The e-mp series features high pressure multistage pumps designed according to ISO 5199 standards, suitable for various applications in industries such as oil and gas, power plants, mining, and agriculture. The pumps are characterized by their flexible configurations, hydraulic performance, and ability to handle a wide range of fluids, including hot, grey, and seawater. Detailed technical specifications, including design versions, operating data, and pumpable fluids, are provided to assist in project management and selection.

![HYDRAULIC PERFORMANCE RANGE AT 60 Hz, 2 POLES

HYDRAULIC PERFORMANCE RANGE AT 60 Hz, 4 POLES

Q [US gpm]

005004003002080706050403028765 10 100

H[ft]

200

300

400

600

700

800

900

500

Q [l/s]

008006005004003002080605040302 100 1000

H[m]

500

1000

1500

2000

2500

3000

Q [Imp gpm]

080706050403028765432 10 100

Q [m 3

/h]

000200800700600500400300208070605040302 100 1000

e-MP 2102:6099OSI]mpr[0553

GA0009_A_CH

e-MP 50, 65, 100, 125

00400300208070605040302876543 10 100

H[ft]

100

150

200

250

300

Q [l/s]

00800600500400300208060504030210 100 1000

H[m]

200

300

400

500

600

700

800

900

1000

1100

Q [Imp gpm]

0807060504030287654328.07.0 1 10 100

Q [m 3

/h]

000200800600500400300208060504030210 100 1000

e-MP 2102:6099OSI]mpr[0571

GA0010_A_CH

e-MP 50, 65, 100, 125, 150

Q [US gpm]

--- G&L 100 bar version. Contact factory for more information.

PAGE 4

e-MP Series

Goulds Water Technology](https://image.slidesharecdn.com/bemp-r1-171024181502/85/The-e-MP-Series-4-320.jpg)

![Pump Type [2 characters]

[MP] = Highly efficient and flexible

Multistage, radially split, segmented

casing Pump, the new member of

Xylem’s e-product range

Configuration [1 character]

[A] = Horizontal design

Axial suction, radial discharge

1 Roller bearing discharge side

1 Slide bearing suction side

[R] = Horizontal design

Radial suction and discharge

1 Roller bearing discharge side

1 Slide bearing suction side

[V] = Vertical design

Radial suction and discharge

1 Roller bearing discharge side

1 Slide bearing suction side

[D] = Horizontal design

Radial suction and discharge

2 Roller bearings

Double bearing

Pump size [3 to 4 characters]

[50A]

[50B]

[65A]

[65B]

[100A]

[100B]

[125A]

[125B]

[150A]

[150B]

Motor enclosure

[1 character]

[D] = ODPE

[T] = TEPE

[W] = WDPE

[X] = XPE

Motor HP

[2 to 4 characters]

e.g. [0500] = 500HP

No. of poles

[1 character]

[2] = 2 poles

[4] = 4 poles

M P V 1 2 5 B - 0 2 A B R S - 0 5 0 0 T T F 2 6 B - N N N 4

Combination of full and trimmed impellers

[1 character]:

[A] = all impeller full diameter

[B] = trimmed/full impellers combination 1

[C] = trimmed/full impellers combination 2

[D] = trimmed/full impellers combination 3

[E] = trimmed/full impellers combination 4

[X] = duty point trimmed

Motor frequency and voltage

[2 characters]

50 Hz

[5B]= 190/380-415V

[5C]= 190/380V

[5D]= 220V

[5E]= 380V

[5F]= 415V

[5X]= Other Voltage

60 Hz

[6B]= 208-230/460V

[6C]= 230/460V

[6D]= 200V

[6E]= 230V

[6F]= 460V

[6G]= 575V

[6X]= Other voltage

Casing material [1 character]

[C] = Cast iron

[D] = Ductile iron

[F] = Cast steel

[N] = Stainless steel

[R] = Duplex

[T] = Super duplex

[X] = Others

Impeller material [1 character]

[C] = Cast iron

[B] = Bronze

[N] = Stainless steel

[R] = Duplex

[T] = Super duplex

[X] = Others

Mechanical Seal and O-Ring materials

[1 character]

[4] = Carbon/SiC/EPDM

[2] = Carbon/SiC/FPM

[Z] = SiC/SiC/EPDM

[W] = SiC/SiC/FPM

[N] = Tungsten carbide/ SiC/FPM

[X] = Others

[-] = Soft packing

IDENTIFICATION CODE

EXAMPLES:

Pump coupled with motor

MPV125B-02ABRS-0500TTF26B-NNN4

Series eMP,vertical configuration,radial

suction and discharge,size DN125,hydraulic

B,2 stages/impellers,all impellers with full

diameter,flange orientation: left suction and

rear discharge,ANSI suction flange class

150,ANSI discharge flange class 300,500HP

factory choice motor withTEPE enclosure,

5009SD frame size,2 poles,60Hz at 208-

230/460V,stainlesssteelcasings,stainlesssteel

impeller,stainless steel diffusers,mechanical

seal Carbon/SiC/EPDM.

Material diffuser [1 character]

[C] = Cast iron

[N] = Stainless steel

[R] = Duplex

[T] = Super duplex

[X] = Others

Number of stages/impellers [2 characters], e.g.:

[04] = 4 stages

ANSI suction flange class

[1 character]

[R] = 150

[S] = 300

Seal Type [1 character]

[ ] = Mechanical seal, standard

[C] = Cartridge seal

[P] = Soft packing

ANSI discharge flange class

[1 character]

[R] = 150

[S] = 300

[T] = 600

NOTE:

1) “e-” in front of MP is used for all marketing materials and in the

selection tools.

2) “e-” in front of MP is NOT used on the name plate and NOT in

denomination of pumps.

3)Notusednomenclaturecharacters,e.g.ifthecharacterdescription

is[]areskippedandthenextusedcharacterisshiftedtotheleft.

Frame size

[1 character]

[B] = 182TD/184TD

[C] = 213TD/215TD

[D] = 254TD/256TD

[E] = 284TSD/286TSD

[F] = 284TD/286TD

[G] = 324TSD/326TSD

[H] = 324TD/326TD

[J] = 364TSD/365TSD

[K] = 364TD/365TD

[L] = 404TSD/405TSD

[M] = 404TD/405TD

[N] = 444TSD/445TSD

[P] = 444TD/445TD

[R] = 447TSD/449TSD

[S] = 447TD/449TD

[T] = 5007SD/5008SD

[U] = 5009SD/5010SD

[V] = 5011DZ/5012DZ

[W] = G40S

Motor type

[1 character]

[F ]= Factory choice

[X] = Other

[A] = Motor not part of scope

Flange Orientation [1 character]

MPA

[A]= End Suction, Top Discharge (code AO)

[B]= End Suction, Left Discharge (code AL)

[C]= End Suction, Right Discharge (code AR)

MPD and MPR

[A]= Left Suction, Top Discharge (code LO)

[B]= Right Suction, Top Discharge (code RO)

[C]= Top Suction, Top Discharge (code OO)

[D]= Left Suction, Right Discharge (code LR)

[E]= Top Suction, Right Discharge (code OR)

[F]= Right Suction, Right Discharge (code RR)

[G]=Right Suction, Left Discharge (code RL)

[H]= Top Suction, Left Discharge (code OL)

[J]= Left Suction, Left Discharge (code LL)

MPD shaft driven from the suction end

[1]= Left Suction, Top Discharge (code LOS)

[2]= Right Suction, Top Discharge (code ROS)

[3]= Top Suction, Top Discharge (code OOS)

[4]= Left Suction, Right Discharge (code LRS)

[5]= Top Suction, Right Discharge (code ORS)

[6]= Right Suction, Right Discharge (code RRS)

[7]=Right Suction, Left Discharge (code RLS)

[8]= Top Suction, Left Discharge (code OLS)

[9]= Left Suction, Left Discharge (code LLS)

MPV

[A] = Left Suction, Left Discharge (code OO)

[B] = Left Suction, Rear Discharge (code OR)

[C] = Left Suction, Front Discharge (code OL)

[D] = Left Suction, Right Discharge (code OG)

Pump mounted on frame,with coupling,

motor not part of scope

MPV125B-02ABRS-0500TTA26B-NNN4

Series eMP,vertical configuration,radial

suction and discharge,size DN125,hydraulic

B,2 stages/impellers,all impellers with full

diameter,flange orientation: left suction and

rear discharge,ANSI suction flange class

150,ANSI discharge flange class 300,to be

used with motor frame size 5009SD,2 poles

(motor not part of scope),stainless steel

casings,stainless steel impeller,stainless

steel diffusers,mechanical seal Carbon/

SiC/EPDM.

Bareshaft pump (only for horizontal

configurations)

MPA125B-02AARS-NNN4

SerieseMP,verticalconfiguration,radialsuction

anddischarge,sizeDN125,hydraulicB,2stages/

impellers,allimpellerswithfulldiameter,flange

orientation:endsuctionandtopdischarge,ANSI

suctionflangeclass150,ANSIdischargeflange

class300,motorandcouplingnotpartofscope,

stainless steel casings, stainless steel impeller,

stainlesssteeldiffusers,mechanicalsealCarbon/

SiC/EPDM.of scope), stainless steel casings,

stainless steel impeller, stainless steel diffusers,

mechanical seal Carbon/SiC/EPDM.

PAGE 9

e-MP Series

Goulds Water Technology](https://image.slidesharecdn.com/bemp-r1-171024181502/85/The-e-MP-Series-9-320.jpg)

![MECHANICAL SEAL SELECTION DIAGRAM

0

100

200

300

400

500

600

0 50 100 150 200 250 300

pIN[psi]

t [°F]

Limit - X

Limit - Y

Limit - Z

..............

minimum pressure

on suction flange

C1 C2

A

B

MP_Limit_Mech_Seal-en_a_td

LIMIT CURVES

DEPENDING ON PUMP HYDRAULICS AND MOTOR SPEED

U

U

U

Up to 580 psi inlet pressure at maximum 176°F (up to 435 psi inlet

pressure at maximum 284°F).

MP_Mech_Seal-us_a_td

PIN

....Pump inlet pressure at suction flange [psi]

GENERAL CONSIDERATIONS

This diagram and selection table is valid for clean water (solids < 0.0013 oz/US gallon) or water for feeding

boilers, partially or totally demineralized.

If the water temperature exceeds 176 °F, minimum inlet pressure must be guaranteed.

3550 2900 1750 1450

PAGE 23

e-MP Series

Goulds Water Technology](https://image.slidesharecdn.com/bemp-r1-171024181502/85/The-e-MP-Series-23-320.jpg)

![PRESSURE / TEMPERATURE CHARTS FOR PUMP FLANGES

ACCORDING TO ANSI B16.5 AND CASING MATERIAL

0

50

100

150

200

250

300

350

400

450

500

550

600

0 50 100 150 200 250 300

Pressure(psi)

Temperature (°F)

Material: Cast Iron - Cast Iron (JL 1040)

Class 300

Class 150

0

100

200

300

400

500

600

700

800

900

1000

0 50 100 150 200 250 300 350 400

Pressure(psi)

Temperature [°F]

Material: Ductile Iron (JS 1030)

Class 150

Class 300

Class 600

0

50

100

150

200

250

300

350

400

450

500

550

600

650

0 50 100 150 200 250 300 350 400

Pressure(psi)

Temperature [°F]

Material: Austenitic Stainless Steel (1.4408)

Class 150

Class 300

0

100

200

300

400

500

600

700

800

900

1000

0 50 100 150 200 250 300 350 400

Pressure(psi)

Temperature [°F]

Material: Duplex (1.4517) & Super Duplex (1.4469)

Class 150

Class 300

Class 600

PAGE 24

e-MP Series

Goulds Water Technology](https://image.slidesharecdn.com/bemp-r1-171024181502/85/The-e-MP-Series-24-320.jpg)

![HYDRAULIC PERFORMANCE RANGE AT 60 Hz, 2 POLES

HYDRAULIC PERFORMANCE RANGE AT 60 Hz, 4 POLES

Q [US gpm]

006005004003002090807060504030298765 10 100

H[ft]

250

350

450

550

200

300

400

500

600

Q [l/s]

20 30 40 50 60 80 200 300 400 500 600 800 2000100 1000

H[m]

500

1000

1500

2000

Q [Imp gpm]

090807060504030298765432 10 100

Q [m 3

/h]

00020090080070060050040030020908070605040302 100 1000

e-MP ~ 3550 [rpm] ISO 9906:2012

GA0007_A_CH

125B125A100B100A65B65A50B50A

Q [US gpm]

00400300208070605040302876543 10 100

H[ft]

100

150

200

250

300

Q [l/s]

00800600500400300208060504030210 100 1000

H[m]

200

300

400

500

600

700

800

900

1000

1100

Q [Imp gpm]

0807060504030287654328,07,0 1 10 100

Q [m 3

/h]

