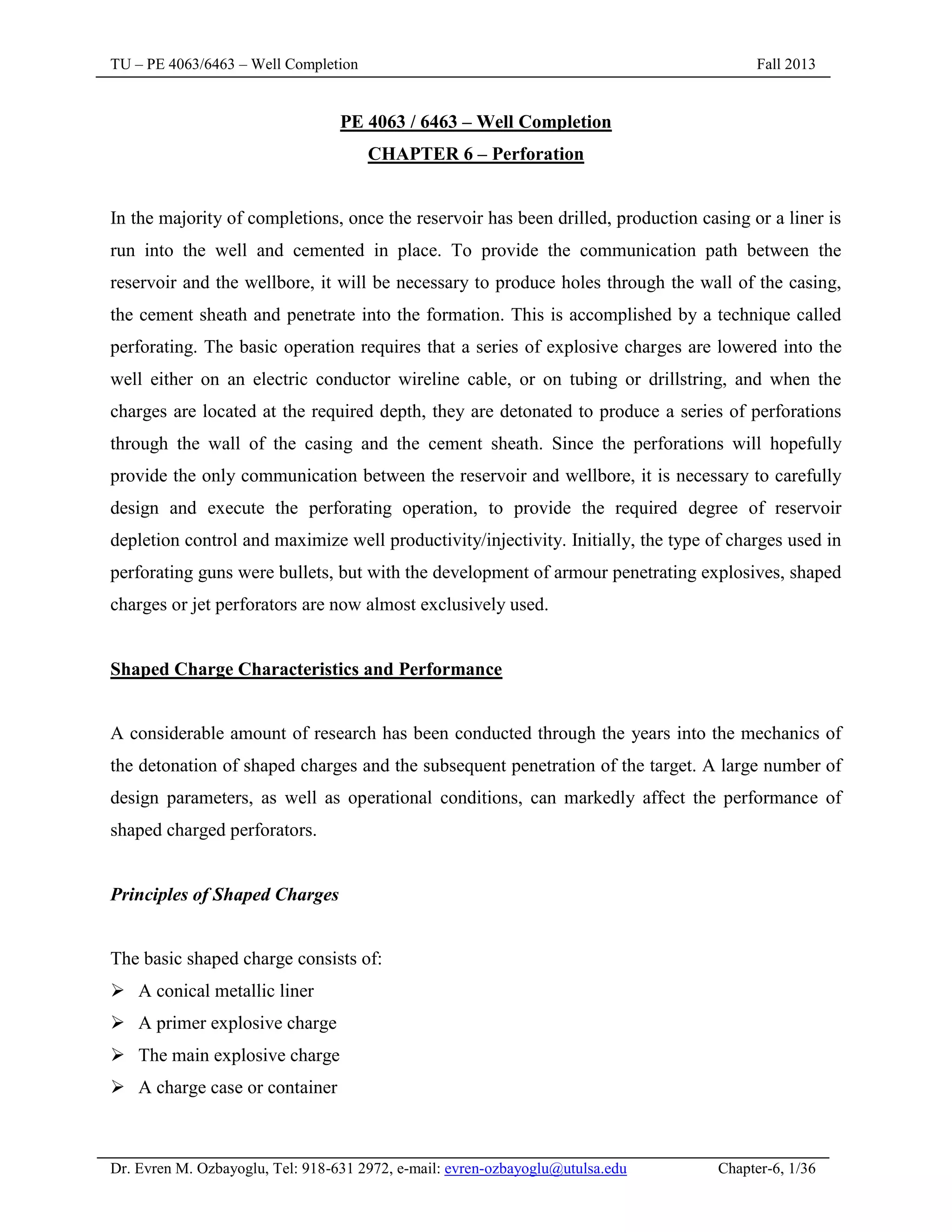

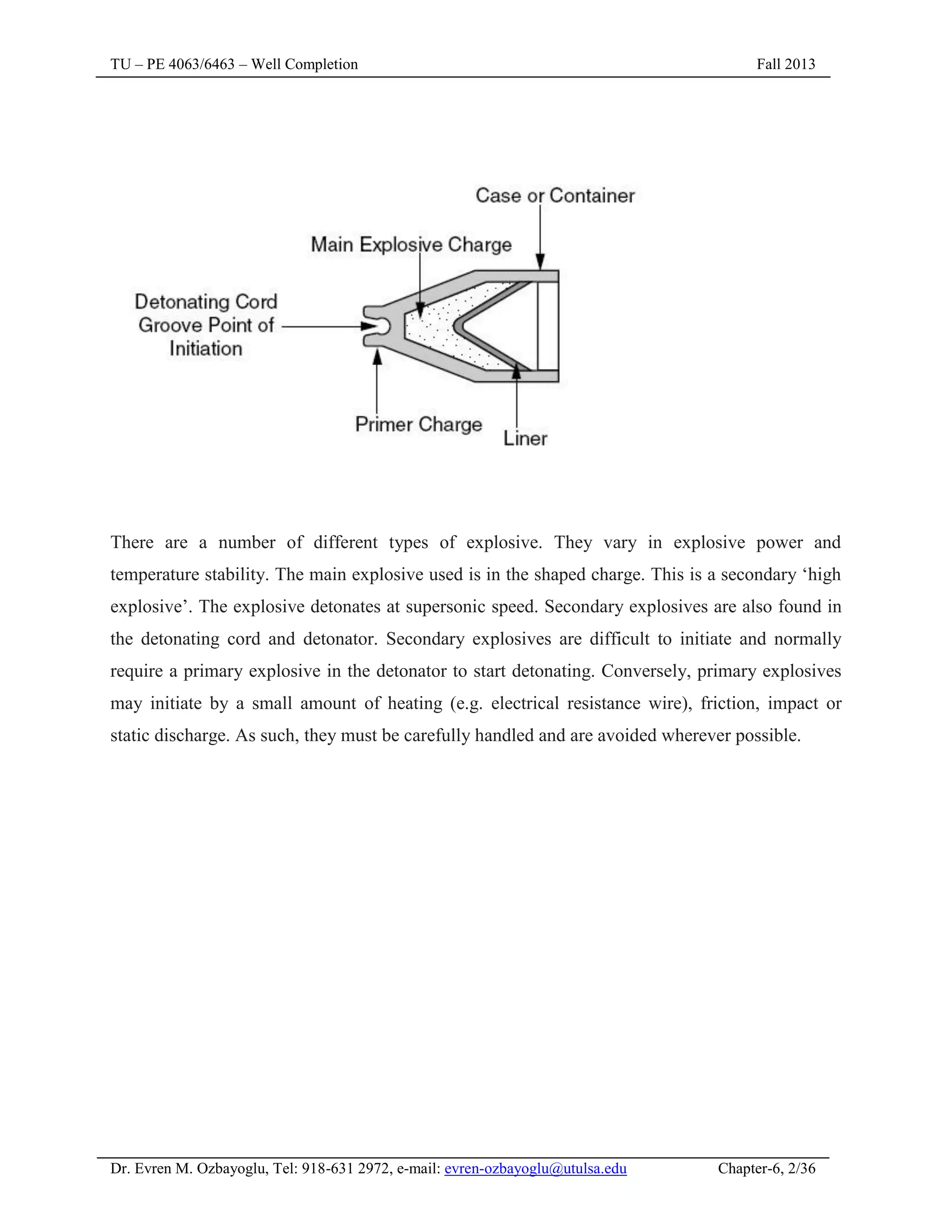

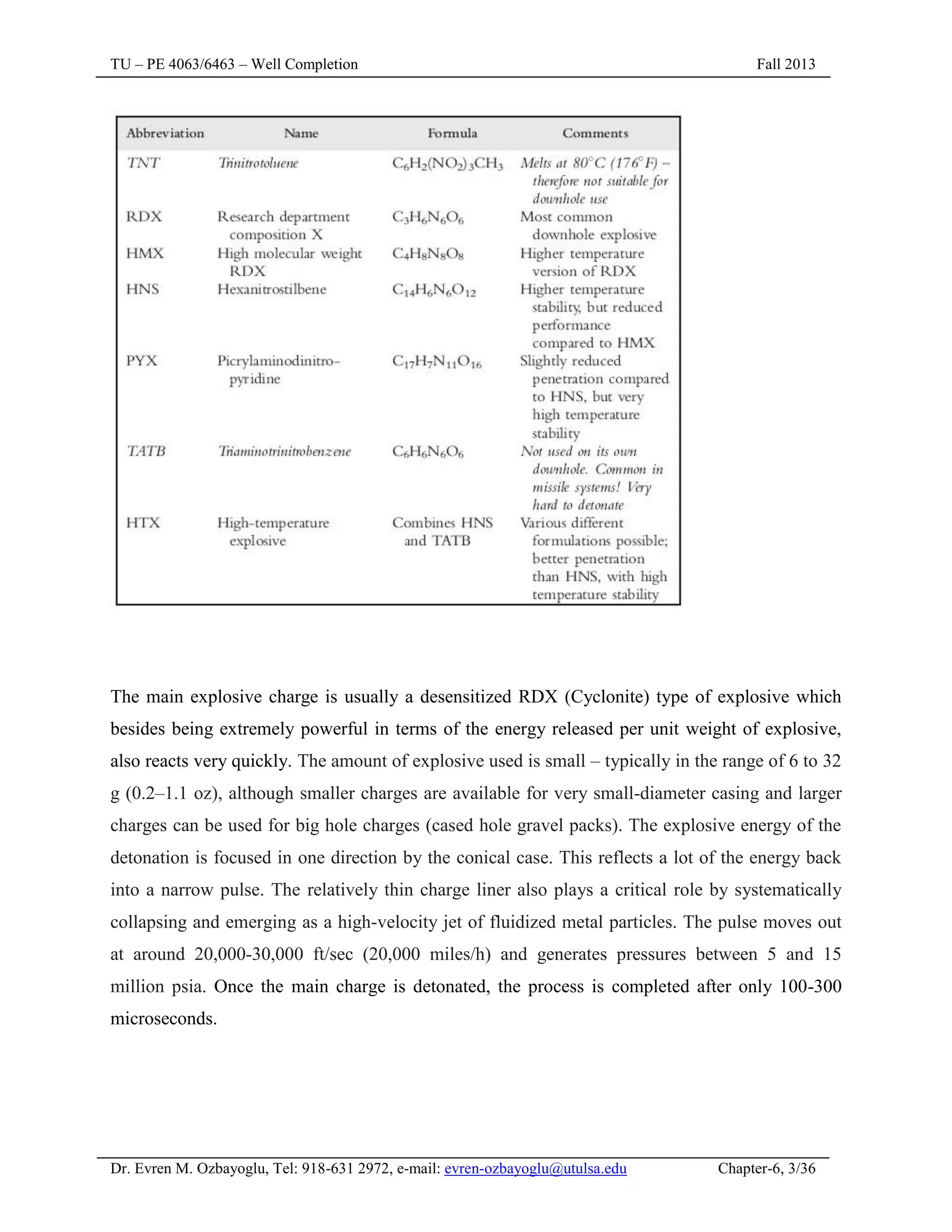

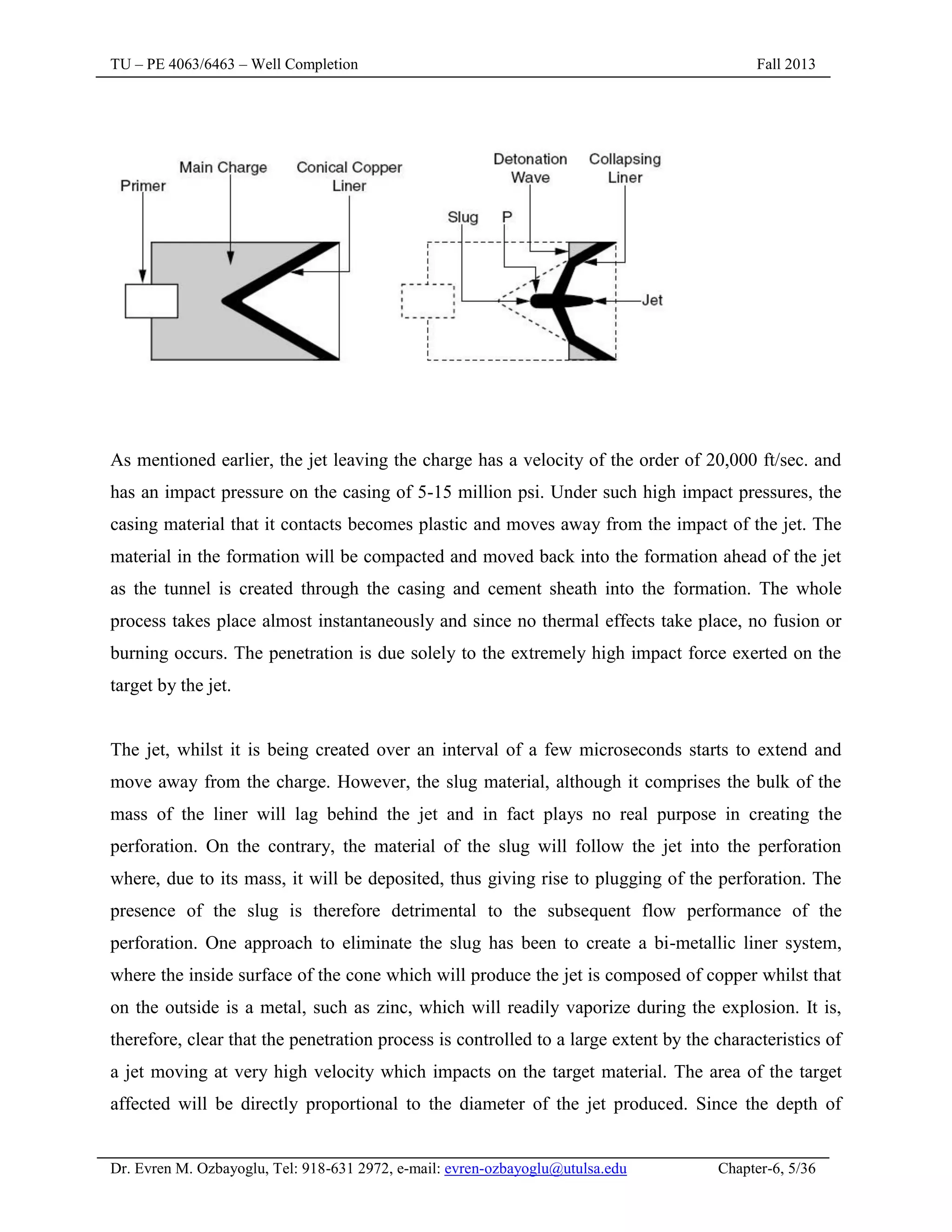

