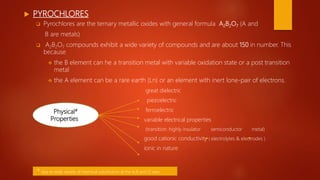

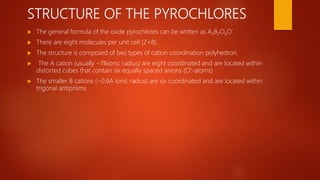

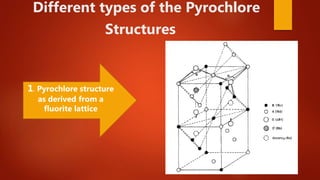

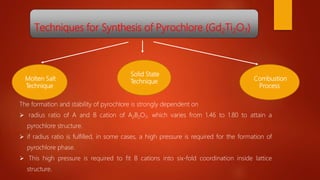

This document summarizes the synthesis and characterization of the pyrochlore gadolinium titanium oxide (Gd2Ti2O7). It describes pyrochlores as a class of ternary metallic oxides with the general formula A2B2O7. Three techniques are discussed for synthesizing Gd2Ti2O7: molten salt, solid state reaction, and combustion process. The document characterizes the synthesized Gd2Ti2O7 using X-ray diffraction, which confirms a single pyrochlore phase with the expected crystal structure. Finally, some applications of oxide pyrochlores in electronic materials, electrodes, and waste disposal are mentioned.

![COMBUSTION PROCESS:

Gadolinium oxide (Gd2O3) + titanium oxide (TiO2) + nitric acid + distilled

water to form an aqueous solution.

Citric acid is then added to the aqueous solution keeping its citric acid to

(Gd3+, Ti4+) ratio to 1:1.

This mixture is stirred and then ammonium hydroxide NH4OH is added to

maintain a ph of 7 [NH4OH act as an oxidant].

The whole mixture is heated at 250° c on hot plate.

After some time, dehydration occur forming a dark foam.

On persistent heating this dark foam gets auto ignited to give a fluffy powder.

The prepared powder is calcined at 600°c to remove carbon content to give

pure Gd2Ti2O7 crystals.](https://image.slidesharecdn.com/synthesisandcharacterizationofpyrochloregd2ti2o7-210503182246/85/Synthesis-and-characterization-of-pyrochlore-Gd2Ti2O7-10-320.jpg)