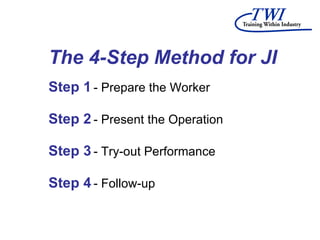

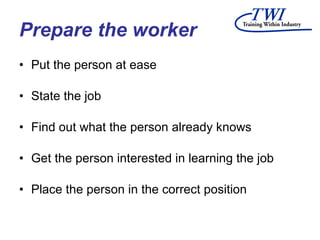

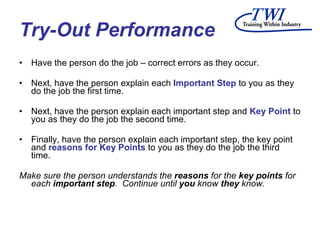

The document outlines the Job Instruction (JI) training method for teaching workers how to perform jobs quickly, safely, and effectively. The 4-step JI method includes preparing the worker, presenting the operation through demonstration and explanation, having the worker try out the task, and following up for support and evaluation. Key aspects of JI training are breaking down each job into important steps, highlighting key points for each step, and explaining the reasons for those key points to help workers learn why certain techniques are important. The goal of this approach is reduced training time and improved job performance through a structured yet personalized teaching process.