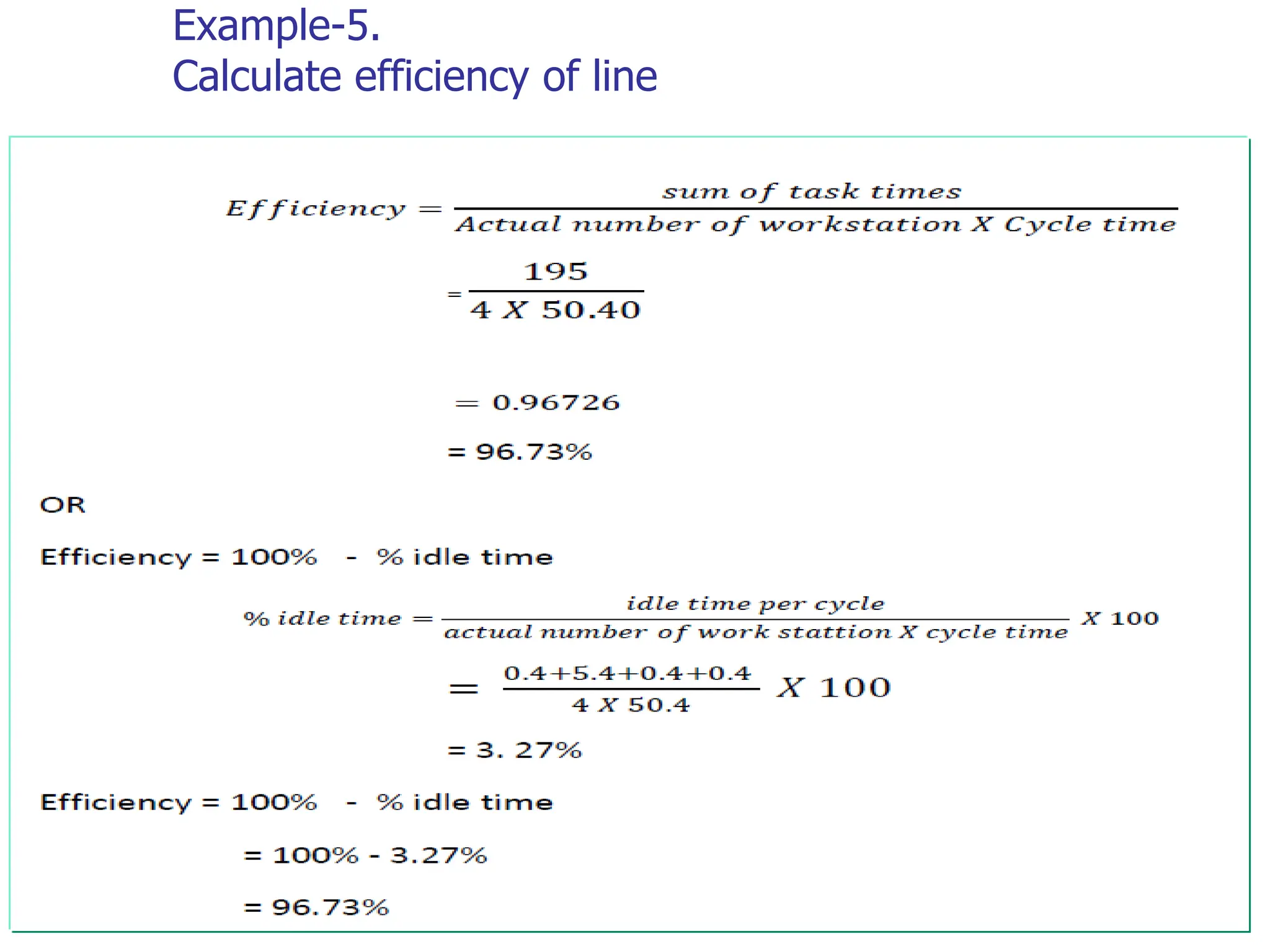

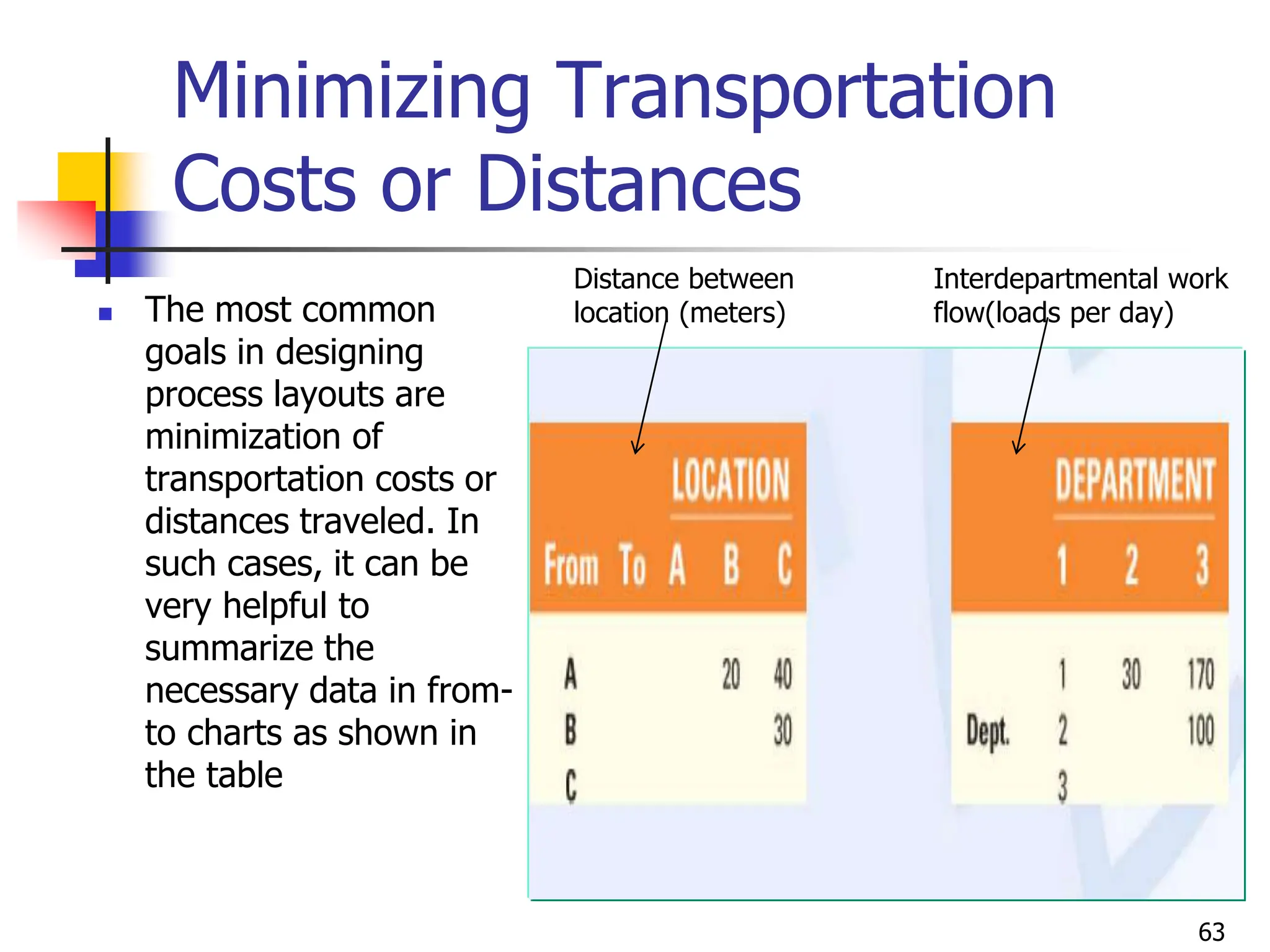

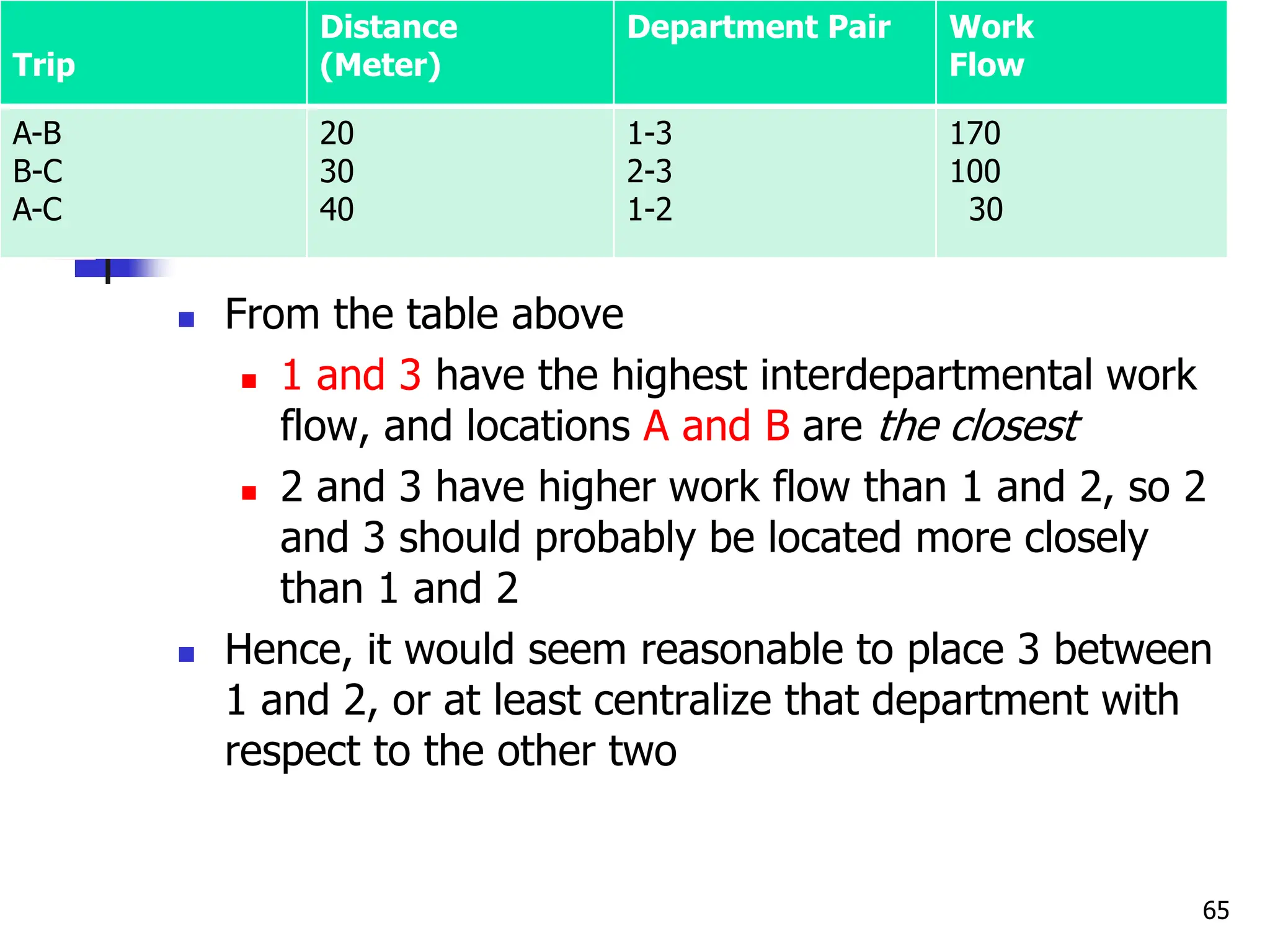

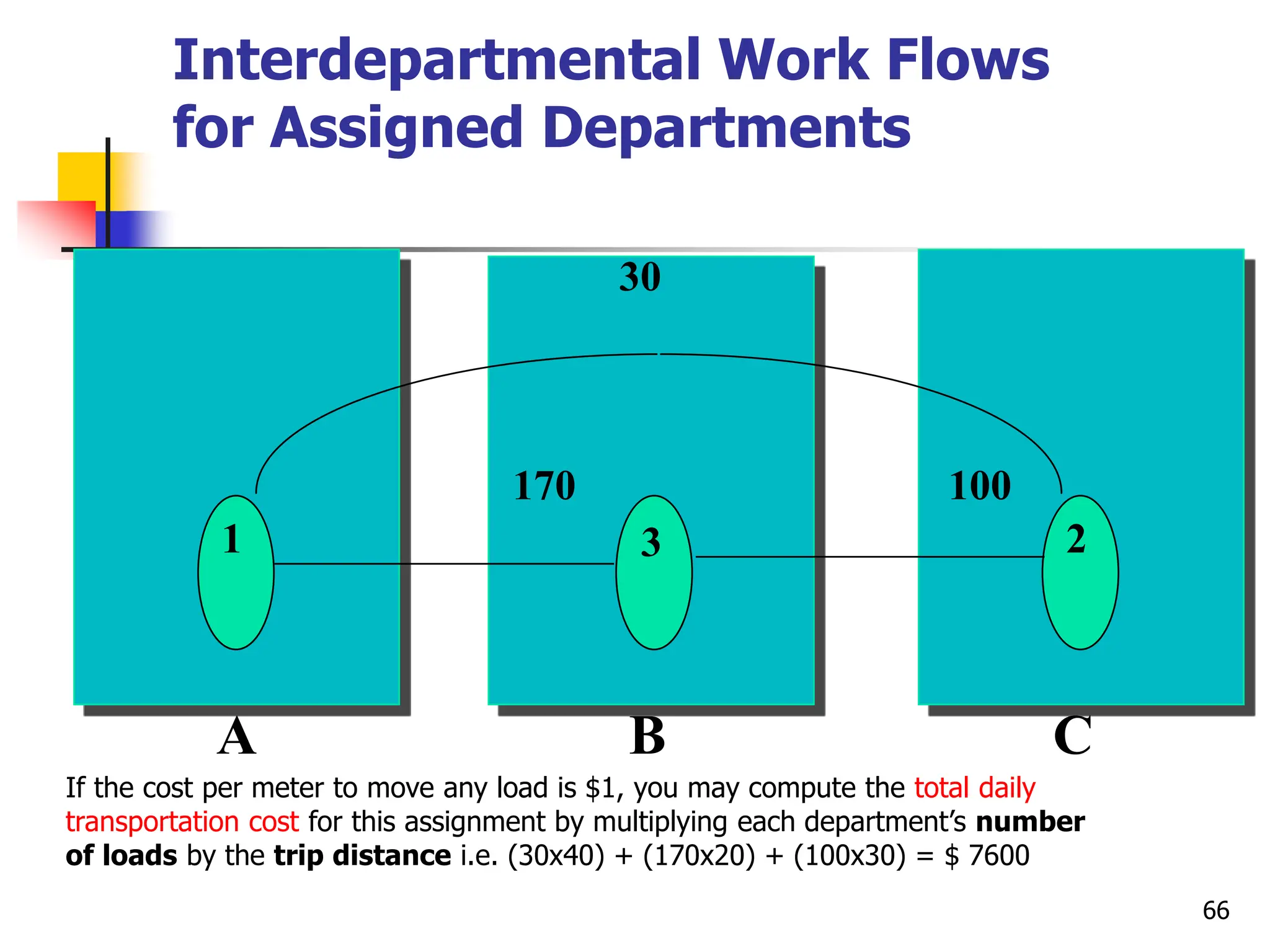

