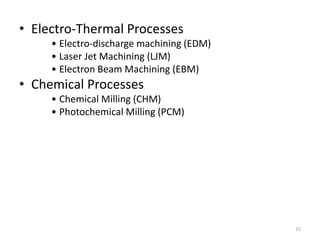

Manufacturing processes transform raw materials into finished products through steps of modifying materials. There are two main types of manufacturing processes - primary processes provide basic shape and size, while secondary processes provide tighter dimensional control and surface finishes. Non-traditional manufacturing (NTM) processes such as abrasive jet machining remove materials using mechanical, thermal, electrical, or chemical energy without sharp cutting tools. NTM is needed for hard or complex materials and can machine at the atomic level without chip formation. Products of advanced manufacturing are technologically complex, innovative, and solve societal problems, while manufacturing processes use computer technologies, robotics, and sustainable methods.