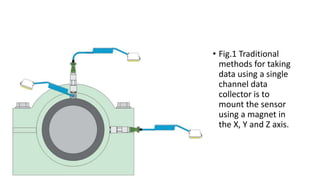

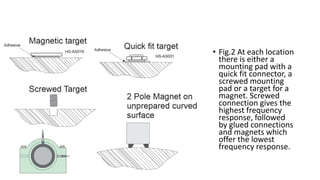

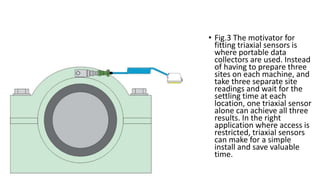

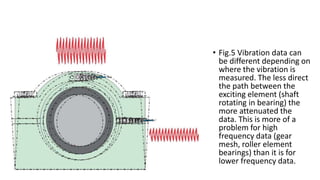

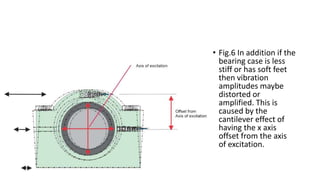

The document compares triaxial and single-axis accelerometers, outlining the advantages of triaxial sensors, such as reduced installation time and preserved phase information in vibration analysis due to simultaneous data collection from three axes. It discusses the various mounting options and the impact of installation on frequency response, as well as potential cost savings in cabling for permanently installed systems. Additionally, it notes the higher cost of triaxial sensors and alternatives for specific machine geometries.