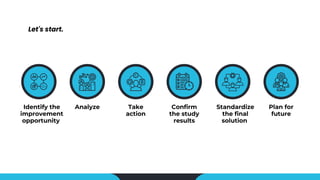

Lean continuous improvement is a method for reducing waste and increasing productivity through ongoing evaluation of work processes. It provides tangible benefits such as minimizing costs, improving process flow, and enhancing employee engagement. Implementing lean requires a systematic approach to identify and standardized improvements within an organization.