The document discusses emulsion polymerization. Key points include:

1) Emulsion polymerization is an economically important process that is used to produce over 30% of polymers made by free radical methods.

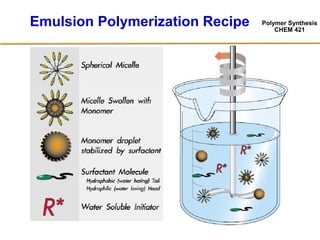

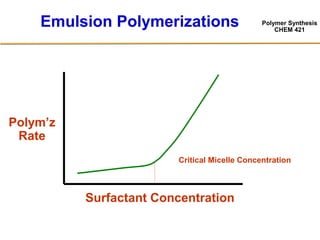

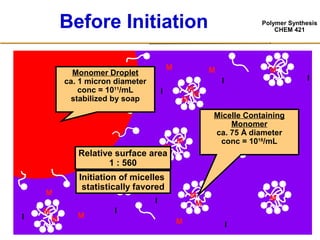

2) The recipe for emulsion polymerization involves water, water-insoluble monomer, water-soluble initiator, and surfactant.

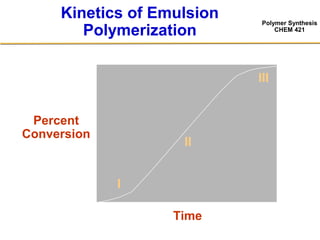

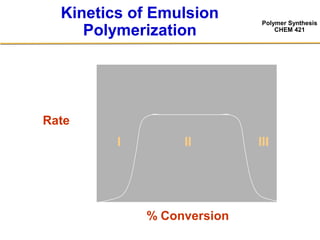

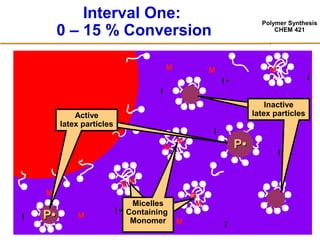

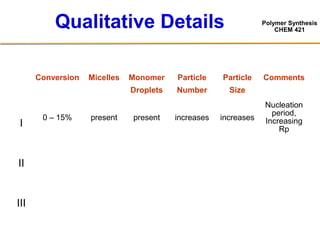

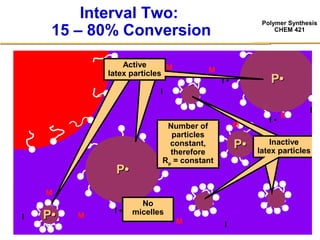

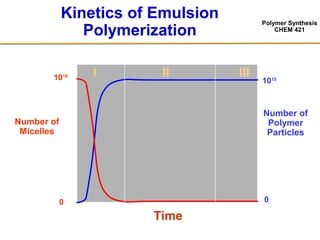

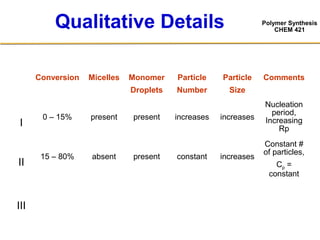

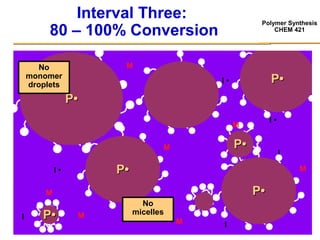

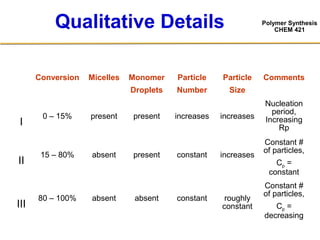

3) The kinetics of emulsion polymerization occurs in three stages: nucleation and particle growth (0-15% conversion), constant particle number (15-80% conversion), and final conversion (80-100% conversion).

![Polymer Synthesis

CHEM 421

Emulsion Polymerization Kinetics

• Once inside a particle, radical propagates

as rp = kp[M]

• Overall rate: Rp = kp[M][P.

]

• [P.

] = N’ñ (where N’ = the sum of micelle

and particle concentrations and

ñ = average # of radicals per particle)

• Therefore,

–Increase N’ to increase rate!

][' MknNR pp =](https://image.slidesharecdn.com/synthesispoly-140425110303-phpapp01/85/Synthesis-poly-18-320.jpg)

![Polymer Synthesis

CHEM 421

Emulsion Polymerization Kinetics

• How to increase Rp?

–Increase N’ to increase rate

»Increase surfactant concentration to increase N’

][' MknNR pp =](https://image.slidesharecdn.com/synthesispoly-140425110303-phpapp01/85/Synthesis-poly-20-320.jpg)

![Polymer Synthesis

CHEM 421

Molecular Weight in Emulsion

Polymerizations

• Molecular weight determined by rate of growth

of a chain divided by rate of radical entry (ri)

–How to increase molecular weight?

DP

rp

= ——ri

Ri

= ——

N

ri = kp[M]rp

N kp [M]

Ri

= ———DP](https://image.slidesharecdn.com/synthesispoly-140425110303-phpapp01/85/Synthesis-poly-21-320.jpg)

![Polymer Synthesis

CHEM 421

Free Radical Solution

Polymerizations

• Recall

– To increase molecular weight…

» Increase monomer concentration

» Decrease initiator concentration

– To increase Rate of Polymerization

» Increase monomer concentration

» Increase initiator concentration

٧ =

kp [M]

2 (kt kd f [I])1/2

= —————

Can’t do

both!

Rp = kp [M] (kd f [I] / kt)1/2](https://image.slidesharecdn.com/synthesispoly-140425110303-phpapp01/85/Synthesis-poly-22-320.jpg)