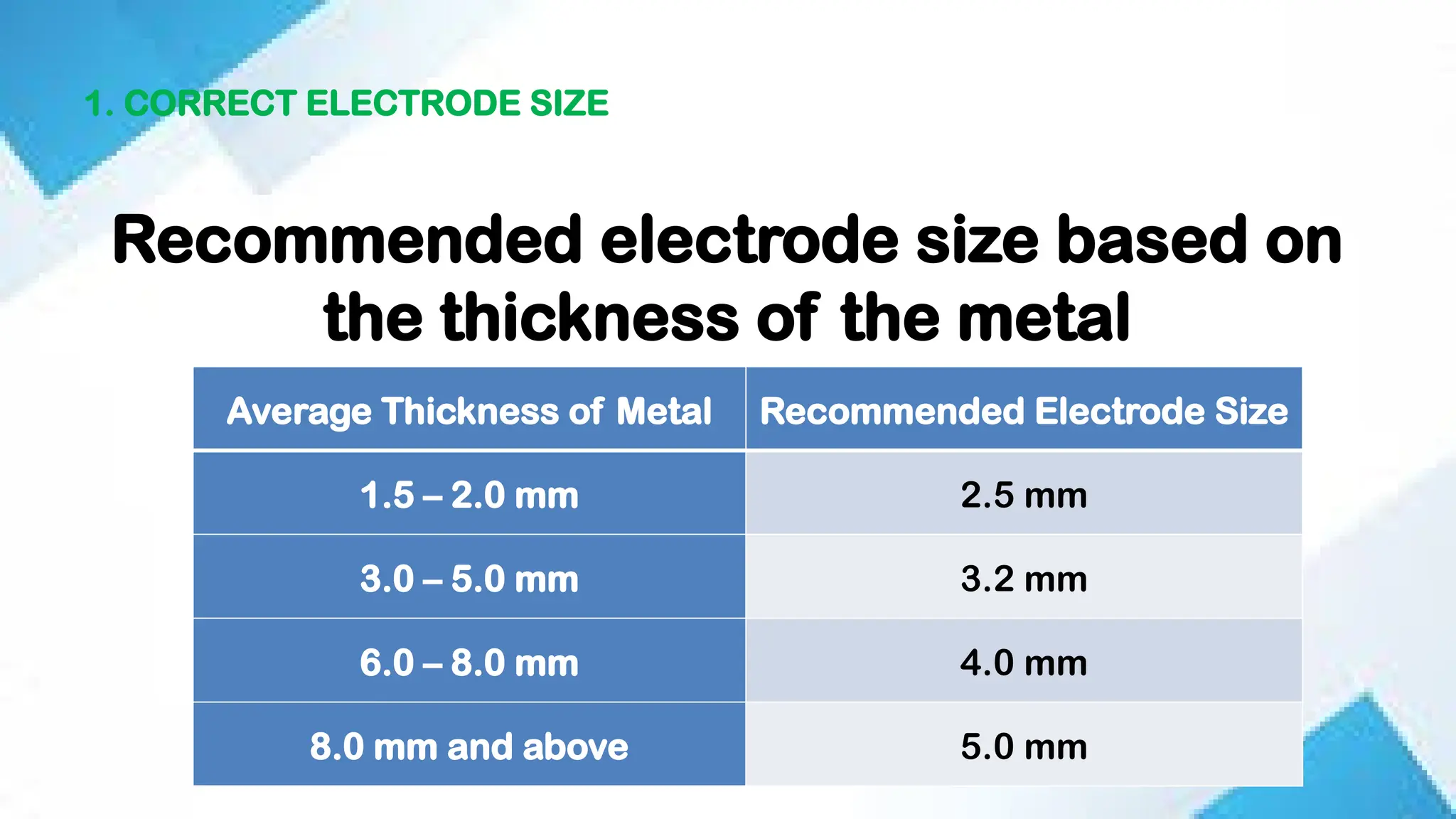

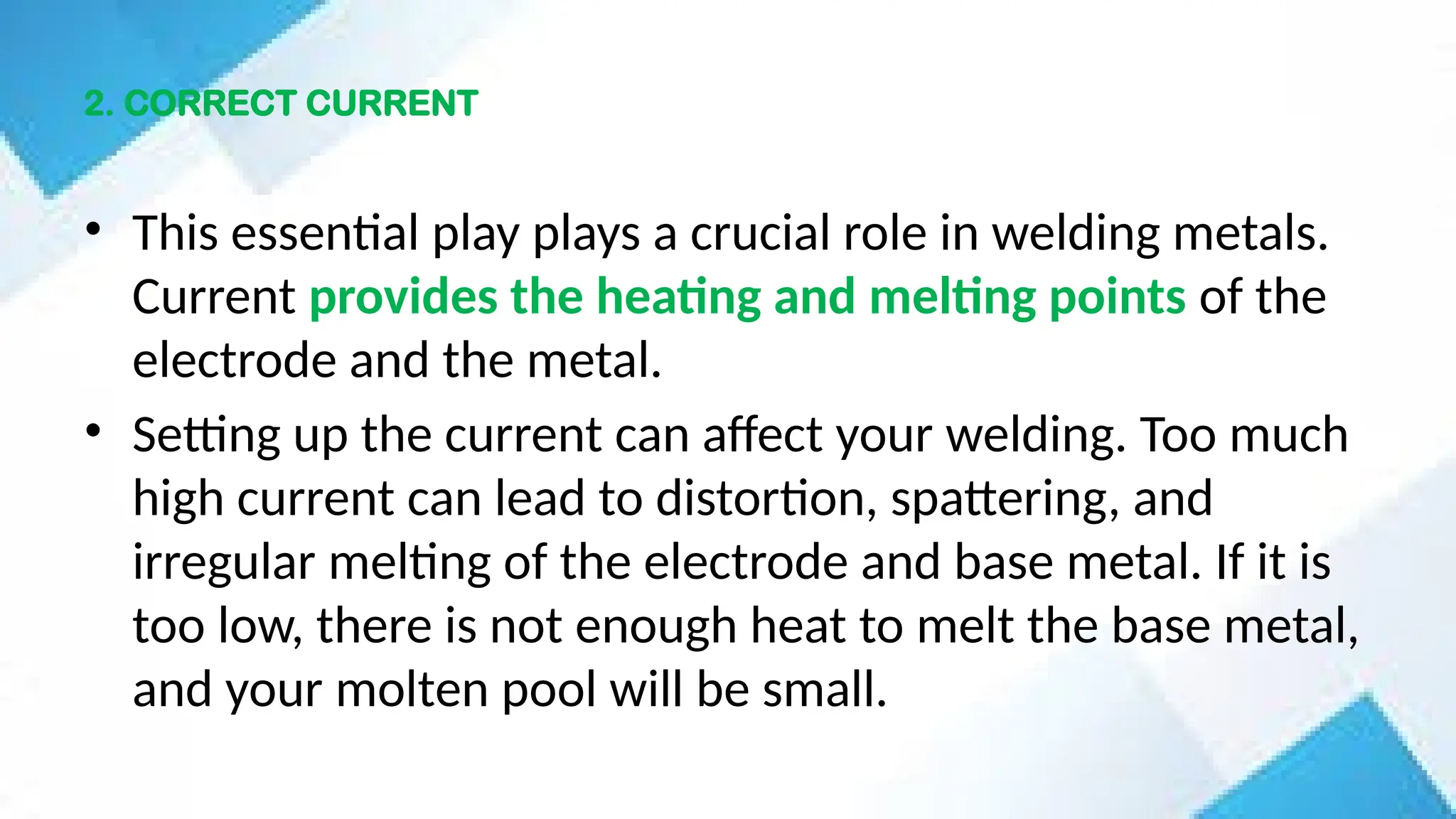

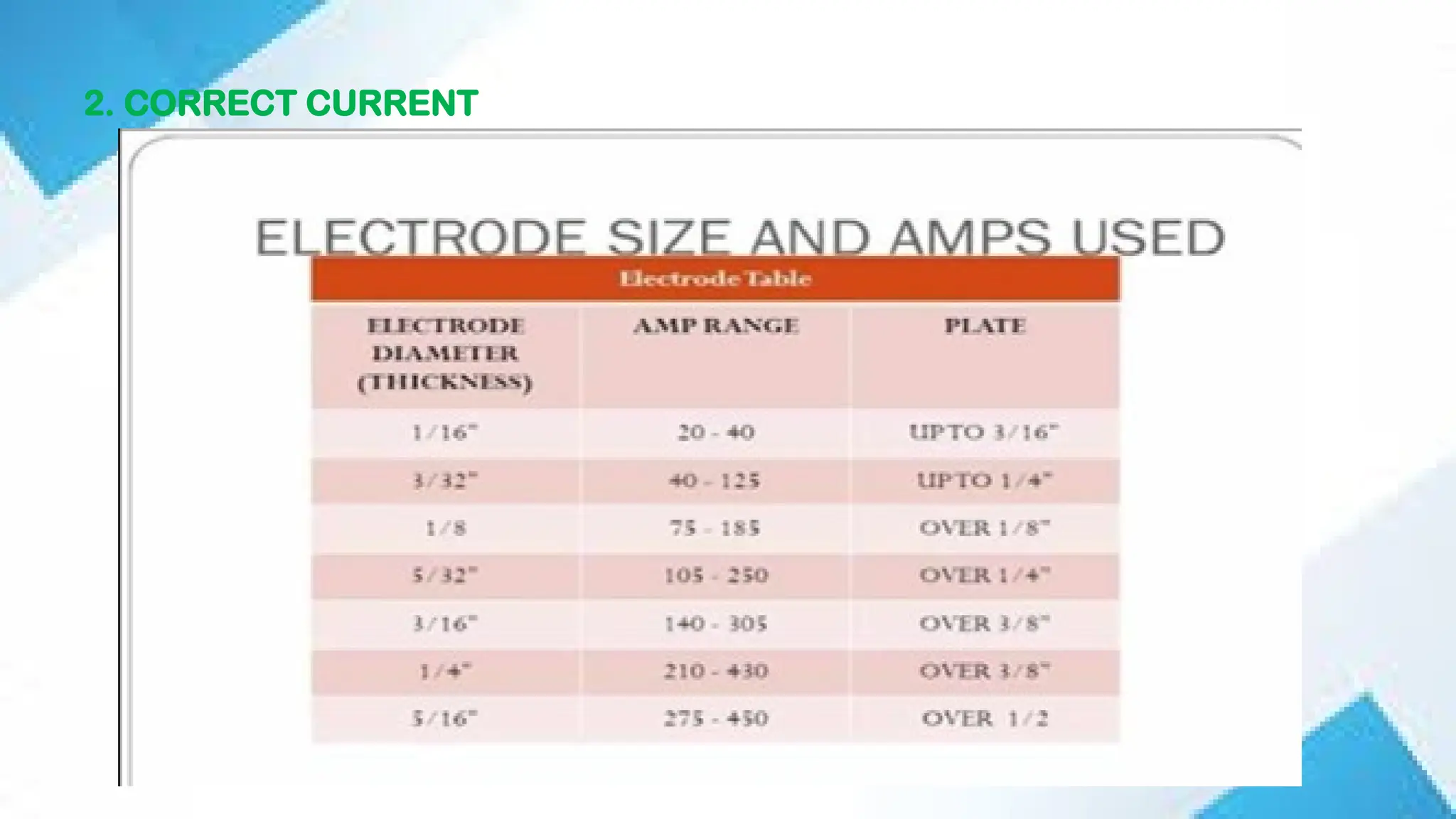

The document outlines the 5 essentials for obtaining quality welds, including correct electrode size, current, arc length, travel speed, and electrode angle. It provides descriptions, synonyms, and the importance of each factor in the welding process, as well as activities for group participation and evaluation criteria. Additionally, the document includes multiple-choice questions to assess understanding of the material.