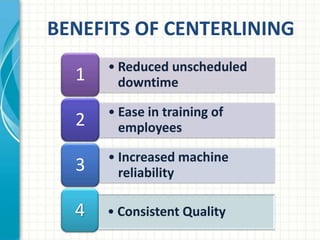

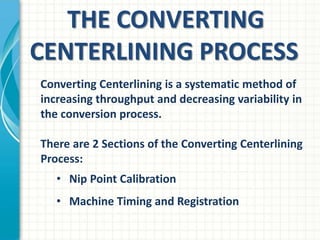

This document discusses converting centerlining, which aims to increase consistency and reduce variability in the converting process. It does this through nip point calibration and machine timing/registration. Nip point calibration ensures components are properly distanced, reducing errors. Timing/registration decreases set-up times and waste by properly positioning machine section gears. Maintaining accurate timing is important as crews' failure to do so commonly undermines centerlining efforts. The document provides examples of external timing marks and emphasizes that consistently keeping machines timed is key to establishing a centerlined, efficient converting process.