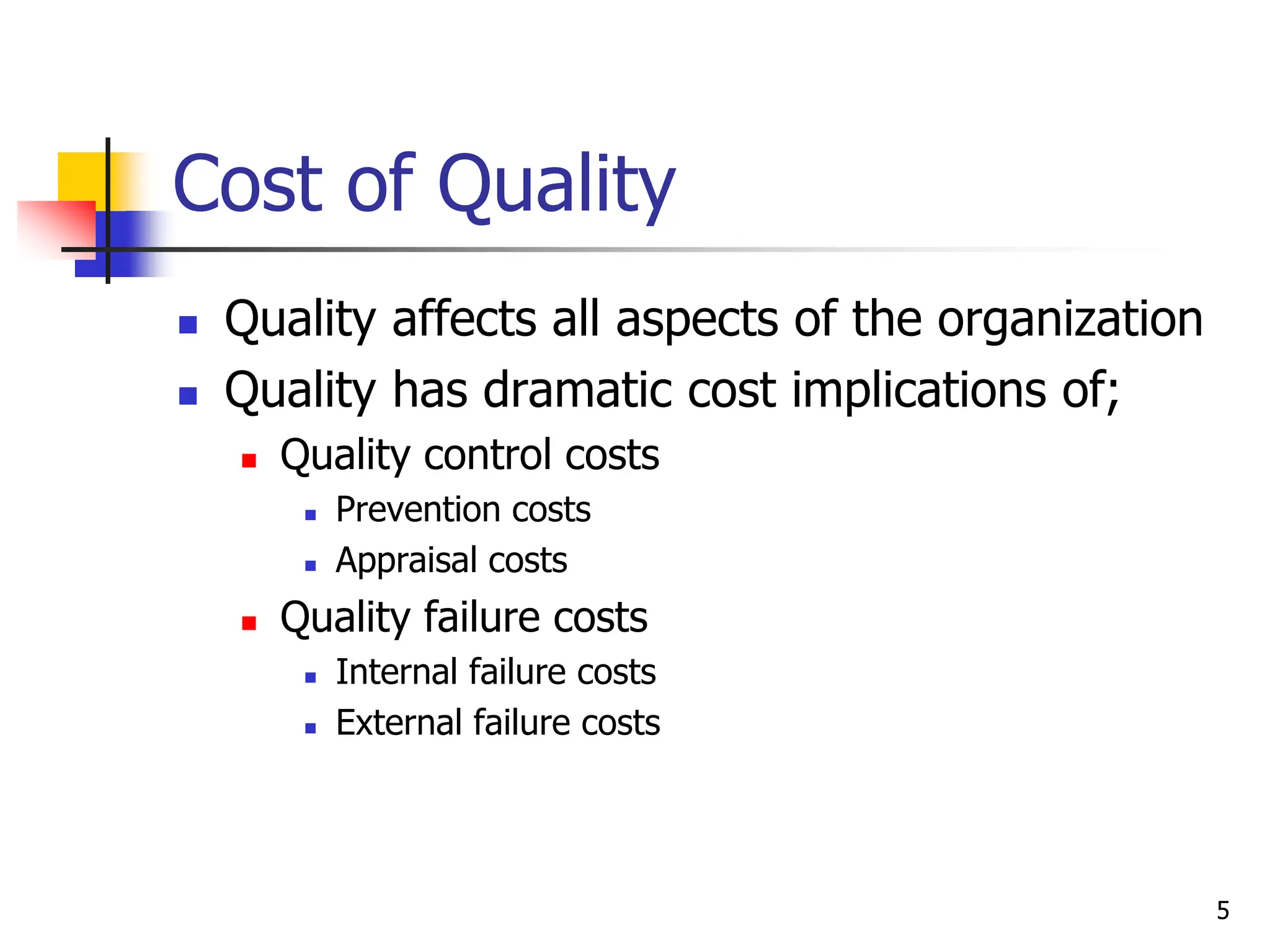

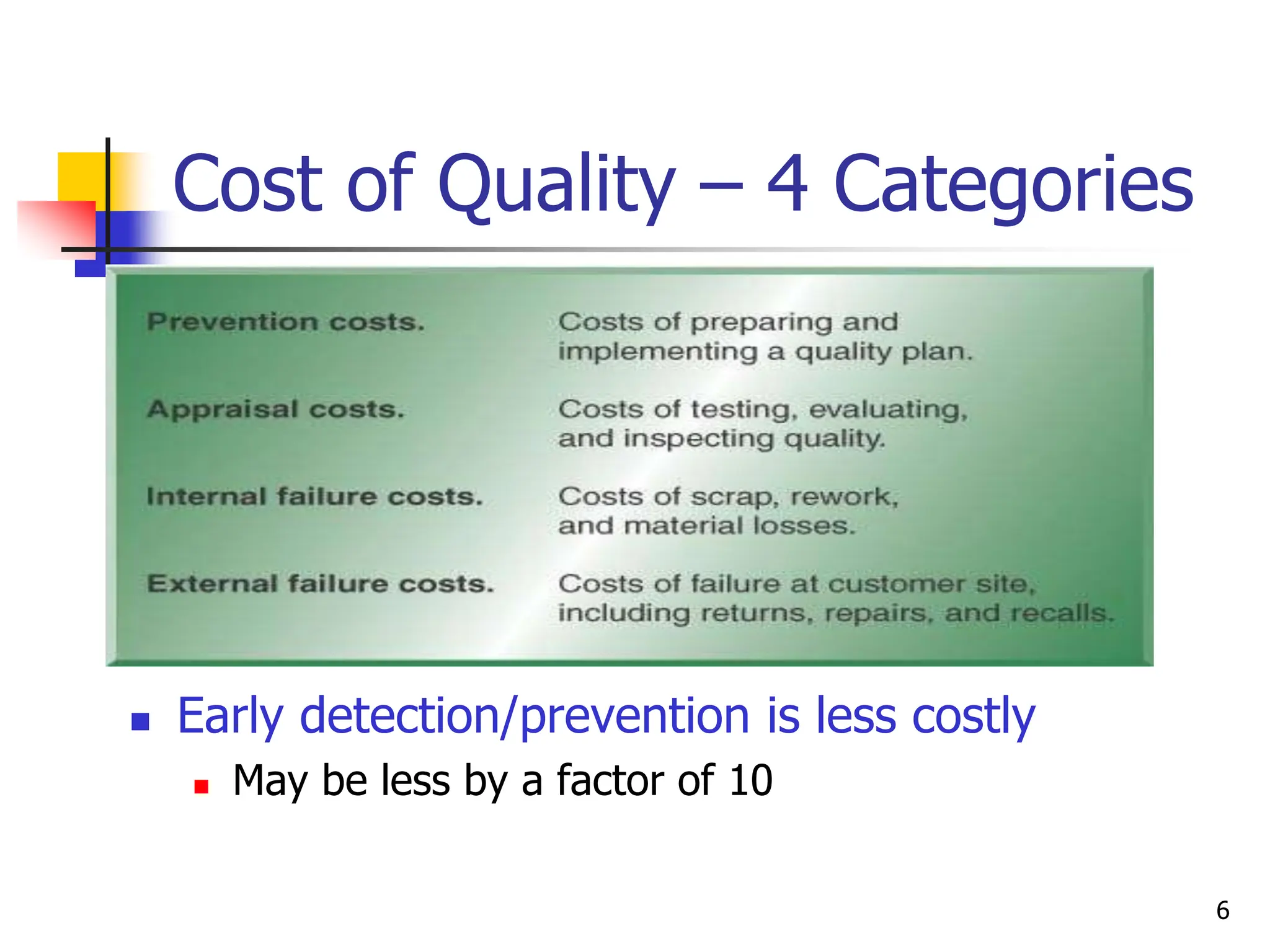

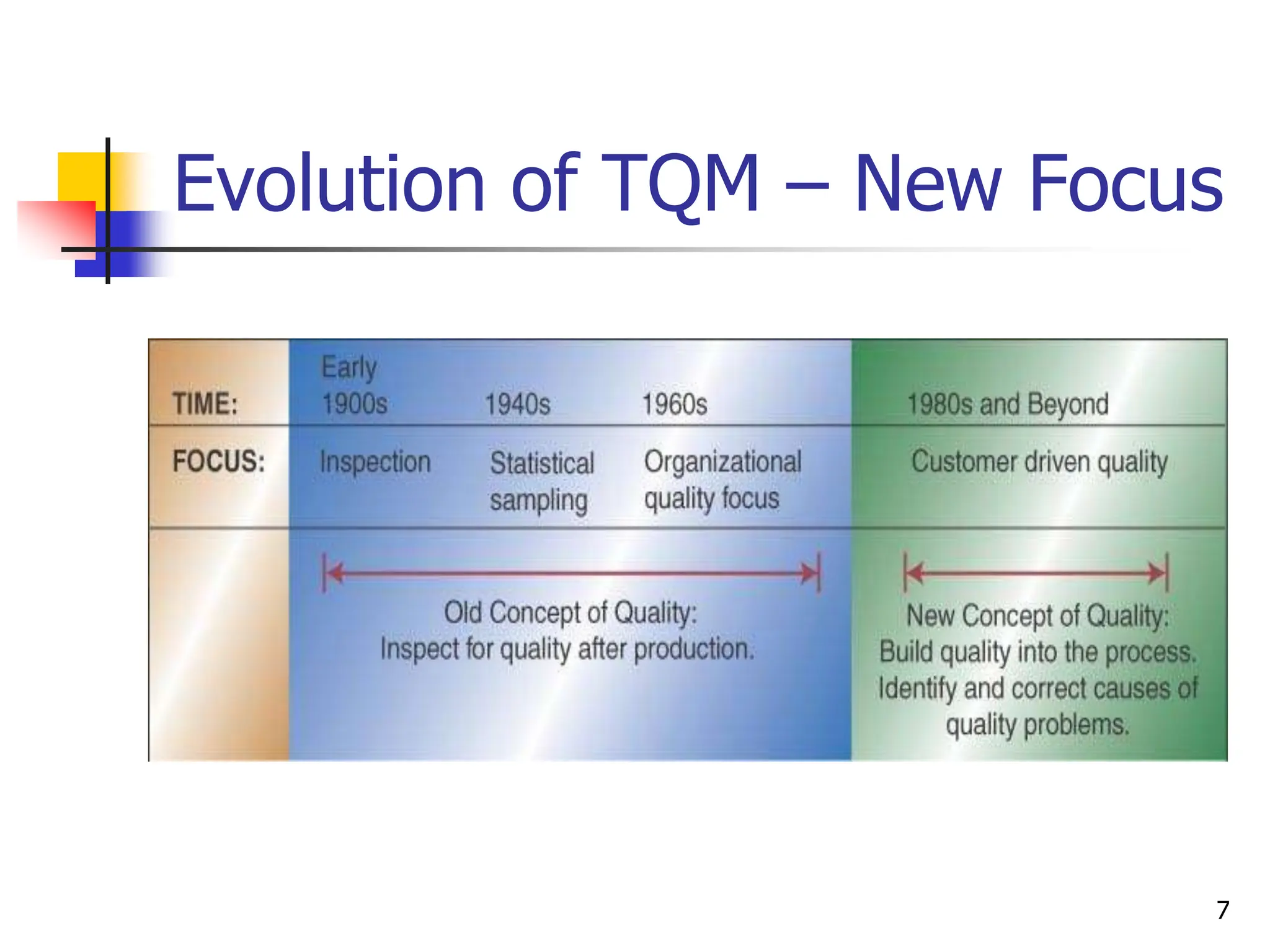

