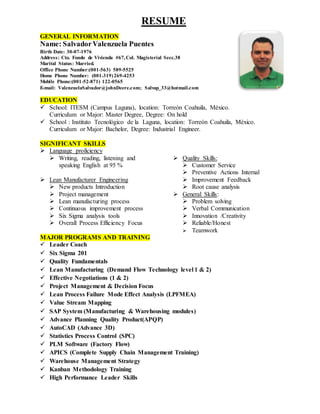

Salvador Valenzuela Puentes is an industrial engineer from Mexico with over 15 years of experience in lean manufacturing, quality control, and project management. He holds a master's degree and has worked at John Deere in both Mexico and the United States, leading quality improvement and efficiency projects. He is proficient in English, Six Sigma, and lean manufacturing tools and software like SAP, AutoCAD, and Factory Flow.