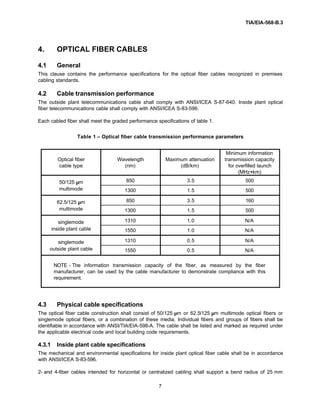

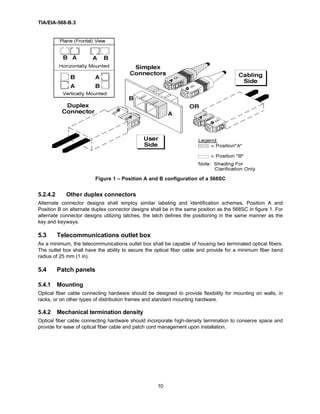

This document provides standards for optical fiber cabling components. It specifies requirements for optical fiber cables, connecting hardware like connectors and patch panels, patch cords, and field test instruments. Requirements include physical specifications, transmission performance, connector design and identification, mounting density, and test methods. The document aims to ensure interoperability between components from different manufacturers.