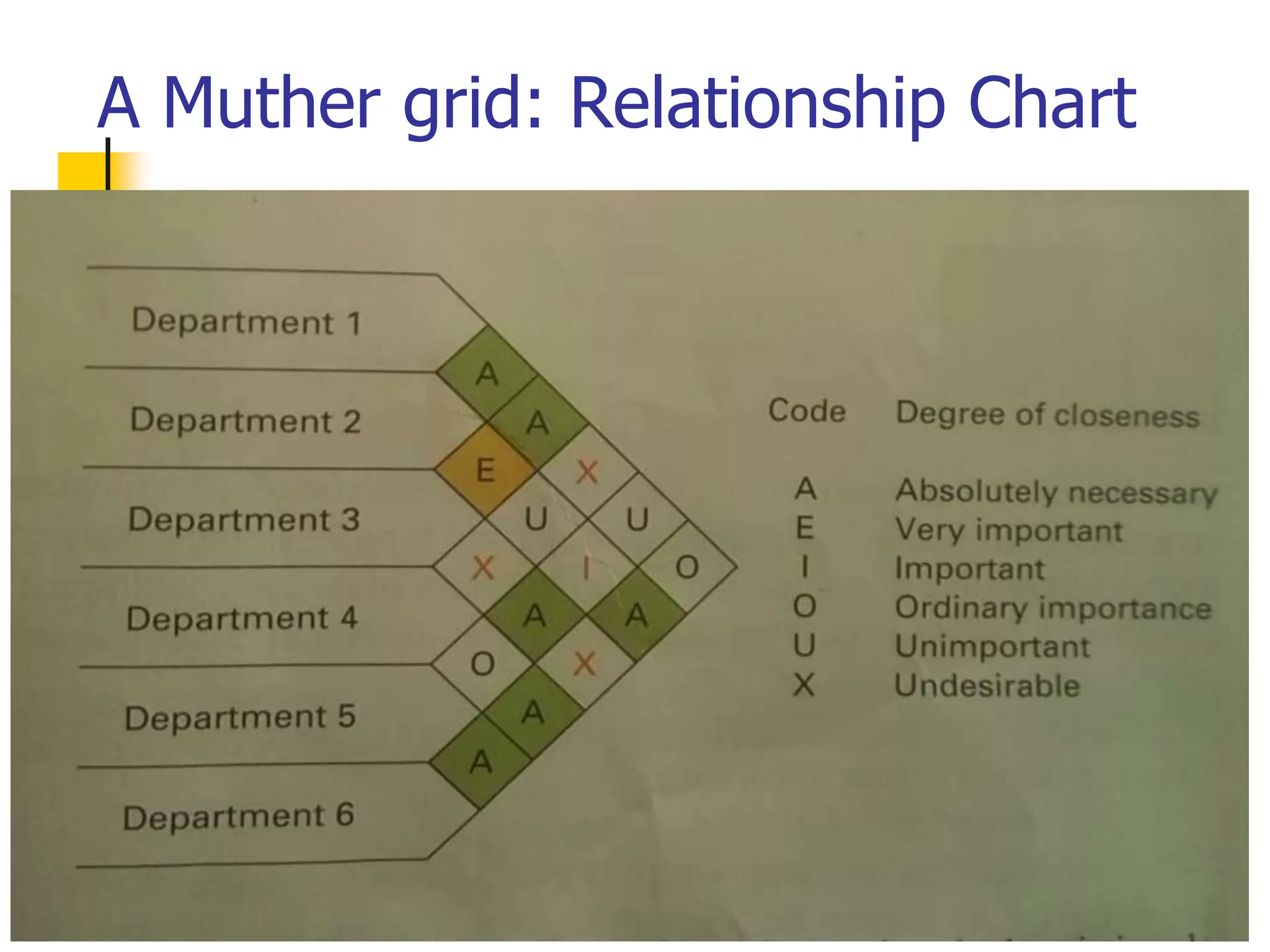

The document outlines key concepts related to process selection and facility layout, emphasizing the importance of choosing appropriate production processes based on factors such as variety, flexibility, and volume. It details various process types including project, job shop, batch, repetitive/assembly, and continuous, as well as describes different facility layouts like product, process, fixed-position, and hybrid. The text further discusses the impact of automation and technology on production efficiency and highlights the necessity of effective layout design to optimize workflow and minimize costs.