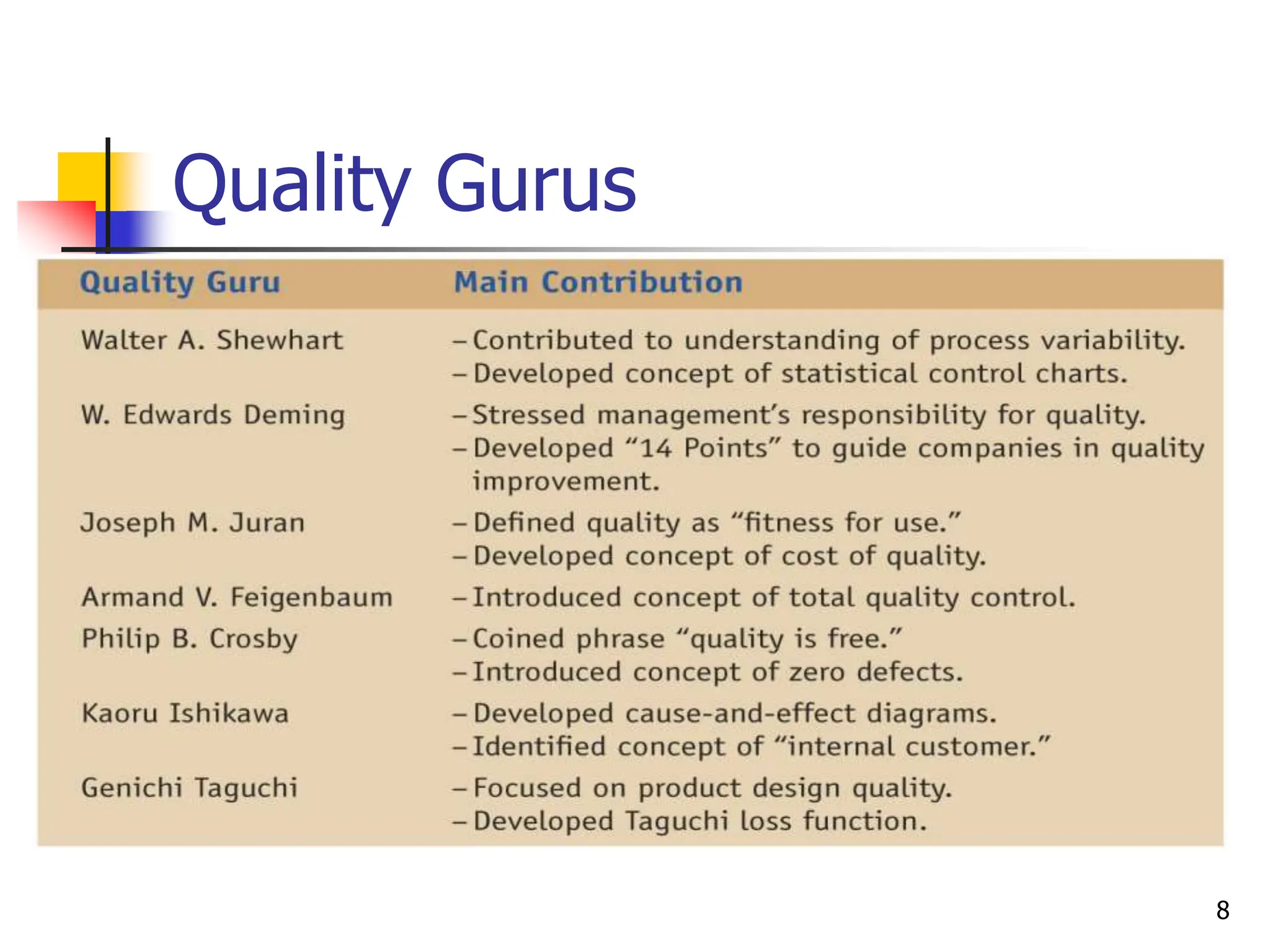

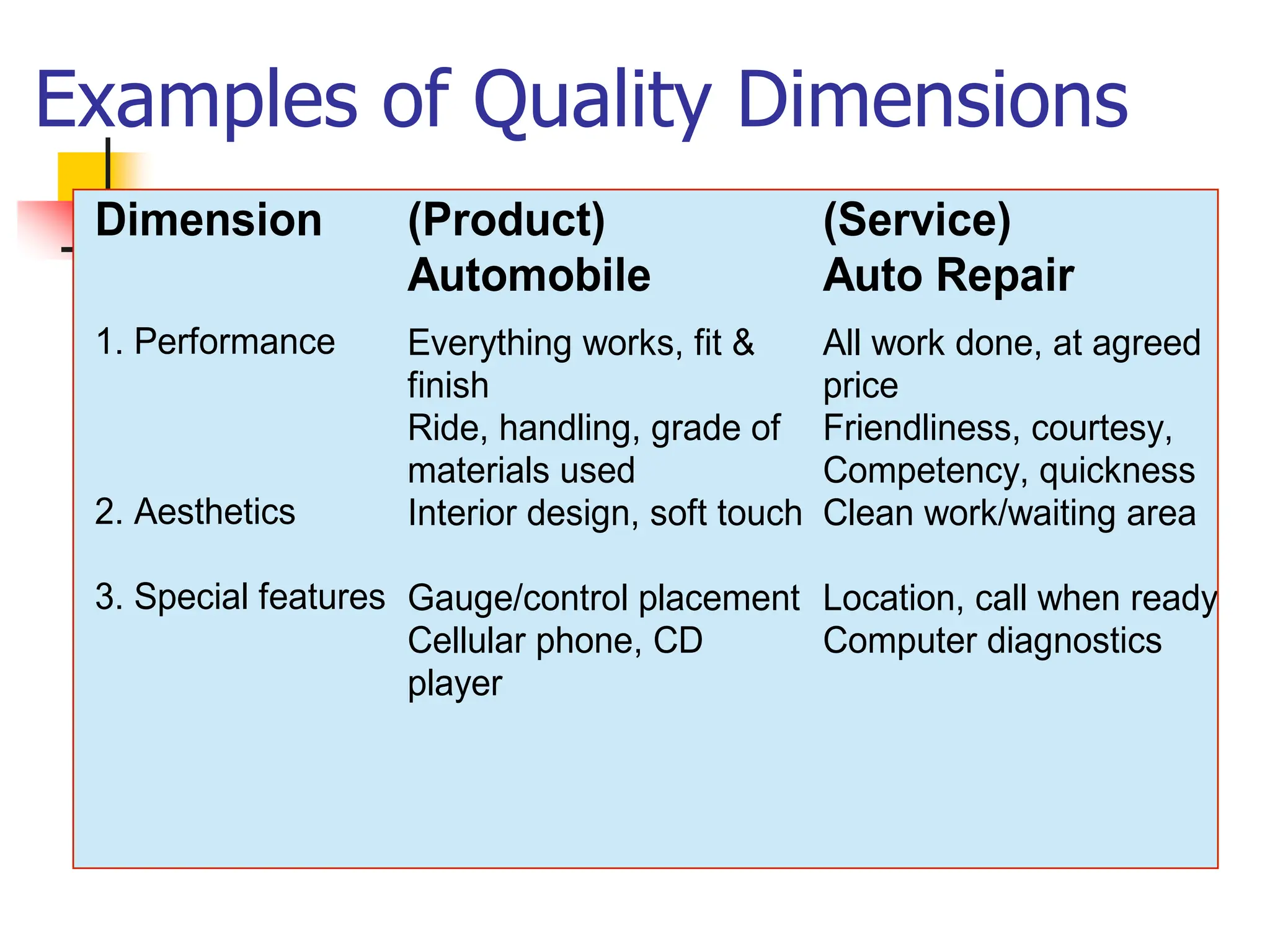

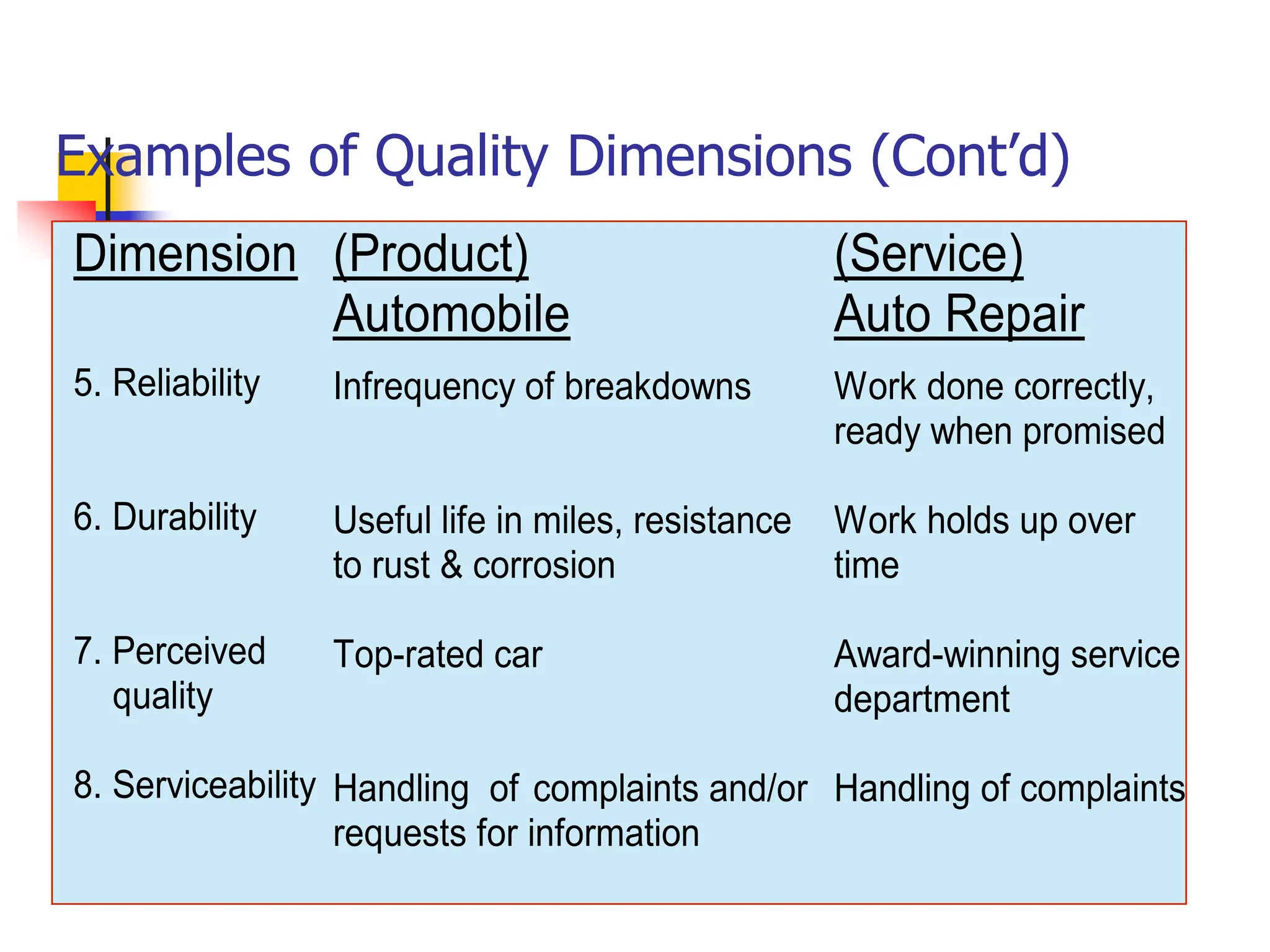

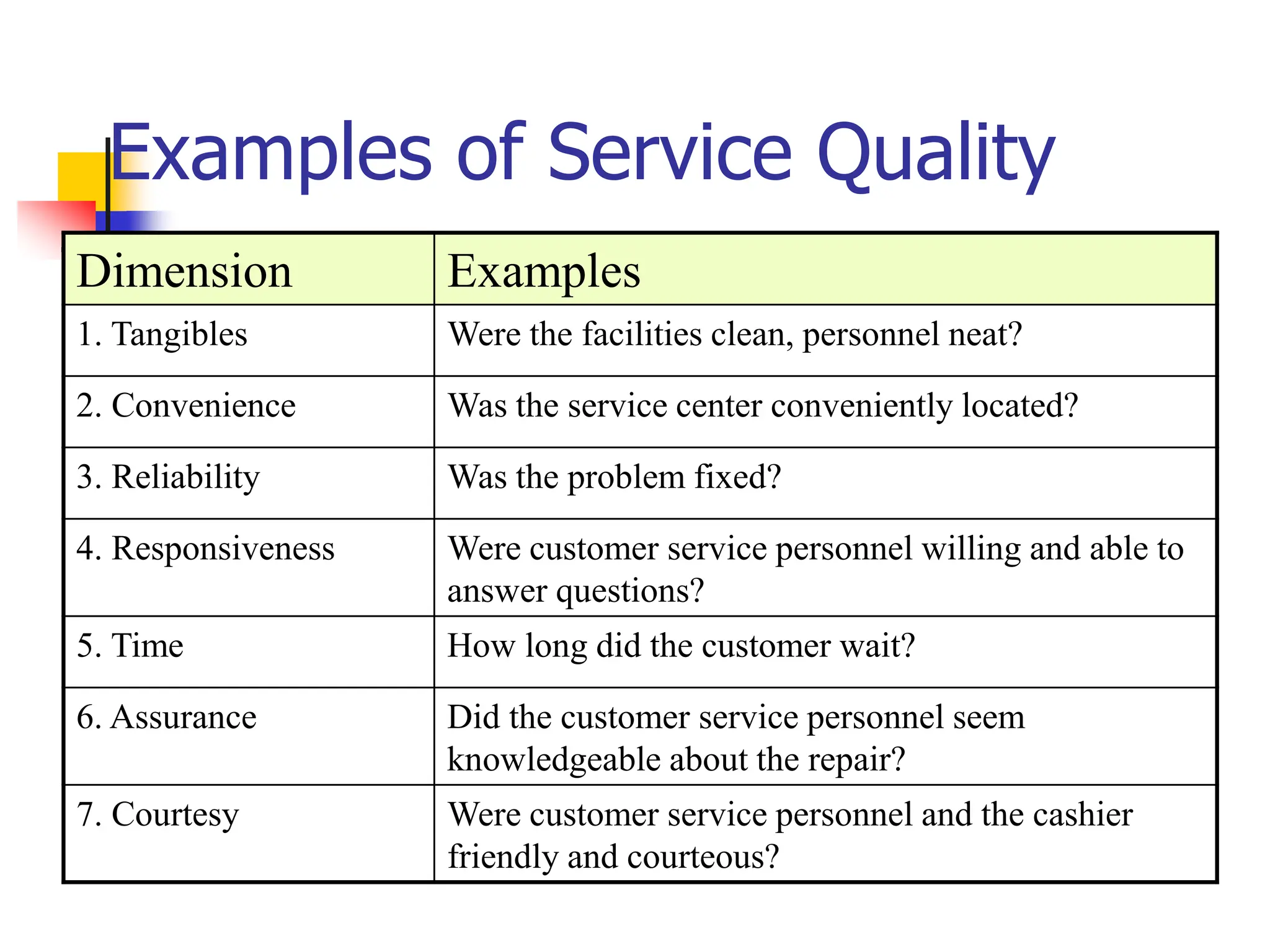

