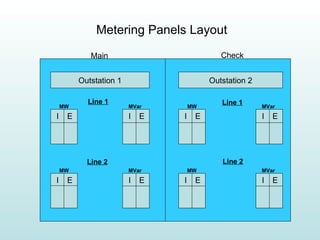

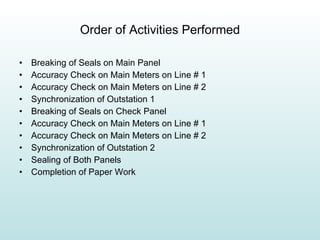

The document summarizes the current tariff metering system at Hub Power Station and identifies issues. It discusses replacing the aging energy meters and outstation system to address reliability problems. The proposed solution involves installing intelligent digital meters and upgrading the outstation system to improve flexibility and synchronization. Key benefits of the new system include reading instant parameters, automatic time synchronization, and reduced number of meters needed.