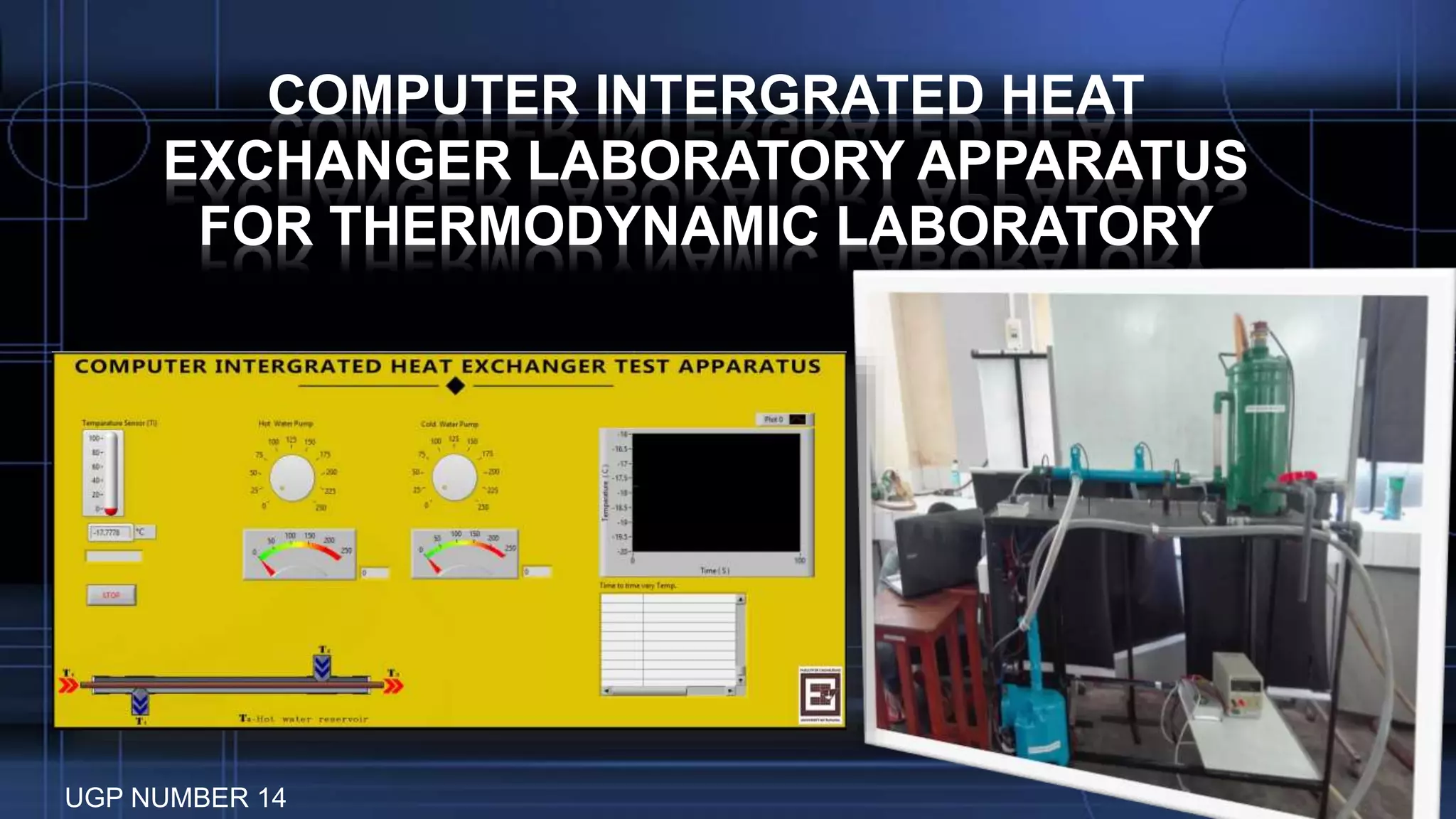

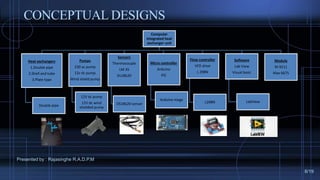

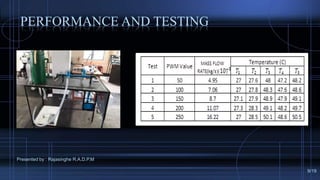

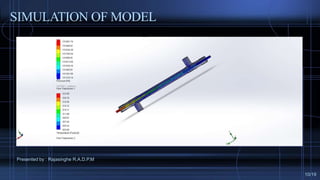

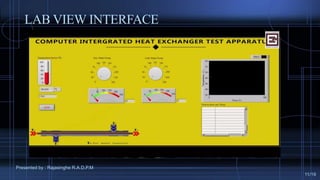

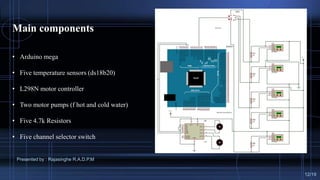

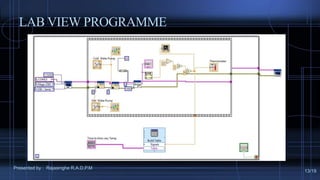

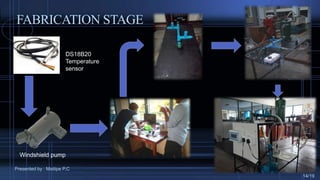

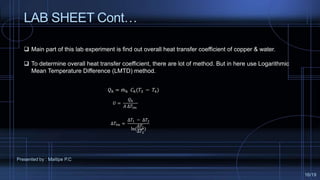

This project developed a computer-integrated heat exchanger test apparatus for use in a thermodynamics laboratory. A team of three students designed, fabricated, and tested the apparatus under the supervision of faculty members. Key aspects included integrating temperature sensors, pumps, and a microcontroller to the double pipe heat exchanger design. Performance testing was conducted and results were analyzed using a LabView interface created to control the system and log data from the integrated sensors. Further planned work involves modifying the design to study both parallel and counterflow configurations and improving insulation to reduce heat losses.