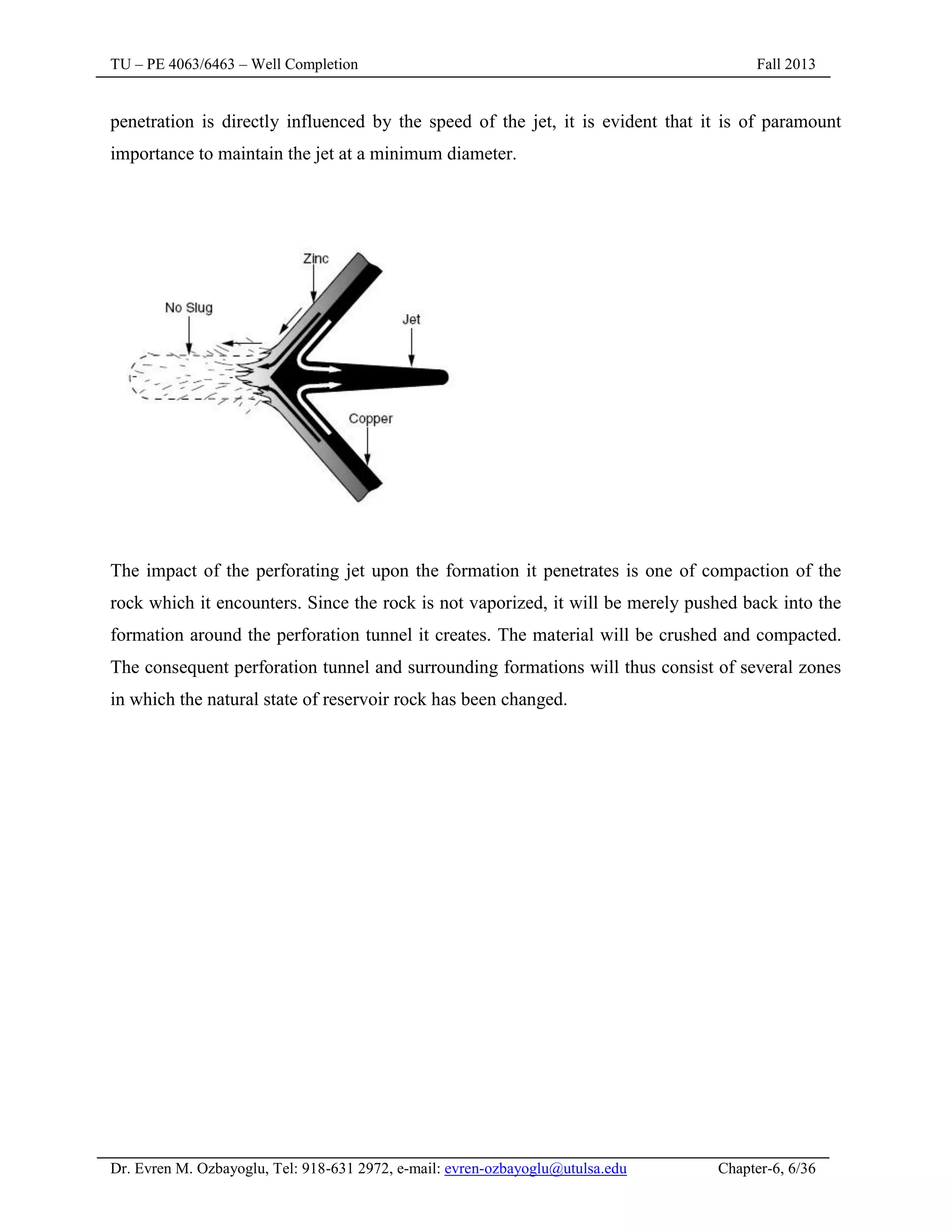

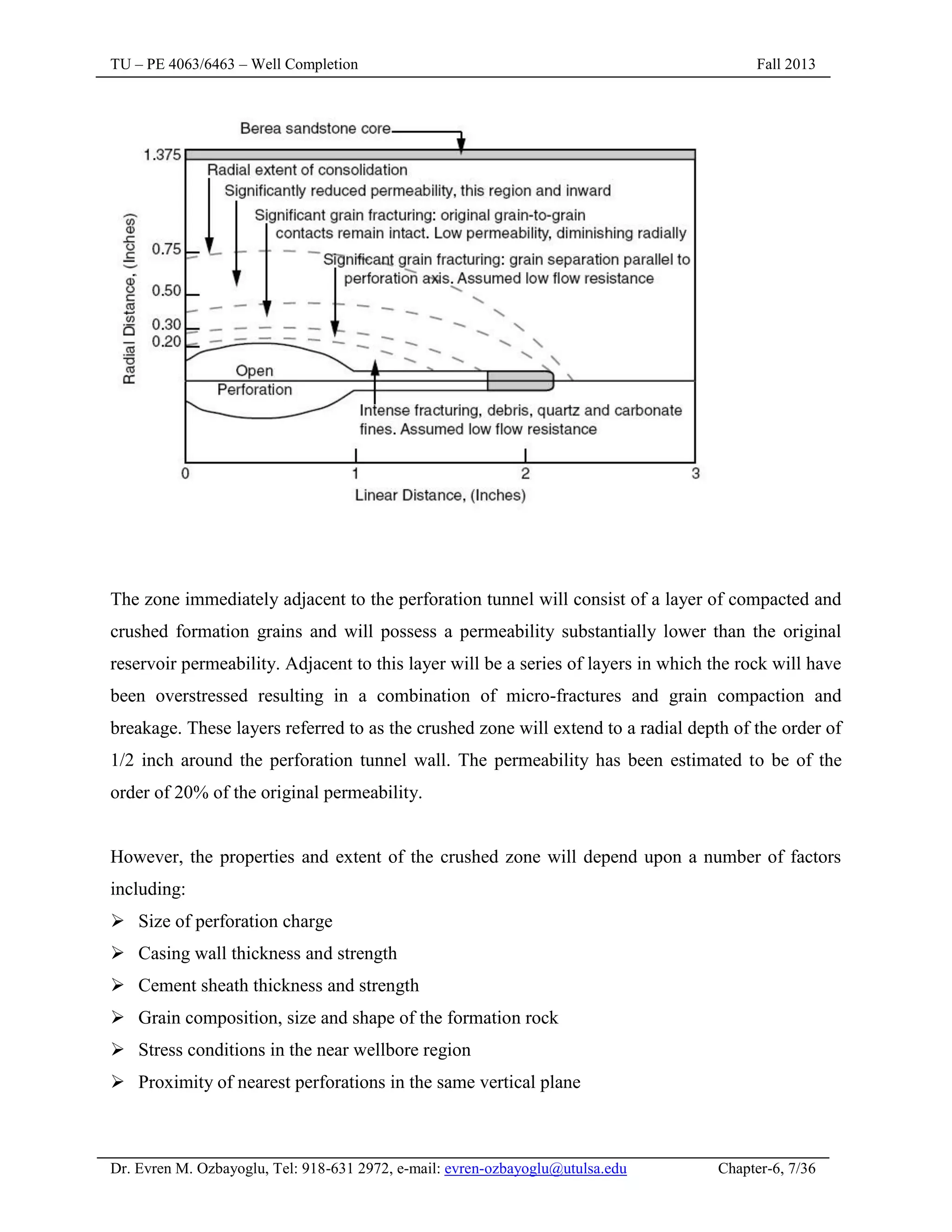

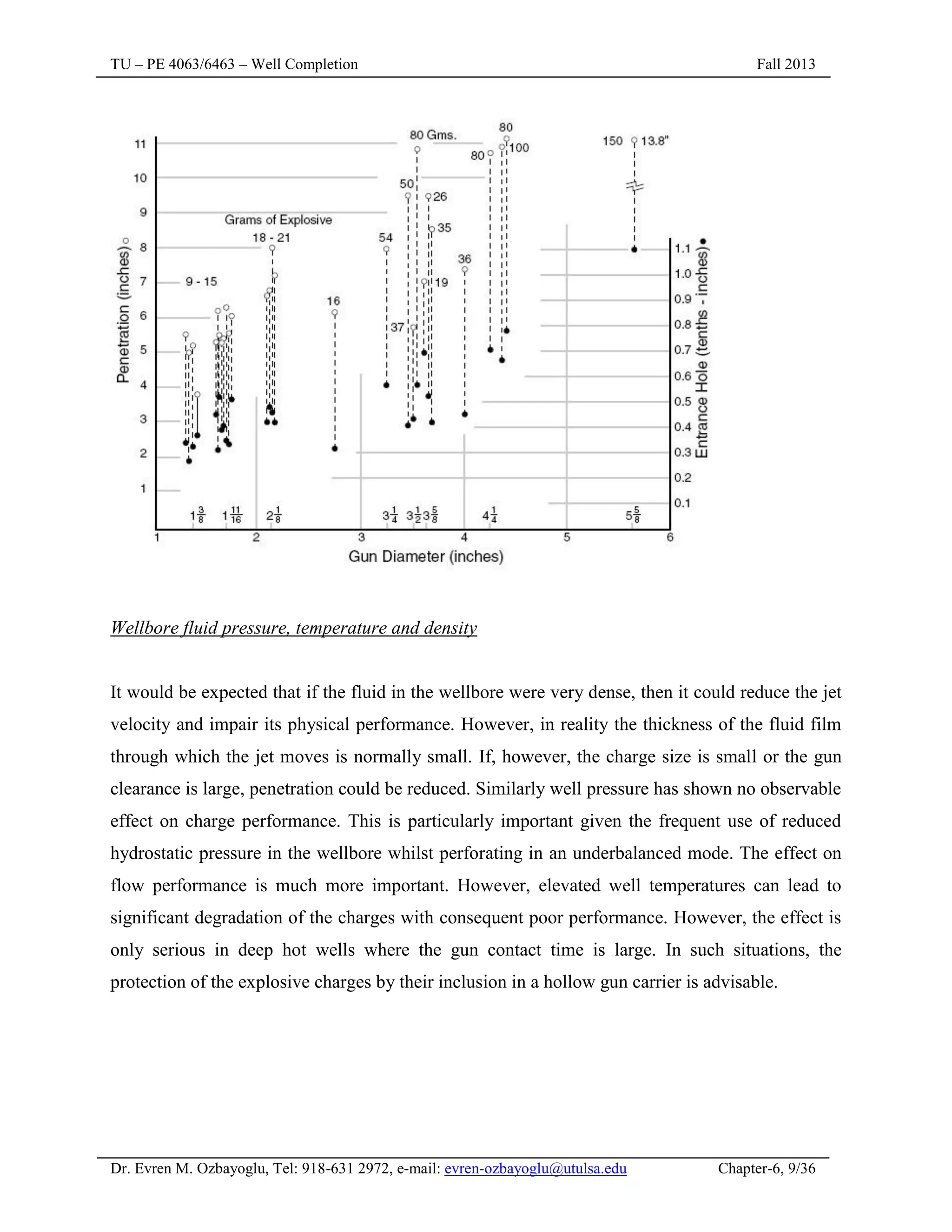

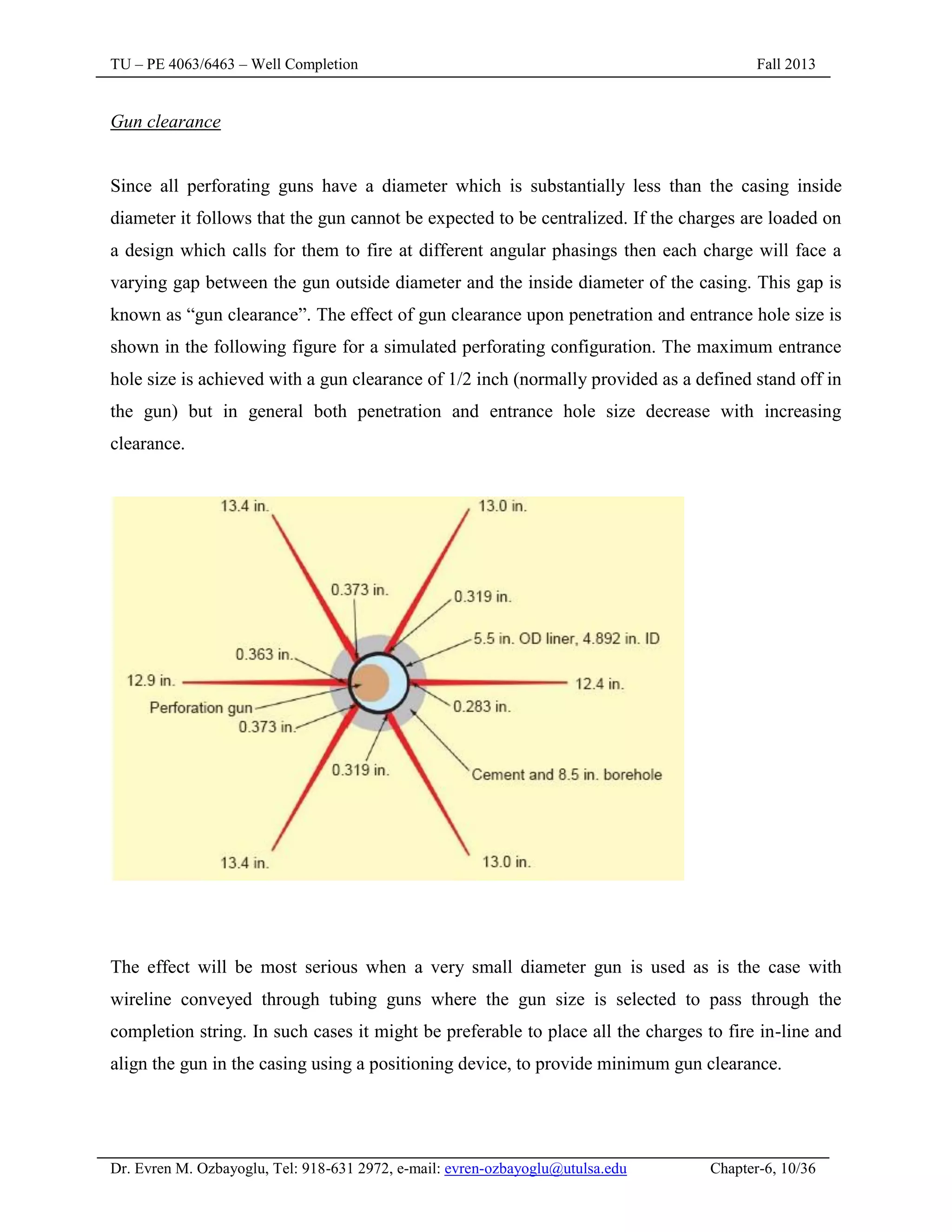

