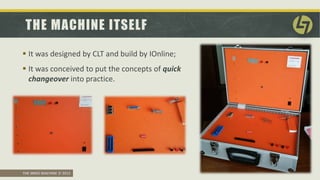

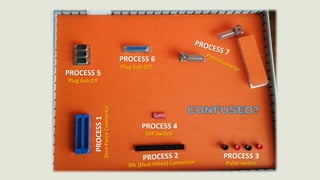

The SMED machine, designed by CLT and built by Ionline, implements quick changeover principles through a series of seven processes crucial for quality production. Each process involves specific procedures, including preparing connectors and switches, with an emphasis on reducing complexity and recording observations for future improvements. Successful completion of these processes allows for machine operation, followed by a review and enhancement of the setup time and efficiency.

![THE SMED MACHINE © 2015

LET’S ANALYSE THE RESULTS

INITIAL SETUP:

TOTAL TIME TO PREPARE THE MACHINE: _______ min

TOTAL RESETS _______

COMMENTS, SUGGESTIONS AND WHAT CAN BE CHANGED?

[…]

FINAL SETUP:

TOTAL TIME TO PREPARE THE MACHINE _______ min

Main improvements made?

Lessons learned?](https://image.slidesharecdn.com/thesmedmachine-150212163024-conversion-gate02/85/The-Setup-Machine-18-320.jpg)