- Bill Smith, president of Great British Kettles, called industrial designer Scott Stropkay to design an electric teakettle called Ukettle.

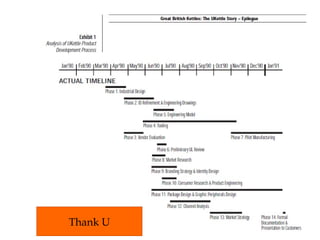

- Scott worked with Polymer Solutions on the design over six intense months to develop the kettle in time for a January trade show.

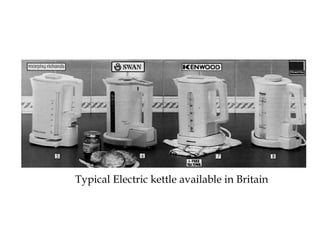

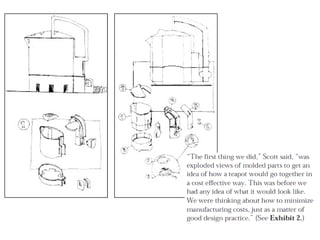

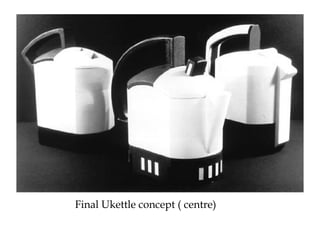

- The goal was to create an innovative design that still looked like a traditional teakettle. Key challenges included designing for disassembly and using high-quality, recyclable plastics.

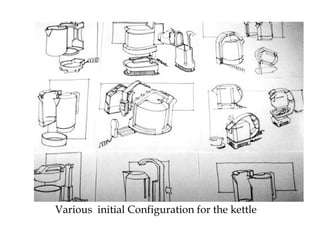

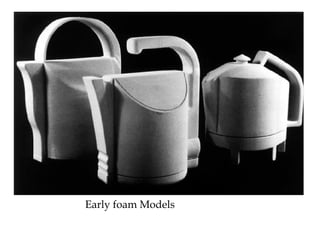

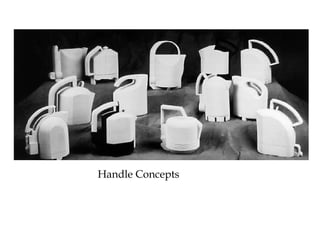

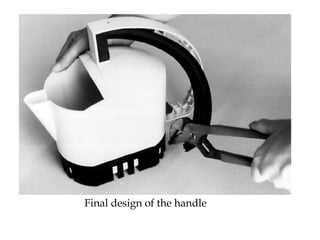

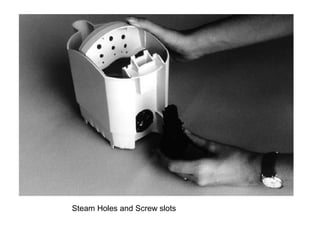

- Through sketches, prototypes, and focus groups, Scott refined the design which featured snap-fit assembly, a large vessel for the heating element, and two-tone color options that tested well.