0080060040020806040210 100 1000

e-MP 2102:6099OSI]mpr[0571~

GA0008_A_CH

150B150A125B125A100B100A65B65A50B50A

PAGE 31

e-MP Series

Goulds Water Technology](https://image.slidesharecdn.com/bemp-r1-171024181502/85/The-e-MP-Series-31-320.jpg)

![e-MP50A SERIES - OPERATING CHARACTERISTICS AT 60 Hz, 2 POLES

e-MP50A/01 3550 [rpm] ISO 9906:2012 - Grade 2B

0 2 4 6 8 10 12 14 16 18

0 50 100 150 200 Q [Imp gpm]

Q [l/s]

1A

1B

1C

68.4

66.8

63.3

67

67

65

65

60

60

5550

0 10 20 30 40 50 60

0

10

20

30

40

50

60

0

20

40

60

80

100

120

140

160

180

200

Q [m3/h]

H[m]

H[ft]

η[%]

0

2

4

6

8

0

5

10

15

20

25

30

NPSH[m]

NPSH[ft]

e-MPR, e-MPD, e-MPV

1A

1B

1C01C

0

1

2

3

4

5

6

7

8

0

2

4

6

8

10

12

0 50 100 150 200 250 300

PP[kW]

Pp[HP]

Q [US gpm]

e-MP50A-01_60Hz_2_US_A

Ø169mm

Ø157mm

Ø145mm

e-MPA

e-MP50A/02 3550 [rpm] ISO 9906:2012 - Grade 2B

0 2 4 6 8 10 12 14 16 18

0 50 100 150 200 Q [Imp gpm]

Q [l/s]

2A

2B

2C

68.4

66.8

63.363.363.3

0 10 20 30 40 50 60

0

20

40

60

80

100

120

0

50

100

150

200

250

300

350

400

Q [m3/h]

H[m]

H[ft]

η[%]

0

2

4

6

8

0

10

20

30

NPSH[m]

NPSH[ft]

e-MPR, e-MPD, e-MPV

2A

2B

2C2C2C

0

2

4

6

8

10

12

14

16

18

0

5

10

15

20

25

0 50 100 150 200 250 300

PP[kW]

Pp[HP]

Q [US gpm]

e-MP50A-02_60Hz_2_US_A

2xØ242mm

2xØ157mm

2xØ145mm

e-MPA

e-MP50A/03 3550 [rpm] ISO 9906:2012 - Grade 2B

0 2 4 6 8 10 12 14 16 18

0 50 100 150 200 Q [Imp gpm]

Q [l/s]

3A

3B

3C3C

68.4

67.3

64.964.964.9

0 10 20 30 40 50 60

0

20

40

60

80

100

120

140

160

180

0

100

200

300

400

500

600

Q [m3/h]

H[m]

H[ft]

η[%]

0

2

4

6

8

0

10

20

30

NPSH[m]

NPSH[ft]

e-MPR, e-MPD, e-MPV

3A

3B

3C3C3C

0

5

10

15

20

25

0

5

10

15

20

25

30

35

0 50 100 150 200 250 300

PP[kW]

Pp[HP]

Q [US gpm]

e-MP50A-03_60Hz_2_US_A

3xØ169mm

1xØ169mm/2xØ157mm

1xØ169mm/2xØ145mm

e-MPA

e-MP50A/04 3550 [rpm] ISO 9906:2012 - Grade 2B

0 2 4 6 8 10 12 14 16 18

0 50 100 150 200 Q [Imp gpm]

Q [l/s]

4A4B4C

68.4

67.6

66.866.866.8

0 10 20 30 40 50 60

61

81

101

121

141

161

181

201

221

241

200

300

400

500

600

700

800

Q [m3/h]

H[m]

H[ft]

η[%]

0

2

4

6

8

0

10

20

30

NPSH[m]

NPSH[ft]

e-MPR, e-MPD, e-MPV

4A

4B

4C4C4C

0

5

10

15

20

25

30

35

0

10

20

30

40

50

0 50 100 150 200 250 300

PP[kW]

Pp[HP]

Q [US gpm]

e-MP50A-04_60Hz_2_US_A

4xØ169mm

2xØ169mm/2xØ157mm

4xØ157mm

e-MPA

These performances are valid for cold water with density ρ = 62.42 lb/ft3

and viscosity ν = 1cSt.

PAGE 32

e-MP Series

Goulds Water Technology](https://image.slidesharecdn.com/bemp-r1-171024181502/85/The-e-MP-Series-32-320.jpg)

![e-MP50A SERIES - OPERATING CHARACTERISTICS AT 60 Hz, 2 POLES

e-MP50A/05 3550 [rpm] ISO 9906:2012 - Grade 2B

0 2 4 6 8 10 12 14 16 18

0 50 100 150 200 Q [Imp gpm]

Q [l/s]

5A5B5C

68.4

67.8

67.167.167.1

0 10 20 30 40 50 60

122

142

162

182

202

222

242

262

282

302

400

500

600

700

800

900

1000

Q [m3/h]

H[m]

H[ft]

η[%]

0

2

4

6

8

0

10

20

30

NPSH[m]

NPSH[ft]

e-MPR, e-MPD, e-MPV

5A

5B

5C5C5C

0

10

20

30

40

0

10

20

30

40

50

60

0 50 100 150 200 250 300

PP[kW]

Pp[HP]

Q [US gpm]

e-MP50A-05_60Hz_2_US_A

5xØ169mm

3xØ169mm/2xØ157mm

1xØ169mm/4xØ157mm

e-MPA

e-MP50A/06 3550 [rpm] ISO 9906:2012 - Grade 2B

0 2 4 6 8 10 12 14 16 18

0 50 100 150 200 Q [Imp gpm]

Q [l/s]

6A6B6C

68.4

67.9

67.3

0 10 20 30 40 50 60

152

172

192

212

232

252

272

292

312

332

500

600

700

800

900

1000

1100

Q [m3/h]

H[m]

H[ft]

η[%]

0

2

4

6

8

0

10

20

30

NPSH[m]

NPSH[ft]

e-MPR, e-MPD, e-MPV

6A

6B

6C6C6C

0

10

20

30

40

50

0

10

20

30

40

50

60

70

0 50 100 150 200 250 300

PP[kW]

Pp[HP]

Q [US gpm]

e-MP50A-06_60Hz_2_US_A

6xØ169mm

4xØ169mm/2xØ157mm

2xØ169mm/4xØ157mm

e-MPA

e-MP50A/07 3550 [rpm] ISO 9906:2012 - Grade 2B

0 2 4 6 8 10 12 14 16 18

0 50 100 150 200 Q [Imp gpm]

Q [l/s]

7A7B7C

68.4

67.9

67.5

0 10 20 30 40 50 60

183

233

283

333

383

600

700

800

900

1000

1100

1200

1300

Q [m3/h]

H[m]

H[ft]

η[%]

0

2

4

6

8

0

10

20

30

NPSH[m]

NPSH[ft]

e-MPR, e-MPD, e-MPV

7A

7B

7C7C7C

0

10

20

30

40

50

0

20

40

60

80

0 50 100 150 200 250 300

PP[kW]

Pp[HP]

Q [US gpm]

e-MP50A-07_60Hz_2_US_A

7xØ169mm

5xØ169mm/2xØ157mm

3xØ169mm/4xØ157mm

e-MPA

e-MP50A/08-11 3550 [rpm] ISO 9906:2012 - Grade 2B

0 2 4 6 8 10 12 14 16 18

0 50 100 150 200 Q [Imp gpm]

Q [l/s]

10A

11A

8A

9A

68.4

68.4

68.4

68.4

0 10 20 30 40 50 60

183

233

283

333

383

433

483

533

583

633

600

800

1000

1200

1400

1600

1800

2000

Q [m3/h]

H[m]

H[ft]

η[%]

0

2

4

6

8

0

10

20

30

NPSH[m]

NPSH[ft]

e-MPR, e-MPD, e-MPV

10A

11A

8A

9A

0

20

40

60

80

0

20

40

60

80

100

120

0 50 100 150 200 250 300

PP[kW]

Pp[HP]

Q [US gpm]

MP50A-08-11_60Hz_2_US_A

10xØ169mm

11xØ169mm

9xØ169mm

e-MPA

8xØ169mm

These performances are valid for cold water with density ρ = 62.42 lb/ft3

and viscosity ν = 1cSt.

PAGE 33

e-MP Series

Goulds Water Technology](https://image.slidesharecdn.com/bemp-r1-171024181502/85/The-e-MP-Series-33-320.jpg)

![e-MP50B SERIES - OPERATING CHARACTERISTICS AT 60 Hz, 2 POLES

e-MP50B/01 3550 [rpm] ISO 9906:2012 - Grade 2B

0 5 10 15 20 25

0 50 100 150 200 250 300 Q [Imp gpm]

Q [l/s]

1A

1B

1C1C

74.6

72.2

68.8

72

72

70

70

65

65

605555

0 10 20 30 40 50 60 70 80 90

0

10

20

30

40

50

60

0

20

40

60

80

100

120

140

160

180

200

220

Q [m3/h]

H[m]

H[ft]

η[%]

0

2

4

6

8

0

10

20

30

NPSH[m]

NPSH[ft]

e-MPR, e-MPD, e-MPV

1A

1B

1C1C1C

0

2

4

6

8

10

0

5

10

15

0 50 100 150 200 250 300 350 400

PP[kW]

Pp[HP]

Q [US gpm]

e-MP50B-01_60Hz_2_US_A

1xØ173mm

1xØ161mm

1xØ149mm

e-MPA

e-MP50B/02 3550 [rpm] ISO 9906:2012 - Grade 2B

0 5 10 15 20 25

0 50 100 150 200 250 300 Q [Imp gpm]

Q [l/s]

2A

2B

2C

74.6

72.2

68.8

0 10 20 30 40 50 60 70 80 90

0

20

40

60

80

100

120

0

50

100

150

200

250

300

350

400

Q [m3/h]

H[m]

H[ft]

η[%]

0

2

4

6

8

0

10

20

30

NPSH[m]

NPSH[ft]

e-MPR, e-MPD, e-MPV

2A

2B

2C2C2C

0

5

10

15

20

0

5

10

15

20

25

30

0 50 100 150 200 250 300 350 400

PP[kW]

Pp[HP]

Q [US gpm]

e-MP50B-02_60Hz_2_US_A

2xØ242mm

2xØ161mm

2xØ149mm

e-MPA

e-MP50B/03 3550 [rpm] ISO 9906:2012 - Grade 2B

0 5 10 15 20 25

0 50 100 150 200 250 300 Q [Imp gpm]

Q [l/s]

3A

3B

3C3C

74.6

73.0

70.7

0 10 20 30 40 50 60 70 80 90

61

81

101

121

141

161

181

200

250

300

350

400

450

500

550

600

Q [m3/h]

H[m]

H[ft]

η[%]

0

2

4

6

8

0

10

20

30

NPSH[m]

NPSH[ft]

e-MPR, e-MPD, e-MPV

3A

3B

3C3C3C

0

5

10

15

20

25

30

0

5

10

15

20

25

30

35

40

45

0 50 100 150 200 250 300 350 400

PP[kW]

Pp[HP]

Q [US gpm]

e-MP50B-03_60Hz_2_US_A

3xØ173mm

1xØ173mm/2xØ161mm

1xØ173mm/2xØ149mm

e-MPA

e-MP50B/04 3550 [rpm] ISO 9906:2012 - Grade 2B

0 5 10 15 20 25

0 50 100 150 200 250 300 Q [Imp gpm]

Q [l/s]

4A

4B

4C

74.6

73.4

72.2

0 10 20 30 40 50 60 70 80 90

61

81

101

121

141

161

181

201

221

241

200

300

400

500

600

700

800

Q [m3/h]

H[m]

H[ft]

η[%]

0

2

4

6

8

0

10

20

30

NPSH[m]

NPSH[ft]

e-MPR, e-MPD, e-MPV

4A

4B

4C4C4C

0

5

10

15

20

25

30

35

40

0

10

20

30

40

50

60

0 50 100 150 200 250 300 350 400

PP[kW]

Pp[HP]

Q [US gpm]

e-MP50B-04_60Hz_2_US_A

4xØ173mm

2xØ173mm/2xØ161mm

4xØ161mm

e-MPA

These performances are valid for cold water with density ρ = 62.42 lb/ft3

and viscosity ν = 1cSt.