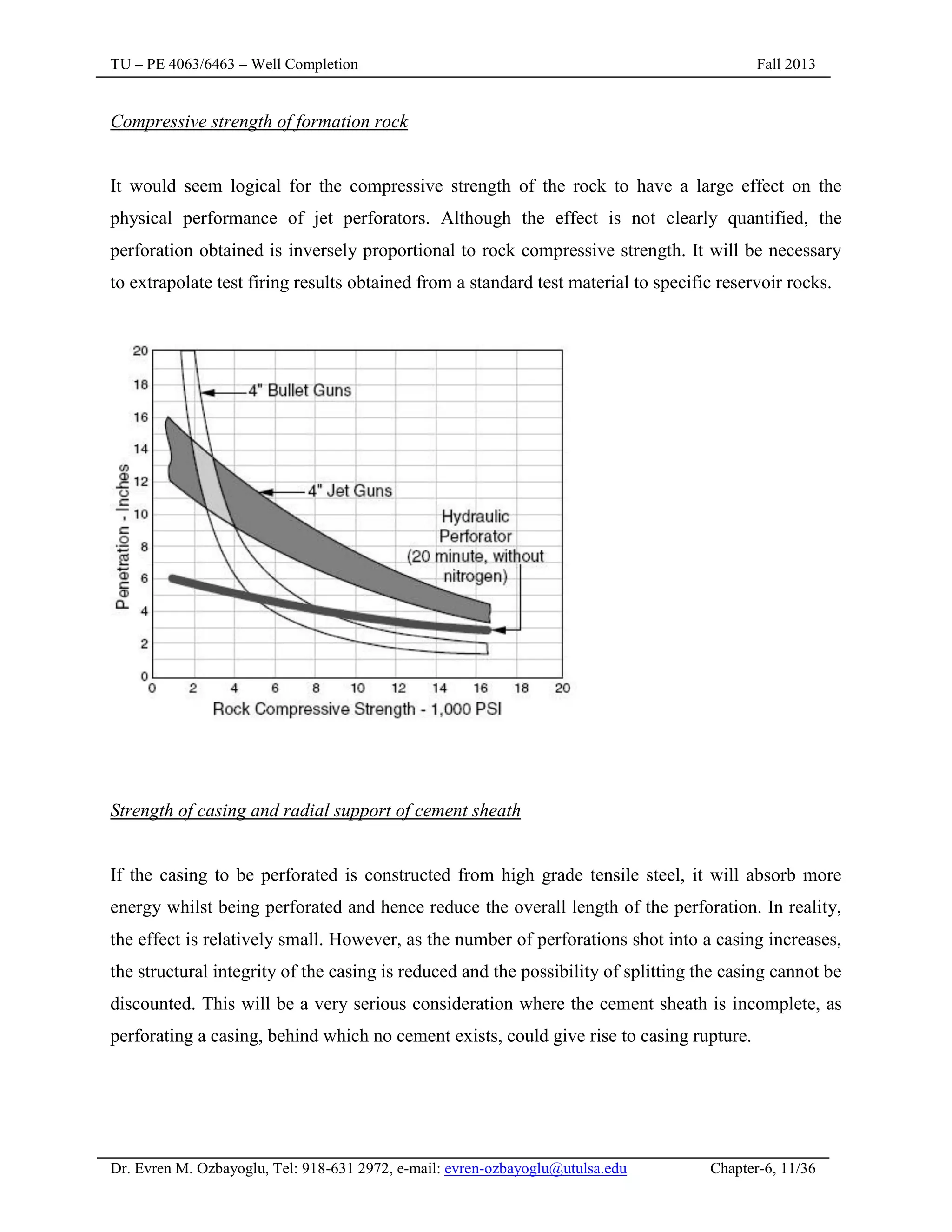

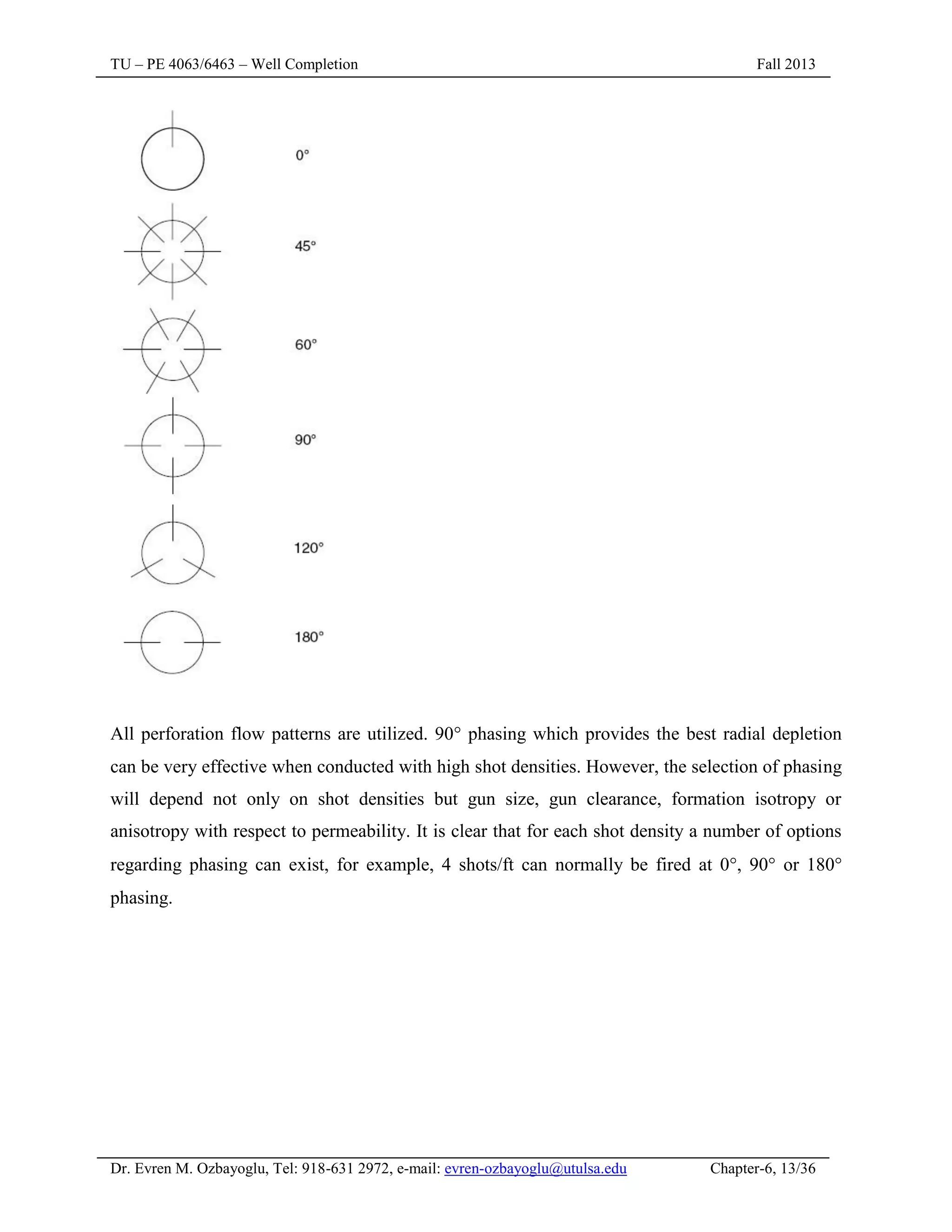

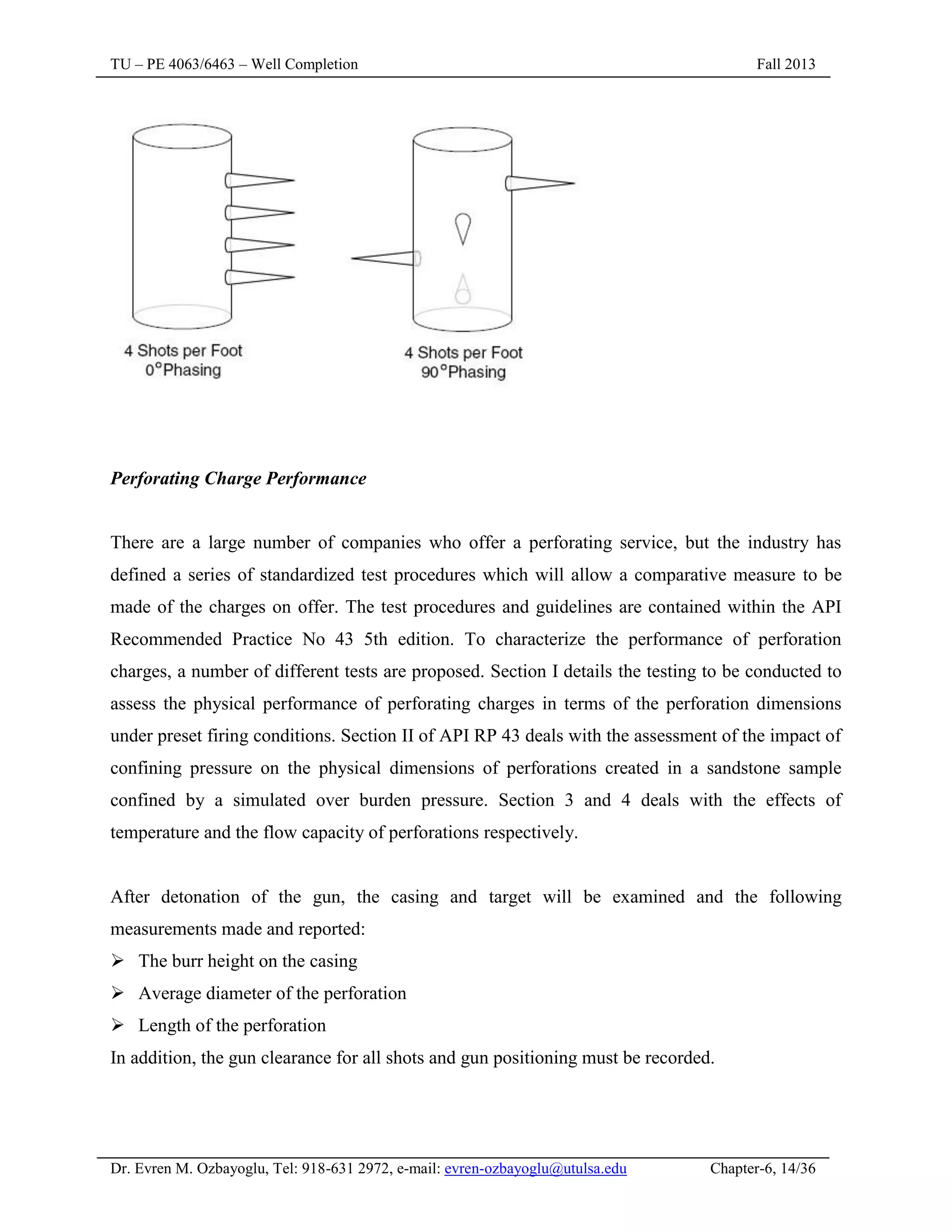

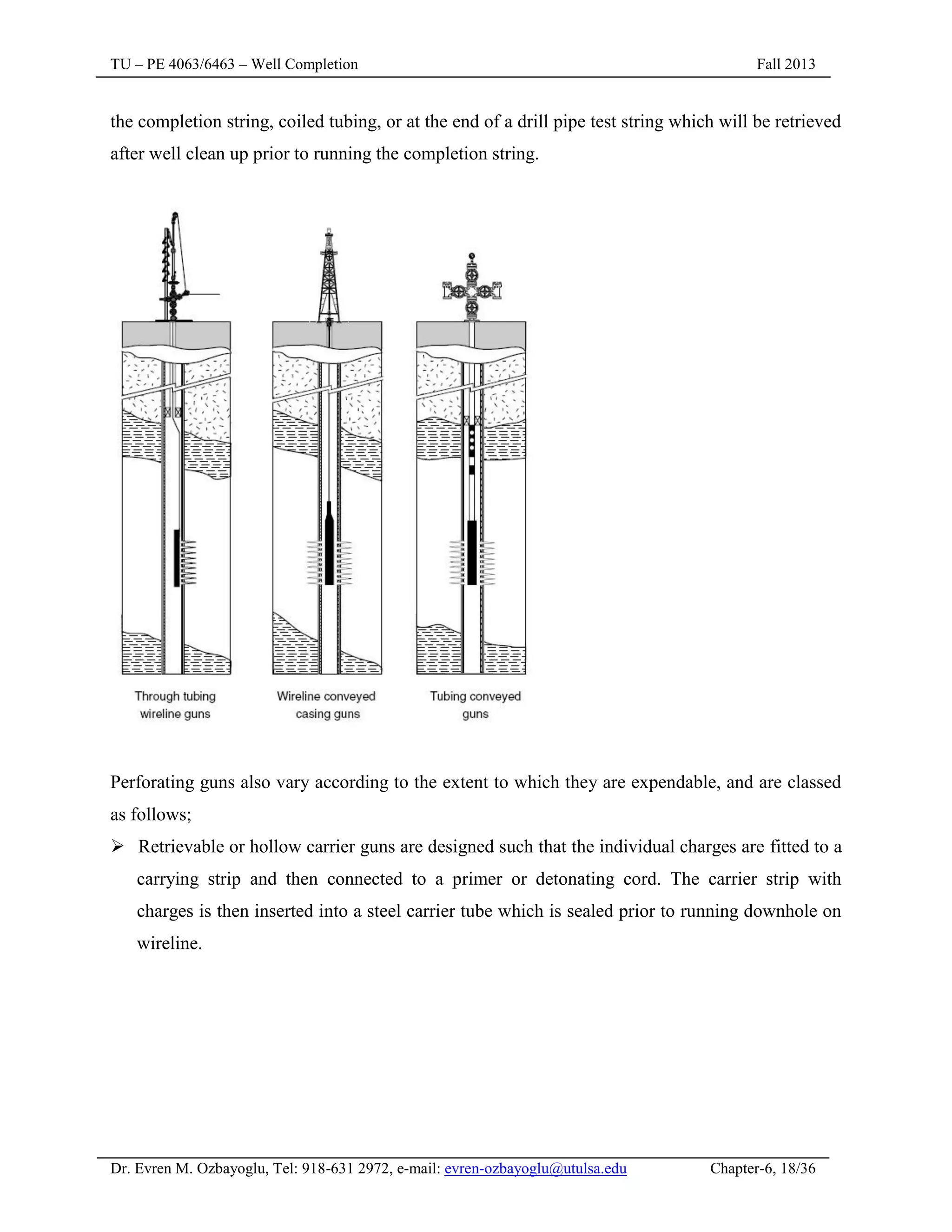

