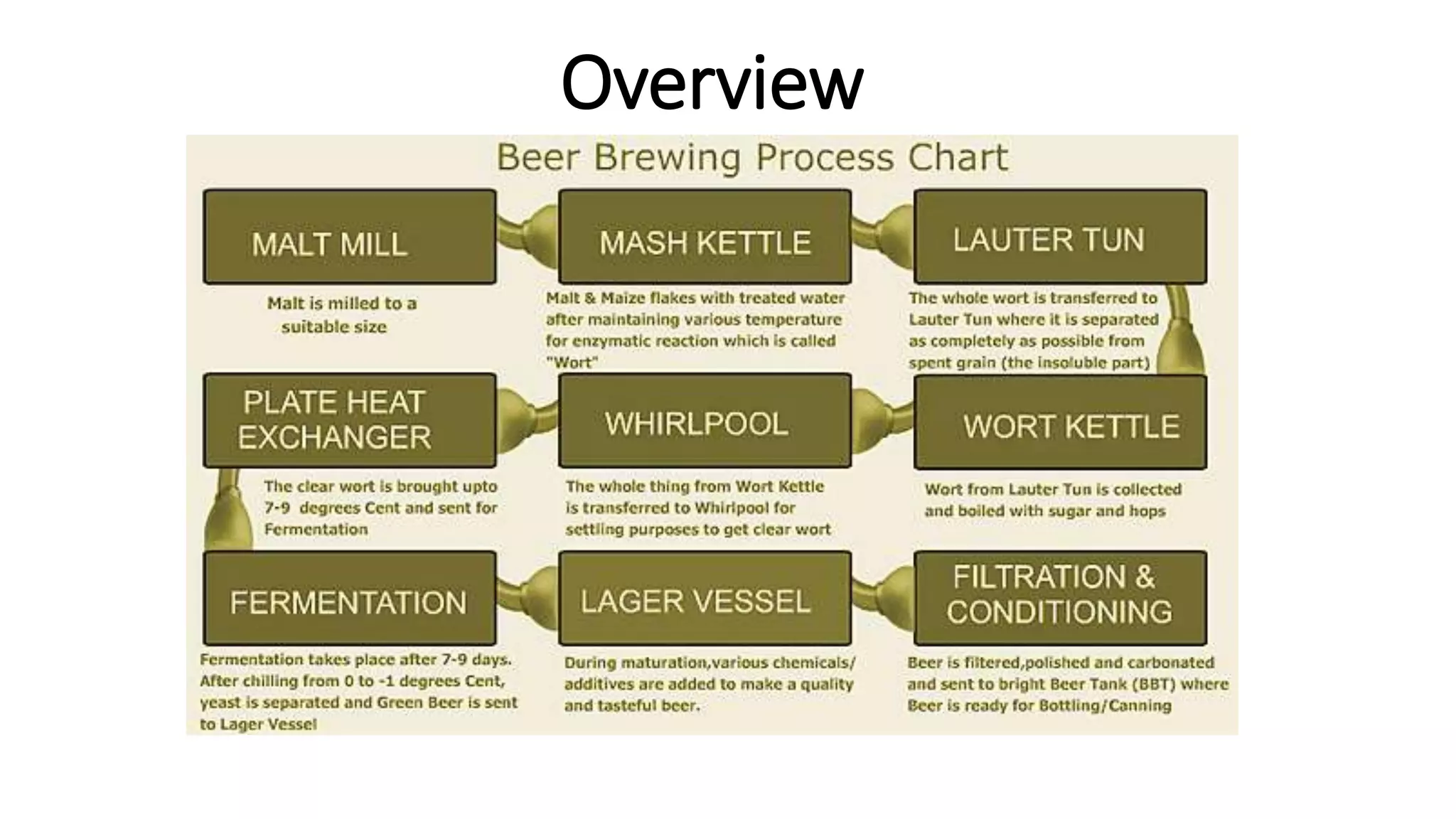

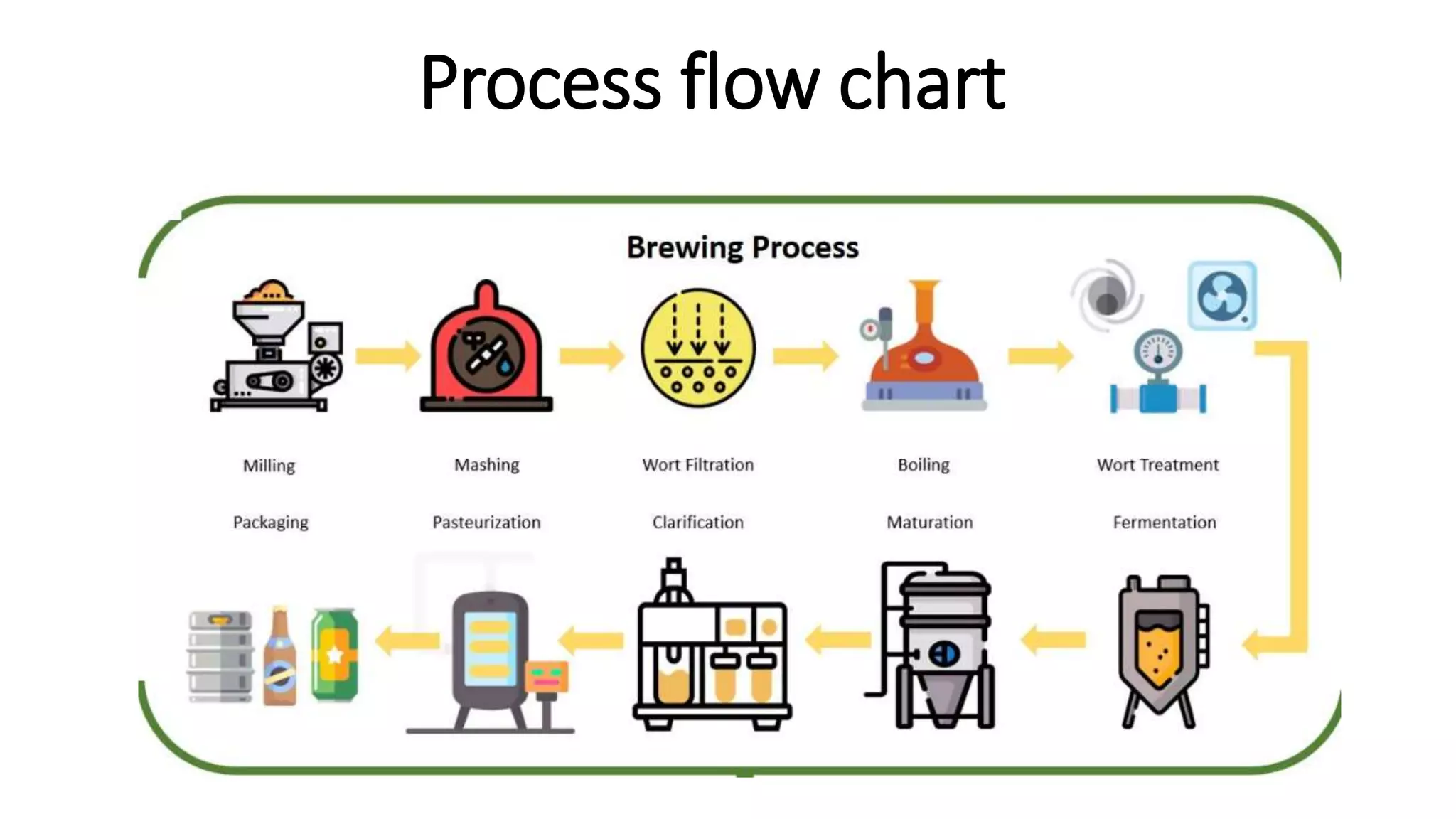

The document summarizes the main stages in the brewing process:

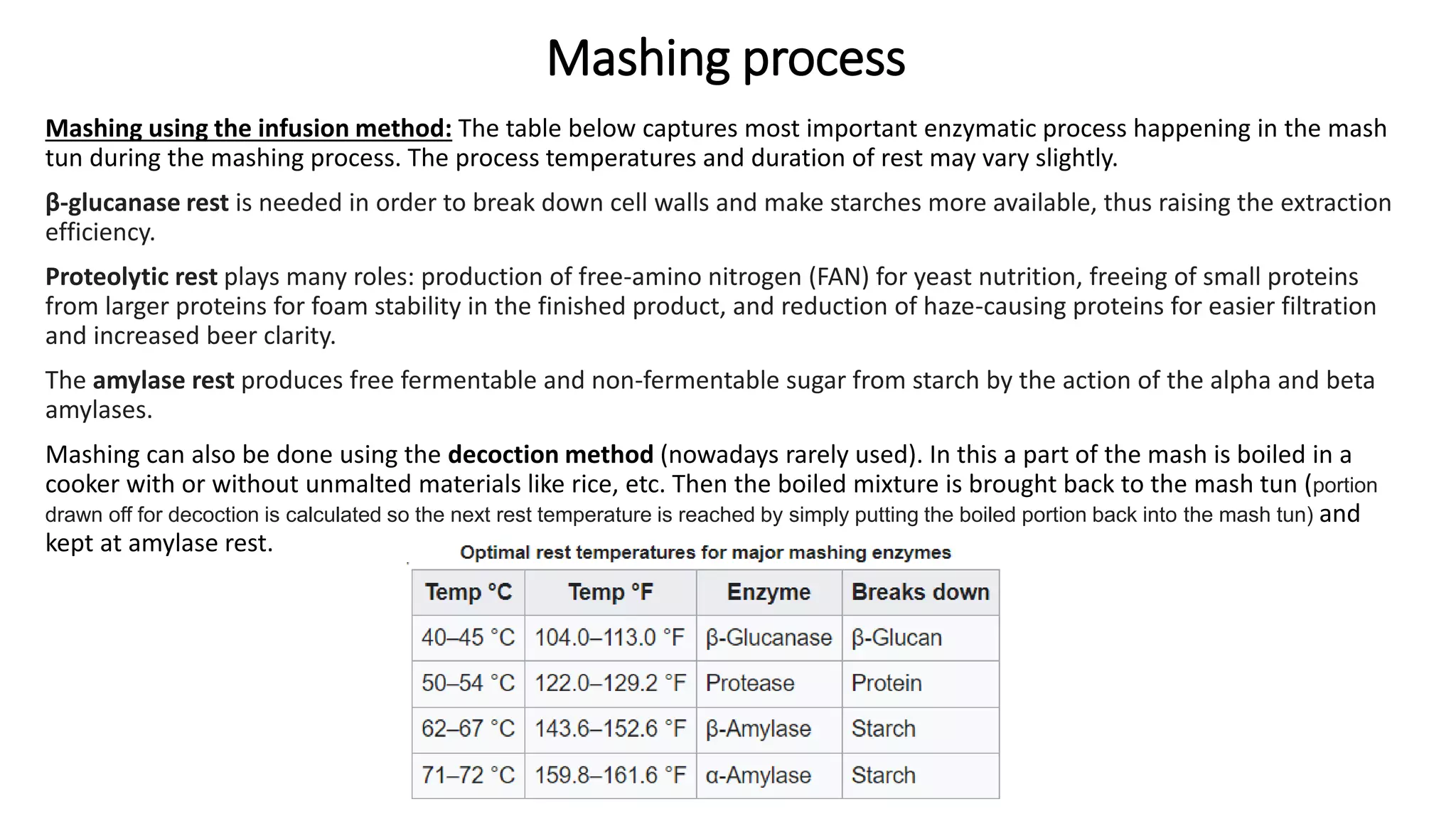

1. Milling and mashing break down grains to make starches accessible to yeast during fermentation.

2. Wort boiling halts enzymatic actions and adds hops.

3. Fermentation and lagering use yeast to convert sugars to alcohol and mature the beer's taste.