PAGE 34

e-MP Series

Goulds Water Technology](https://image.slidesharecdn.com/bemp-r1-171024181502/85/The-e-MP-Series-34-320.jpg)

![e-MP50B SERIES - OPERATING CHARACTERISTICS AT 60 Hz, 2 POLES

e-MP50B/05 3550 [rpm] ISO 9906:2012 - Grade 2B

0 5 10 15 20 25

0 50 100 150 200 250 300 Q [Imp gpm]

Q [l/s]

5A5B5C

74.6

73.6

72.7

0 10 20 30 40 50 60 70 80 90

122

142

162

182

202

222

242

262

282

302

400

500

600

700

800

900

1000

Q [m3/h]

H[m]

H[ft]

η[%]

0

2

4

6

8

0

10

20

30

NPSH[m]

NPSH[ft]

e-MPR, e-MPD, e-MPV

5A

5B

5C5C5C

0

10

20

30

40

50

0

20

40

60

80

0 50 100 150 200 250 300 350 400

PP[kW]

Pp[HP]

Q [US gpm]

e-MP50B-05_60Hz_2_US_A

5xØ173mm

3xØ173mm/2xØ161mm

1xØ173mm/4xØ161mm

e-MPA

e-MP50B/08-10 3550 [rpm] ISO 9906:2012 - Grade 2B

0 5 10 15 20 25

0 50 100 150 200 250 300 Q [Imp gpm]

Q [l/s]

10A

8A

9A

74.6

74.6

74.6

0 10 20 30 40 50 60 70 80 90

183

233

283

333

383

433

483

533

583

600

800

1000

1200

1400

1600

1800

2000

Q [m3/h]

H[m]

H[ft]

η[%]

0

2

4

6

8

0

10

20

30

NPSH[m]

NPSH[ft]

e-MPR, e-MPD, e-MPV

10A

8A

9A

0

20

40

60

80

100

0

50

100

150

0 50 100 150 200 250 300 350 400

PP[kW]

Pp[HP]

Q [US gpm]

e-MP50B-08-10_60Hz_2_US_A

10xØ173mm

8xØ173mm

9xØ173mm

e-MPA

These performances are valid for cold water with density ρ = 62.42 lb/ft3

and viscosity ν = 1cSt.

e-MP50B/06 3550 [rpm] ISO 9906:2012 - Grade 2B

0 5 10 15 20 25

0 50 100 150 200 250 300 Q [Imp gpm]

Q [l/s]

6A

6B

6C

74.6

73.8

73.0

0 10 20 30 40 50 60 70 80 90

152

202

252

302

352

500

600

700

800

900

1000

1100

1200

Q [m3/h]

H[m]

H[ft]

η[%]

0

2

4

6

8

0

10

20

30

NPSH[m]

NPSH[ft]

e-MPR, e-MPD, e-MPV

6A

6B

6C6C6C

0

10

20

30

40

50

60

70

0

20

40

60

80

100

0 50 100 150 200 250 300 350 400

PP[kW]

Pp[HP]

Q [US gpm]

e-MP50B-06_60Hz_2_US_A

6xØ173mm

4xØ173mm/2xØ161mm

2xØ173mm/4xØ161mm

e-MPA

e-MP50B/07 3550 [rpm] ISO 9906:2012 - Grade 2B

0 5 10 15 20 25

0 50 100 150 200 250 300 Q [Imp gpm]

Q [l/s]

7A

7B

7C

74.6

73.9

73.2

0 10 20 30 40 50 60 70 80 90

183

233

283

333

383

600

700

800

900

1000

1100

1200

1300

1400

Q [m3/h]

H[m]

H[ft]

η[%]

0

2

4

6

8

0

10

20

30

NPSH[m]

NPSH[ft]

e-MPR, e-MPD, e-MPV

7A

7B

7C7C7C

0

10

20

30

40

50

60

70

0

20

40

60

80

100

0 50 100 150 200 250 300 350 400

PP[kW]

Pp[HP]

Q [US gpm]

e-MP50B-07_60Hz_2_US_A

7xØ173mm

5xØ173mm/2xØ161mm

3xØ173mm/4xØ161mm

e-MPA

PAGE 35

e-MP Series

Goulds Water Technology](https://image.slidesharecdn.com/bemp-r1-171024181502/85/The-e-MP-Series-35-320.jpg)

![e-MP50A SERIES - OPERATING CHARACTERISTICS AT 60 Hz, 4 POLES

e-MP50A/01 1750 [rpm] ISO 9906:2012 - Grade 2B

0 2 4 6 8 10

0 20 40 60 80 100 120 Q [Imp gpm]

Q [l/s]

1A

1B

1C

67.3

64.6

61.161.161.1

65

65

60

60

65

55

55

5050

50

50

0 5 10 15 20 25 30 35

0

2

4

6

8

10

12

14

0

5

10

15

20

25

30

35

40

45

50

Q [m3/h]

H[m]

H[ft]

η[%]

0

1

2

3

4

0

5

10

15

NPSH[m]

NPSH[ft]

e-MPR, e-MPD, e-MPV

1A

1B

1C1C1C

.0

1.0

0

1

0 20 40 60 80 100 120 140 160

PP[kW]

Pp[HP]

Q [US gpm]

e-MP50A-01_60Hz_4_US_A

Ø169mm

Ø157mm

Ø145mm

e-MPA

e-MP50A/02-06 1750 [rpm] ISO 9906:2012 - Grade 2B

0 20 40 60 80 100 120

0 2 4 6 8 10Q [Imp gpm]

Q [l/s]

2A

3A

4A

5A

66.9

66.9

66.9

66.9

66.9

6A

0 5 10 15 20 25 30 35

0

10

20

30

40

50

60

70

80

90

0

50

100

150

200

250

300

Q [m3/h]

H[m]

H[ft]

η[%]

0

2

4

6

0

5

10

15

20

NPSH[m]

NPSH[ft]

e-MPR, e-MPD, e-MPV

2A

3A

4A

5A

6A

0

1

2

3

4

5

0

2

4

6

8

0 20 40 60 80 100 120 140 160

PP[kW]

Pp[HP]

Q [US gpm]

e-MP50A-02-06_60Hz_4_US_A

2xØ169mm

3xØ169mm

4xØ169mm

e-MPA

5xØ169mm

6xØ169mm

These performances are valid for cold water with density ρ = 62.42 lb/ft3

and viscosity ν = 1cSt.

e-MP50A/12-16 1750 [rpm] ISO 9906:2012 - Grade 2B

0 2 4 6 8 10

0 20 40 60 80 100 120 Q [Imp gpm]

Q [l/s]

16A

13A

14A

15A

67.3

67.3

67.3

67.3

67.3

12A

0 5 10 15 20 25 30 35

0

50

100

150

200

0

100

200

300

400

500

600

700

800

Q [m3/h]

H[m]

H[ft]

η[%]

0

2

4

6

0

5

10

15

20

NPSH[m]

NPSH[ft]

e-MPR, e-MPD, e-MPV

16A

13A

14A

15A

12A

0

5

10

15

0

5

10

15

20

25

0 20 40 60 80 100 120 140 160

PP[kW]

Pp[HP]

Q [US gpm]

e-MP50A-12-16_60Hz_4_US_A

16xØ169mm

13xØ169mm

14xØ169mm

e-MPA

15xØ169mm

12xØ169mm

e-MP50A/07-11 1750 [rpm] ISO 9906:2012 - Grade 2B

0 2 4 6 8 10

0 20 40 60 80 100 120 Q [Imp gpm]

Q [l/s]

7A

8A

9A

10A

67.3

67.3

67.3

67.3

67.3

11A

0 5 10 15 20 25 30 35

0

20

40

60

80

100

120

140

0

50

100

150

200

250

300

350

400

450

500

Q [m3/h]

H[m]

H[ft]

η[%]

0

2

4

6

0

5

10

15

20

NPSH[m]

NPSH[ft]

e-MPR, e-MPD, e-MPV

7A

8A

9A

10A

11A

0

2

4

6

8

10

0

5

10

15

0 20 40 60 80 100 120 140 160

PP[kW]

Pp[HP]

Q [US gpm]

e-MP50A-07-11_60Hz_4_US_A

7xØ169mm

8xØ169mm

9xØ169mm

e-MPA

10xØ169mm

11xØ169mm

PAGE 36

e-MP Series

Goulds Water Technology](https://image.slidesharecdn.com/bemp-r1-171024181502/85/The-e-MP-Series-36-320.jpg)

![e-MP50B SERIES - OPERATING CHARACTERISTICS AT 60 Hz, 4 POLES

These performances are valid for cold water with density ρ = 62.42 lb/ft3

and viscosity ν = 1cSt.

e-MP50B/01 1750 [rpm] ISO 9906:2012 - Grade 2B

0 2 4 6 8 10 12 14

0 50 100 150 200Q [Imp gpm]

Q [l/s]

1A

1B

1C

72.6

69.8

67.067.067.0

70

70

65

65

65

60

60

5550

50

0 10 20 30 40 50

0

2

4

6

8

10

12

14

0

5

10

15

20

25

30

35

40

45

50

Q [m3/h]

H[m]

H[ft]

η[%]

0

1

2

3

4

0

5

10

15

NPSH[m]

NPSH[ft]

e-MPR, e-MPD, e-MPV

1A

1B

1C1C

.0

1.0

.0

1.0

2.0

0 50 100 150 200 250

PP[kW]

Pp[HP]

Q [US gpm]

e-MP50B-01_60Hz_4_US_A

Ø173mm

Ø161mm

Ø149mm

e-MPA

e-MP50B/02-06 1750 [rpm] ISO 9906:2012 - Grade 2B

0 2 4 6 8 10 12 14

0 50 100 150 200Q [Imp gpm]

Q [l/s]

2A

3A

4A

5A

72.6

72.6

72.6

72.6

72.6 6A

0 10 20 30 40 50

0

10

20

30

40

50

60

70

80

90

0

50

100

150

200

250

300

Q [m3/h]

H[m]

H[ft]

η[%]

0

1

2

3

4

0

5

10

15

NPSH[m]

NPSH[ft]

e-MPR, e-MPD, e-MPV

2A

3A

4A

5A

6A

0

2

4

6

8

0

4

8

12

0 50 100 150 200 250

PP[kW]

Pp[HP]

Q [US gpm]

e-MP50B-02-06_60Hz_4_US_A

2xØ173mm

3xØ173mm

4xØ173mm

e-MPA

5xØ173mm

6xØ173mm

e-MP50B/12-16 1750 [rpm] ISO 9906:2012 - Grade 2B

0 2 4 6 8 10 12 14

0 50 100 150 200Q [Imp gpm]

Q [l/s]

16A

13A

14A

15A

72.6

72.6

72.6

72.6

72.6

12A

0 10 20 30 40 50

0

50

100

150

200

0

100

200

300

400

500

600

700

800

Q [m3/h]

H[m]

H[ft]

η[%]

0

1

2

3

4

0

5

10

15

NPSH[m]

NPSH[ft]

e-MPR, e-MPD, e-MPV

16A

13A

14A

15A

12A

0

5

10

15

20

0

5

10

15

20

25

30

0 50 100 150 200 250

PP[kW]

Pp[HP]

Q [US gpm]

e-MP50B-12-16_60Hz_4_US_A

16xØ173mm

13xØ173mm

14xØ173mm

e-MPA

15xØ173mm

12xØ173mm

e-MP50B/07-11 1750 [rpm] ISO 9906:2012 - Grade 2B

0 2 4 6 8 10 12 14

0 50 100 150 200Q [Imp gpm]

Q [l/s]

7A

8A

9A

10A

72.6

72.6

72.6

72.6

72.6

11A

0 10 20 30 40 50

0

20

40

60

80

100

120

140

160

180

0

100

200

300

400

500

600

Q [m3/h]

H[m]

H[ft]

η[%]

0

1

2

3

4

0

5

10

15

NPSH[m]

NPSH[ft]

e-MPR, e-MPD, e-MPV

7A

8A

9A

10A

11A

0

2

4

6

8

10

12

14

0

5

10

15

20

0 50 100 150 200 250

PP[kW]

Pp[HP]

Q [US gpm]

e-MP50B-07-11_60Hz_4_US_A

7xØ173mm

8xØ173mm

9xØ173mm

e-MPA

10xØ173mm

11xØ173mm

PAGE 37

e-MP Series

Goulds Water Technology](https://image.slidesharecdn.com/bemp-r1-171024181502/85/The-e-MP-Series-37-320.jpg)

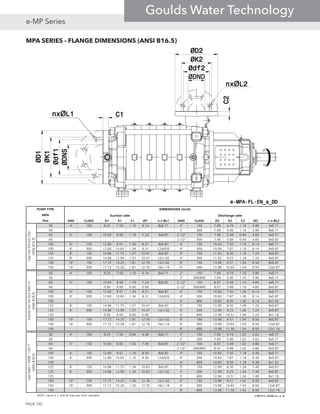

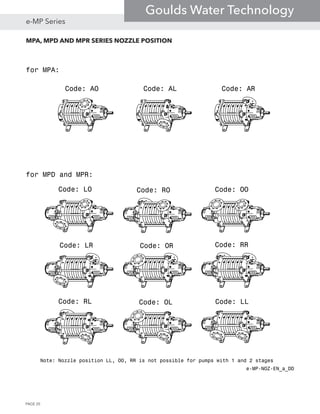

![MPA SERIES - DN50 - DIMENSIONS AND WEIGHTS AT 60 Hz

a1 f

ym1

m4 m3

m2 m2

d1 b

n2

n1

h1h2

l

s1

v1

u

t

d

h2h2

Position Connection Size

PM1 Vacuum gauge G1

4

PM2 Pressure gauge G1

4

D Drain G1

4

G Grease nipple M8

L Leakage G1

2

V Vent G1

4

G

L

D

V PM2DND

DNS

PM1

e-MPA-EN_a_DD

PUMP TYPEPUMP TYPEPUMP TYPEPUMP TYPE

MPAMPAMPAMPA

SizeSizeSizeSize DNSDNSDNSDNS DNDDNDDNDDND ffff h1h1h1h1 h2h2h2h2 v1v1v1v1 yyyy m2m2m2m2 m3m3m3m3 m4m4m4m4 n1n1n1n1 n2n2n2n2 bbbb d1d1d1d1 s1s1s1s1 dddd tttt uuuu llll

