Embed presentation

Download to read offline

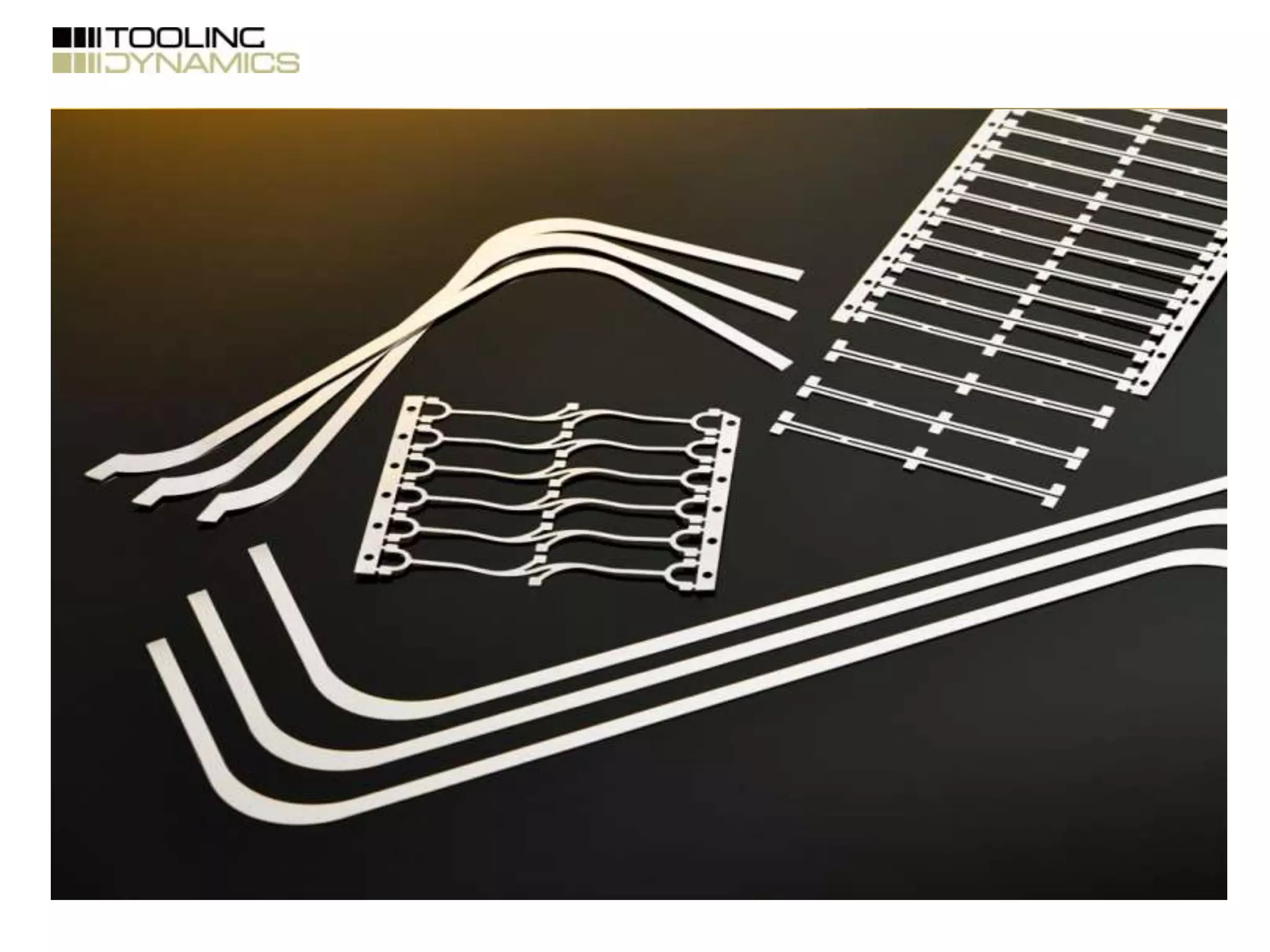

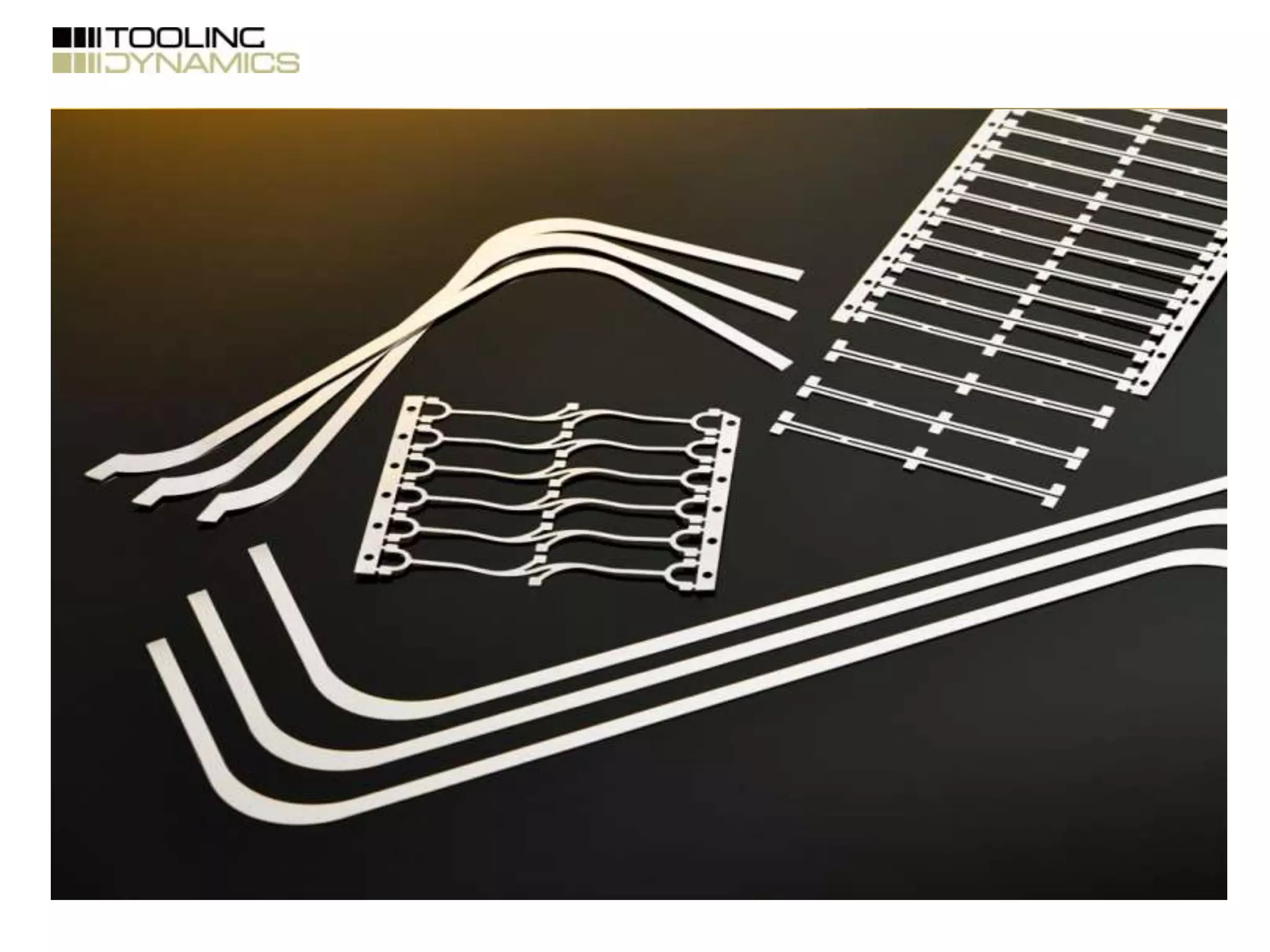

This company has over 30 years of experience manufacturing thin gauge metals with tight tolerances. They have a 80,000 square foot facility with over 70 presses and 40 tool and die makers. They offer full design, prototyping, and production services certified under ISO and TS quality standards.