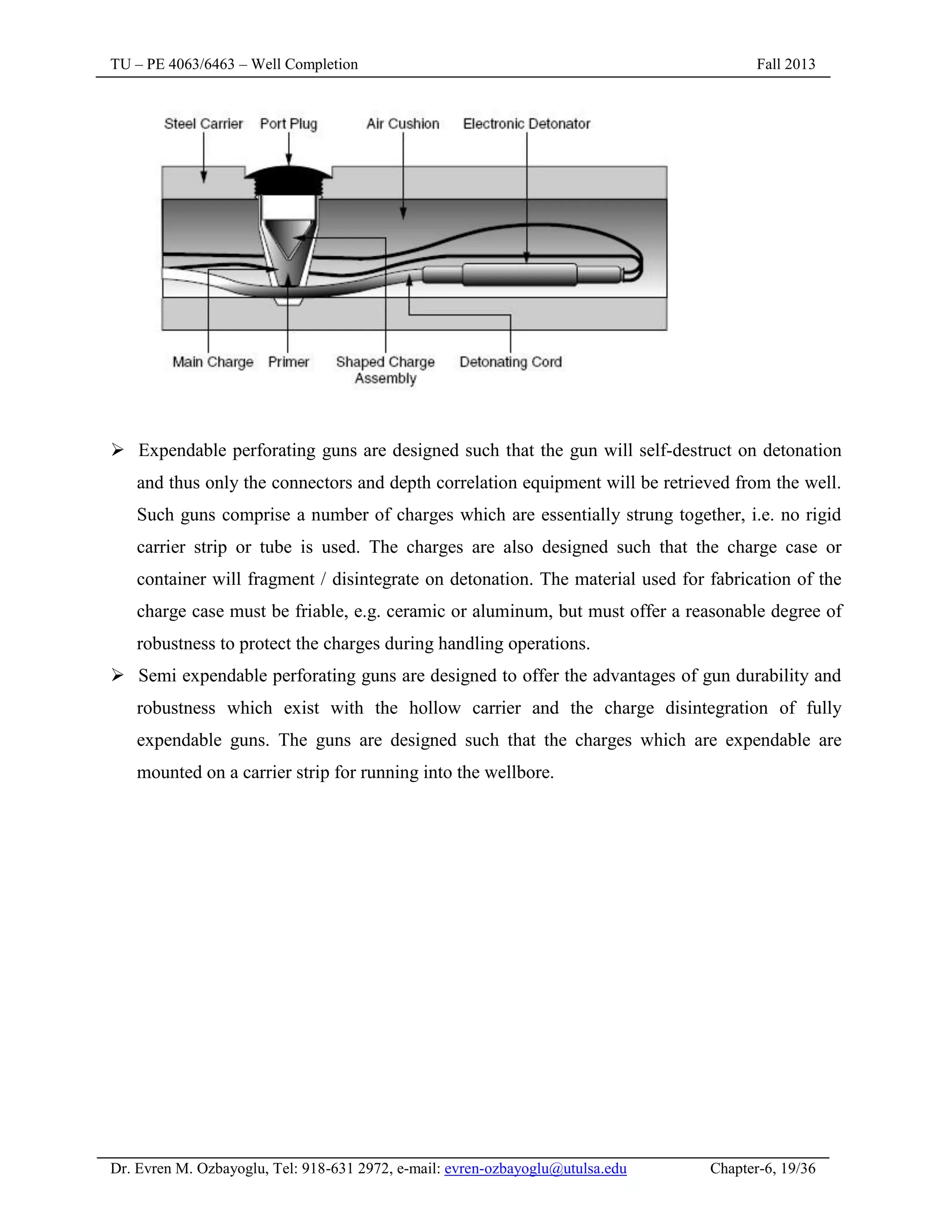

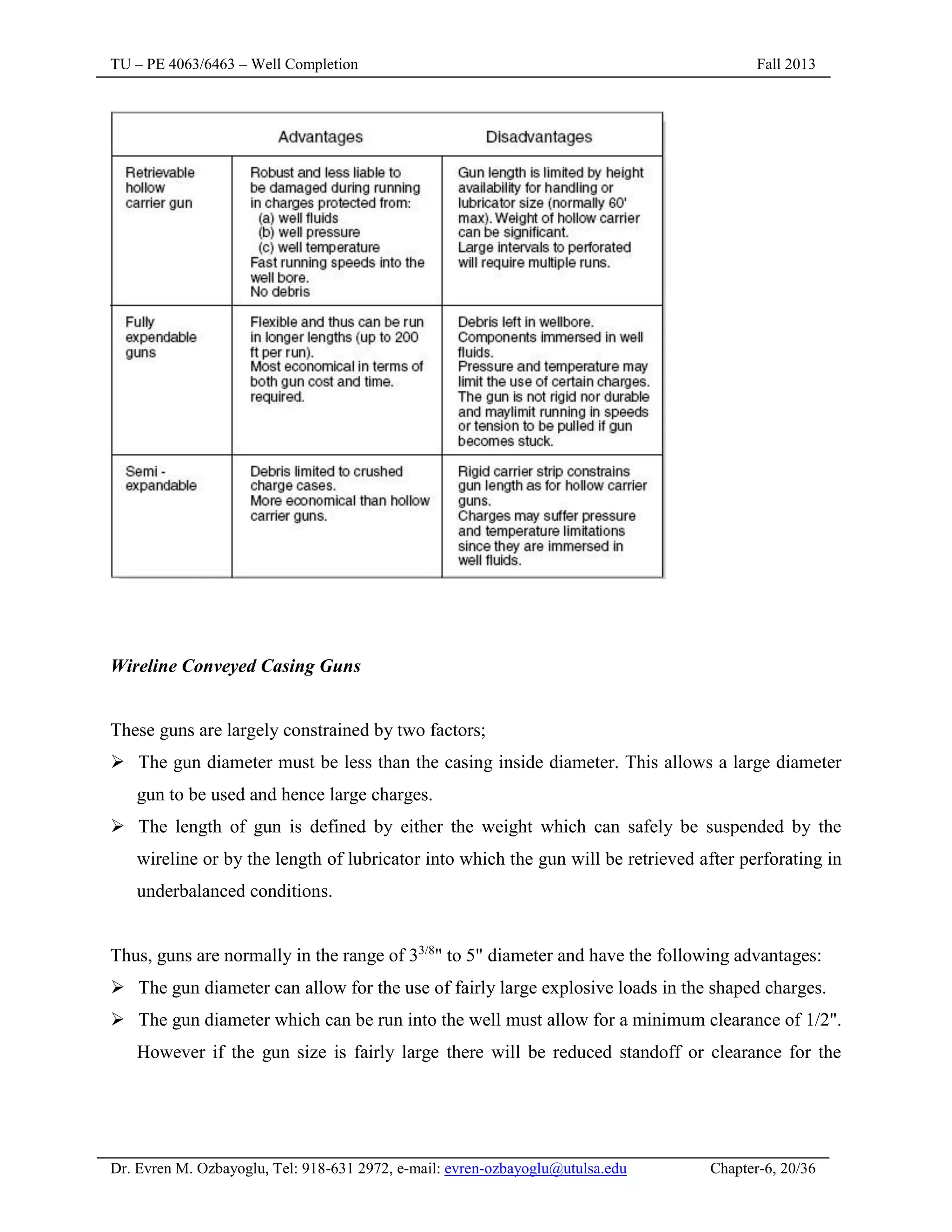

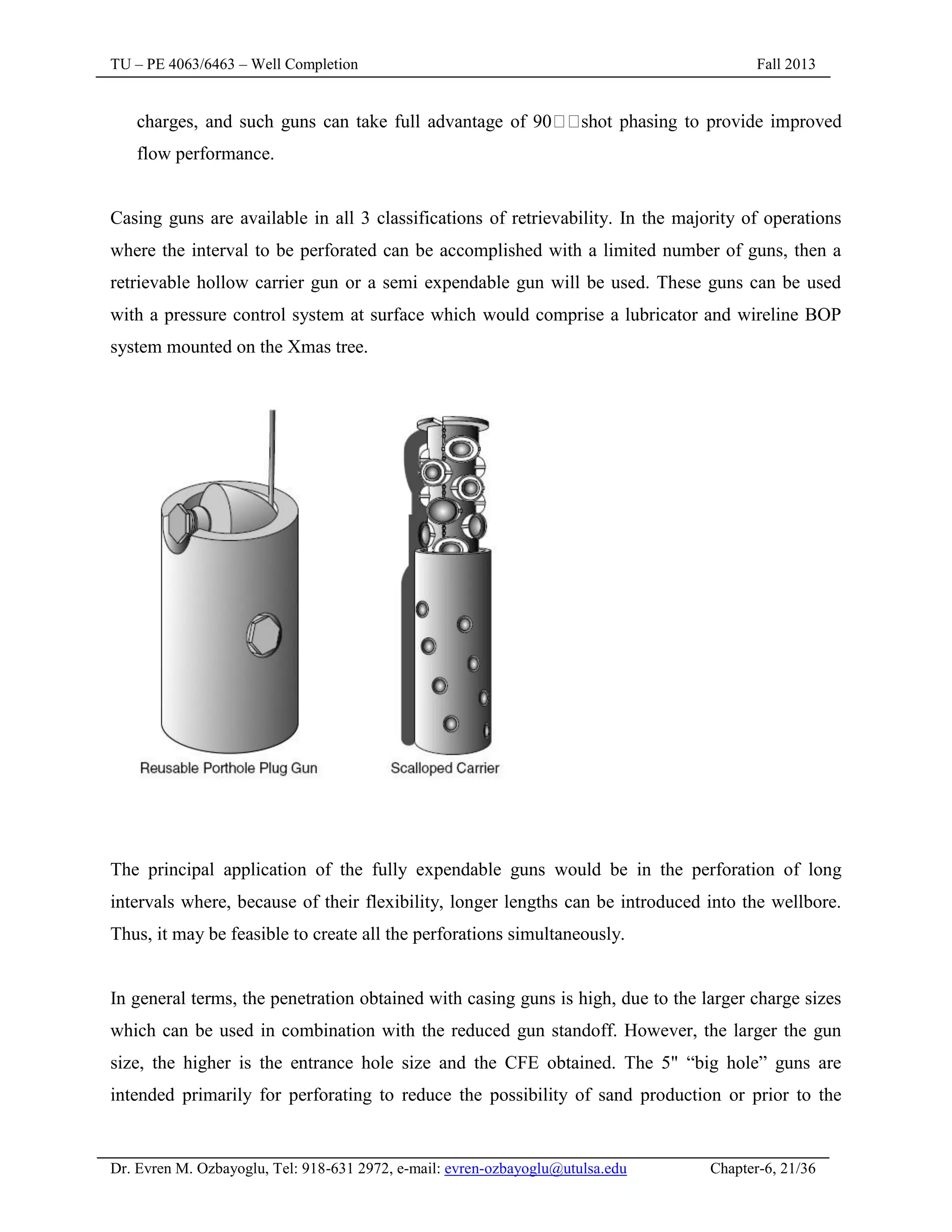

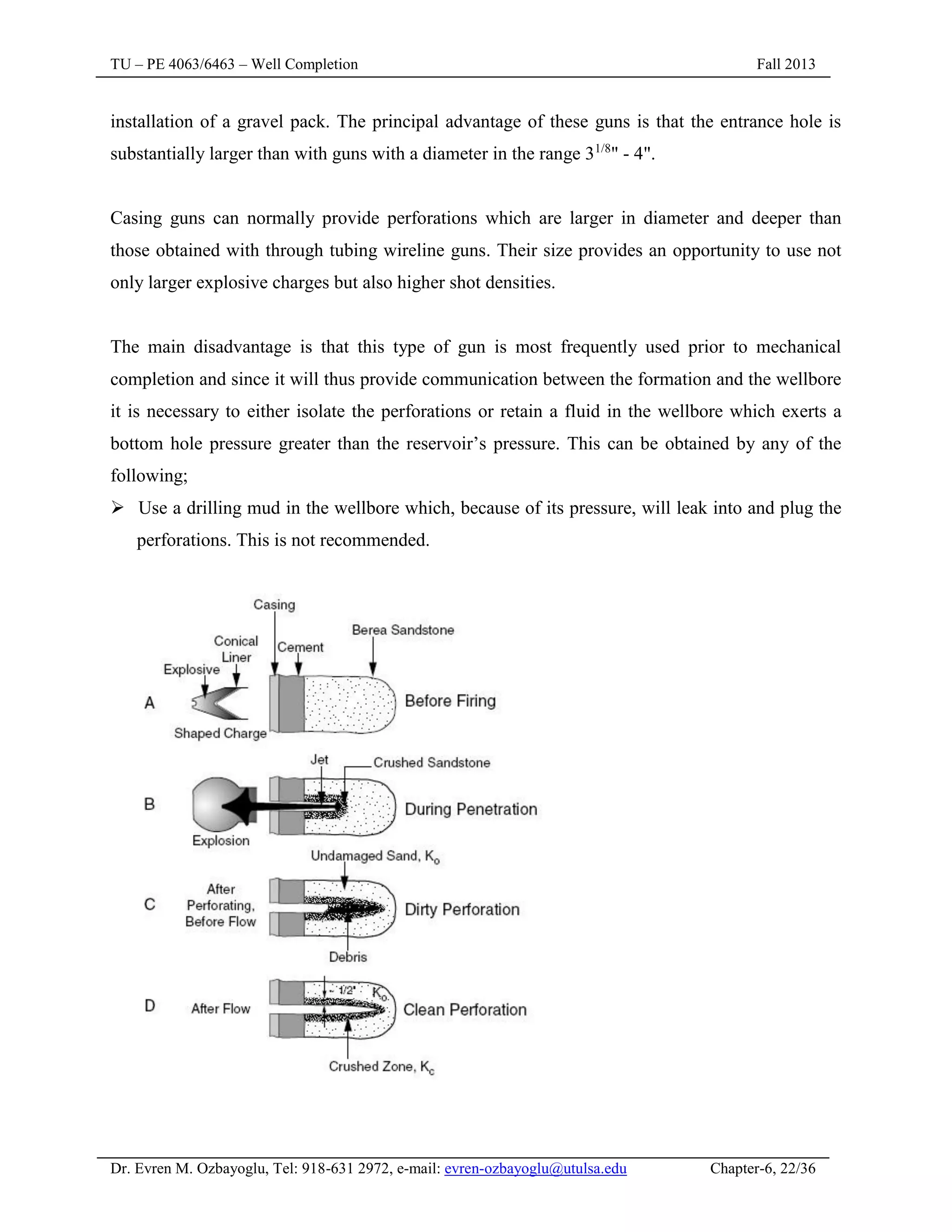