50 4'' 2'' 13.8 5.9 7.9 7.9 13.8 2.1 0.9 1.1 13.1 11.4 3.5 0.6 0.8 1.1 1.2 0.3 2.8

e-MPA-60-50-us_a_td

DIMENSIONS [inch]DIMENSIONS [inch]DIMENSIONS [inch]DIMENSIONS [inch]

Pump dimensionsPump dimensionsPump dimensionsPump dimensions Feet dimensionsFeet dimensionsFeet dimensionsFeet dimensions Shaft endShaft endShaft endShaft end

Size

Number

of stages

2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

a1 (inch) 7.87 10.31 12.76 15.20 17.64 20.08 22.52 24.96 27.40 29.84 32.28 34.72 37.17 39.61 42.05

m1 (inch) 4.57 7.01 9.45 11.89 14.33 16.77 19.21 21.65 24.09 26.54 28.98 31.42 33.86 36.30 38.74

G (lb) 40 46 51 57 62 68 73 78 84 89 95 100 106 111 117

e-MPA-60-50_stage_a_td

50

NOTE: Pumps supplied with ANSI B16.5 flanges. Flanges according to EN 1092-2 are available on request.

For flanges dimensions see drawing on pages 102-103.

* Adaptors for US dimensions outlets are available upon request.

*

*

PAGE 38

e-MP Series

Goulds Water Technology](https://image.slidesharecdn.com/bemp-r1-171024181502/85/The-e-MP-Series-38-320.jpg)

![MPA SERIES - DN50 - DIMENSIONS AND WEIGHTS AT 60 Hz

PUMP-PUMP-PUMP-PUMP-

TYPETYPETYPETYPE

MPAMPAMPAMPA

SizeSizeSizeSize [hp][hp][hp][hp] [hp][hp][hp][hp] DNSDNSDNSDNS DNDDNDDNDDND a1a1a1a1 ffff B1B1B1B1 B2B2B2B2 L1L1L1L1 L2L2L2L2 L3L3L3L3 L4L4L4L4 HHHH h2h2h2h2 ssss HmaxHmaxHmaxHmax LmaxLmaxLmaxLmax G [lb]G [lb]G [lb]G [lb]

160M 15 4" 2" 7.9 13.8 19.3 17.7 43.3 13.8 7.9 8.0 11.3 7.9 6xØ0,75 (M16) 20.8 45.7 571 B95A

160M 20 4" 2" 7.9 13.8 19.3 17.7 43.3 13.8 7.9 8.0 11.3 7.9 6xØ0,75 (M16) 20.8 45.7 573 B95A

160L 25 4" 2" 7.9 13.8 19.3 17.7 43.3 13.8 7.9 8.0 11.3 7.9 6xØ0,75 (M16) 20.8 45.7 589 B95A

180M 30 4" 2" 7.9 13.8 19.3 17.7 47.2 15.7 7.9 10.5 12.1 7.9 6xØ0,75 (M16) 23.2 50.6 736 B110B

100L 3 4" 2" 7.9 13.8 19.1 17.7 33.5 10.8 5.9 8.0 9.2 7.9 6xØ0,6 (M12) 17.0 39.4 368 B80A

100L 4 4" 2" 7.9 13.8 19.1 17.7 33.5 10.8 5.9 8.0 9.2 7.9 6xØ0,6 (M12) 17.0 39.4 375 B80A

180M 30 4" 2" 10.3 13.8 19.3 17.7 47.2 15.7 7.9 10.5 12.1 7.9 6xØ0,75 (M16) 23.2 50.6 763 B110B

200L 40 4" 2" 10.3 13.8 25.6 24.0 51.2 17.7 7.9 12.9 12.9 7.9 6xØ0,75 (M16) 25.5 57.0 970 B125A

200L 50 4" 2" 10.3 13.8 25.6 24.0 51.2 17.7 7.9 12.9 12.9 7.9 6xØ0,75 (M16) 25.5 57.0 1003 B125A

100L 4 4" 2" 10.3 13.8 19.1 17.7 39.4 13.8 5.9 12.9 9.2 7.9 6xØ0,6 (M12) 17.0 44.3 414 B80A

132S/M 7 4" 2" 10.3 13.8 19.3 17.7 43.3 15.7 5.9 12.9 9.8 7.9 6xØ0,75 (M16) 17.7 45.9 483 B80B

200L 40 4" 2" 12.8 13.8 25.6 24.0 51.2 17.7 7.9 12.9 12.9 7.9 6xØ0,75 (M16) 25.5 57.0 996 B125A

200L 50 4" 2" 12.8 13.8 25.6 24.0 51.2 17.7 7.9 12.9 12.9 7.9 6xØ0,75 (M16) 25.5 57.0 1030 B125A

225S/M 61 4" 2" 12.8 13.8 26.0 24.0 53.1 18.7 7.9 12.9 14.5 7.9 6xØ0,75 (M16) 29.6 60.6 1362 B125A

112M 5 4" 2" 12.8 13.8 19.1 17.7 41.3 14.8 5.9 15.4 9.2 7.9 6xØ0,6 (M12) 17.0 46.7 481 B80A

132S/M 10 4" 2" 12.8 13.8 19.3 17.7 43.3 15.7 5.9 12.9 9.8 7.9 6xØ0,75 (M16) 17.7 45.9 509 B80B

200L 50 4" 2" 15.2 13.8 25.6 24.0 57.1 20.7 7.9 17.8 12.9 7.9 6xØ0,75 (M16) 25.5 61.9 1082 B125A

225S/M 60 4" 2" 15.2 13.8 26.0 24.0 57.1 20.7 7.9 17.8 14.5 7.9 6xØ0,75 (M16) 29.6 65.4 1418 B125A

250S/M 75 4" 2" 15.2 13.8 28.3 26.4 61.0 22.6 7.9 17.8 15.5 7.9 6xØ0,75 (M16) 31.1 69.7 1629 B140A

280S/M 102 4" 2" 15.2 13.8 32.3 30.3 65.0 24.6 7.9 17.8 17.6 7.9 6xØ0,75 (M16) 35.9 73.9 2227 B160A

132S/M 7 4" 2" 15.2 13.8 19.3 17.7 47.2 17.7 5.9 17.8 9.8 7.9 6xØ0,75 (M16) 17.7 50.8 540 B80B

132S/M 10 4" 2" 15.2 13.8 19.3 17.7 47.2 17.7 5.9 17.8 9.8 7.9 6xØ0,75 (M16) 17.7 50.8 540 B80B

225S/M 61 4" 2" 17.6 13.8 26.0 24.0 57.1 20.7 7.9 17.8 14.5 7.9 6xØ0,75 (M16) 29.6 65.4 1444 B125A

250S/M 75 4" 2" 17.6 13.8 28.3 26.4 61.0 22.6 7.9 17.8 15.5 7.9 6xØ0,75 (M16) 31.1 69.7 1656 B140A

280S/M 100 4" 2" 17.6 13.8 32.3 30.3 65.0 24.6 7.9 17.8 17.6 7.9 6xØ0,75 (M16) 35.9 73.9 2253 B160A

132S/M 10 4" 2" 17.6 13.8 19.3 17.7 47.2 17.7 5.9 17.8 9.8 7.9 6xØ0,75 (M16) 17.7 50.8 567 B80B

160M 15 4" 2" 17.6 13.8 19.3 17.7 53.1 18.7 7.9 17.8 11.3 7.9 6xØ0,75 (M16) 20.8 55.5 657 B95A

250S/M 75 4" 2" 20.1 13.8 28.3 26.4 66.9 25.6 7.9 22.7 15.5 7.9 6xØ0,75 (M16) 31.1 74.6 1695 B140A

280S/M 100 4" 2" 20.1 13.8 32.3 30.3 70.9 27.6 7.9 22.7 17.6 7.9 6xØ0,75 (M16) 35.9 78.8 2293 B160A

280S/M 125 4" 2" 20.1 13.8 32.3 30.3 70.9 27.6 7.9 22.7 17.6 7.9 6xØ0,75 (M16) 35.9 78.8 2359 B160A

132S/M 10 4" 2" 20.1 13.8 19.3 17.7 53.1 20.7 5.9 22.7 9.8 7.9 6xØ0,75 (M16) 17.7 55.7 600 B80B

160M 15 4" 2" 20.1 13.8 19.3 17.7 57.1 20.7 7.9 22.7 11.3 7.9 6xØ0,75 (M16) 20.8 60.4 688 B95A

280S/M 100 4" 2" 22.5 13.8 32.3 30.3 70.9 27.6 7.9 22.7 17.6 7.9 6xØ0,75 (M16) 35.9 78.8 2319 B160A

280S/M 125 4" 2" 22.5 13.8 32.3 30.3 70.9 27.6 7.9 22.7 17.6 7.9 6xØ0,75 (M16) 35.9 78.8 2385 B160A

160M 15 4" 2" 22.5 13.8 19.3 17.7 57.1 20.7 7.9 22.7 11.3 7.9 6xØ0,75 (M16) 20.8 60.4 714 B95A

160L 20 4" 2" 22.5 13.8 19.3 17.7 57.1 20.7 7.9 22.7 11.3 7.9 6xØ0,75 (M16) 20.8 60.4 809 B95A

280S/M 102 4" 2" 25.0 13.8 32.3 30.3 74.8 29.5 7.9 27.6 17.6 7.9 6xØ0,75 (M16) 35.9 83.7 2284 B160A

315S/M 150 4" 2" 25.0 13.8 33.9 31.9 78.7 31.5 7.9 27.6 19.8 7.9 6xØ1 (M20) 40.7 90.5 2956 B160A

160M 15 4" 2" 25.0 13.8 19.3 17.7 63.0 23.6 7.9 27.6 11.3 7.9 6xØ0,75 (M16) 20.8 65.3 750 B95A

160L 20 4" 2" 25.0 13.8 19.3 17.7 63.0 23.6 7.9 27.6 11.3 7.9 6xØ0,75 (M16) 20.8 65.3 844 B95A

280S/M 122 4" 2" 27.4 13.8 32.3 30.3 74.8 29.5 7.9 27.6 17.6 7.9 6xØ0,75 (M16) 35.9 83.7 2377 B160A

315S/M 150 4" 2" 27.4 13.8 33.9 31.9 78.7 31.5 7.9 27.6 19.8 7.9 6xØ1 (M20) 40.7 90.5 2983 B160A

160M 15 4" 2" 27.4 13.8 19.3 17.7 63.0 23.6 7.9 27.6 11.3 7.9 6xØ0,75 (M16) 20.8 65.3 776 B95A

160L 20 4" 2" 27.4 13.8 19.3 17.7 63.0 23.6 7.9 27.6 11.3 7.9 6xØ0,75 (M16) 20.8 65.3 871 B95A

280S/M 125 4" 2" 29.8 13.8 32.3 30.3 78.7 31.5 7.9 32.4 17.6 7.9 6xØ0,75 (M16) 35.9 88.5 2476 B160A

160L 20 4" 2" 29.8 13.8 19.3 17.7 66.9 25.6 7.9 32.4 11.3 7.9 6xØ0,75 (M16) 20.8 70.2 902 B95A

180M 25 4" 2" 29.8 13.8 19.3 17.7 68.9 26.6 7.9 32.4 12.1 7.9 6xØ0,75 (M16) 23.2 72.5 1003 B110B

160L 20 4" 2" 32.3 13.8 19.3 17.7 66.9 25.6 7.9 32.4 11.3 7.9 6xØ0,75 (M16) 20.8 70.2 928 B95A

180M 25 4" 2" 32.3 13.8 19.3 17.7 68.9 26.6 7.9 32.4 12.1 7.9 6xØ0,75 (M16) 23.2 72.5 1030 B110B

160L 20 4" 2" 34.7 13.8 19.3 17.7 72.8 28.5 7.9 37.3 11.3 7.9 6xØ0,75 (M16) 20.8 75.0 963 B95A

180M 25 4" 2" 34.7 13.8 19.3 17.7 72.8 28.5 7.9 37.3 12.1 7.9 6xØ0,75 (M16) 23.2 77.4 1058 B110B

160L 20 4" 2" 37.2 13.8 19.3 17.7 72.8 28.5 7.9 37.3 11.3 7.9 6xØ0,75 (M16) 20.8 75.0 990 B95A

180L 30 4" 2" 37.2 13.8 19.3 17.7 72.8 28.5 7.9 37.3 12.1 7.9 6xØ0,75 (M16) 23.2 78.9 1122 B110B

180M 25 4" 2" 39.6 13.8 19.3 17.7 78.7 31.5 7.9 42.2 12.1 7.9 6xØ0,75 (M16) 23.2 82.3 1122 B110B

180L 30 4" 2" 39.6 13.8 19.3 17.7 78.7 31.5 7.9 42.2 12.1 7.9 6xØ0,75 (M16) 23.2 83.8 1160 B110B

180M 25 4" 2" 42.0 13.8 19.3 17.7 78.7 31.5 7.9 42.2 12.1 7.9 6xØ0,75 (M16) 23.2 82.3 1149 B110B

180L 30 4" 2" 42.0 13.8 19.3 17.7 78.7 31.5 7.9 42.2 12.1 7.9 6xØ0,75 (M16) 23.2 83.8 1186 B110B

e-MPA-AS-60-50-us_a_td

COUPLINGCOUPLINGCOUPLINGCOUPLING

TYPETYPETYPETYPE

2

3

NUMBERNUMBERNUMBERNUMBER

OFSTAGESOFSTAGESOFSTAGESOFSTAGES

IECIECIECIEC

MOTORMOTORMOTORMOTOR

FRAMEFRAMEFRAMEFRAME

3550[rpm]3550[rpm]3550[rpm]3550[rpm]