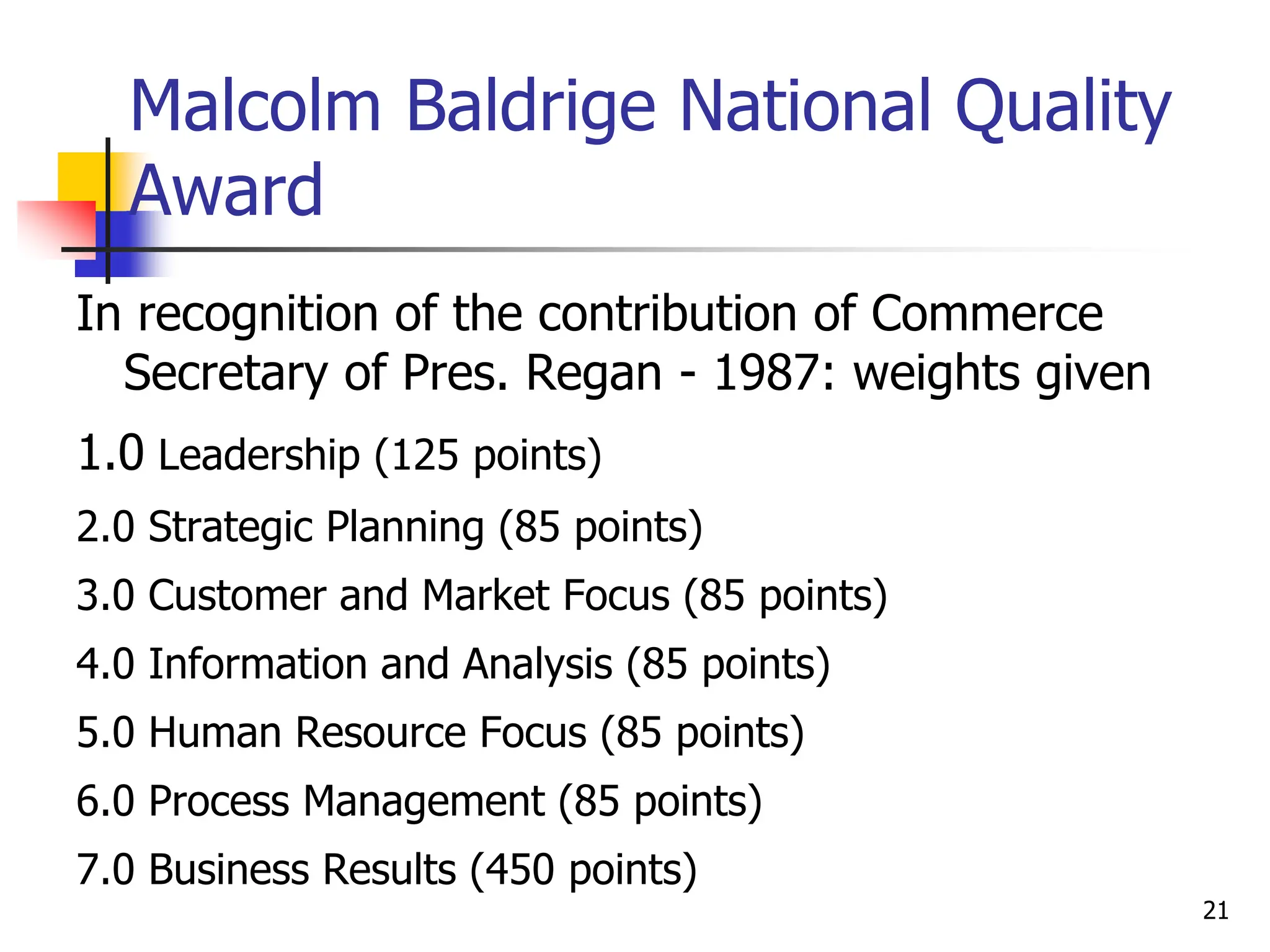

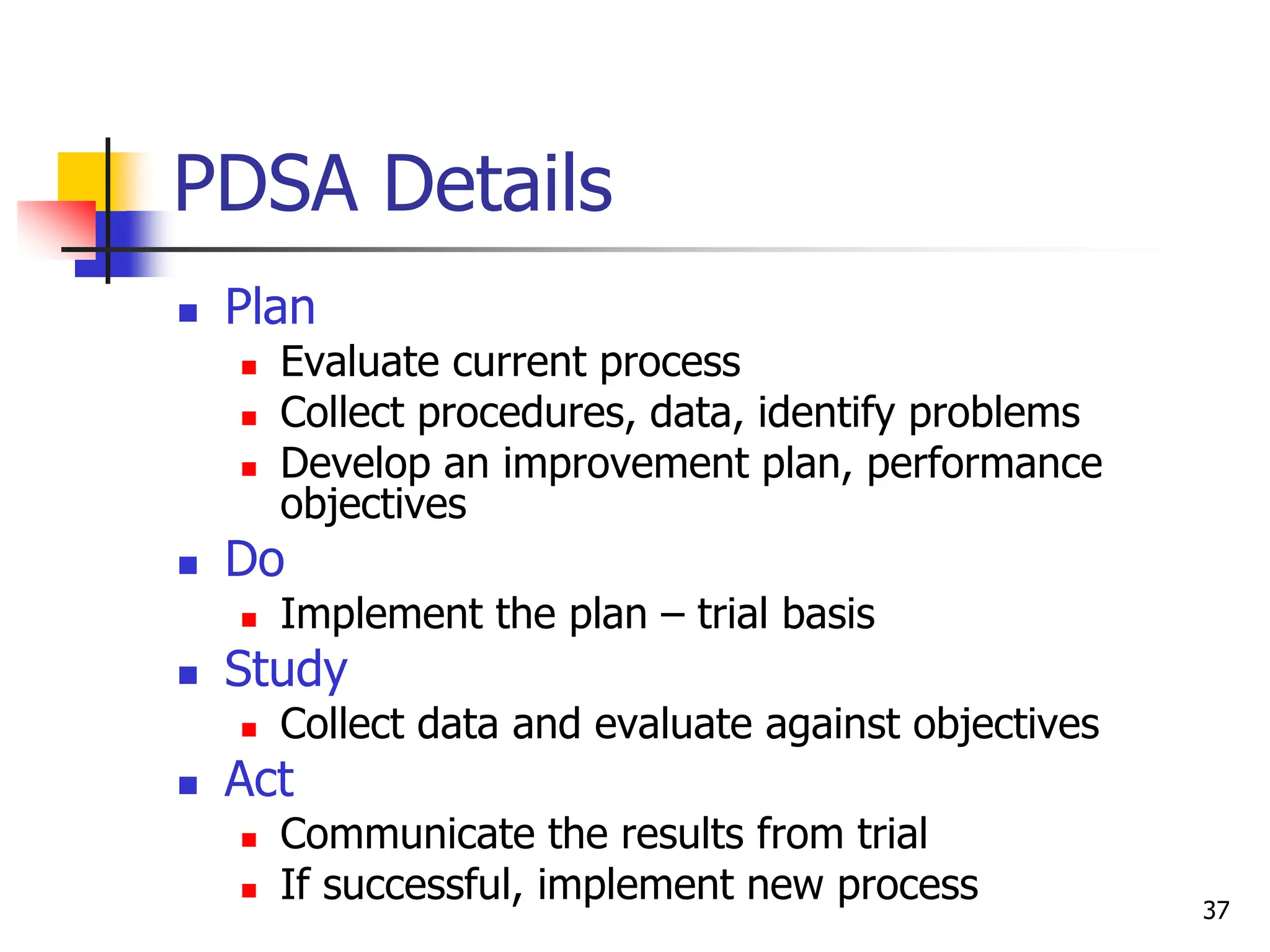

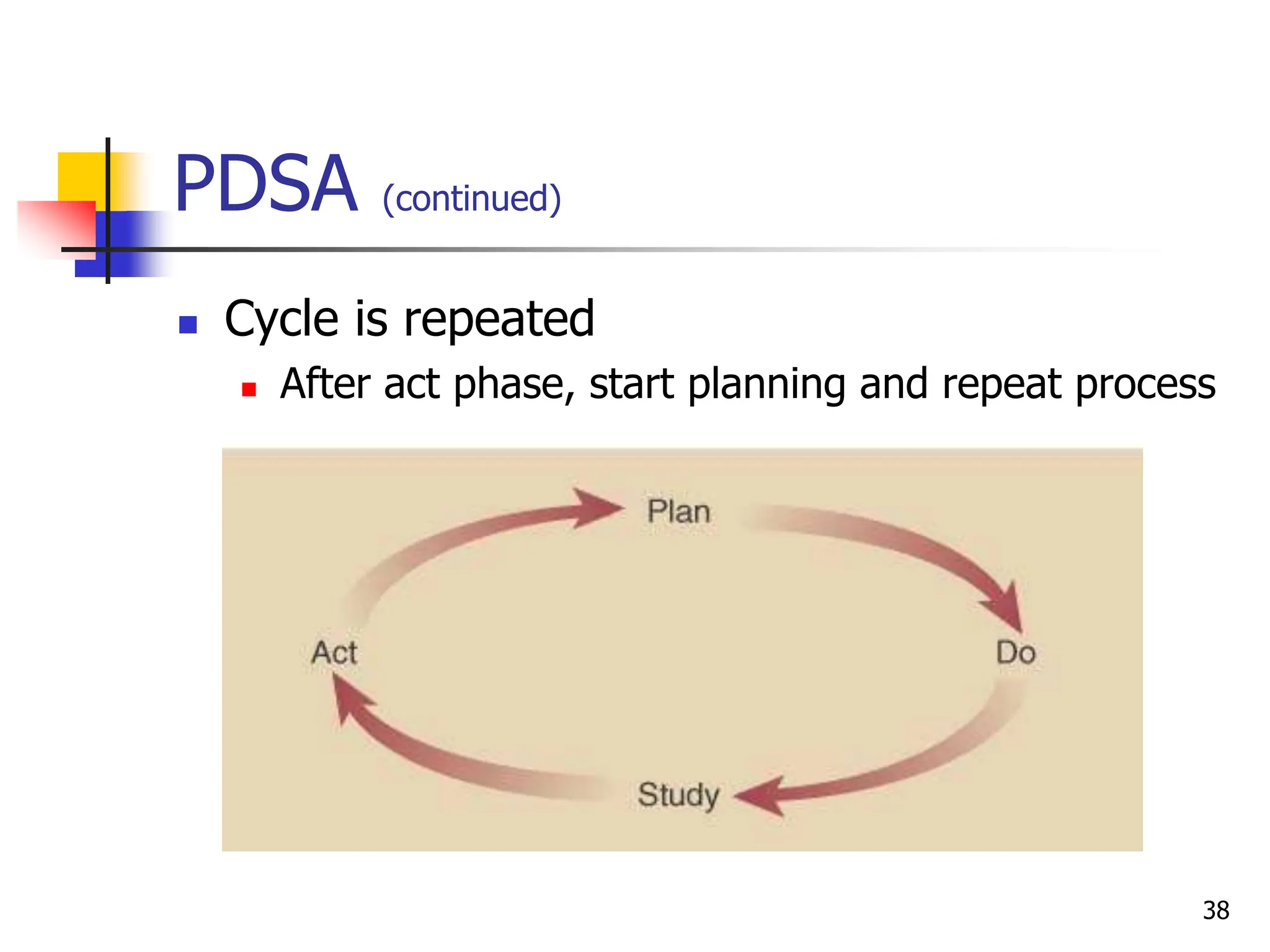

