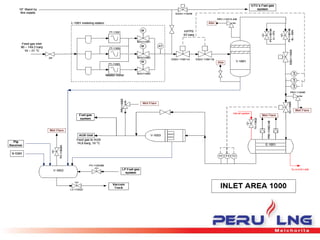

The document provides an overview of Unit 1000, the inlet gas area of an LNG plant. It receives natural gas from a pipeline via a metering system that measures flow rates and gas composition. It then reduces the pressure through HIPPS valves and pressure control valves. It separates liquids and solids in a KO drum and filters small particles in a gas filter. Additional components heat the gas and separate any remaining liquids before the gas proceeds to downstream processes.