1750[rpm]1750[rpm]1750[rpm]1750[rpm]

16

DIMENSIONS [inch]DIMENSIONS [inch]DIMENSIONS [inch]DIMENSIONS [inch]

WEIGHTWEIGHTWEIGHTWEIGHT

15

50

4

5

6

7

10

9

8

14

11

12

13

NOTE: Pumps supplied with ANSI B16.5 flanges. Flanges according to EN 1092-2 are available on request.

For flanges dimensions see drawing on pages 102-103.

Dimensions and weights in the next table are for reference only and correspond to IEC motor frames. NEMA corresponding dimensions

and weights to be published soon. Please contact factory for more information.

PAGE 40

e-MP Series

Goulds Water Technology](https://image.slidesharecdn.com/bemp-r1-171024181502/85/The-e-MP-Series-40-320.jpg)

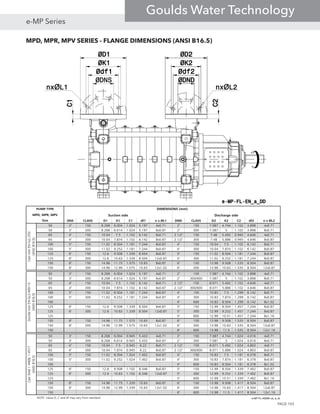

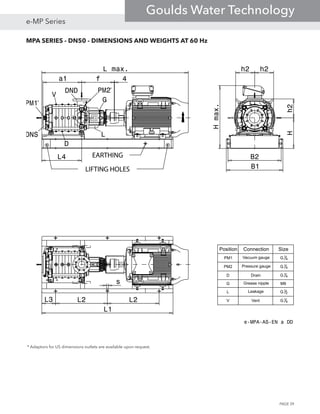

![MPR SERIES - DN50 - DIMENSIONS AND WEIGHTS AT 60 Hz

a f

ym

m4 m3

m2 m2

d1 b

n2

n1

h1h2

h2

l

s1

v

u

t

d

h2

Position Connection Size

PM1 Vacuum gauge G1

4

PM2 Pressure gauge G1

4

D Drain G1

4

G Grease nipple M8

L Leakage G1

2

V Vent G1

4

G

L

D

V PM2

DNS

DND

PM1

e-MPR-EN_a_DD

PUMP TYPEPUMP TYPEPUMP TYPEPUMP TYPE

MPRMPRMPRMPR

SizeSizeSizeSize DNSDNSDNSDNS DNDDNDDNDDND ffff h1h1h1h1 h2h2h2h2 vvvv yyyy m2m2m2m2 m3m3m3m3 m4m4m4m4 n1n1n1n1 n2n2n2n2 bbbb d1d1d1d1 s1s1s1s1 dddd tttt uuuu llll

50 3" 2" 13.8 5.9 7.9 7.9 13.8 2.1 0.9 1.1 13.1 11.4 3.5 0.6 0.8 1.1 1.2 0.3 2.8

e-MPR-60-50-us_a_td

DIMENSIONS [inch]DIMENSIONS [inch]DIMENSIONS [inch]DIMENSIONS [inch]

Pump dimensionsPump dimensionsPump dimensionsPump dimensions Feet dimensionsFeet dimensionsFeet dimensionsFeet dimensions Shaft endShaft endShaft endShaft end

Size

Number

of stages

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

a (inch) 3.43 5.87 8.31 10.75 13.19 15.63 18.07 20.51 22.95 25.39 27.83 30.28 32.72 35.16 37.60 40.04

m (inch) 3.43 5.87 8.31 10.75 13.19 15.63 18.07 20.51 22.95 25.39 27.83 30.28 32.72 35.16 37.60 40.04

G (lb) 185 212 238 265 291 317 344 370 397 423 450 476 503 529 556 582

e-MPR-60-50_stage_a_td

50

NOTE: Pumps supplied with ANSI B16.5 flanges. Flanges according to EN 1092-2 are available on request.

For flanges dimensions see drawing on pages 102-103.

* Adaptors for US dimensions outlets are available upon request.

*

*

PAGE 41

e-MP Series

Goulds Water Technology](https://image.slidesharecdn.com/bemp-r1-171024181502/85/The-e-MP-Series-41-320.jpg)

![MPR SERIES - DN50 - DIMENSIONS AND WEIGHTS AT 60 Hz

PUMP-PUMP-PUMP-PUMP-

TYPETYPETYPETYPE

MPRMPRMPRMPR

SizeSizeSizeSize [hp][hp][hp][hp] [hp][hp][hp][hp] DNSDNSDNSDNS DNDDNDDNDDND aaaa ffff B1B1B1B1 B2B2B2B2 L1L1L1L1 L2L2L2L2 L3L3L3L3 L4L4L4L4 HHHH h2h2h2h2 ssss HmaxHmaxHmaxHmax LmaxLmaxLmaxLmax G [lb]G [lb]G [lb]G [lb]