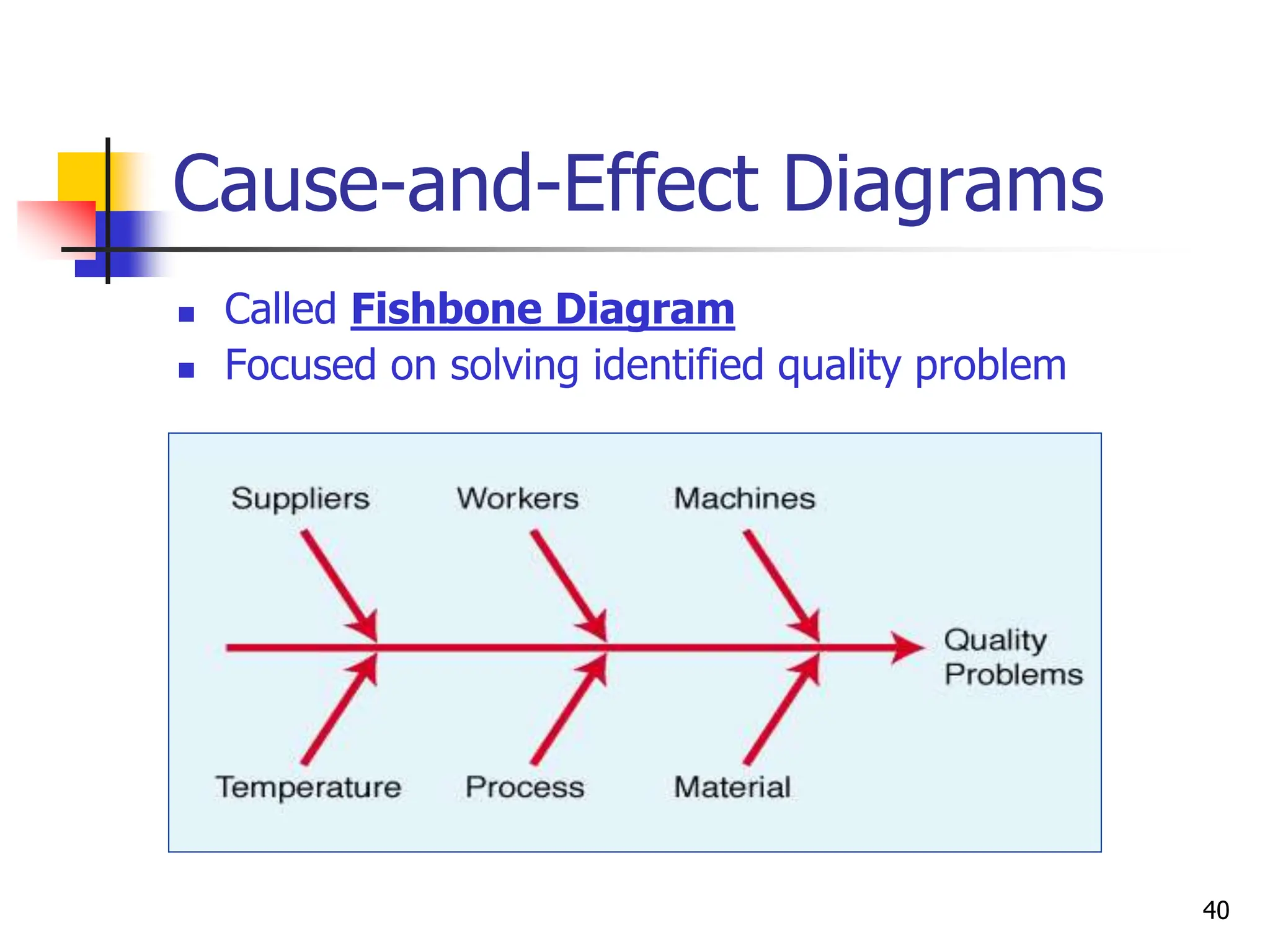

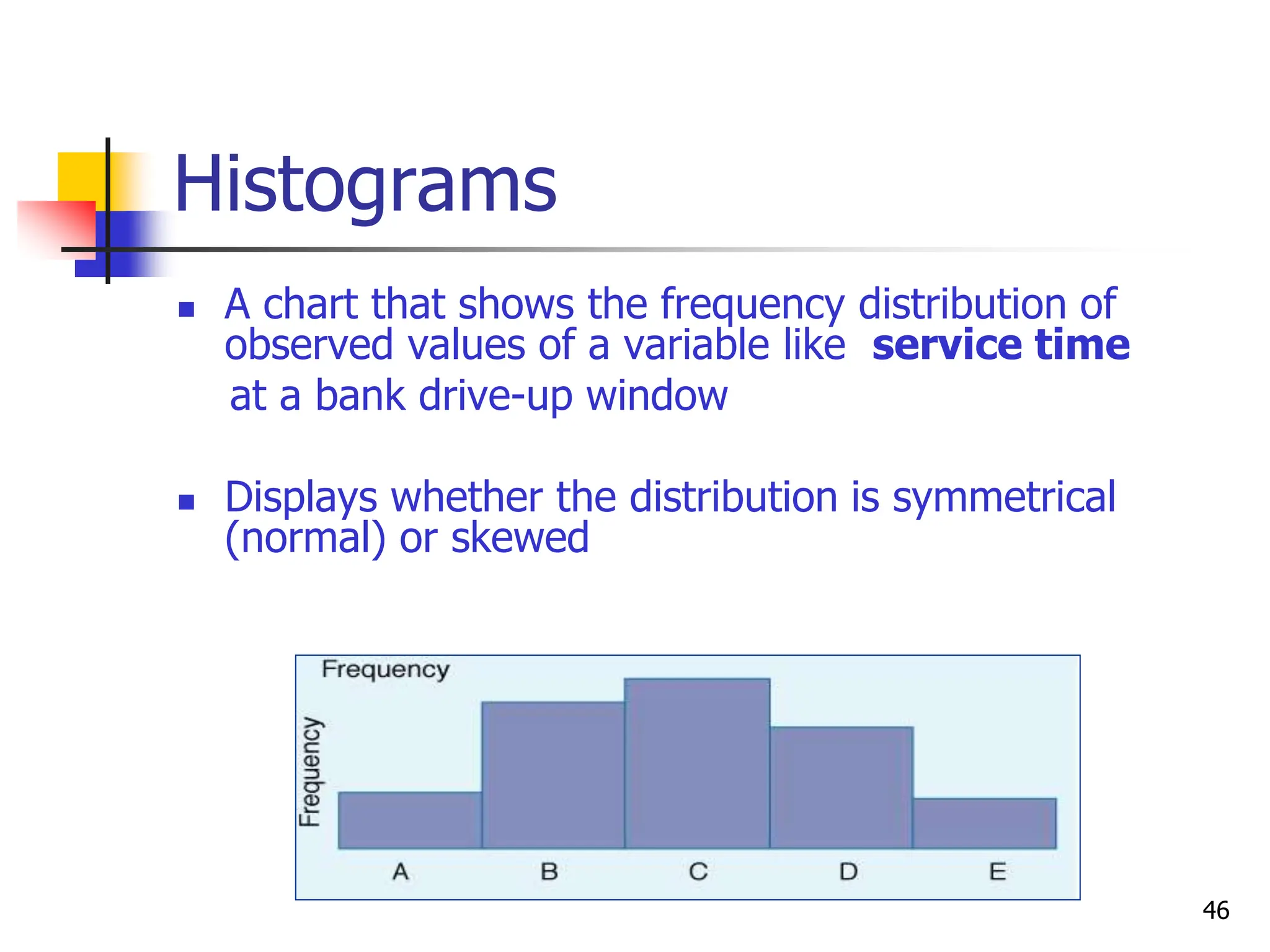

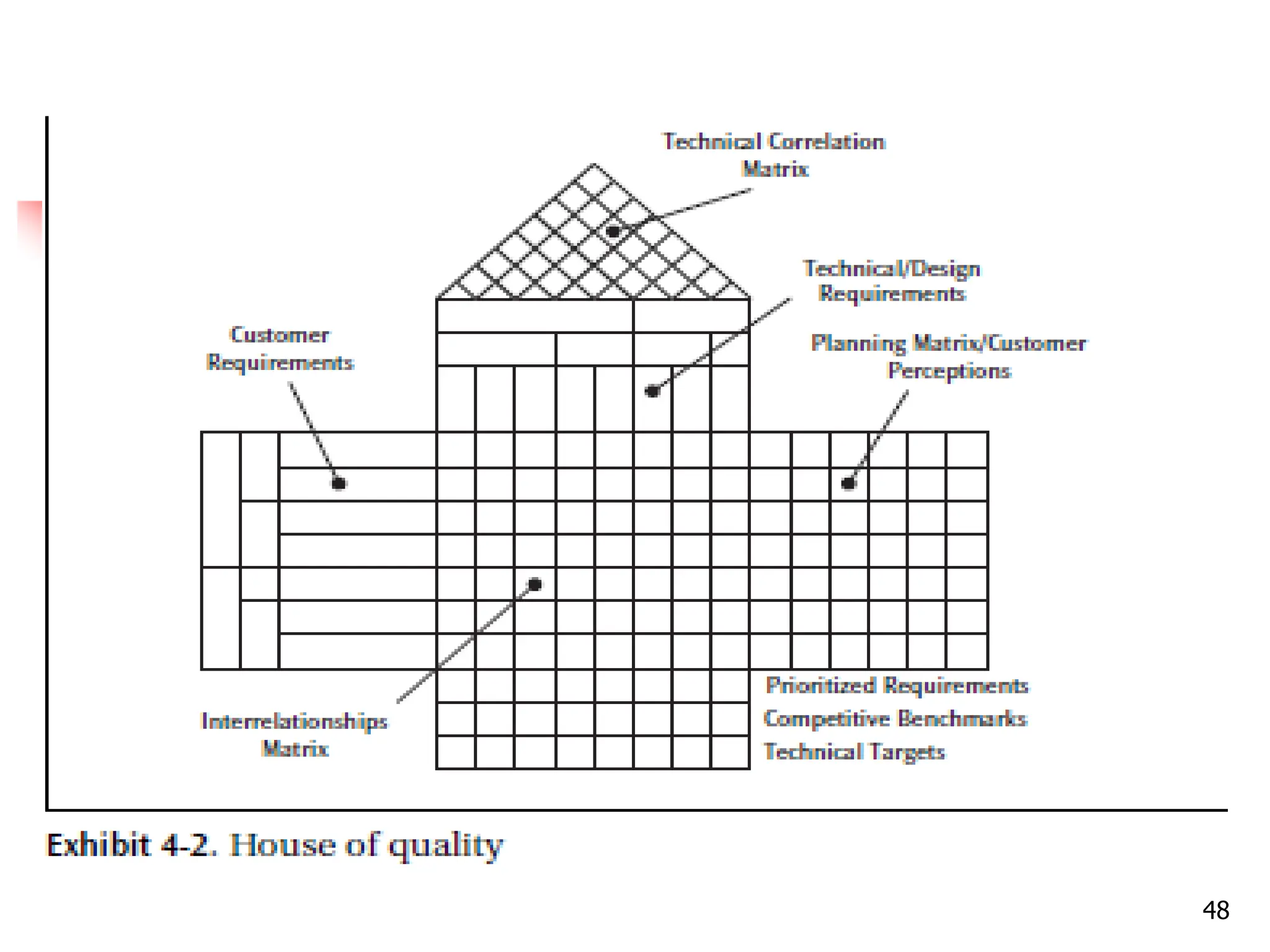

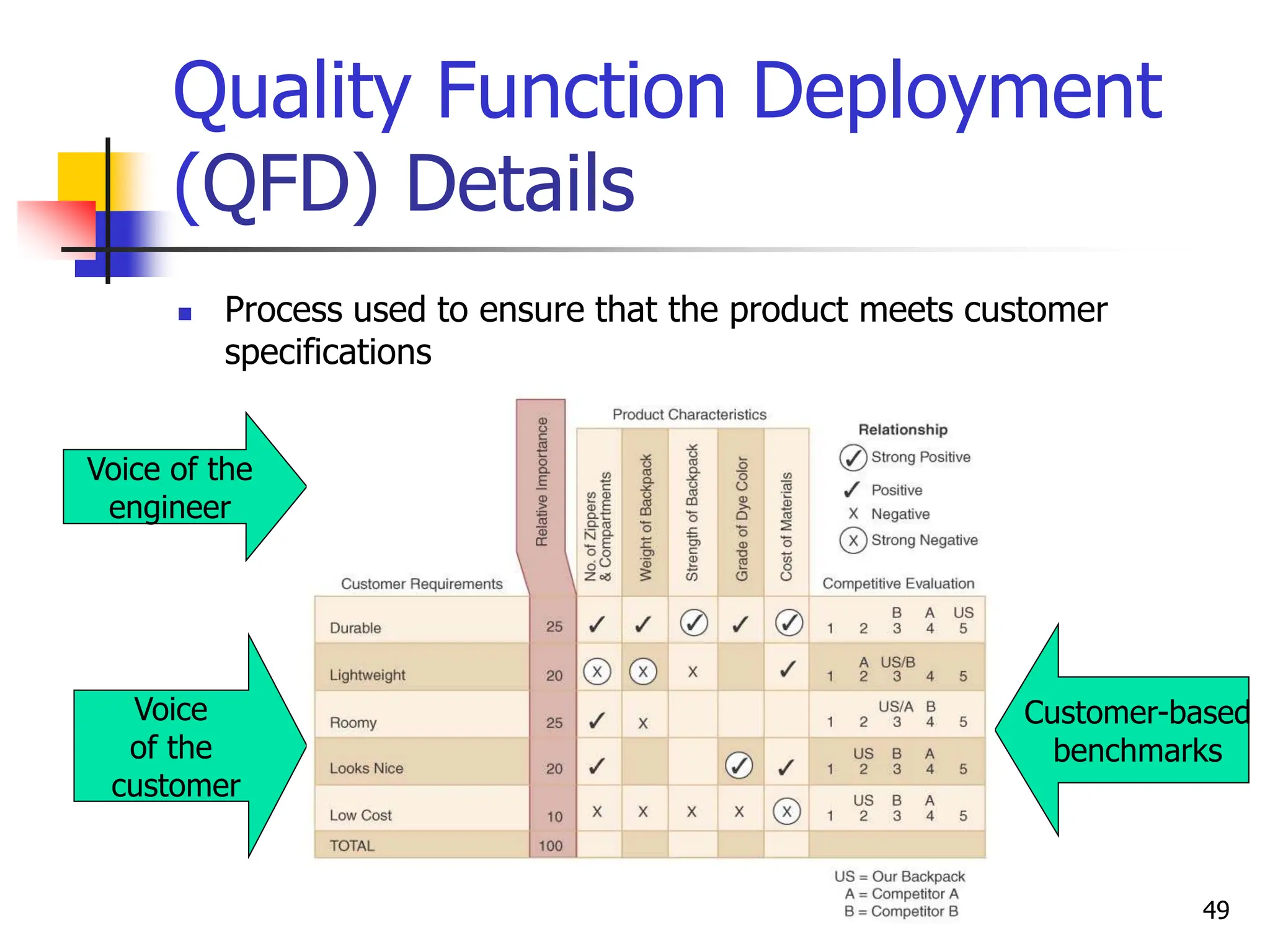

