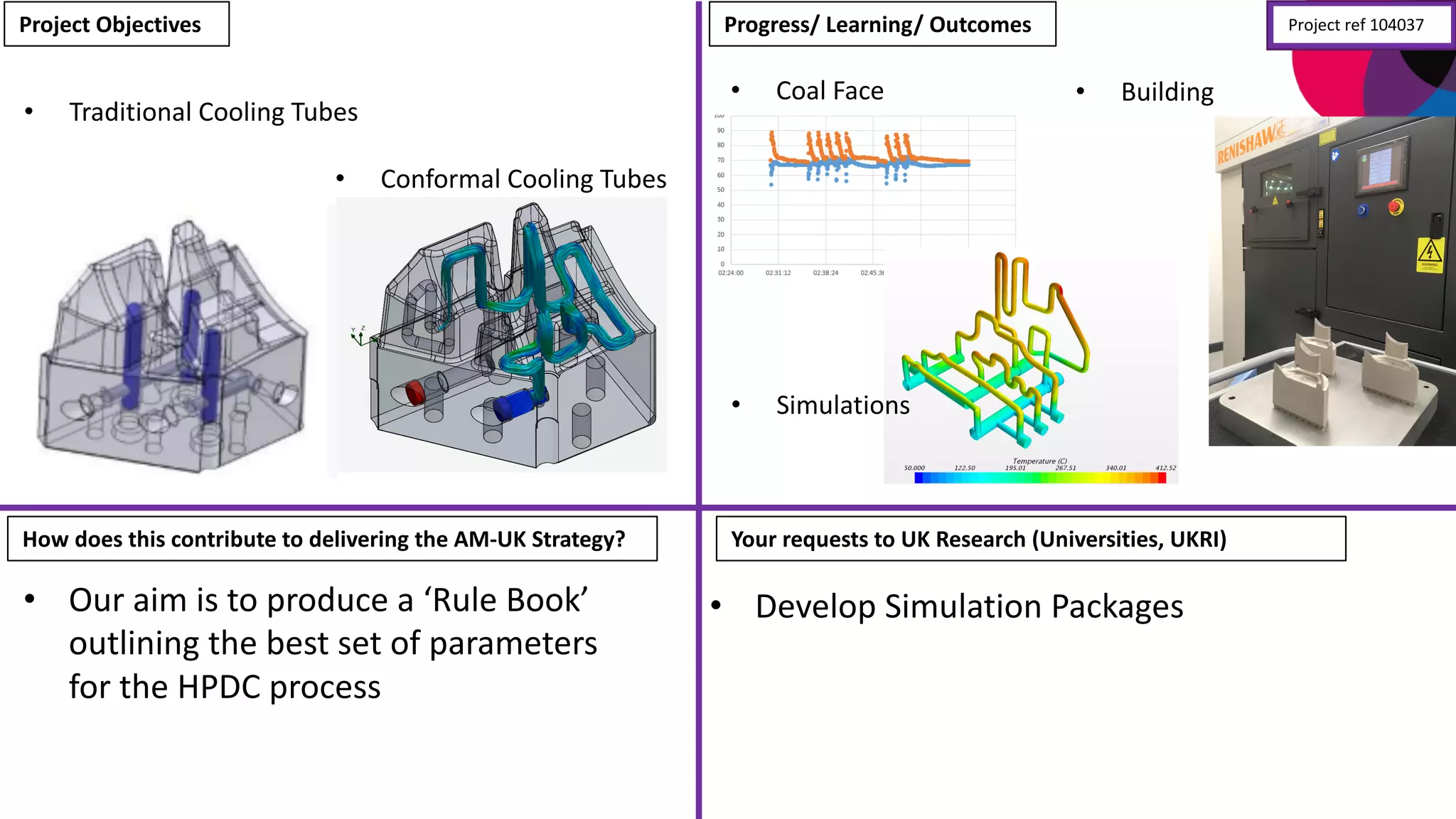

The document presents various projects related to tooling applications and hybrid processes in additive manufacturing, detailing objectives, progress, and outcomes for each initiative. Key projects include conformal cooling for high pressure die casting, an advanced modular platform for faster production, and digital hybrid units aimed at improving repair methods. The emphasis is on collaboration, commercial viability, and the integration of new technologies to enhance efficiency and reduce costs in manufacturing.