160M 15 - 3" 2" 3.4 13.8 19.3 17.7 43.3 13.8 7.9 8.0 11.3 7.9 6xØ0,59 (M16) 20.8 45.7 560 B95A

100L - 3 3" 2" 3.4 13.8 19.1 17.7 33.5 10.8 5.9 8.0 9.2 7.9 6xØ0,59 (M12) 17.0 39.4 357 B80A

160M 15 - 3" 2" 5.9 13.8 19.3 17.7 43.3 13.8 7.9 8.0 11.3 7.9 6xØ0,59 (M16) 20.8 47.7 586 B95A

160M 20 - 3" 2" 5.9 13.8 19.3 17.7 43.3 13.8 7.9 8.0 11.3 7.9 6xØ0,59 (M16) 20.8 47.7 589 B95A

160L 25 - 3" 2" 5.9 13.8 19.3 17.7 43.3 13.8 7.9 8.0 11.3 7.9 6xØ0,59 (M16) 20.8 47.7 604 B95A

180M 30 - 3" 2" 5.9 13.8 19.3 17.7 47.2 15.7 7.9 10.5 12.1 7.9 6xØ0,59 (M16) 23.2 50.6 752 B110B

100L - 3 3" 2" 5.9 13.8 19.1 17.7 33.5 10.8 5.9 8.0 9.2 7.9 6xØ0,59 (M12) 17.0 41.3 384 B80A

100L - 4 3" 2" 5.9 13.8 19.1 17.7 33.5 10.8 5.9 8.0 9.2 7.9 6xØ0,59 (M12) 17.0 41.3 390 B80A

180M 30 - 3" 2" 8.3 13.8 19.3 17.7 47.2 15.7 7.9 10.5 12.1 7.9 6xØ0,59 (M16) 23.2 52.5 778 B110B

200L 40 - 3" 2" 8.3 13.8 25.6 24.0 51.2 17.7 7.9 12.9 12.9 7.9 6xØ0,59 (M16) 25.5 57.0 985 B125A

200L 50 - 3" 2" 8.3 13.8 25.6 24.0 51.2 17.7 7.9 12.9 12.9 7.9 6xØ0,59 (M16) 25.5 57.0 1019 B125A

100L - 5.5 3" 2" 8.3 13.8 19.1 17.7 39.4 13.8 5.9 12.9 9.2 7.9 6xØ0,59 (M12) 17.0 44.3 430 B80A

132S/M - 7.5 3" 2" 8.3 13.8 19.3 17.7 43.3 15.7 5.9 12.9 9.8 7.9 6xØ0,59 (M16) 17.7 45.9 498 B80B

200L 40 - 3" 2" 10.7 13.8 25.6 24.0 51.2 17.7 7.9 12.9 12.9 7.9 6xØ0,59 (M16) 25.5 59.0 1012 B125A

200L 50 - 3" 2" 10.7 13.8 25.6 24.0 51.2 17.7 7.9 12.9 12.9 7.9 6xØ0,59 (M16) 25.5 59.0 1045 B125A

225S/M 60 - 3" 2" 10.7 13.8 26.0 24.0 53.1 18.7 7.9 12.9 14.5 7.9 6xØ0,59 (M16) 29.6 62.5 1378 B125A

112M - 5.5 3" 2" 10.7 13.8 19.1 17.7 41.3 14.8 5.9 15.4 9.2 7.9 6xØ0,59 (M12) 17.0 46.7 496 B80A

132S/M - 10 3" 2" 10.7 13.8 19.3 17.7 43.3 15.7 5.9 12.9 9.8 7.9 6xØ0,59 (M16) 17.7 47.9 525 B80B

200L 50 - 3" 2" 13.2 13.8 25.6 24.0 57.1 20.7 7.9 17.8 12.9 7.9 6xØ0,59 (M16) 25.5 61.9 1098 B125A

225S/M 60 - 3" 2" 13.2 13.8 26.0 24.0 57.1 20.7 7.9 17.8 14.5 7.9 6xØ0,59 (M16) 29.6 65.4 1433 B125A

250S/M 75 - 3" 2" 13.2 13.8 28.3 26.4 61.0 22.6 7.9 17.8 15.5 7.9 6xØ0,59 (M16) 31.1 69.7 1645 B140A

280S/M 100 - 3" 2" 13.2 13.8 32.3 30.3 65.0 24.6 7.9 17.8 17.6 7.9 6xØ0,59 (M16) 35.9 73.9 2242 B160A

132S/M - 7.5 3" 2" 13.2 13.8 19.3 17.7 47.2 17.7 5.9 17.8 9.8 7.9 6xØ0,59 (M16) 17.7 50.8 556 B80B

132S/M - 10 3" 2" 13.2 13.8 19.3 17.7 47.2 17.7 5.9 17.8 9.8 7.9 6xØ0,59 (M16) 17.7 50.8 556 B80B

225S/M 60 - 3" 2" 15.6 13.8 26.0 24.0 57.1 20.7 7.9 17.8 14.5 7.9 6xØ0,59 (M16) 29.6 67.4 1459 B125A

250S/M 75 - 3" 2" 15.6 13.8 28.3 26.4 61.0 22.6 7.9 17.8 15.5 7.9 6xØ0,59 (M16) 31.1 71.7 1671 B140A

280S/M 100 - 3" 2" 15.6 13.8 32.3 30.3 65.0 24.6 7.9 17.8 17.6 7.9 6xØ0,59 (M16) 35.9 75.9 2269 B160A

132S/M - 10 3" 2" 15.6 13.8 19.3 17.7 47.2 17.7 5.9 17.8 9.8 7.9 6xØ0,59 (M16) 17.7 52.8 582 B80B

160M - 15 3" 2" 15.6 13.8 19.3 17.7 53.1 18.7 7.9 17.8 11.3 7.9 6xØ0,59 (M16) 20.8 57.5 672 B95A

250S/M 75 - 3" 2" 18.1 13.8 28.3 26.4 66.9 25.6 7.9 22.7 15.5 7.9 6xØ0,59 (M16) 31.1 74.6 1711 B140A

280S/M 100 - 3" 2" 18.1 13.8 32.3 30.3 70.9 27.6 7.9 22.7 17.6 7.9 6xØ0,59 (M16) 35.9 78.8 2308 B160A

280S/M 125 - 3" 2" 18.1 13.8 32.3 30.3 70.9 27.6 7.9 22.7 17.6 7.9 6xØ0,59 (M16) 35.9 78.8 2374 B160A

132S/M - 10 3" 2" 18.1 13.8 19.3 17.7 53.1 20.7 5.9 22.7 9.8 7.9 6xØ0,59 (M16) 17.7 55.7 615 B80B

160M - 15 3" 2" 18.1 13.8 19.3 17.7 57.1 20.7 7.9 22.7 11.3 7.9 6xØ0,59 (M16) 20.8 60.4 703 B95A

280S/M 100 - 3" 2" 20.5 13.8 32.3 30.3 70.9 27.6 7.9 22.7 17.6 7.9 6xØ0,59 (M16) 35.9 80.7 2335 B160A

280S/M 125 - 3" 2" 20.5 13.8 32.3 30.3 70.9 27.6 7.9 22.7 17.6 7.9 6xØ0,59 (M16) 35.9 80.7 2401 B160A

160M - 15 3" 2" 20.5 13.8 19.3 17.7 57.1 20.7 7.9 22.7 11.3 7.9 6xØ0,59 (M16) 20.8 62.4 730 B95A

160L - 20 3" 2" 20.5 13.8 19.3 17.7 57.1 20.7 7.9 22.7 11.3 7.9 6xØ0,59 (M16) 20.8 62.4 825 B95A

280S/M 100 - 3" 2" 23.0 13.8 32.3 30.3 74.8 29.5 7.9 27.6 17.6 7.9 6xØ0,59 (M16) 35.9 83.7 2299 B160A

315S/M 150 - 3" 2" 23.0 13.8 33.9 31.9 78.7 31.5 7.9 27.6 19.8 7.9 6xØ1 (M20) 40.7 90.5 2972 B160A

160M - 15 3" 2" 23.0 13.8 19.3 17.7 63.0 23.6 7.9 27.6 11.3 7.9 6xØ0,59 (M16) 20.8 65.3 765 B95A

160L - 20 3" 2" 23.0 13.8 19.3 17.7 63.0 23.6 7.9 27.6 11.3 7.9 6xØ0,59 (M16) 20.8 65.3 860 B95A

280S/M 125 - 3" 2" 25.4 13.8 32.3 30.3 74.8 29.5 7.9 27.6 17.6 7.9 6xØ0,59 (M16) 35.9 85.6 2392 B160A

315S/M 150 - 3" 2" 25.4 13.8 33.9 31.9 78.7 31.5 7.9 27.6 19.8 7.9 6xØ1 (M20) 40.7 92.4 2998 B160A

160M - 15 3" 2" 25.4 13.8 19.3 17.7 63.0 23.6 7.9 27.6 11.3 7.9 6xØ0,59 (M16) 20.8 67.2 791 B95A

160L - 20 3" 2" 25.4 13.8 19.3 17.7 63.0 23.6 7.9 27.6 11.3 7.9 6xØ0,59 (M16) 20.8 67.2 886 B95A

280S/M 125 - 3" 2" 27.8 13.8 32.3 30.3 78.7 31.5 7.9 32.4 17.6 7.9 6xØ0,59 (M16) 35.9 88.5 2491 B160A

160L - 20 3" 2" 27.8 13.8 19.3 17.7 66.9 25.6 7.9 32.4 11.3 7.9 6xØ0,59 (M16) 20.8 70.2 917 B95A

180M - 25 3" 2" 27.8 13.8 19.3 17.7 68.9 26.6 7.9 32.4 12.1 7.9 6xØ0,59 (M16) 23.2 72.5 1019 B110B

160L - 20 3" 2" 30.3 13.8 19.3 17.7 66.9 25.6 7.9 32.4 11.3 7.9 6xØ0,59 (M16) 20.8 72.1 944 B95A

180M - 25 3" 2" 30.3 13.8 19.3 17.7 68.9 26.6 7.9 32.4 12.1 7.9 6xØ0,59 (M16) 23.2 74.5 1045 B110B

160L - 20 3" 2" 32.7 13.8 19.3 17.7 72.8 28.5 7.9 37.3 11.3 7.9 6xØ0,59 (M16) 20.8 75.0 979 B95A

180M - 25 3" 2" 32.7 13.8 19.3 17.7 72.8 28.5 7.9 37.3 12.1 7.9 6xØ0,59 (M16) 23.2 77.4 1074 B110B

160L - 20 3" 2" 35.2 13.8 19.3 17.7 72.8 28.5 7.9 37.3 11.3 7.9 6xØ0,59 (M16) 20.8 77.0 1005 B95A

180L - 30 3" 2" 35.2 13.8 19.3 17.7 72.8 28.5 7.9 37.3 12.1 7.9 6xØ0,59 (M16) 23.2 80.9 1138 B110B

180M - 25 3" 2" 37.6 13.8 19.3 17.7 78.7 31.5 7.9 42.2 12.1 7.9 6xØ0,59 (M16) 23.2 82.3 1138 B110B

180L - 30 3" 2" 37.6 13.8 19.3 17.7 78.7 31.5 7.9 42.2 12.1 7.9 6xØ0,59 (M16) 23.2 83.8 1175 B110B

180M - 25 3" 2" 40.0 13.8 19.3 17.7 78.7 31.5 7.9 42.2 12.1 7.9 6xØ0,59 (M16) 23.2 84.3 1164 B110B

180L - 30 3" 2" 40.0 13.8 19.3 17.7 78.7 31.5 7.9 42.2 12.1 7.9 6xØ0,59 (M16) 23.2 85.7 1202 B110B

e-MPR-AS-60-50-us_a_td

13

15

16

DIMENSIONS [inch]DIMENSIONS [inch]DIMENSIONS [inch]DIMENSIONS [inch]

9

10

11

12

WEIGHTWEIGHTWEIGHTWEIGHT

14

COUPLINGCOUPLINGCOUPLINGCOUPLING

TYPETYPETYPETYPE

50

1

2

3

4

5

6

7

8

NUMBERNUMBERNUMBERNUMBER

OFSTAGESOFSTAGESOFSTAGESOFSTAGES

IECIECIECIEC

MOTORMOTORMOTORMOTOR

FRAMEFRAMEFRAMEFRAME

3550[rpm]3550[rpm]3550[rpm]3550[rpm]

1750[rpm]1750[rpm]1750[rpm]1750[rpm]

NOTE: Pumps supplied with ANSI B16.5 flanges. Flanges according to EN 1092-2 are available on request.

For flanges dimensions see drawing on pages 102-103.

Dimensions and weights in the next table are for reference only and correspond to IEC motor frames. NEMA corresponding dimensions

and weights to be published soon. Please contact factory for more information.

PAGE 43

e-MP Series

Goulds Water Technology](https://image.slidesharecdn.com/bemp-r1-171024181502/85/The-e-MP-Series-43-320.jpg)

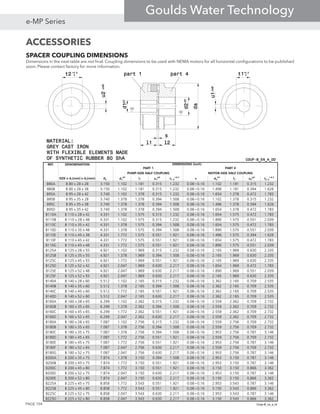

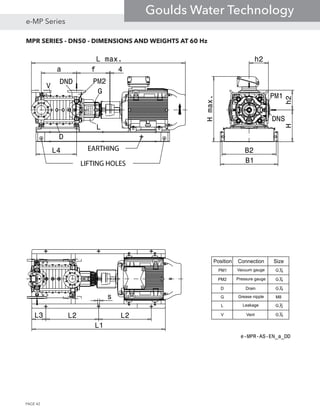

![MPD SERIES - DN50 - DIMENSIONS AND WEIGHTS AT 60 Hz

e a f

ym

m4 m3

m2 m2

d1 b

n2

n1

h1h2

h2

l

s1

v

u

t

d

h2

Position Connection Size

PM1 Vacuum gauge G1

4

PM2 Pressure gauge G1

4

D Drain G1

4

G Grease nipple M8

L Leakage G1

2

V Vent G1

4

G G

LL

D

V PM2

DND

PM1

DNS

e-MPD-EN_a_DD

PUMP TYPEPUMP TYPEPUMP TYPEPUMP TYPE

MPDMPDMPDMPD

SizeSizeSizeSize DNSDNSDNSDNS DNDDNDDNDDND eeee ffff h1h1h1h1 h2h2h2h2 vvvv yyyy m2m2m2m2 m3m3m3m3 m4m4m4m4 n1n1n1n1 n2n2n2n2 bbbb d1d1d1d1 s1s1s1s1 dddd tttt uuuu llll

50 3" 2" 11.1 13.8 5.9 7.9 7.9 13.8 2.1 0.9 1.1 13.1 11.4 3.5 0.6 0.8 1.1 1.2 0.3 2.8

e-MPD-60-50-us_a_td

DIMENSIONS [inch]DIMENSIONS [inch]DIMENSIONS [inch]DIMENSIONS [inch]

Pump dimensionsPump dimensionsPump dimensionsPump dimensions Feet dimensionsFeet dimensionsFeet dimensionsFeet dimensions Shaft endShaft endShaft endShaft end

DIMENSIONS AND WEIGHTS e-MPD AT 60Hz [drive on discharge side]DIMENSIONS AND WEIGHTS e-MPD AT 60Hz [drive on discharge side]DIMENSIONS AND WEIGHTS e-MPD AT 60Hz [drive on discharge side]DIMENSIONS AND WEIGHTS e-MPD AT 60Hz [drive on discharge side]

Size

Number

of stages

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

a (inch) 3.43 5.87 8.31 10.75 13.19 15.63 18.07 20.51 22.95 25.39 27.83 30.28 32.72 35.16 37.60 40.04

m (inch) 3.43 5.87 8.31 10.75 13.19 15.63 18.07 20.51 22.95 25.39 27.83 30.28 32.72 35.16 37.60 40.04

G (lb) 229 256 282 309 335 362 388 414 441 467 494 520 547 573 600 626

e-MPD-60-50_stage_a_td

50

NOTE: Pumps supplied with ANSI B16.5 flanges. Flanges according to EN 1092-2 are available on request.

For flanges dimensions see drawing on pages 102-103.

* Adaptors for US dimensions outlets are available upon request.

*

*

PAGE 44

e-MP Series

Goulds Water Technology](https://image.slidesharecdn.com/bemp-r1-171024181502/85/The-e-MP-Series-44-320.jpg)

![MPD SERIES - DN50 - DIMENSIONS AND WEIGHTS AT 60 Hz

PUMP-PUMP-PUMP-PUMP-

TYPETYPETYPETYPE

MPDMPDMPDMPD

SizeSizeSizeSize [hp][hp][hp][hp] [hp][hp][hp][hp] DNSDNSDNSDNS DNDDNDDNDDND aaaa eeee ffff B1B1B1B1 B2B2B2B2 L1L1L1L1 L2L2L2L2 L3L3L3L3 L4L4L4L4 HHHH h2h2h2h2 ssss HmaxHmaxHmaxHmax LmaxLmaxLmaxLmax G [lb]G [lb]G [lb]G [lb]

