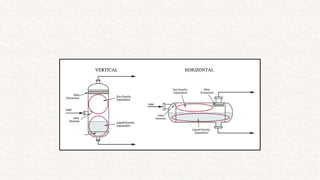

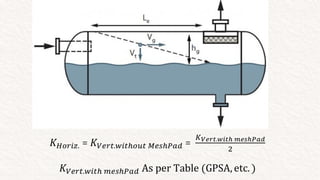

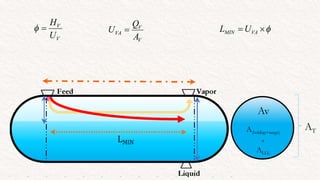

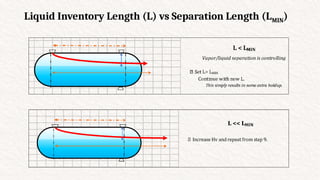

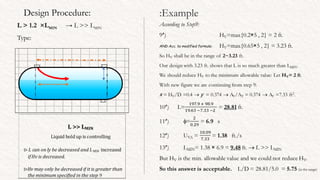

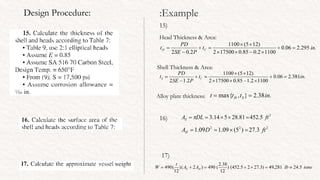

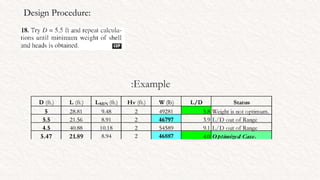

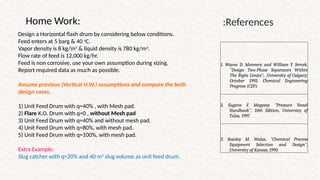

This document outlines the design procedure for a horizontal two-phase separator, detailing operating pressures, temperatures, and design calculations involved. It includes specific design formulas, examples, and rules of thumb for calculating vessel thickness and pressure. Additionally, there are homework assignments related to the design of various types of drums and references for further study.