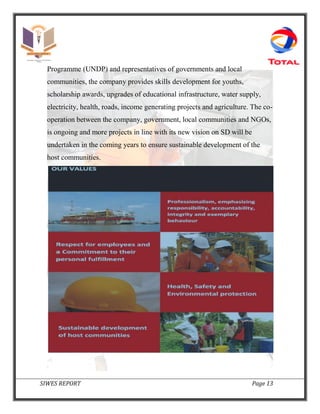

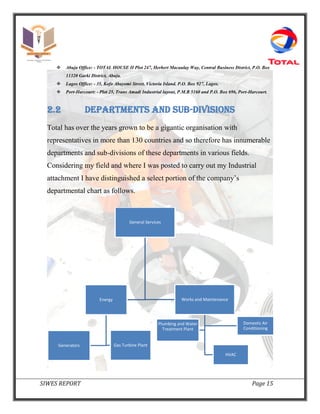

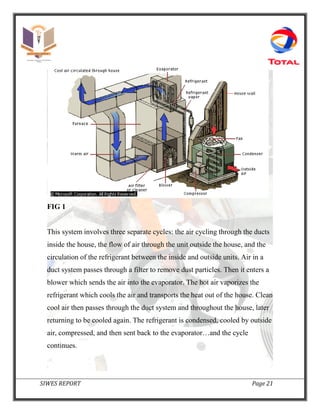

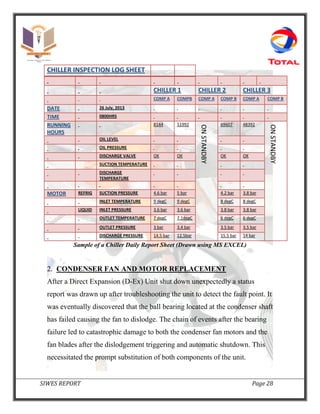

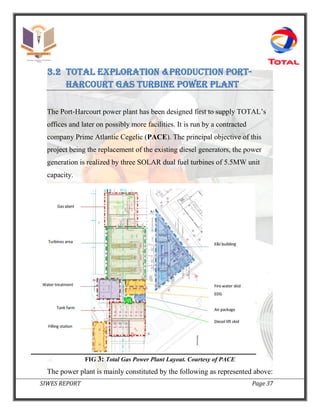

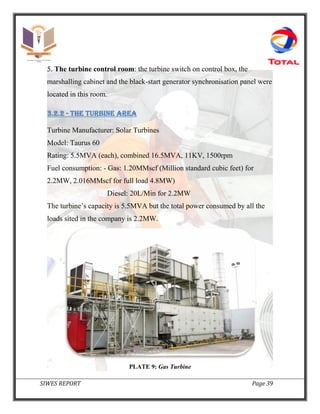

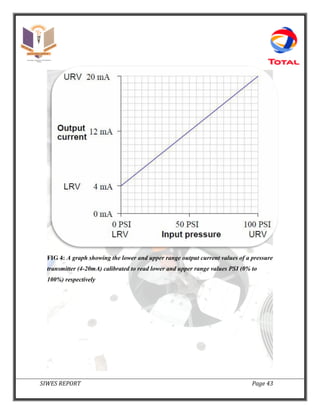

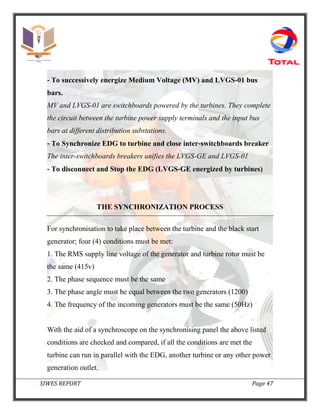

This document is a report summarizing the student's experience during their industrial training placement through the Student Industrial Work Experience Scheme (SIWES) program. It provides background on SIWES and its objectives to bridge the gap between classroom theory and practical work experience. The report then gives an overview of Total Exploration and Production Nigeria Limited, where the student completed their placement. It describes the various departments and work experiences the student had in heating, ventilation and air conditioning systems, as well as the gas turbine power plant.