160M 15 3" 2" 3.4 11.1 13.8 19.3 17.7 43.3 13.8 7.9 8.0 11.3 7.9 6xØ0,75 (M16) 20.8 52.3 604 B95A

100L 3 3" 2" 3.4 11.1 13.8 19.1 17.7 33.5 10.8 5.9 8.0 9.2 7.9 6xØ0,59 (M12) 17.0 45.9 401 B80A

160M 15 3" 2" 5.9 11.1 13.8 19.3 17.7 43.3 13.8 7.9 8.0 11.3 7.9 6xØ0,75 (M16) 20.8 54.7 631 B95A

160M 20 3" 2" 5.9 11.1 13.8 19.3 17.7 43.3 13.8 7.9 8.0 11.3 7.9 6xØ0,75 (M16) 20.8 54.7 633 B95A

160L 25 3" 2" 5.9 11.1 13.8 19.3 17.7 43.3 13.8 7.9 8.0 11.3 7.9 6xØ0,75 (M16) 20.8 54.7 648 B95A

180M 30 3" 2" 5.9 11.1 13.8 19.3 17.7 47.2 15.7 7.9 10.5 12.1 7.9 6xØ0,75 (M16) 23.2 57.1 796 B110B

100L 3 3" 2" 5.9 11.1 13.8 19.1 17.7 33.5 10.8 5.9 8.0 9.2 7.9 6xØ15 (M12) 17.0 48.3 428 B80A

100L 4 3" 2" 5.9 11.1 13.8 19.1 17.7 33.5 10.8 5.9 8.0 9.2 7.9 6xØ0,59 (M12) 17.0 48.3 434 B80A

180M 30 3" 2" 8.3 11.1 13.8 19.3 17.7 47.2 15.7 7.9 10.5 12.1 7.9 6xØ0,75 (M16) 23.2 59.5 822 B110B

200L 40 3" 2" 8.3 11.1 13.8 25.6 24.0 51.2 17.7 7.9 12.9 12.9 7.9 6xØ0,75 (M16) 25.5 63.6 1030 B125A

200L 50 3" 2" 8.3 11.1 13.8 25.6 24.0 51.2 17.7 7.9 12.9 12.9 7.9 6xØ0,75 (M16) 25.5 63.6 1063 B125A

100L 4 3" 2" 8.3 11.1 13.8 19.1 17.7 39.4 13.8 5.9 12.9 9.2 7.9 6xØ0,59 (M12) 17.0 50.8 474 B80A

132S/M 8 3" 2" 8.3 11.1 13.8 19.3 17.7 43.3 15.7 5.9 12.9 9.8 7.9 6xØ0,75 (M16) 17.7 52.5 542 B80B

200L 40 3" 2" 10.7 11.1 13.8 25.6 24.0 51.2 17.7 7.9 12.9 12.9 7.9 6xØ0,75 (M16) 25.5 66.0 1056 B125A

200L 50 3" 2" 10.7 11.1 13.8 25.6 24.0 51.2 17.7 7.9 12.9 12.9 7.9 6xØ0,75 (M16) 25.5 66.0 1089 B125A

225S/M 60 3" 2" 10.7 11.1 13.8 26.0 24.0 53.1 18.7 7.9 12.9 14.5 7.9 6xØ0,75 (M16) 29.6 69.5 1422 B125A

112M 5 3" 2" 10.7 11.1 13.8 19.1 17.7 41.3 14.8 5.9 15.4 9.2 7.9 6xØ15 (M12) 17.0 53.2 540 B80A

132S/M 10 3" 2" 10.7 11.1 13.8 19.3 17.7 43.3 15.7 5.9 12.9 9.8 7.9 6xØ0,75 (M16) 17.7 54.9 569 B80B

200L 50 3" 2" 13.2 11.1 13.8 25.6 24.0 57.1 20.7 7.9 17.8 12.9 7.9 6xØ0,75 (M16) 25.5 68.4 1142 B125A

225S/M 60 3" 2" 13.2 11.1 13.8 26.0 24.0 57.1 20.7 7.9 17.8 14.5 7.9 6xØ0,75 (M16) 29.6 71.9 1477 B125A

250S/M 75 3" 2" 13.2 11.1 13.8 28.3 26.4 61.0 22.6 7.9 17.8 15.5 7.9 6xØ0,75 (M16) 31.1 76.2 1689 B140A

280S/M 100 3" 2" 13.2 11.1 13.8 32.3 30.3 65.0 24.6 7.9 17.8 17.6 7.9 6xØ0,75 (M16) 35.9 80.4 2286 B160A

132S/M 8 3" 2" 13.2 11.1 13.8 19.3 17.7 47.2 17.7 5.9 17.8 9.8 7.9 6xØ0,75 (M16) 17.7 57.3 600 B80B

132S/M 10 3" 2" 13.2 11.1 13.8 19.3 17.7 47.2 17.7 5.9 17.8 9.8 7.9 6xØ0,75 (M16) 17.7 57.3 600 B80B

225S/M 60 3" 2" 15.6 11.1 13.8 26.0 24.0 57.1 20.7 7.9 17.8 14.5 7.9 6xØ0,75 (M16) 29.6 74.4 1504 B125A

250S/M 75 3" 2" 15.6 11.1 13.8 28.3 26.4 61.0 22.6 7.9 17.8 15.5 7.9 6xØ0,75 (M16) 31.1 78.7 1715 B140A

280S/M 100 3" 2" 15.6 11.1 13.8 32.3 30.3 65.0 24.6 7.9 17.8 17.6 7.9 6xØ0,75 (M16) 35.9 82.9 2313 B160A

132S/M 10 3" 2" 15.6 11.1 13.8 19.3 17.7 47.2 17.7 5.9 17.8 9.8 7.9 6xØ0,75 (M16) 17.7 59.8 626 B80B

160M 15 3" 2" 15.6 11.1 13.8 19.3 17.7 53.1 18.7 7.9 17.8 11.3 7.9 6xØ0,75 (M16) 20.8 64.5 717 B95A

250S/M 75 3" 2" 18.1 11.1 13.8 28.3 26.4 66.9 25.6 7.9 22.7 15.5 7.9 6xØ0,75 (M16) 31.1 81.1 1755 B140A

280S/M 100 3" 2" 18.1 11.1 13.8 32.3 30.3 70.9 27.6 7.9 22.7 17.6 7.9 6xØ0,75 (M16) 35.9 85.3 2352 B160A

280S/M 125 3" 2" 18.1 11.1 13.8 32.3 30.3 70.9 27.6 7.9 22.7 17.6 7.9 6xØ0,75 (M16) 35.9 85.3 2418 B160A

132S/M 10 3" 2" 18.1 11.1 13.8 19.3 17.7 53.1 20.7 5.9 22.7 9.8 7.9 6xØ0,75 (M16) 17.7 62.2 659 B80B

160M 15 3" 2" 18.1 11.1 13.8 19.3 17.7 57.1 20.7 7.9 22.7 11.3 7.9 6xØ0,75 (M16) 20.8 66.9 747 B95A

280S/M 100 3" 2" 20.5 11.1 13.8 32.3 30.3 70.9 27.6 7.9 22.7 17.6 7.9 6xØ0,75 (M16) 35.9 87.7 2379 B160A

280S/M 125 3" 2" 20.5 11.1 13.8 32.3 30.3 70.9 27.6 7.9 22.7 17.6 7.9 6xØ0,75 (M16) 35.9 87.7 2445 B160A

160M 15 3" 2" 20.5 11.1 13.8 19.3 17.7 57.1 20.7 7.9 22.7 11.3 7.9 6xØ0,75 (M16) 20.8 69.4 774 B95A

160L 20 3" 2" 20.5 11.1 13.8 19.3 17.7 57.1 20.7 7.9 22.7 11.3 7.9 6xØ0,75 (M16) 20.8 69.4 869 B95A

280S/M 100 3" 2" 23.0 11.1 13.8 32.3 30.3 74.8 29.5 7.9 27.6 17.6 7.9 6xØ0,75 (M16) 35.9 90.2 2344 B160A

315S/M 150 3" 2" 23.0 11.1 13.8 33.9 31.9 78.7 31.5 7.9 27.6 19.8 7.9 6xØ0,1 (M20) 40.7 97.0 3016 B160A

160M 15 3" 2" 23.0 11.1 13.8 19.3 17.7 63.0 23.6 7.9 27.6 11.3 7.9 6xØ0,75 (M16) 20.8 71.8 809 B95A

160L 20 3" 2" 23.0 11.1 13.8 19.3 17.7 63.0 23.6 7.9 27.6 11.3 7.9 6xØ0,75 (M16) 20.8 71.8 904 B95A

280S/M 125 3" 2" 25.4 11.1 13.8 32.3 30.3 74.8 29.5 7.9 27.6 17.6 7.9 6xØ0,75 (M16) 35.9 92.6 2436 B160A

315S/M 150 3" 2" 25.4 11.1 13.8 33.9 31.9 78.7 31.5 7.9 27.6 19.8 7.9 6xØ0,1 (M20) 40.7 99.4 3042 B160A

160M 15 3" 2" 25.4 11.1 13.8 19.3 17.7 63.0 23.6 7.9 27.6 11.3 7.9 6xØ0,75 (M16) 20.8 74.2 836 B95A

160L 20 3" 2" 25.4 11.1 13.8 19.3 17.7 63.0 23.6 7.9 27.6 11.3 7.9 6xØ0,75 (M16) 20.8 74.2 930 B95A

280S/M 125 3" 2" 27.8 11.1 13.8 32.3 30.3 78.7 31.5 7.9 32.4 17.6 7.9 6xØ0,75 (M16) 35.9 95.1 2535 B160A

160L 20 3" 2" 27.8 11.1 13.8 19.3 17.7 66.9 25.6 7.9 32.4 11.3 7.9 6xØ0,75 (M16) 20.8 76.7 961 B95A

180M 25 3" 2" 27.8 11.1 13.8 19.3 17.7 68.9 26.6 7.9 32.4 12.1 7.9 6xØ0,75 (M16) 23.2 79.0 1063 B110B

160L 20 3" 2" 30.3 11.1 13.8 19.3 17.7 66.9 25.6 7.9 32.4 11.3 7.9 6xØ0,75 (M16) 20.8 79.1 988 B95A

180M 25 3" 2" 30.3 11.1 13.8 19.3 17.7 68.9 26.6 7.9 32.4 12.1 7.9 6xØ0,75 (M16) 23.2 81.5 1089 B110B

160L 20 3" 2" 32.7 11.1 13.8 19.3 17.7 72.8 28.5 7.9 37.3 11.3 7.9 6xØ0,75 (M16) 20.8 81.6 1023 B95A

180M 25 3" 2" 32.7 11.1 13.8 19.3 17.7 72.8 28.5 7.9 37.3 12.1 7.9 6xØ0,75 (M16) 23.2 83.9 1118 B110B

160L 20 3" 2" 35.2 11.1 13.8 19.3 17.7 72.8 28.5 7.9 37.3 11.3 7.9 6xØ0,75 (M16) 20.8 84.0 1049 B95A

180L 30 3" 2" 35.2 11.1 13.8 19.3 17.7 72.8 28.5 7.9 37.3 12.1 7.9 6xØ0,75 (M16) 23.2 87.9 1182 B110B

180M 25 3" 2" 37.6 11.1 13.8 19.3 17.7 78.7 31.5 7.9 42.2 12.1 7.9 6xØ0,75 (M16) 23.2 88.8 1182 B110B

180L 30 3" 2" 37.6 11.1 13.8 19.3 17.7 78.7 31.5 7.9 42.2 12.1 7.9 6xØ0,75 (M16) 23.2 90.3 1219 B110B

180M 25 3" 2" 40.0 11.1 13.8 19.3 17.7 78.7 31.5 7.9 42.2 12.1 7.9 6xØ0,75 (M16) 23.2 91.2 1208 B110B

180L 30 3" 2" 40.0 11.1 13.8 19.3 17.7 78.7 31.5 7.9 42.2 12.1 7.9 6xØ0,75 (M16) 23.2 92.7 1246 B110B

e-MPD-AS-60-50-us_a_td

13

15

16

DIMENSIONS [inch]DIMENSIONS [inch]DIMENSIONS [inch]DIMENSIONS [inch]

9

10

11

12

WEIGHTWEIGHTWEIGHTWEIGHT

14

COUPLINGCOUPLINGCOUPLINGCOUPLING

TYPETYPETYPETYPE

50

1

2

3

4

5

6

7

8

NUMBERNUMBERNUMBERNUMBER

OFSTAGESOFSTAGESOFSTAGESOFSTAGES

IECIECIECIEC

MOTORMOTORMOTORMOTOR

FRAMEFRAMEFRAMEFRAME

3550355035503550

[rpm][rpm][rpm][rpm]

1750175017501750

[rpm][rpm][rpm][rpm]

NOTE: Pumps supplied with ANSI B16.5 flanges. Flanges according to EN 1092-2 are available on request.

For flanges dimensions see drawing on pages 102-103.

Dimensions and weights in the next table are for reference only and correspond to IEC motor frames. NEMA corresponding dimensions

and weights to be published soon. Please contact factory for more information.

PAGE 46

e-MP Series

Goulds Water Technology](https://image.slidesharecdn.com/bemp-r1-171024181502/85/The-e-MP-Series-46-320.jpg)

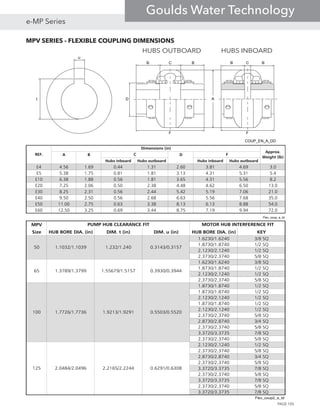

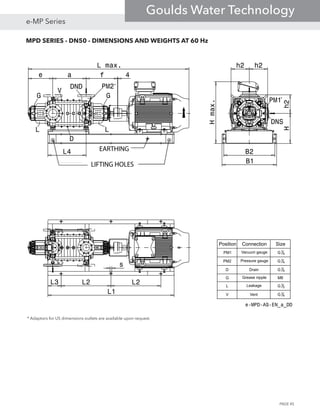

![MPV SERIES - DN50 - DIMENSIONS AND WEIGHTS AT 60 Hz

* Adaptors for US dimensions outlets are available upon request.

d

t

u

v2

t1

AD

b11

e1

Ød2

m6

m5

h2

s2

l

E

Ød

4-6

h5

ØD

ØP

h4ah3

DND

DNS

G

D

PM2

PM1

g (optional)

DND

pump shaft end

e-MPV-US_a_DD

*

*

PUMP TYPEPUMP TYPEPUMP TYPEPUMP TYPE

MPVMPVMPVMPV

SizeSizeSizeSize DNSDNSDNSDNS DNDDNDDNDDND h2h2h2h2 h3h3h3h3 d2d2d2d2 m5m5m5m5 m6m6m6m6 s2s2s2s2 v2v2v2v2 dddd tttt uuuu llll b11b11b11b11 e1e1e1e1 t1t1t1t1 gggg

50 3" 2" 7.9 5.4 0.8 14.8 11.0 0.9 7.9 1.1 1.2 0.3 2.8 22.8 3.1 11.8 0.8

e-MPV-60-50-us_a_td

DIMENSIONS [inch]DIMENSIONS [inch]DIMENSIONS [inch]DIMENSIONS [inch]

Pump dimensionsPump dimensionsPump dimensionsPump dimensions Base dimensionsBase dimensionsBase dimensionsBase dimensions

Size

Number

of stages

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

a (inch) 3.43 5.87 8.31 10.75 13.19 15.63 18.07 20.51 22.95 25.39 27.83 30.28 32.72 35.16 37.60 40.04

G1 (lb) 196 223 249 276 302 328 355 381 408 434 461 487 514 540 567 593

e-MPV-60-50_stage_a_td

50

NOTE: Pumps supplied with ANSI B16.5 flanges. Flanges according to EN 1092-2 are available on request.