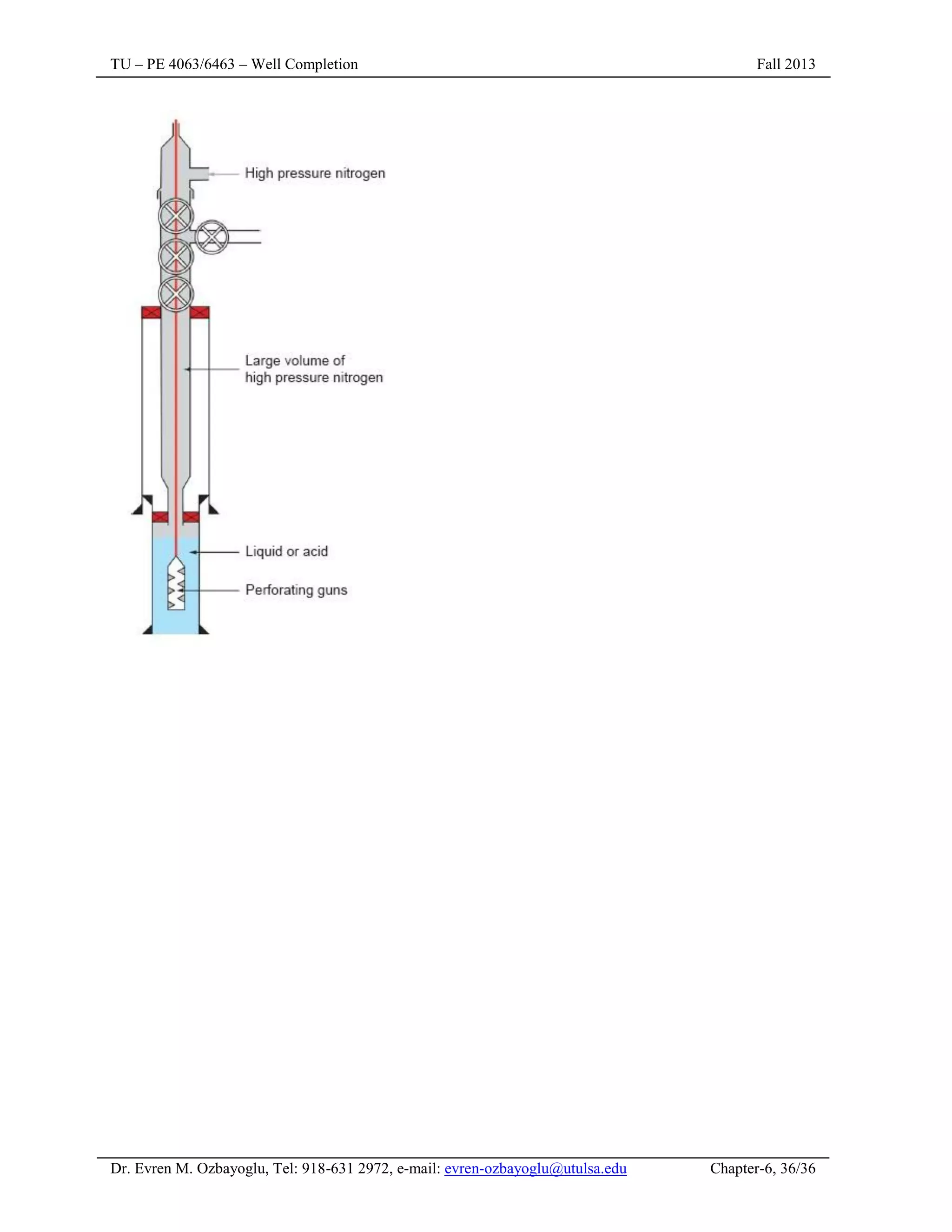

The document discusses perforation, which is the process of using explosive charges to create holes through casing, cement, and into the reservoir formation to provide a connection between the wellbore and reservoir. Shaped charges, which focus explosive energy into a high velocity jet, are used for perforation. Key aspects of shaped charge operation are discussed, including liner design, explosive types, detonation mechanics, and the effects on the formation including compaction and reduced permeability in the perforation tunnel zone. Factors that influence charge performance such as penetration length and perforation diameter are also summarized.