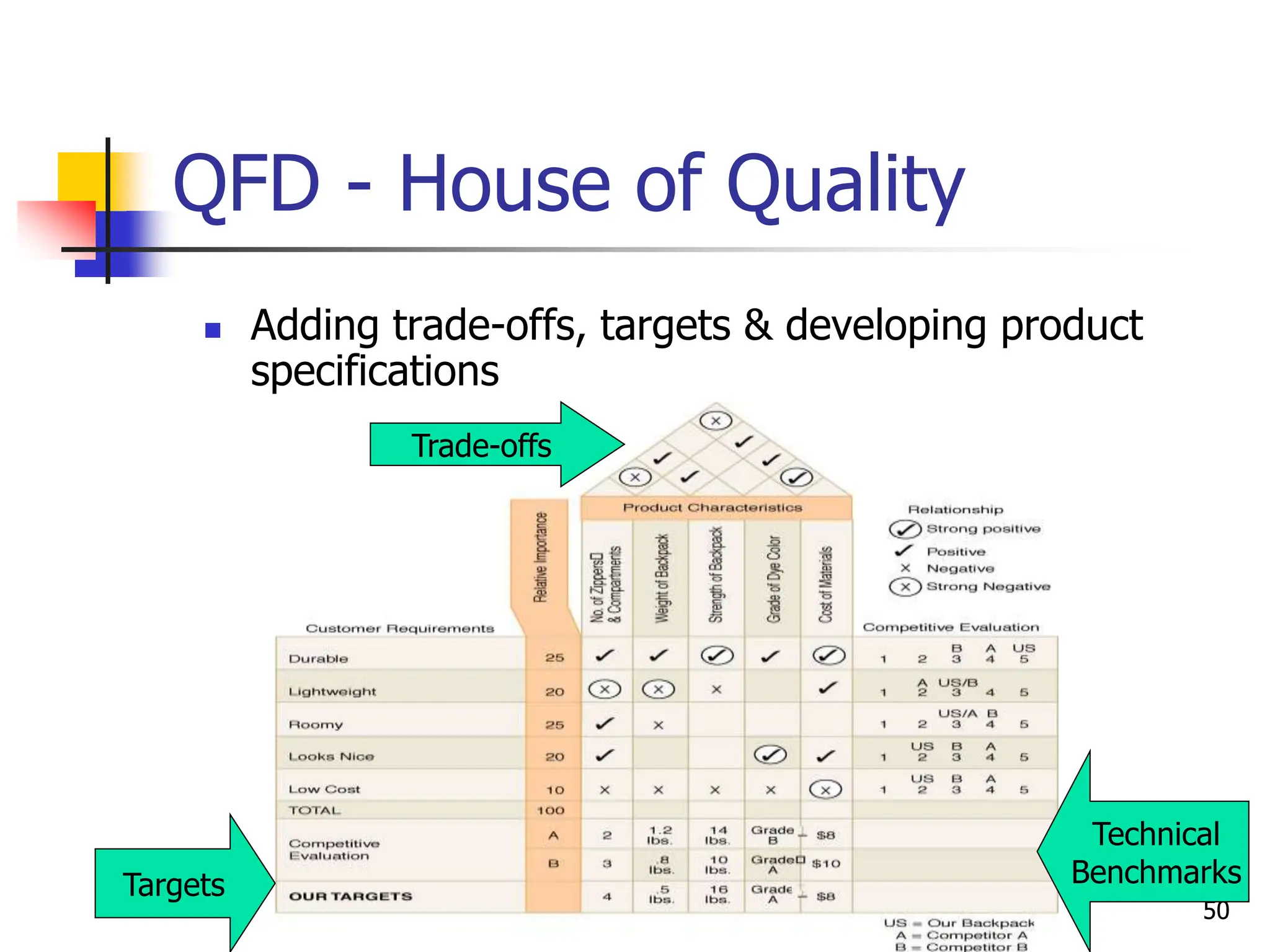

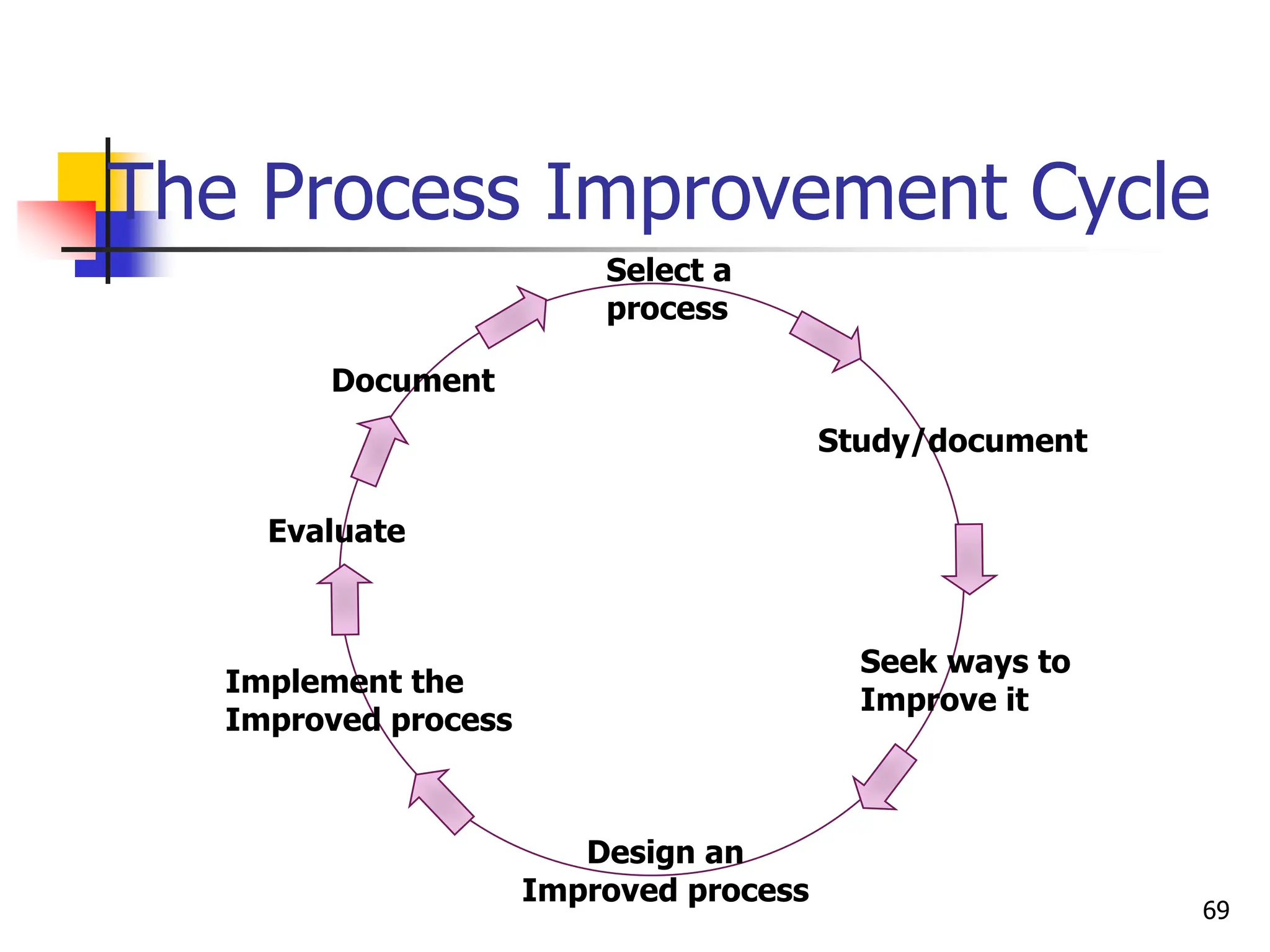

Chapter 5 discusses quality management and control, emphasizing that quality definitions vary and can include conformance to specifications, fitness for use, and perceived quality. It contrasts manufacturing quality, which focuses on tangible product features, with service quality, defined by customer perceptions. The chapter also covers quality costs, the importance of total quality management (TQM), and introduces methodologies like Six Sigma for process improvement and defect reduction.