For flanges dimensions see drawing on pages 102-103.

PAGE 47

e-MP Series

Goulds Water Technology](https://image.slidesharecdn.com/bemp-r1-171024181502/85/The-e-MP-Series-47-320.jpg)

![MPV SERIES - DN50 - DIMENSIONS AND WEIGHTS AT 60 Hz

3600 [rpm] 1800 [rpm] h4 G2 h5 P D E AD

[HP] [HP] [in] [lb] [in] [in] [in] [in] [in]

254 TD 15 15 18.27 77 22.09 14 1.625 4.00 9.49

256 TD 20 20 18.27 77 22.09 14 1.625 4.00 9.49

284 TD - 25 18.27 77 25.93 14 1.875 4.38 13.11

284 TSD 25 - 18.27 77 21.99 14 1.625 3.25 11.52

286 TD - 30 18.27 77 25.93 14 1.875 4.38 13.11

286 TSD 30 - 18.27 77 21.99 14 1.625 3.25 11.52

324 TD - 40 - - 28.35 18 2.125 5.25 14.13

324 TSD 40 - 18.27 95 27.78 18 1.875 3.75 14.11

326 TD - 50 - - 28.35 18 2.125 5.25 14.13

326 TSD 50 - 18.27 95 27.78 18 1.875 3.75 14.11

364 TD - 60 - - 30.34 18 2.375 5.88 18.06

364 TSD 60 - 18.27 95 27.35 18 1.875 3.75 18.06

365 TD - 75 - - 30.34 18 2.375 5.88 18.06

365 TSD 75 - 18.27 95 27.35 18 1.875 3.75 18.06

405 TD - 100 - - 33.83 22 2.875 7.25 19.31

405 TSD 100 - 19.45 127 33.83 22 2.125 4.25 19.31

444 TD - 125 - - 38.89 22 3.375 8.50 23.38

444 TSD 125 - 19.45 127 38.89 22 2.375 4.75 23.38

445 TD - 150 - - 38.89 22 3.375 8.50 23.38

445 TSD 150 - 19.45 127 38.89 22 2.375 4.75 23.38

Total pump unit weight G = weight G1 + weight G2 + weight G3 (±5%) e-MPV-50-AS-us_a_td

NEMA

Size

Speed Pump dimensions Motor dimensions

PAGE 48

e-MP Series

Goulds Water Technology](https://image.slidesharecdn.com/bemp-r1-171024181502/85/The-e-MP-Series-48-320.jpg)

![e-MP65A SERIES - OPERATING CHARACTERISTICS AT 60 Hz, 2 POLES

These performances are valid for cold water with density ρ = 62.42 lb/ft3

and viscosity ν = 1cSt.

e-MP65A/01 3550 [rpm] ISO 9906:2012 - Grade 2B

0 5 10 15 20 25 30 35 40

0 100 200 300 400 500

Q [l/s]

Q [Imp gpm]

1A

1B

1C

76.4

73.9

69.769.769.7

74

74

70

70

65

65

60

60

5050

0 20 40 60 80 100 120 140

0

10

20

30

40

50

60

70

80

90

0

50

100

150

200

250

300

Q [m3/h]

H[m]

H[ft]

η[%]

0

5

10

15

0

10

20

30

40

50

NPSH[m]

NPSH[ft]

e-MPR, e-MPD, e-MPV

1A

1B

1C1C1C

0

5

10

15

20

0

5

10

15

20

25

30

0 100 200 300 400 500 600 700

PP[kW]

Pp[HP]

Q [US gpm]

e-MP65A-01_60Hz_2_US_A

Ø206mm

Ø190mm

Ø174mm

e-MPA

e-MP65A/02 3550 [rpm] ISO 9906:2012 - Grade 2B

0 5 10 15 20 25 30 35 40

0 100 200 300 400 500

Q [l/s]

Q [Imp gpm]

2A

2B2C

2D

76.3

75.1

73.9

71.9

69.7

2E

0 20 40 60 80 100 120 140

0

50

100

150

0

100

200

300

400

500

600

Q [m3/h]

H[m]

H[ft]

η[%]

0

5

10

15

0

10

20

30

40

50

NPSH[m]

NPSH[ft]

e-MPR, e-MPD, e-MPV

2A

2B

2C

2D

2E

0

10

20

30

40

0

10

20

30

40

50

60

0 100 200 300 400 500 600 700

PP[kW]

Pp[HP]

Q [US gpm]

e-MP65A-02_60Hz_2_US_A

2XØ242mm

1XØ242mm/1XØ190mm

1XØ190mm/1XØ174mm

e-MPA

2XØ190mm

2XØ174mm

e-MP65A/04 3550 [rpm] ISO 9906:2012 - Grade 2B

0 5 10 15 20 25 30 35 40

0 100 200 300 400 500

Q [l/s]

Q [Imp gpm]

4A

4B

4C4C

76.3

74.8

73.2

4C

0 20 40 60 80 100 120 140

61

111

161

211

261

311

361

200

300

400

500

600

700

800

900

1000

1100

1200

Q [m3/h]

H[m]

H[ft]

η[%]

3XØ206mm/1XØ174mm

2XØ206mm/2XØ174mm

0

5

10

15

0

10

20

30

40

50

NPSH[m]

NPSH[ft]

e-MPR, e-MPD, e-MPV

4A

4B

4C4C4C

0

10

20

30

40

50

60

70

80

0

20

40

60

80

100

120

0 100 200 300 400 500 600 700

PP[kW]

Pp[HP]

Q [US gpm]

e-MP65A-04_60Hz_2_US_A

e-MPA

4XØ206mm

e-MP65A/03 3550 [rpm] ISO 9906:2012 - Grade 2B

0 5 10 15 20 25 30 35 40

0 100 200 300 400 500

Q [l/s]

Q [Imp gpm]

3A

3B

3C3C

76.3

74.3

72.1

3C

0 20 40 60 80 100 120 140

0

50

100

150

200

250

0

100

200

300

400

500

600

700

800

900

Q [m3/h]

H[m]

H[ft]

η[%]

0

5

10

15

0

10

20

30

40

50

NPSH[m]

NPSH[ft]

e-MPR, e-MPD, e-MPV

3A

3B

3C3C3C

0

10

20

30

40

50

60

70

0

20

40

60

80

100

0 100 200 300 400 500 600 700

PP[kW]

Pp[HP]

Q [US gpm]

e-MP65A-03_60Hz_2_US_A

3XØ206mm

2XØ206mm/1XØ174mm

1XØ206mm/2XØ174mm

e-MPA

PAGE 49

e-MP Series

Goulds Water Technology](https://image.slidesharecdn.com/bemp-r1-171024181502/85/The-e-MP-Series-49-320.jpg)

![e-MP65A SERIES - OPERATING CHARACTERISTICS AT 60 Hz, 2 POLES

These performances are valid for cold water with density ρ = 62.42 lb/ft3

and viscosity ν = 1cSt.

e-MP65A/05 3550 [rpm] ISO 9906:2012 - Grade 2B

0 5 10 15 20 25 30 35 40

0 100 200 300 400 500

Q [l/s]

Q [Imp gpm]

5A

5B

76.3

75.1

73.9

5C

0 20 40 60 80 100 120 140

122

172

222

272

322

372

422

400

500

600

700

800

900

1000

1100

1200

1300

1400

Q [m3/h]

H[m]

H[ft]

η[%]

0

5

10

15

0

10

20

30

40

50

NPSH[m]

NPSH[ft]

e-MPR, e-MPD, e-MPV

5A

5B

5C

0

20

40

60

80

100

0

20

40

60

80

100

120

140

160

0 100 200 300 400 500 600 700

PP[kW]

Pp[HP]

Q [US gpm]

e-MP65A-05_60Hz_2_US_A

5XØ206mm

4XØ206mm/1XØ174mm

3XØ206mm/2XØ174mm

e-MPA

e-MP65A/06 3550 [rpm] ISO 9906:2012 - Grade 2B

0 5 10 15 20 25 30 35 40

0 100 200 300 400 500

Q [l/s]

Q [Imp gpm]

6A

6B

76.3

75.3

74.3

6C

0 20 40 60 80 100 120 140

122

172

222

272

322

372

422

472

522

400

600

800

1000

1200

1400

1600

1800

Q [m3/h]

H[m]

H[ft]

η[%]

0

5

10

15

0

10

20

30

40

50

NPSH[m]

NPSH[ft]

e-MPR, e-MPD, e-MPV

6A

6B

6C

0

20

40

60

80

100

120

0

20

40

60

80

100

120

140

160

180

0 100 200 300 400 500 600 700

PP[kW]

Pp[HP]

Q [US gpm]

e-MP65A-06_60Hz_2_US_A

6XØ206mm

5XØ206mm/1XØ174mm

4XØ206mm/2XØ174mm

e-MPA

e-MP65A/07 3550 [rpm] ISO 9906:2012 - Grade 2B

0 5 10 15 20 25 30 35 40

0 100 200 300 400 500

Q [l/s]

Q [Imp gpm]

7A

7B

76.3

75.5

74.6

7C

0 20 40 60 80 100 120 140

183

233

283

333

383

433

483

533

583

600

800

1000

1200

1400

1600

1800

2000

Q [m3/h]

H[m]

H[ft]

η[%]

0

5

10

15

0

10

20

30

40

50

NPSH[m]

NPSH[ft]

e-MPR, e-MPD, e-MPV

7A

7B

7C

0

20

40

60

80

100

120

140

0

50

100

150

200

0 100 200 300 400 500 600 700

PP[kW]

Pp[HP]

Q [US gpm]

e-MP65A-07_60Hz_2_US_A

7XØ206mm

6XØ206mm/1XØ174mm

5XØ206mm/2XØ174mm

e-MPA

PAGE 50

e-MP Series

Goulds Water Technology](https://image.slidesharecdn.com/bemp-r1-171024181502/85/The-e-MP-Series-50-320.jpg)

![e-MP65B SERIES - OPERATING CHARACTERISTICS AT 60 Hz, 2 POLES

These performances are valid for cold water with density ρ = 62.42 lb/ft3

and viscosity ν = 1cSt.

e-MP65B/01 3550 [rpm] ISO 9906:2012 - Grade 2B

0 10 20 30 40 50

0 100 200 300 400 500 600

Q [l/s]

Q [Imp gpm]

1A

1B

1C

80.0

77.3

73.6

77

77

75

75

70

70

656055

0 20 40 60 80 100 120 140 160 180

0

20

40

60

80

100

0

50

100

150

200

250

300

350

Q [m3/h]

H[m]

H[ft]

η[%]

0

5

10

15

0

10

20

30

40

50

NPSH[m]

NPSH[ft]

e-MPR, e-MPD, e-MPV

1A

1B

1C

0

5

10

15

20

25

30

35

0

10

20

30

40

50

0 100 200 300 400 500 600 700 800

PP[kW]

Pp[HP]

Q [US gpm]

e-MP65B-01_60Hz_2_US_A

Ø214mm

Ø198mm

Ø182mm

e-MPA

e-MP65B/02 3550 [rpm] ISO 9906:2012 - Grade 2B

0 10 20 30 40 50

0 100 200 300 400 500 600

Q [l/s]

Q [Imp gpm]

2A

2B

2C

2D

80.0

78.7

77.3

75.5

69.7

2E

0 20 40 60 80 100 120 140 160 180

0

20

40

60

80

100

120

140

160

180

0

100

200

300

400

500

600

Q [m3/h]

H[m]

H[ft]

η[%]

0

5

10

15

0

20

40

60

NPSH[m]

NPSH[ft]

e-MPR, e-MPD, e-MPV

2A

2B

2C

2D

2E

15

25

35

45

55

65

20

40

60