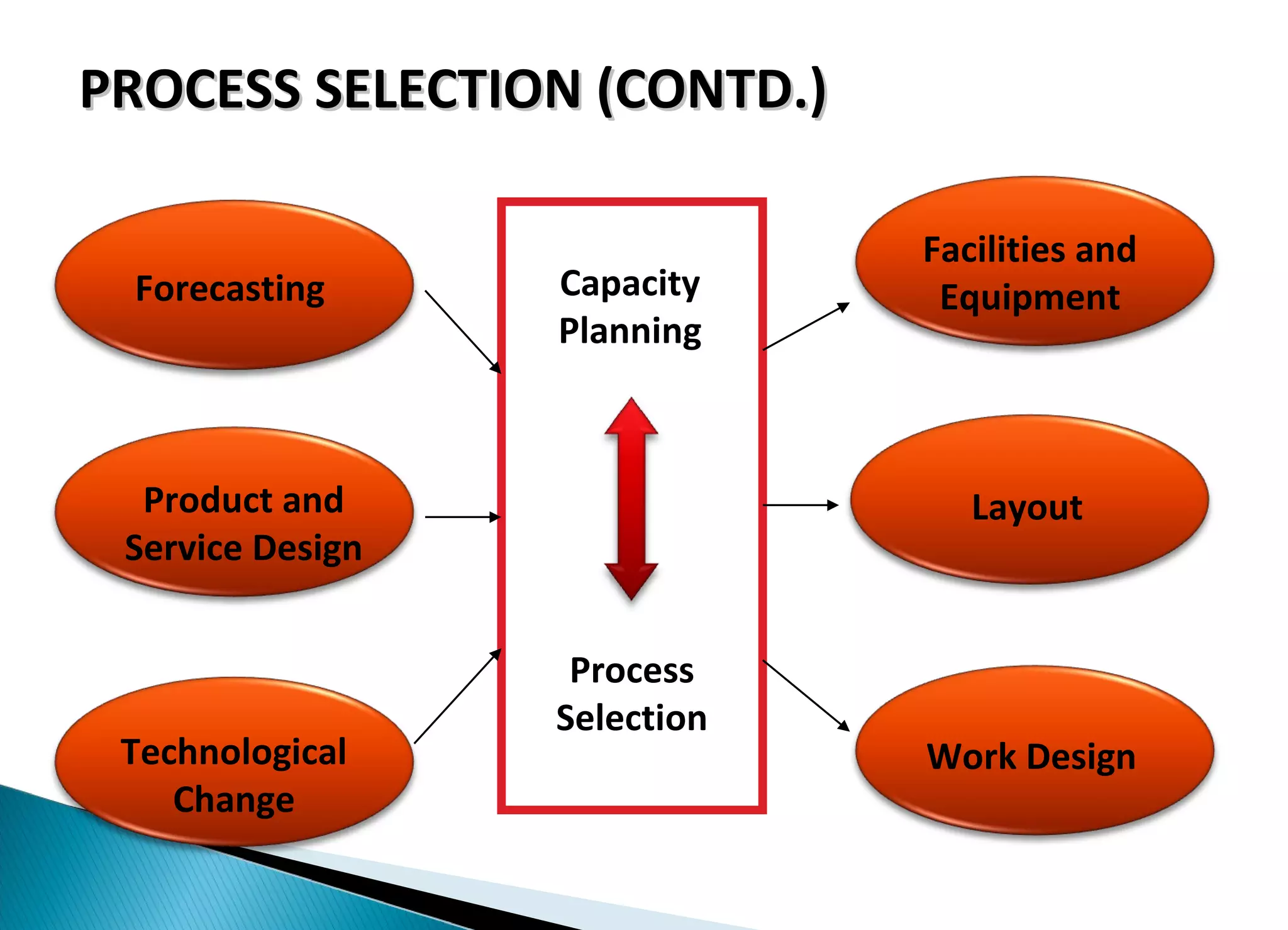

The document discusses process selection and facility layout. It describes different types of processes - job shop, batch, repetitive, continuous flow, and project - and factors like volume, variety, and flexibility that determine which type is suitable. It also covers automation levels from fixed to programmable to flexible. Facility layout depends on the process and aims to optimize efficiency, flow, and safety. Product and process layouts are introduced.